Welding Electrode Classification Australia . Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. Wia’s general purpose electrodes include the popular austarc 12p and 13s. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking.

from brokeasshome.com

The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Wia’s general purpose electrodes include the popular austarc 12p and 13s. Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking.

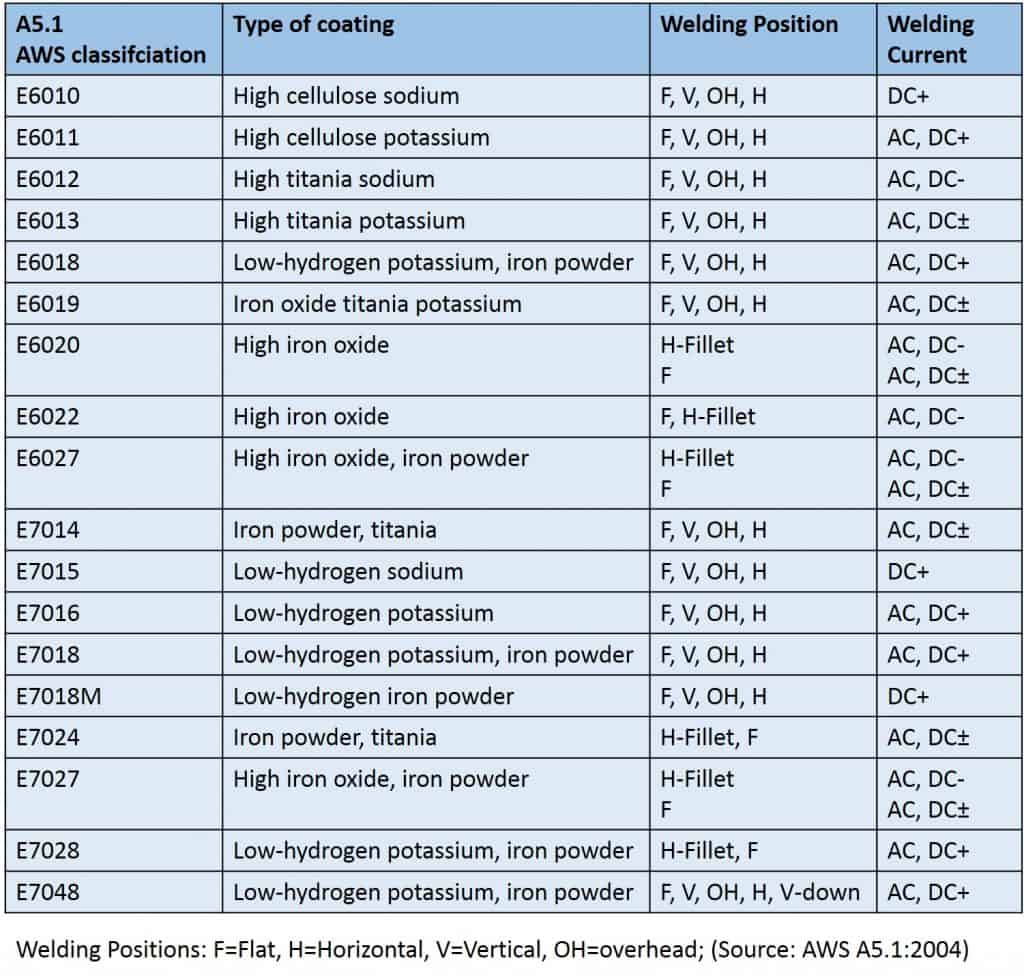

welding electrode classifications table

Welding Electrode Classification Australia Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. Wia’s general purpose electrodes include the popular austarc 12p and 13s. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Stick welding electrodes come in a range of classifications and sizes for every kind of weld.

From quizzmediasophie.z13.web.core.windows.net

Tig Tungsten Color Chart Welding Electrode Classification Australia Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed. Welding Electrode Classification Australia.

From www.oceanproperty.co.th

Welding Electrodes Understanding The SMAW Electrode, 47 OFF Welding Electrode Classification Australia The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Wia’s comprehensive filler metal range spans from mild steel and low hydrogen. Welding Electrode Classification Australia.

From www.slideserve.com

PPT SMAW Welding PowerPoint Presentation, free download ID750562 Welding Electrode Classification Australia Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. Wia’s general purpose electrodes include the popular austarc 12p and 13s. The first thing you need to do. Welding Electrode Classification Australia.

From yeowchuan.com.my

How to read the Welding Electrode Classifications on Coating Welding Electrode Classification Australia Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Before welding, it is recommended by. Welding Electrode Classification Australia.

From www.theweldingmaster.com

Types of Welding Electrodes Complete Guide Welding Electrode Classification Australia Wia’s general purpose electrodes include the popular austarc 12p and 13s. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. Thick materials require an electrode with maximum ductility and low hydrogen. Welding Electrode Classification Australia.

From ids-deutschland.de

Electrode Classifications 10 E6013 E Arc Welding Electrode, 58 OFF Welding Electrode Classification Australia Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a. Welding Electrode Classification Australia.

From ookpranzatu1986.mystrikingly.com

Stainless Steel Welding Electrode Classification Welding Electrode Classification Australia The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Wia’s general purpose electrodes include the popular austarc 12p and 13s. Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified. Welding Electrode Classification Australia.

From www.hobartbrothers.com

Basics of AWS Filler Metal and Electrode Classification Hobart Brothers Welding Electrode Classification Australia Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. Wia’s general purpose. Welding Electrode Classification Australia.

From www.pinterest.com

Electrode Classifications 10 E6013 E = Arc welding electrode Tensile Welding Electrode Classification Australia Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size. Welding Electrode Classification Australia.

From www.weldinghandbook.com

Welding Electrodes Coatings and Classifications The Welding Handbook Welding Electrode Classification Australia The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes. Welding Electrode Classification Australia.

From www.onestopndt.com

CLASSIFICATION OF WELDING ELECTRODES Welding Electrode Classification Australia Stick welding electrodes come in a range of classifications and sizes for every kind of weld. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Wia’s general purpose electrodes include the popular austarc 12p and 13s. Wia’s. Welding Electrode Classification Australia.

From www.scribd.com

Smaw Welding Electrode Classification PDF Crystalline Solids Welding Electrode Classification Australia Wia’s general purpose electrodes include the popular austarc 12p and 13s. Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. Stick welding electrodes come in a range. Welding Electrode Classification Australia.

From www.studypool.com

SOLUTION Mechanical Engineering Electrode classification Studypool Welding Electrode Classification Australia The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. Stick welding electrodes come in a range of. Welding Electrode Classification Australia.

From weldguru.com

Welding Electrode Chart and Selection Weld Guru Welding Electrode Classification Australia Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Wia’s comprehensive filler metal range spans from mild steel. Welding Electrode Classification Australia.

From brokeasshome.com

welding electrode classifications table Welding Electrode Classification Australia Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Wia’s general purpose electrodes include the popular austarc 12p and 13s. Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding. Welding Electrode Classification Australia.

From www.koviwelding.com

Welding Electrode Classification Welding Electrode Classification Australia Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. The first thing. Welding Electrode Classification Australia.

From mavink.com

Welding Electrode Diagram Welding Electrode Classification Australia The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Wia’s general purpose electrodes include the popular austarc 12p and 13s. Before. Welding Electrode Classification Australia.

From brokeasshome.com

welding electrode classifications table Welding Electrode Classification Australia Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. Wia’s general purpose electrodes include the popular austarc 12p and 13s. Stick welding electrodes come in a range of classifications and sizes for. Welding Electrode Classification Australia.

From www.axxair.com

The different types of electrodes used in orbital TIG welding Welding Electrode Classification Australia Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a. Welding Electrode Classification Australia.

From www.fabricatingandmetalworking.com

11 AWS Classification System for FC Electrodes Fabricating and Welding Electrode Classification Australia Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you. Welding Electrode Classification Australia.

From www.pinterest.com

5.6 Carbon and LowAlloy Steel Covered Electrode Classification Welding Electrode Classification Australia Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. Wia’s general purpose electrodes include the popular austarc 12p and 13s. Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. The first thing you need to do is match your electrode to your parent. Welding Electrode Classification Australia.

From www.youtube.com

welding Electrode Classification Detail of Electrode YouTube Welding Electrode Classification Australia Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. Wia’s general purpose electrodes include the popular austarc 12p and 13s. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you. Welding Electrode Classification Australia.

From informacionpublica.svet.gob.gt

Welding Electrodes Understanding The SMAW Electrode Welding Electrode Classification Australia The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. Stick welding electrodes come in a range of classifications and sizes for every. Welding Electrode Classification Australia.

From www.wcwelding.com

Arc Welding Rods Guide Welding Electrode Classification Australia Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. Wia’s general purpose electrodes include the popular. Welding Electrode Classification Australia.

From strleng.blogspot.com

Selection of Welding Electrode Engineer Diary Welding Electrode Classification Australia Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant. Welding Electrode Classification Australia.

From workshopinsider.com

Welding Electrodes Types & Selection of Welding Rods Welding Electrode Classification Australia Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Wia’s general purpose electrodes include the. Welding Electrode Classification Australia.

From www.scribd.com

Welding Electrode Classifications Wallchart.pdf Nickel Titanium Welding Electrode Classification Australia Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you. Welding Electrode Classification Australia.

From fitterkipurijankari.com

Types of Arc Welding Electrode FITTER KI PURI JANKARI Welding Electrode Classification Australia The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. Wia’s general purpose electrodes include the popular austarc 12p and 13s. Wia’s comprehensive. Welding Electrode Classification Australia.

From www.youtube.com

Welding Tips_ Electrode Classifications E7018,6010,7024 ..etc YouTube Welding Electrode Classification Australia Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. Wia’s general purpose electrodes include the popular. Welding Electrode Classification Australia.

From www.welding.com.au

Austarc Premium Welding Electrodes WIA Welding Electrode Classification Australia Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes. Welding Electrode Classification Australia.

From elisejoyce.z13.web.core.windows.net

Welding Electrode Selection Chart Pdf Welding Electrode Classification Australia Wia’s comprehensive filler metal range spans from mild steel and low hydrogen electrodes to solid mig and specialist flux cored wires as. Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. Wia’s general purpose electrodes include the popular austarc 12p and 13s. Thick materials require an electrode with maximum. Welding Electrode Classification Australia.

From www.academia.edu

(PDF) Welding Electrode Classifications Danilo Muñoz Academia.edu Welding Electrode Classification Australia Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. Wia’s general purpose electrodes include the popular austarc 12p and 13s. Stick welding electrodes come in a range of classifications and sizes for every kind of weld. The first thing you need to do is match your electrode to your. Welding Electrode Classification Australia.

From www.weldingandndt.com

Welding electrodes Understanding the SMAW electrode symbols Welding Welding Electrode Classification Australia Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Thick materials require an electrode with maximum ductility. Welding Electrode Classification Australia.

From www.vrogue.co

Key To Electrode Classification Numbers Welding Rods vrogue.co Welding Electrode Classification Australia The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed by a suitably qualified welding specialist in. Wia’s comprehensive filler metal range spans from mild. Welding Electrode Classification Australia.

From www.arcraftplasma.com

electrode classification, Welding consultants Micro for welding Welding Electrode Classification Australia Thick materials require an electrode with maximum ductility and low hydrogen to prevent weld cracking. The first thing you need to do is match your electrode to your parent metal, and then you need to pick a size that’s relevant for the thickness you want to weld. Before welding, it is recommended by wia that the materials weldability/compatibility be confirmed. Welding Electrode Classification Australia.