Flush Joint Surface . In this type, mortar is pressed hard in the raked joints and by. A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. The pointed surface is kept wet for at least a week or till it sets after application. The flush joint is the simplest.

from www.alamy.com

In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. The flush joint is the simplest. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. In this type, mortar is pressed hard in the raked joints and by. The pointed surface is kept wet for at least a week or till it sets after application.

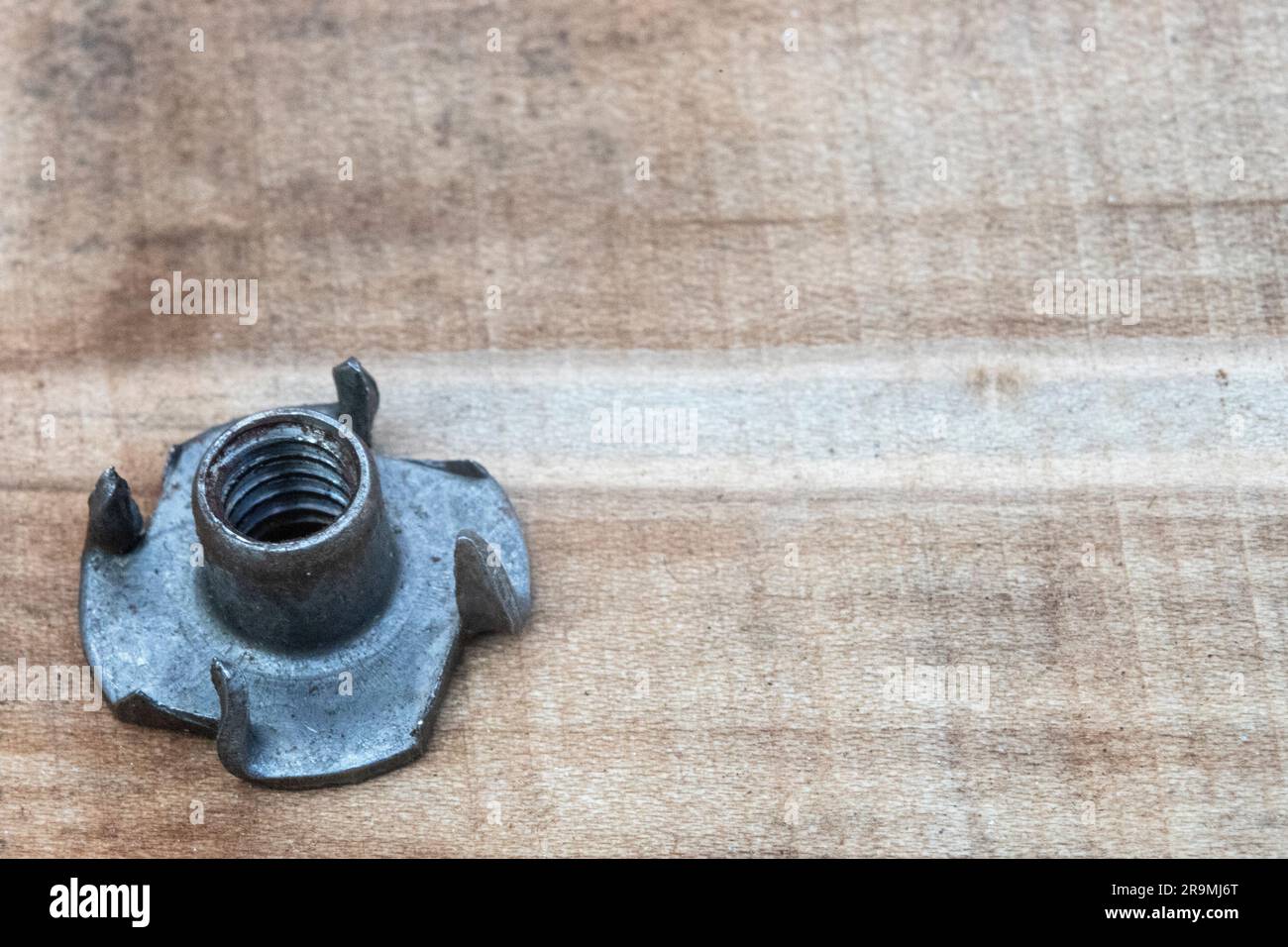

T nut, tee nut, blind nut, flush fitting, pronged nut, used to mount

Flush Joint Surface Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. The flush joint is the simplest. In this type, mortar is pressed hard in the raked joints and by. The pointed surface is kept wet for at least a week or till it sets after application.

From www.funktionalhome.com

Flush vs Overlap Stair Nose 6 Differences You Need to Know Flush Joint Surface In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. The pointed surface is kept wet for at least a week or till it sets after application. A flush joint refers to a construction technique where the joints between two surfaces are filled and. Flush Joint Surface.

From www.lrbuilding.co.uk

Repointing lrbuilding Flush Joint Surface Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. The flush joint is the simplest. Commonly used masonry joints in bricklaying include the. Flush Joint Surface.

From www.9wood.com

2600 Flush Joint Linear 9Wood Flush Joint Surface Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. In this type, mortar is pressed hard in the raked joints and by. The flush joint is the simplest. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. A flush joint refers to a construction. Flush Joint Surface.

From www.c-sgroup.co.uk

Gasketed Floor Joint Covers CS Allway® Expansion Joints Flush Joint Surface The pointed surface is kept wet for at least a week or till it sets after application. The flush joint is the simplest. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. In. Flush Joint Surface.

From www.cnexpansionjoint.com

Flush ThinLine Single Seal Floor Expansion Joint 25MM 50MM Flush Joint Surface The flush joint is the simplest. The pointed surface is kept wet for at least a week or till it sets after application. A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. In lower status work, such as random rubble walls, joints would often be filled flush,. Flush Joint Surface.

From flex-craft.com

Flush Joint 50083010 FlexCraft Flush Joint Surface The pointed surface is kept wet for at least a week or till it sets after application. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. The flush joint is the simplest. In lower status. Flush Joint Surface.

From www.roof2floordrains.co.uk

Aluminium Flush Joint Rectangular 112 Degree Adjustable 2 Part Swan Neck Flush Joint Surface In this type, mortar is pressed hard in the raked joints and by. A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to. Flush Joint Surface.

From purefreeform.com

Flush/Reveal Pure + FreeForm Flush Joint Surface In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. The pointed surface is kept wet for at least a week or till it. Flush Joint Surface.

From www.ompipeindustries.com

Flush Joint RCC Pipe Manufacturer,Flush Joint RCC Pipe Supplier,Sonipat Flush Joint Surface In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. The flush joint is the simplest. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. A flush joint refers to a construction technique where the joints between two surfaces. Flush Joint Surface.

From triscosystems.com

The Different Types of Mortar Joints Trisco Systems, Inc. Flush Joint Surface Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. The flush joint is the simplest. In this type, mortar is pressed hard in the raked joints and by. A flush joint refers to a construction. Flush Joint Surface.

From budewindows.co.uk

Flush Casement Windows Bude Flush Sash Window Prices Cornwall Flush Joint Surface In this type, mortar is pressed hard in the raked joints and by. The flush joint is the simplest. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. The pointed surface is kept wet for. Flush Joint Surface.

From www.alamy.com

T nut, tee nut, blind nut, flush fitting, pronged nut, used to mount Flush Joint Surface In this type, mortar is pressed hard in the raked joints and by. In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. The pointed surface is kept wet for at least a week or till it sets after application. A flush joint refers. Flush Joint Surface.

From www.9wood.com

2600 Flush Joint Linear 9Wood Flush Joint Surface Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. In this type, mortar is pressed hard in the raked joints and by. In lower status work, such. Flush Joint Surface.

From www.cnexpansionjoint.com

Flush Seismic Floor Expansion Joint With Rubber Strip SFFS Flush Joint Surface Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. In this type, mortar is pressed hard in the raked joints and by. The pointed surface is kept wet for at least a week or till it sets after application. A flush joint refers to a construction technique where the. Flush Joint Surface.

From www.pinterest.com

How to Grout a Flush Mortar Joint YouTube Flush, Brick fireplace, Joint Flush Joint Surface In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. The pointed surface is kept wet for at least a week or till it sets after application. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. Some joint profiles. Flush Joint Surface.

From theconstructor.org

What is the Laying and Jointing Procedure of Concrete Pipes? [PDF Flush Joint Surface Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. The pointed surface is kept wet for at least a week or till it sets after application. The flush joint is the simplest. In this type, mortar is pressed hard in the raked joints and by. A flush joint refers to a construction technique where the. Flush Joint Surface.

From imiweb.org

01.410.1001 Mortar Joint Profiles International Masonry Institute Flush Joint Surface Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. In lower status work,. Flush Joint Surface.

From welditu.com

Types of Welding Joints and Welds Color Graphics • WelditU Flush Joint Surface The pointed surface is kept wet for at least a week or till it sets after application. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. In lower status work, such as random rubble walls,. Flush Joint Surface.

From www.pinterest.es

Flush jointsAll metal technical building materials in 2019 Flush Joint Surface In this type, mortar is pressed hard in the raked joints and by. A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to. Flush Joint Surface.

From constructowiki.com

How Can You Master Flush Joints For Seamless Surfaces? Flush Joint Surface In this type, mortar is pressed hard in the raked joints and by. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. The flush joint is the simplest. A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material,. Flush Joint Surface.

From purefreeform.com

Flush/Reveal Pure + FreeForm Flush Joint Surface Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. The flush joint is the simplest. The pointed surface is kept wet for at. Flush Joint Surface.

From www.spec-net.com.au

Flush Floor Joints for Ramsay Health Care by Unison Joints Flush Joint Surface The pointed surface is kept wet for at least a week or till it sets after application. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. In this type, mortar is pressed hard in the. Flush Joint Surface.

From bleckarchitects.com

Exploring Masonry Mortar Joints Bleck & Bleck Architects Flush Joint Surface The flush joint is the simplest. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. In this type, mortar is pressed hard in the raked joints and by. Some joint profiles accentuate their. Flush Joint Surface.

From constructowiki.com

How Can You Master Flush Joints For Seamless Surfaces? Flush Joint Surface The pointed surface is kept wet for at least a week or till it sets after application. In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a. Flush Joint Surface.

From www.researchgate.net

Bolted joint with tortuous depth path between flush exterior and Flush Joint Surface In this type, mortar is pressed hard in the raked joints and by. The flush joint is the simplest. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. A flush joint refers to a construction. Flush Joint Surface.

From flex-craft.com

Flush Joint 50083010 FlexCraft Flush Joint Surface A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. In this type, mortar is pressed hard in the raked joints and by. The pointed surface is kept wet for at least a week. Flush Joint Surface.

From www.cnexpansionjoint.com

Flush ThinLine Single Seal Floor Expansion Joint 25MM 50MM Flush Joint Surface A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. In this type, mortar is pressed hard in the raked joints and by. The flush joint is the simplest. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. In lower status work, such. Flush Joint Surface.

From welditu.com

Guide to Welding Joint Types and Parts WelditU Flush Joint Surface In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. Commonly used masonry joints in bricklaying include the flush joint and the. Flush Joint Surface.

From www.onestopndt.com

An ultimate Guide to Weld Joints OnestopNDT Flush Joint Surface In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. The pointed surface is kept wet for at least a week or till it sets after application. Some joint profiles. Flush Joint Surface.

From dreamcivil.com

Flush Mortar Joint Working, Effect, Advantages & Disadvantages of Flush Joint Surface The flush joint is the simplest. The pointed surface is kept wet for at least a week or till it sets after application. In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. Some joint profiles accentuate their individual designs, while others merge the. Flush Joint Surface.

From guttercentre.co.uk

Aluminium Flush Joint Round 112 Degree Branch Flush Joint Surface Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. The flush joint is. Flush Joint Surface.

From www.designingthepast.com

Mortar Joint Profiles A Brief Guide — Designing The Past Flush Joint Surface The pointed surface is kept wet for at least a week or till it sets after application. In this type, mortar is pressed hard in the raked joints and by. A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting. The flush joint is the simplest. Commonly used. Flush Joint Surface.

From welditu.com

Guide to Welding Joint Types and Parts WelditU Flush Joint Surface In this type, mortar is pressed hard in the raked joints and by. In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. The pointed surface is kept wet for at least a week or till it sets after application. Some joint profiles accentuate. Flush Joint Surface.

From www.pinterest.co.uk

FLUSH JOINT Brick cladding, Cladding, Finishing tools Flush Joint Surface In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. Some joint profiles accentuate their individual designs, while others merge the bricks and mortar to form a flush, homogeneous surface. In this type, mortar is pressed hard in the raked joints and by. A. Flush Joint Surface.

From civilmart.com.au

Flush Joint (FJ/IJ) Concrete Pipes Civilmart Flush Joint Surface Commonly used masonry joints in bricklaying include the flush joint and the weathered joint. In this type, mortar is pressed hard in the raked joints and by. In lower status work, such as random rubble walls, joints would often be filled flush, with mortar spreading onto the surface of the stone, to give. Some joint profiles accentuate their individual designs,. Flush Joint Surface.