Helical Gear Damage . Note that misalignment greatly increases most of the. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. Helical gear is a fundamental component in modern machinery, offering advantages over their spur gear counterparts in. The procedure takes into account the pitting. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high.

from www.zhygear.com

Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Helical gear is a fundamental component in modern machinery, offering advantages over their spur gear counterparts in. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. The procedure takes into account the pitting. Note that misalignment greatly increases most of the.

Failure form and mechanism of automobile gear ZHY Gear

Helical Gear Damage Note that misalignment greatly increases most of the. The procedure takes into account the pitting. Note that misalignment greatly increases most of the. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Helical gear is a fundamental component in modern machinery, offering advantages over their spur gear counterparts in. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given.

From www.researchgate.net

A helical gear cracked tooth Download Scientific Diagram Helical Gear Damage In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. Note that misalignment greatly increases most of the. There are various types of damage. Helical Gear Damage.

From www.semanticscholar.org

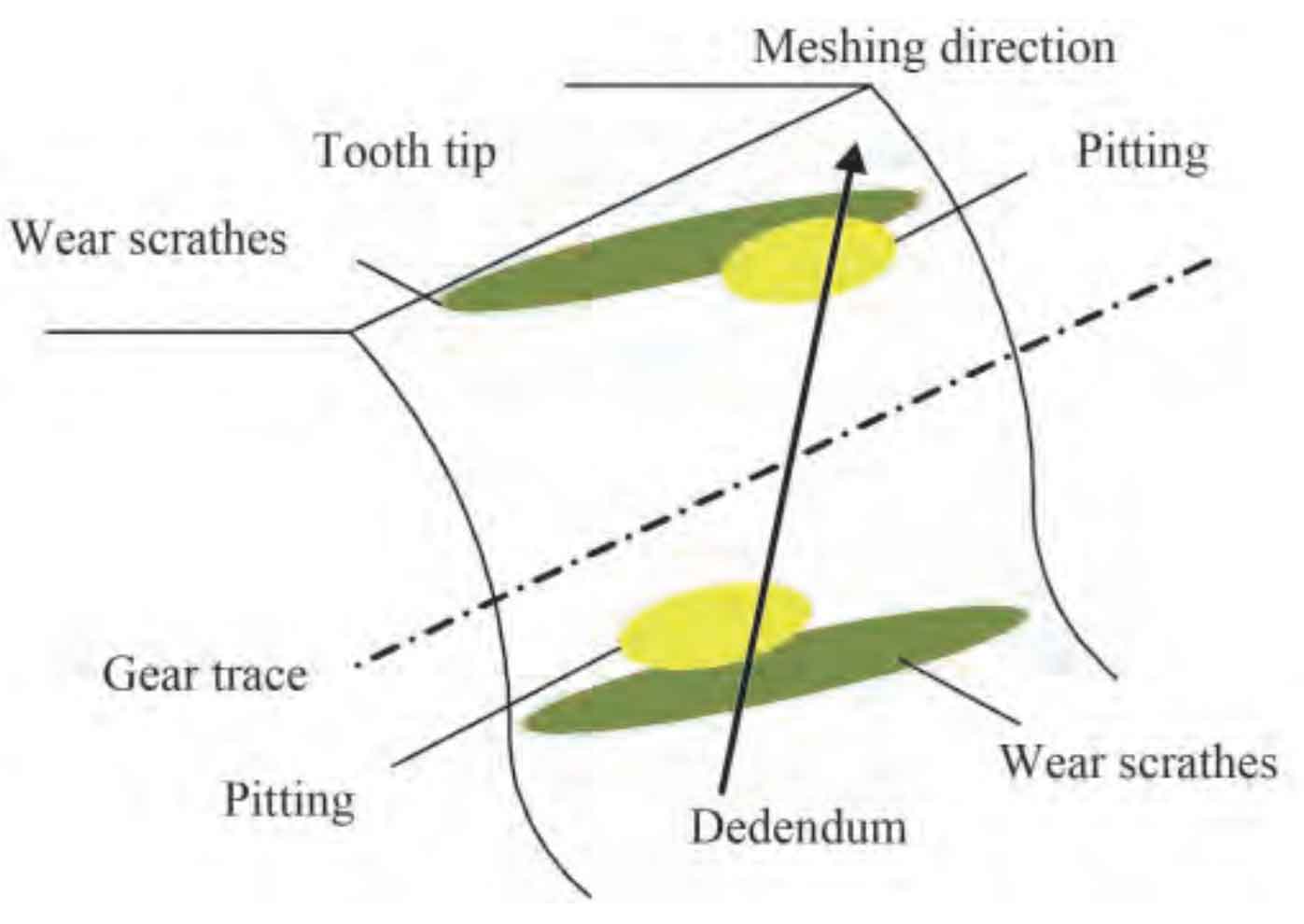

Figure 10 from Contact Fatigue Failure Analysis of Helical Gears with NonEntire Tooth Meshing Helical Gear Damage Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. The procedure takes into account the pitting. Helical gear is a fundamental. Helical Gear Damage.

From www.mdpi.com

Metals Free FullText Contact Fatigue Failure Analysis of Helical Gears with NonEntire Helical Gear Damage Note that misalignment greatly increases most of the. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. The procedure takes into. Helical Gear Damage.

From www.researchgate.net

Schematic diagram of helical gear transverse face with crack fault. Download Scientific Diagram Helical Gear Damage In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. Note that misalignment greatly increases most of the. Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. The procedure takes into account the pitting. Wear in helical gear is the gradual removal. Helical Gear Damage.

From www.slideshare.net

Failure analysis of helical gear Helical Gear Damage Note that misalignment greatly increases most of the. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. Exposure to corrosive environments or moisture can degrade helical. Helical Gear Damage.

From www.mdpi.com

Applied Sciences Free FullText Pinion Failure Analysis of a Helical Reduction Gearbox in a Helical Gear Damage Note that misalignment greatly increases most of the. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. Helical gear teeth are affected by cratering. Helical Gear Damage.

From www.mdpi.com

Applied Sciences Free FullText Pinion Failure Analysis of a Helical Reduction Gearbox in a Helical Gear Damage Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a. Helical Gear Damage.

From www.mdpi.com

Applied Sciences Free FullText Pinion Failure Analysis of a Helical Reduction Gearbox in a Helical Gear Damage Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Helical gear is a fundamental component in modern machinery, offering advantages over. Helical Gear Damage.

From www.mdpi.com

Applied Sciences Free FullText Pinion Failure Analysis of a Helical Reduction Gearbox in a Helical Gear Damage There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. The procedure takes into account the pitting. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. Exposure to corrosive environments or moisture can degrade. Helical Gear Damage.

From www.semanticscholar.org

Figure 5 from Contact Fatigue Failure Analysis of Helical Gears with NonEntire Tooth Meshing Helical Gear Damage In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. Note that misalignment greatly increases most of the. Helical gear is a fundamental component. Helical Gear Damage.

From www.semanticscholar.org

Figure 19 from Contact Fatigue Failure Analysis of Helical Gears with NonEntire Tooth Meshing Helical Gear Damage There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. Exposure to corrosive environments or moisture can degrade helical gear material, leading. Helical Gear Damage.

From www.mdpi.com

Machines Free FullText Vibration Analysis of TwoStage Helical Gear Transmission with Helical Gear Damage The procedure takes into account the pitting. Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Helical gear teeth are affected by cratering wear — particularly in the regions of. Helical Gear Damage.

From www.zhygear.com

Cloud chart of equivalent stress distribution during helical gear meshing ZHY Gear Helical Gear Damage Note that misalignment greatly increases most of the. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Exposure to corrosive environments or moisture can. Helical Gear Damage.

From honda-tech.com

***Aftermarket Gear Failures?*** HondaTech Helical Gear Damage There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. Helical gear teeth are affected by cratering wear — particularly in the regions of low. Helical Gear Damage.

From www.mdpi.com

Machines Free FullText Dynamic Simulation of Cracked Spiral Bevel Gear Pair Considering Helical Gear Damage Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. Helical gear is a fundamental component in modern machinery, offering advantages over their spur gear counterparts in. The procedure takes into account the pitting. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. Helical gear. Helical Gear Damage.

From www.zhygear.com

Comprehensive Analysis of Broken Teeth of Large Helical Gear of Loader Drive Axle ZHY Gear Helical Gear Damage The procedure takes into account the pitting. Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. Note that misalignment greatly increases most of the. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. There are various types of damage and breakage that can occur. Helical Gear Damage.

From www.eng-tips.com

Through vs Case Hardening to Fix Root Fatigue Failure Gear & Pulley engineering EngTips Helical Gear Damage Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. The procedure takes into account the pitting. Note that misalignment greatly increases most of the. Helical gear is a fundamental component in modern. Helical Gear Damage.

From www.zhygear.com

Failure Analysis of Broken Tooth of Large Helical Gear of Loader Drive Axle ZHY Gear Helical Gear Damage The procedure takes into account the pitting. Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil. Helical Gear Damage.

From www.semanticscholar.org

Figure 13 from Contact Fatigue Failure Analysis of Helical Gears with NonEntire Tooth Meshing Helical Gear Damage Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Helical gear is a fundamental component in modern machinery, offering advantages over. Helical Gear Damage.

From www.mdpi.com

Metals Free FullText Contact Fatigue Failure Analysis of Helical Gears with NonEntire Helical Gear Damage The procedure takes into account the pitting. Helical gear is a fundamental component in modern machinery, offering advantages over their spur gear counterparts in. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. There are various types of damage and breakage that can occur to gears, this section introduces. Helical Gear Damage.

From www.elkeme.gr

Bending fatigue failure of a helical bevel pinion gear Elkeme Helical Gear Damage There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Note that misalignment greatly increases most of the. The procedure takes into account the pitting. Helical gear is a fundamental component in modern machinery, offering advantages over their spur gear counterparts in. Wear in helical. Helical Gear Damage.

From www.academia.edu

(PDF) Damage types of crossed helical gears with wheels from sintered steel Aleksandar Helical Gear Damage Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. Note that misalignment greatly increases most of the. The procedure takes into account the pitting. Helical gear is a fundamental component in modern machinery, offering advantages over their spur gear counterparts in. Wear in helical gear is the gradual removal of material from the gear teeth. Helical Gear Damage.

From www.academia.edu

(PDF) Prevention of helical gear tooth damage in wind turbine generator a case study Mnj Helical Gear Damage There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. The procedure takes into account the pitting. Note that misalignment greatly increases most of the. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank. Helical Gear Damage.

From www.semanticscholar.org

Figure 1 from Pitting failure of helical gears induced by trochoidal interference and Helical Gear Damage The procedure takes into account the pitting. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. Helical gear teeth are affected by cratering wear — particularly. Helical Gear Damage.

From www.researchgate.net

Picture of gear damage from the borescope inspection Download Scientific Diagram Helical Gear Damage Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. The procedure takes into account the pitting. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for. Helical Gear Damage.

From www.zhygear.com

Helical Gear Failure Analysis ZHY Gear Helical Gear Damage Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. The procedure takes. Helical Gear Damage.

From www.pinterest.com

The micropitting image comes from the Failure modes section of the website. It includes many Helical Gear Damage Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. Note that misalignment. Helical Gear Damage.

From seven.edu.vn

Discover 108+ helical gear drawing best seven.edu.vn Helical Gear Damage Note that misalignment greatly increases most of the. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. In this presentation, the. Helical Gear Damage.

From www.mdpi.com

Applied Sciences Free FullText Pinion Failure Analysis of a Helical Reduction Gearbox in a Helical Gear Damage There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. In this presentation, the procedure and formulas to estimate a value of. Helical Gear Damage.

From www.zhygear.com

Transmission error and meshing impact of Helical Gears Considering tooth surface friction ZHY Gear Helical Gear Damage Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Note. Helical Gear Damage.

From www.machinerylubrication.com

Guidelines for Determining the Cause of Gear Failures Helical Gear Damage Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. The procedure takes into account the pitting. Helical gear is a fundamental component in modern machinery, offering. Helical Gear Damage.

From www.reddit.com

Double helical gear failure Excessive oil velocity from spray nozzles resulted in foaming of Helical Gear Damage Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. Helical gear is a fundamental component in modern machinery, offering advantages over their spur gear counterparts in. There are various types of damage and breakage that can occur to gears, this section introduces some of those as. Helical Gear Damage.

From www.zhygear.com

Failure form and mechanism of automobile gear ZHY Gear Helical Gear Damage Wear in helical gear is the gradual removal of material from the gear teeth due to friction and contact stresses. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. The procedure takes into account the pitting. Helical gear teeth are affected by cratering wear. Helical Gear Damage.

From www.researchgate.net

(PDF) Damage Types of Crossed Helical Gears with Wheels from Sintered Steel Helical Gear Damage Exposure to corrosive environments or moisture can degrade helical gear material, leading to failure. In this presentation, the procedure and formulas to estimate a value of gear life expectancy for a high number of cycles is given. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the. Helical Gear Damage.

From www.zhygear.com

Calculation of contact fatigue life of highspeed helical gears in electric vehicles ZHY Gear Helical Gear Damage Note that misalignment greatly increases most of the. Helical gear teeth are affected by cratering wear — particularly in the regions of low oil film thicknesses, high flank pressures and high. There are various types of damage and breakage that can occur to gears, this section introduces some of those as defined by the jgma 7001. Exposure to corrosive environments. Helical Gear Damage.