What Size Welding Wire For 1/8 Steel . This is the most basic welding position where the weld is performed from the top side of the joint, and the face of the weld is horizontal. according to charts for thicker material you should use.035 but most welding shops say.030 works great on. find the right welding electrode or filler wire for different materials, such as carbon steel, stainless steel, duplex. learn how to select the right mig wire size for different metal thicknesses and welding applications. learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. follow these basic guidelines for choosing welding wire based on the four main welding positions: See the chart for solid wire and. Flat position (1g or 1f): learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding.

from weldguru.com

follow these basic guidelines for choosing welding wire based on the four main welding positions: learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding. find the right welding electrode or filler wire for different materials, such as carbon steel, stainless steel, duplex. This is the most basic welding position where the weld is performed from the top side of the joint, and the face of the weld is horizontal. See the chart for solid wire and. Flat position (1g or 1f): learn how to select the right mig wire size for different metal thicknesses and welding applications. learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. according to charts for thicker material you should use.035 but most welding shops say.030 works great on.

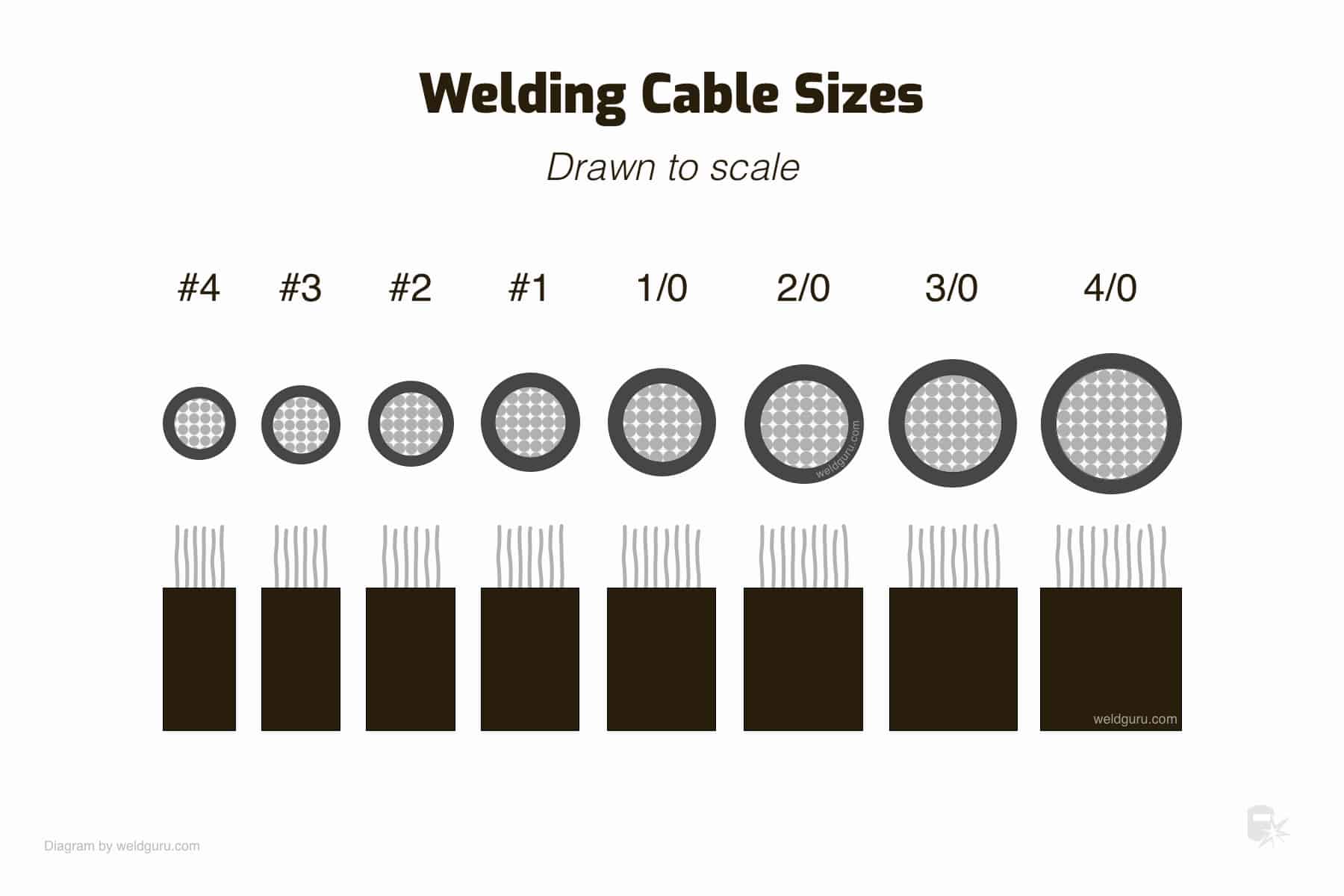

Welding Cable Size Guide Charts & Tips for the Right Choice

What Size Welding Wire For 1/8 Steel learn how to select the right mig wire size for different metal thicknesses and welding applications. according to charts for thicker material you should use.035 but most welding shops say.030 works great on. This is the most basic welding position where the weld is performed from the top side of the joint, and the face of the weld is horizontal. find the right welding electrode or filler wire for different materials, such as carbon steel, stainless steel, duplex. See the chart for solid wire and. follow these basic guidelines for choosing welding wire based on the four main welding positions: learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. Flat position (1g or 1f): learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding. learn how to select the right mig wire size for different metal thicknesses and welding applications.

From classschoolziegler.z19.web.core.windows.net

Thickness Welding Rod Sizes Chart What Size Welding Wire For 1/8 Steel This is the most basic welding position where the weld is performed from the top side of the joint, and the face of the weld is horizontal. learn how to select the right mig wire size for different metal thicknesses and welding applications. Flat position (1g or 1f): learn how to select the right mig wire size for. What Size Welding Wire For 1/8 Steel.

From www.walmart.com

Steel OTC Wire Feeder Roller Dual Size Welding Wire Feeding Guide Wheel(0.81.0mm) What Size Welding Wire For 1/8 Steel learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. Flat position (1g or 1f): according to charts for thicker material you should use.035 but most welding shops say.030 works great on. follow these basic guidelines for choosing welding wire based on the four main. What Size Welding Wire For 1/8 Steel.

From weldguru.com

Welding Cable Size Guide Charts & Tips for the Right Choice What Size Welding Wire For 1/8 Steel follow these basic guidelines for choosing welding wire based on the four main welding positions: learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. See the chart for solid wire and. learn how to select the right mig wire size for your welding project. What Size Welding Wire For 1/8 Steel.

From sharkind.com

3 PK E6011 All position, all purpose mild steel welding rod1/8"Job Shark Industries What Size Welding Wire For 1/8 Steel Flat position (1g or 1f): follow these basic guidelines for choosing welding wire based on the four main welding positions: learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding. learn how to choose and adjust the optimal mig welding settings for steel with solid wire,. What Size Welding Wire For 1/8 Steel.

From charliewyatt.z13.web.core.windows.net

Welding Cable Sizes Chart What Size Welding Wire For 1/8 Steel Flat position (1g or 1f): learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. find the right welding electrode or filler wire for different materials, such as carbon steel, stainless steel, duplex. according to charts for thicker material you should use.035 but most welding. What Size Welding Wire For 1/8 Steel.

From shopee.com.my

1kg MIG Wire Gasless Steel Flux Cored Low Temperature Simple Welding Rods (E71TGS) 0.8MM 1.0MM What Size Welding Wire For 1/8 Steel follow these basic guidelines for choosing welding wire based on the four main welding positions: Flat position (1g or 1f): See the chart for solid wire and. learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding. learn how to select the right mig wire size. What Size Welding Wire For 1/8 Steel.

From weldguru.com

How To MIG Weld Aluminum Beginners Guide (with Chart) What Size Welding Wire For 1/8 Steel This is the most basic welding position where the weld is performed from the top side of the joint, and the face of the weld is horizontal. find the right welding electrode or filler wire for different materials, such as carbon steel, stainless steel, duplex. See the chart for solid wire and. learn how to select the right. What Size Welding Wire For 1/8 Steel.

From circuitchamullegt.z14.web.core.windows.net

Welding Cable Size For 200 Amp What Size Welding Wire For 1/8 Steel learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. This is the most basic welding position where the weld is performed from the top side of the joint, and the face of the weld is horizontal. learn how to select the right mig wire size. What Size Welding Wire For 1/8 Steel.

From makemoneywelding.com

MIG Welding Wire Essentials A Guide to Types & Uses What Size Welding Wire For 1/8 Steel follow these basic guidelines for choosing welding wire based on the four main welding positions: learn how to select the right mig wire size for different metal thicknesses and welding applications. learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. according to charts. What Size Welding Wire For 1/8 Steel.

From www.shopjfi.com

1/8" x 36" ER70S3 Mild Steel Tig Welding Wire (1 lb) What Size Welding Wire For 1/8 Steel learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding. follow these basic guidelines for choosing welding wire based on the four main welding. What Size Welding Wire For 1/8 Steel.

From jodiebarnes.z21.web.core.windows.net

Mig Welding Amps To Metal Thickness Chart What Size Welding Wire For 1/8 Steel learn how to select the right mig wire size for different metal thicknesses and welding applications. learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. This is the most basic welding position where the weld is performed from the top side of the joint, and. What Size Welding Wire For 1/8 Steel.

From harrisweldingsupplies.com

Harris 309L .035 x 2 lb. Spool Stainless Steel Welding Wire 0309LF2 What Size Welding Wire For 1/8 Steel learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. See the chart for solid wire and. according to charts for thicker material you should use.035 but most welding shops say.030 works great on. This is the most basic welding position where the weld is performed. What Size Welding Wire For 1/8 Steel.

From weldguru.com

Welding Cable Size What's Best? (with Chart) What Size Welding Wire For 1/8 Steel See the chart for solid wire and. find the right welding electrode or filler wire for different materials, such as carbon steel, stainless steel, duplex. learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. follow these basic guidelines for choosing welding wire based on. What Size Welding Wire For 1/8 Steel.

From www.homedepot.ca

Forney Industries ER308L, .030 inch x 2 lbs., Stainless Steel MIG Welding Wire The Home Depot What Size Welding Wire For 1/8 Steel follow these basic guidelines for choosing welding wire based on the four main welding positions: learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. according to charts for thicker material you should use.035 but most welding shops say.030 works great on. Flat position (1g. What Size Welding Wire For 1/8 Steel.

From www.sakysteel.com

ER Stainless Steel Welding Wire Saky Steel What Size Welding Wire For 1/8 Steel learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. follow these basic guidelines for choosing welding wire based on the four main welding positions: learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration,. What Size Welding Wire For 1/8 Steel.

From www.homedepot.com

How to MIG Weld The Home Depot What Size Welding Wire For 1/8 Steel Flat position (1g or 1f): This is the most basic welding position where the weld is performed from the top side of the joint, and the face of the weld is horizontal. learn how to select the right mig wire size for different metal thicknesses and welding applications. according to charts for thicker material you should use.035 but. What Size Welding Wire For 1/8 Steel.

From weldguru.com

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru What Size Welding Wire For 1/8 Steel See the chart for solid wire and. learn how to select the right mig wire size for different metal thicknesses and welding applications. follow these basic guidelines for choosing welding wire based on the four main welding positions: learn how to select the right mig wire size for your welding project based on the material thickness, joint. What Size Welding Wire For 1/8 Steel.

From www.weldingcity.com

WeldingCity® 11lb 0.030" ER309L Stainless Steel MIG Welding Wire 8in Spool What Size Welding Wire For 1/8 Steel learn how to select the right mig wire size for different metal thicknesses and welding applications. learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. Flat position (1g or 1f): See the chart for solid wire and. This is the most basic welding position where. What Size Welding Wire For 1/8 Steel.

From arcflowindustries.com

430L Welding Stainless Steel MIG Wire Arcflow What Size Welding Wire For 1/8 Steel follow these basic guidelines for choosing welding wire based on the four main welding positions: learn how to select the right mig wire size for different metal thicknesses and welding applications. learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding. according to charts for. What Size Welding Wire For 1/8 Steel.

From dxoducuxe.blob.core.windows.net

Welding Rod Position Chart at Derek Nickel blog What Size Welding Wire For 1/8 Steel learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. follow these basic guidelines for choosing welding wire based on the four main welding positions: See the chart for solid wire and. learn how to select the right mig wire size for your welding project. What Size Welding Wire For 1/8 Steel.

From ratemywelder.com

Best MIG Welding Wire Reviews (2023) For Mild Steel & More What Size Welding Wire For 1/8 Steel learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding. find the right welding electrode or filler wire for different materials, such as carbon steel, stainless steel, duplex. follow these basic guidelines for choosing welding wire based on the four main welding positions: learn how. What Size Welding Wire For 1/8 Steel.

From www.welspring.com

MIG Wire — Welspring Universal What Size Welding Wire For 1/8 Steel Flat position (1g or 1f): follow these basic guidelines for choosing welding wire based on the four main welding positions: according to charts for thicker material you should use.035 but most welding shops say.030 works great on. This is the most basic welding position where the weld is performed from the top side of the joint, and the. What Size Welding Wire For 1/8 Steel.

From www.youtube.com

MIG Welding What Size Wire Should I Use? YouTube What Size Welding Wire For 1/8 Steel follow these basic guidelines for choosing welding wire based on the four main welding positions: This is the most basic welding position where the weld is performed from the top side of the joint, and the face of the weld is horizontal. Flat position (1g or 1f): See the chart for solid wire and. learn how to select. What Size Welding Wire For 1/8 Steel.

From exoqdqeub.blob.core.windows.net

Hobart Welding Wire Chart at Kayleigh Mohr blog What Size Welding Wire For 1/8 Steel according to charts for thicker material you should use.035 but most welding shops say.030 works great on. learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding. follow these basic guidelines for choosing welding wire based on the four main welding positions: This is the most. What Size Welding Wire For 1/8 Steel.

From weldingpros.net

Stick Welding Rod Charts and Calculator Amps, Sizes, Types What Size Welding Wire For 1/8 Steel learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding. follow these basic guidelines for choosing welding wire based on the four main welding positions: This is the most basic welding position where the weld is performed from the top side of the joint, and the face. What Size Welding Wire For 1/8 Steel.

From www.tollgas.com

WeldingCableSizeAmperageChart Toll Gas & Welding Supply What Size Welding Wire For 1/8 Steel find the right welding electrode or filler wire for different materials, such as carbon steel, stainless steel, duplex. learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding. Flat position (1g or 1f): follow these basic guidelines for choosing welding wire based on the four main. What Size Welding Wire For 1/8 Steel.

From studycampuslemann.z19.web.core.windows.net

Welding Wire Gauge Chart What Size Welding Wire For 1/8 Steel See the chart for solid wire and. learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding. find the right welding electrode or filler wire for different materials, such as carbon steel, stainless steel, duplex. This is the most basic welding position where the weld is performed. What Size Welding Wire For 1/8 Steel.

From weldguru.com

Welding Cable Size Guide Charts & Tips for the Right Choice What Size Welding Wire For 1/8 Steel according to charts for thicker material you should use.035 but most welding shops say.030 works great on. learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding. learn how to select the right mig wire size for different metal thicknesses and welding applications. learn how. What Size Welding Wire For 1/8 Steel.

From www.indiamart.com

Stainless Steel MIG Welding Wire, Thickness 3 mm, Packaging Type Roll, Rs 455 /kilogram ID What Size Welding Wire For 1/8 Steel learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. learn how to select the right mig wire size for different metal thicknesses and welding applications. Flat position (1g or 1f): learn how to select the right mig wire size for your welding project based. What Size Welding Wire For 1/8 Steel.

From 1xtechnologies.com

Welding Cable [Price/Pricing/Cost, Sizes, Ampacity, Specs] What Size Welding Wire For 1/8 Steel learn how to choose and adjust the optimal mig welding settings for steel with solid wire, based on material thickness, wire size,. learn how to select the right mig wire size for different metal thicknesses and welding applications. follow these basic guidelines for choosing welding wire based on the four main welding positions: find the right. What Size Welding Wire For 1/8 Steel.

From weaversteelweld.com

Sheet Gauge Chart Weaver Steel Welding What Size Welding Wire For 1/8 Steel learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding. learn how to select the right mig wire size for different metal thicknesses and welding applications. according to charts for thicker material you should use.035 but most welding shops say.030 works great on. Flat position (1g. What Size Welding Wire For 1/8 Steel.

From andrewbanks.z19.web.core.windows.net

309 Welding Rod Amperage Chart What Size Welding Wire For 1/8 Steel This is the most basic welding position where the weld is performed from the top side of the joint, and the face of the weld is horizontal. learn how to select the right mig wire size for different metal thicknesses and welding applications. See the chart for solid wire and. according to charts for thicker material you should. What Size Welding Wire For 1/8 Steel.

From www.indiamart.com

SUPERON ER 309L STAINLESS STEEL WELDING FILLER WIRE at Rs 490 in Pune What Size Welding Wire For 1/8 Steel follow these basic guidelines for choosing welding wire based on the four main welding positions: Flat position (1g or 1f): See the chart for solid wire and. according to charts for thicker material you should use.035 but most welding shops say.030 works great on. learn how to choose and adjust the optimal mig welding settings for steel. What Size Welding Wire For 1/8 Steel.

From nicholascook.z21.web.core.windows.net

Metal Thickness Stick Welding Amperage Chart What Size Welding Wire For 1/8 Steel according to charts for thicker material you should use.035 but most welding shops say.030 works great on. Flat position (1g or 1f): learn how to select the right mig wire size for your welding project based on the material thickness, joint configuration, welding. follow these basic guidelines for choosing welding wire based on the four main welding. What Size Welding Wire For 1/8 Steel.

From ratemywelder.com

Best MIG Welding Wire Reviews (2023) For Mild Steel & More What Size Welding Wire For 1/8 Steel learn how to select the right mig wire size for different metal thicknesses and welding applications. Flat position (1g or 1f): This is the most basic welding position where the weld is performed from the top side of the joint, and the face of the weld is horizontal. find the right welding electrode or filler wire for different. What Size Welding Wire For 1/8 Steel.