Handling Stone Slabs . Learn the proper measures needed to be taken when loading and unloading slabs in various situations on and off the jobsite. Safety protocol for slab handling. There are three main techniques for moving slabs of stone safely and efficiently: Depending on the type of stone, slabs run the risk of fissuring and cracking in unpredictable ways and natural stone can crack and shatter without warning. The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner. Stone slabs can be unwieldly and dangerous if not handled properly. A typical slab can weigh from 800 to over 1,000 pounds. For that reason, only a skilled stone professional should be doing the handling. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. Safety should always be at the forefront when moving slabs around a warehouse, fabrication shop or on the jobsite.

from www.rouramh.com

Safety should always be at the forefront when moving slabs around a warehouse, fabrication shop or on the jobsite. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. There are three main techniques for moving slabs of stone safely and efficiently: Safety protocol for slab handling. The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner. Stone slabs can be unwieldly and dangerous if not handled properly. Depending on the type of stone, slabs run the risk of fissuring and cracking in unpredictable ways and natural stone can crack and shatter without warning. For that reason, only a skilled stone professional should be doing the handling. A typical slab can weigh from 800 to over 1,000 pounds. Learn the proper measures needed to be taken when loading and unloading slabs in various situations on and off the jobsite.

Stone Handling Equipment Stone Slab Handling Equipment

Handling Stone Slabs Stone slabs are unique in many ways and the handling risks may depend on the type of stone. The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner. A typical slab can weigh from 800 to over 1,000 pounds. Safety should always be at the forefront when moving slabs around a warehouse, fabrication shop or on the jobsite. For that reason, only a skilled stone professional should be doing the handling. Stone slabs can be unwieldly and dangerous if not handled properly. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. Depending on the type of stone, slabs run the risk of fissuring and cracking in unpredictable ways and natural stone can crack and shatter without warning. There are three main techniques for moving slabs of stone safely and efficiently: Learn the proper measures needed to be taken when loading and unloading slabs in various situations on and off the jobsite. Safety protocol for slab handling.

From www.stoneworld.com

Safely handling slabs in the warehouse and jobsite 20150501 Stone Handling Stone Slabs The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. There are three main techniques for moving slabs of stone safely. Handling Stone Slabs.

From deltaequipment.com.au

Probst Vacuum Handy VH Paver & Slab Lifter for Lifting Pavers and Slabs Handling Stone Slabs Safety protocol for slab handling. Stone slabs can be unwieldly and dangerous if not handled properly. Safety should always be at the forefront when moving slabs around a warehouse, fabrication shop or on the jobsite. There are three main techniques for moving slabs of stone safely and efficiently: The handling and storage of large sheet stone slabs carry a high. Handling Stone Slabs.

From hyglassmachine.en.made-in-china.com

Stone Processing Machine FiveAxis Bridge Saw Capable of Handling Handling Stone Slabs Learn the proper measures needed to be taken when loading and unloading slabs in various situations on and off the jobsite. Stone slabs can be unwieldly and dangerous if not handled properly. Depending on the type of stone, slabs run the risk of fissuring and cracking in unpredictable ways and natural stone can crack and shatter without warning. For that. Handling Stone Slabs.

From cgaxis.com

Large Brown Stone Slabs PBR Texture Handling Stone Slabs Depending on the type of stone, slabs run the risk of fissuring and cracking in unpredictable ways and natural stone can crack and shatter without warning. Safety should always be at the forefront when moving slabs around a warehouse, fabrication shop or on the jobsite. A typical slab can weigh from 800 to over 1,000 pounds. The handling and storage. Handling Stone Slabs.

From pdfslide.net

(PDF) Handling and placing of the slabs ROCKWOOL Masterstatic Handling Stone Slabs The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. Safety should always be at the forefront when moving slabs around. Handling Stone Slabs.

From marootasandstonequarry.com.au

Sandstone Slabs Handling Stone Slabs Stone slabs can be unwieldly and dangerous if not handled properly. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. A typical slab can weigh from 800 to over 1,000 pounds. Safety protocol for slab handling. The handling and storage of large sheet stone slabs carry a high risk of injury. Handling Stone Slabs.

From www.stoneworld.com

Technical Focus Advice on Handling, Fabricating and Installing Handling Stone Slabs For that reason, only a skilled stone professional should be doing the handling. A typical slab can weigh from 800 to over 1,000 pounds. Safety should always be at the forefront when moving slabs around a warehouse, fabrication shop or on the jobsite. The handling and storage of large sheet stone slabs carry a high risk of injury unless you. Handling Stone Slabs.

From shenghengmachinery.en.made-in-china.com

Vacuum Handling Equipment for Slabs and Tiles China Stone Vacuum Handling Stone Slabs For that reason, only a skilled stone professional should be doing the handling. A typical slab can weigh from 800 to over 1,000 pounds. Safety protocol for slab handling. The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner.. Handling Stone Slabs.

From www.a2zsell.com

RPM Tile Handling System for Porcelain Panels and Stone Slabs A2Z Sell Handling Stone Slabs For that reason, only a skilled stone professional should be doing the handling. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. There are three main techniques for moving slabs of stone safely and efficiently: A typical slab can weigh from 800 to over 1,000 pounds. The handling and storage of. Handling Stone Slabs.

From bropark.en.made-in-china.com

Marble Granite Stone Slab Vacuum Lifter Handling Machine China Floor Handling Stone Slabs Safety should always be at the forefront when moving slabs around a warehouse, fabrication shop or on the jobsite. A typical slab can weigh from 800 to over 1,000 pounds. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. Learn the proper measures needed to be taken when loading and unloading. Handling Stone Slabs.

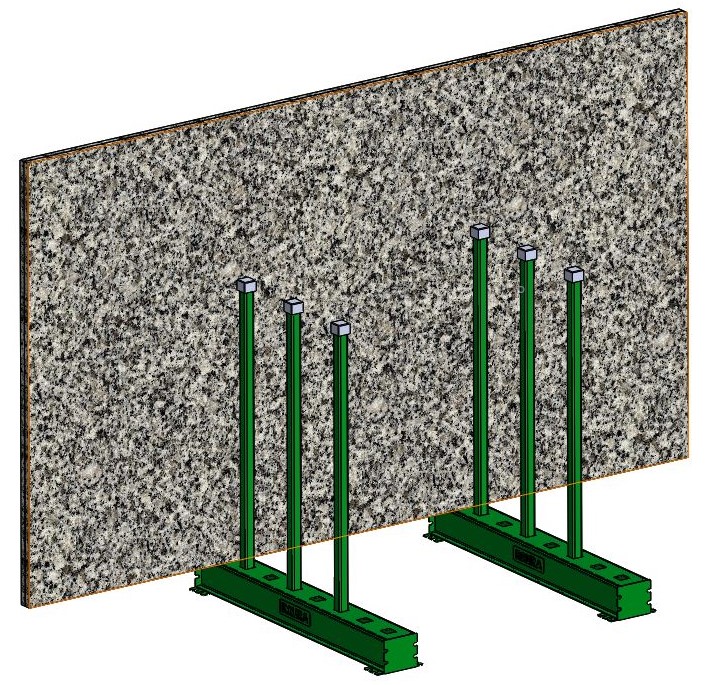

From www.rouramh.com

Granite Slab Racks Marble, Stone Bundle Storage Racks RouraMH Handling Stone Slabs Stone slabs can be unwieldly and dangerous if not handled properly. Safety protocol for slab handling. Safety should always be at the forefront when moving slabs around a warehouse, fabrication shop or on the jobsite. Depending on the type of stone, slabs run the risk of fissuring and cracking in unpredictable ways and natural stone can crack and shatter without. Handling Stone Slabs.

From www.directindustry.com

Stone slab vacuum lifting device LM3RP series Elephant Handling Stone Slabs There are three main techniques for moving slabs of stone safely and efficiently: Learn the proper measures needed to be taken when loading and unloading slabs in various situations on and off the jobsite. A typical slab can weigh from 800 to over 1,000 pounds. Stone slabs are unique in many ways and the handling risks may depend on the. Handling Stone Slabs.

From vac-lifter.en.made-in-china.com

Vacuum Lifter for Handling Stone Slabs and Ceramic Tiles China Handling Stone Slabs A typical slab can weigh from 800 to over 1,000 pounds. The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner. For that reason, only a skilled stone professional should be doing the handling. Safety should always be at. Handling Stone Slabs.

From www.publicdomainpictures.net

A Carpet Of Hail On Slasto Slabs In Free Stock Photo Public Domain Handling Stone Slabs The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner. Stone slabs can be unwieldly and dangerous if not handled properly. Depending on the type of stone, slabs run the risk of fissuring and cracking in unpredictable ways and. Handling Stone Slabs.

From www.youtube.com

Vacuum Lifting Marble/ Granite Slabs YES Machinery YouTube Handling Stone Slabs The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner. Depending on the type of stone, slabs run the risk of fissuring and cracking in unpredictable ways and natural stone can crack and shatter without warning. Safety should always. Handling Stone Slabs.

From www.stonecontact.com

Stone Vacuum Lifter For Handling Slabs And Tiles from China Handling Stone Slabs The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner. There are three main techniques for moving slabs of stone safely and efficiently: For that reason, only a skilled stone professional should be doing the handling. Depending on the. Handling Stone Slabs.

From www.stonecontact.com

Stone Vacuum Lifter For Handling Slabs And Tiles from China Handling Stone Slabs A typical slab can weigh from 800 to over 1,000 pounds. For that reason, only a skilled stone professional should be doing the handling. Depending on the type of stone, slabs run the risk of fissuring and cracking in unpredictable ways and natural stone can crack and shatter without warning. Stone slabs can be unwieldly and dangerous if not handled. Handling Stone Slabs.

From www.youtube.com

Lifting Granite Slabs in a warehouse YouTube Handling Stone Slabs For that reason, only a skilled stone professional should be doing the handling. Stone slabs can be unwieldly and dangerous if not handled properly. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. A typical slab can weigh from 800 to over 1,000 pounds. There are three main techniques for moving. Handling Stone Slabs.

From www.indiamart.com

Polished Grey Slate Stone Slabs, Thickness 15 mm at best price in Rewari Handling Stone Slabs A typical slab can weigh from 800 to over 1,000 pounds. Safety should always be at the forefront when moving slabs around a warehouse, fabrication shop or on the jobsite. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. Learn the proper measures needed to be taken when loading and unloading. Handling Stone Slabs.

From www.publicdomainpictures.net

Wall Of Slate Slabs Free Stock Photo Public Domain Pictures Handling Stone Slabs Stone slabs can be unwieldly and dangerous if not handled properly. The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner. Safety should always be at the forefront when moving slabs around a warehouse, fabrication shop or on the. Handling Stone Slabs.

From shenghengmachinery.en.made-in-china.com

Vacuum Lifting Equipment for Handling Large Stone Slabs and Tiles Handling Stone Slabs There are three main techniques for moving slabs of stone safely and efficiently: Safety should always be at the forefront when moving slabs around a warehouse, fabrication shop or on the jobsite. Stone slabs can be unwieldly and dangerous if not handled properly. For that reason, only a skilled stone professional should be doing the handling. A typical slab can. Handling Stone Slabs.

From edu.naturalstoneinstitute.org

Handling Slabs with Overhead Cranes Natural Stone University Handling Stone Slabs Learn the proper measures needed to be taken when loading and unloading slabs in various situations on and off the jobsite. There are three main techniques for moving slabs of stone safely and efficiently: Safety should always be at the forefront when moving slabs around a warehouse, fabrication shop or on the jobsite. Depending on the type of stone, slabs. Handling Stone Slabs.

From www.youtube.com

Forklift Lifting Granite Slab 1 YouTube Handling Stone Slabs The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner. Depending on the type of stone, slabs run the risk of fissuring and cracking in unpredictable ways and natural stone can crack and shatter without warning. Learn the proper. Handling Stone Slabs.

From www.rouramh.com

Stone Handling Equipment Stone Slab Handling Equipment Handling Stone Slabs Learn the proper measures needed to be taken when loading and unloading slabs in various situations on and off the jobsite. Safety protocol for slab handling. For that reason, only a skilled stone professional should be doing the handling. Safety should always be at the forefront when moving slabs around a warehouse, fabrication shop or on the jobsite. The handling. Handling Stone Slabs.

From www.readkong.com

Tile Handling even for natural stone and concrete slabs Oy Machine Handling Stone Slabs There are three main techniques for moving slabs of stone safely and efficiently: Learn the proper measures needed to be taken when loading and unloading slabs in various situations on and off the jobsite. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. Safety should always be at the forefront when. Handling Stone Slabs.

From www.vaclifter.com

Slab Vacuum Lifter Vacuum Lifter & Light Crane Handling Stone Slabs Safety should always be at the forefront when moving slabs around a warehouse, fabrication shop or on the jobsite. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. For that reason, only a skilled stone professional should be doing the handling. Stone slabs can be unwieldly and dangerous if not handled. Handling Stone Slabs.

From www.stoneworld.com

The safe zone What to know about handling stone slabs 20190311 Handling Stone Slabs For that reason, only a skilled stone professional should be doing the handling. Stone slabs can be unwieldly and dangerous if not handled properly. Learn the proper measures needed to be taken when loading and unloading slabs in various situations on and off the jobsite. The handling and storage of large sheet stone slabs carry a high risk of injury. Handling Stone Slabs.

From www.stoneadd.com

Handling Equipments Stone Machines ATTACHMENTS Forklift granite Handling Stone Slabs Safety protocol for slab handling. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner. There are three main techniques for. Handling Stone Slabs.

From hnnucrane.en.made-in-china.com

Stone Tiles and Slabs Vacuum Lifter for Handling in Storage Glass Handling Stone Slabs Stone slabs can be unwieldly and dangerous if not handled properly. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. A typical slab can weigh from 800 to over 1,000 pounds. For that reason, only a skilled stone professional should be doing the handling. Safety protocol for slab handling. There are. Handling Stone Slabs.

From www.usagranitetools.com

Handling Stone Slabs A more Efficient Granite ShopUSA GT Handling Stone Slabs For that reason, only a skilled stone professional should be doing the handling. The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner. A typical slab can weigh from 800 to over 1,000 pounds. Learn the proper measures needed. Handling Stone Slabs.

From belift.en.made-in-china.com

Glass Vacuum Lifter for Handling Stone Slabs Ceramic Tiles China Handling Stone Slabs There are three main techniques for moving slabs of stone safely and efficiently: A typical slab can weigh from 800 to over 1,000 pounds. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. Depending on the type of stone, slabs run the risk of fissuring and cracking in unpredictable ways and. Handling Stone Slabs.

From www.pinterest.es

Stonemarket Sawn Sandstone 'Beachside' Sand Paving Slabs Garden slabs Handling Stone Slabs A typical slab can weigh from 800 to over 1,000 pounds. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. There are three main techniques for moving slabs of stone safely and efficiently: Depending on the type of stone, slabs run the risk of fissuring and cracking in unpredictable ways and. Handling Stone Slabs.

From www.onlinesafetytrainer.com

Transporting, Storing, & Handling Granite, Marble, & Stone Slabs Handling Stone Slabs The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right equipment and do so in a safe manner. Stone slabs can be unwieldly and dangerous if not handled properly. Learn the proper measures needed to be taken when loading and unloading slabs in various situations on and. Handling Stone Slabs.

From pngtree.com

Tiles Or Stone Slabs, Block, Brick, Brown PNG Transparent Image and Handling Stone Slabs For that reason, only a skilled stone professional should be doing the handling. Stone slabs are unique in many ways and the handling risks may depend on the type of stone. Depending on the type of stone, slabs run the risk of fissuring and cracking in unpredictable ways and natural stone can crack and shatter without warning. There are three. Handling Stone Slabs.

From www.schmalz.ru

Vacuum lifter stone slab Handling Stone Slabs Depending on the type of stone, slabs run the risk of fissuring and cracking in unpredictable ways and natural stone can crack and shatter without warning. A typical slab can weigh from 800 to over 1,000 pounds. The handling and storage of large sheet stone slabs carry a high risk of injury unless you and your team use the right. Handling Stone Slabs.