Laser Cut Edge Hardness . There are many factors that can affect laser cutting quality; However, the most critical parameters to laser cut quality are material thickness and material type. Adjust the feed rate up in increments of 5% with each improving test part. When laser cutting mild steel, does the material develop a hardened edge? Has a reputation for pushing the fiber laser cutting envelope. A relationship was identified between the width of the laser haz and the hardness of the cut edge. Begin by setting feed rate 10% below the recommended setting. The machine, the operator and material can all have a bearing on quality of the cut edge. It is the thickness of the haz that is. My understanding is that mild steel cannot be.

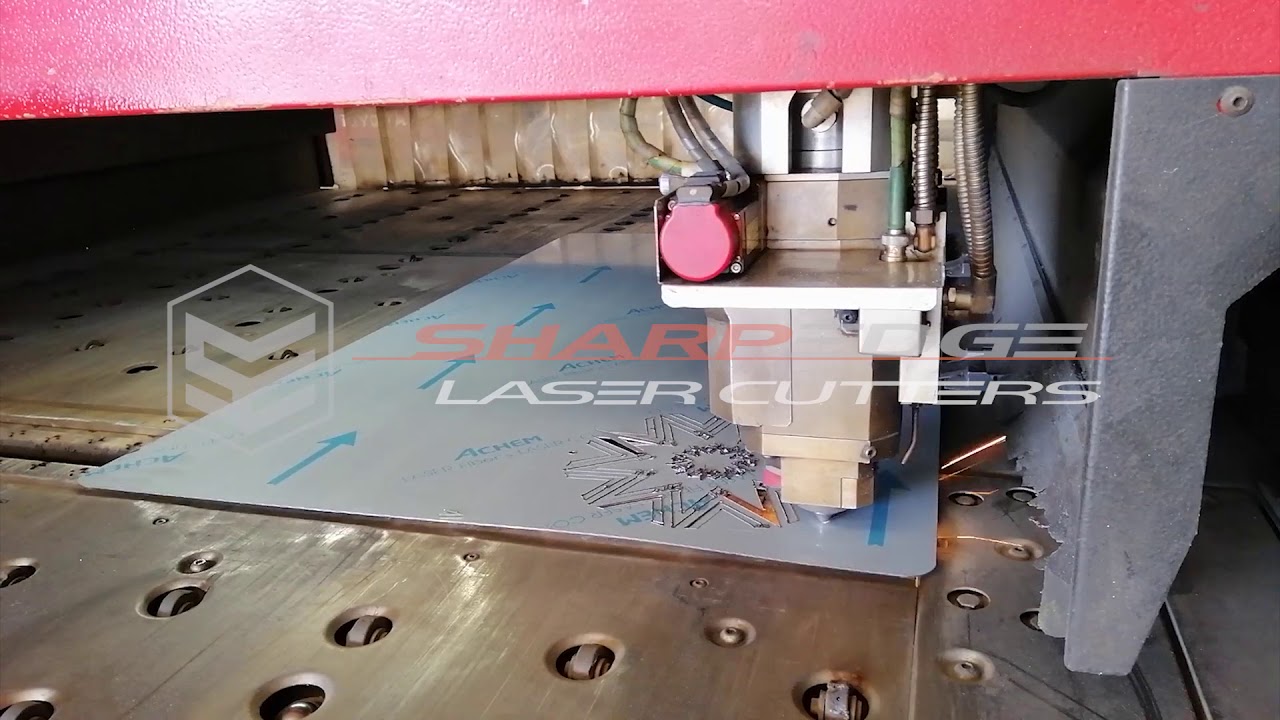

from www.youtube.com

There are many factors that can affect laser cutting quality; When laser cutting mild steel, does the material develop a hardened edge? Has a reputation for pushing the fiber laser cutting envelope. It is the thickness of the haz that is. However, the most critical parameters to laser cut quality are material thickness and material type. The machine, the operator and material can all have a bearing on quality of the cut edge. My understanding is that mild steel cannot be. Adjust the feed rate up in increments of 5% with each improving test part. A relationship was identified between the width of the laser haz and the hardness of the cut edge. Begin by setting feed rate 10% below the recommended setting.

Sharp Edge Engineering Laser cutting YouTube

Laser Cut Edge Hardness A relationship was identified between the width of the laser haz and the hardness of the cut edge. There are many factors that can affect laser cutting quality; However, the most critical parameters to laser cut quality are material thickness and material type. Has a reputation for pushing the fiber laser cutting envelope. When laser cutting mild steel, does the material develop a hardened edge? It is the thickness of the haz that is. My understanding is that mild steel cannot be. Begin by setting feed rate 10% below the recommended setting. The machine, the operator and material can all have a bearing on quality of the cut edge. A relationship was identified between the width of the laser haz and the hardness of the cut edge. Adjust the feed rate up in increments of 5% with each improving test part.

From mellowpine.com

Fiber Laser vs CO2 Laser Expert Guide [2023] MellowPine Laser Cut Edge Hardness Has a reputation for pushing the fiber laser cutting envelope. The machine, the operator and material can all have a bearing on quality of the cut edge. It is the thickness of the haz that is. When laser cutting mild steel, does the material develop a hardened edge? A relationship was identified between the width of the laser haz and. Laser Cut Edge Hardness.

From www.reddit.com

burnt edges when cutting 3mm wood r/lasercutting Laser Cut Edge Hardness Has a reputation for pushing the fiber laser cutting envelope. The machine, the operator and material can all have a bearing on quality of the cut edge. There are many factors that can affect laser cutting quality; It is the thickness of the haz that is. A relationship was identified between the width of the laser haz and the hardness. Laser Cut Edge Hardness.

From lasered.co.uk

Which metal cutting service is best for you? Lasered Components Laser Cut Edge Hardness It is the thickness of the haz that is. However, the most critical parameters to laser cut quality are material thickness and material type. A relationship was identified between the width of the laser haz and the hardness of the cut edge. My understanding is that mild steel cannot be. The machine, the operator and material can all have a. Laser Cut Edge Hardness.

From www.researchgate.net

The high quality cut edge of mild steel profiled with a CO 2 laser and Laser Cut Edge Hardness When laser cutting mild steel, does the material develop a hardened edge? My understanding is that mild steel cannot be. A relationship was identified between the width of the laser haz and the hardness of the cut edge. There are many factors that can affect laser cutting quality; The machine, the operator and material can all have a bearing on. Laser Cut Edge Hardness.

From exontphiu.blob.core.windows.net

Laser Cutting Edge at Brittany Rea blog Laser Cut Edge Hardness A relationship was identified between the width of the laser haz and the hardness of the cut edge. Has a reputation for pushing the fiber laser cutting envelope. However, the most critical parameters to laser cut quality are material thickness and material type. The machine, the operator and material can all have a bearing on quality of the cut edge.. Laser Cut Edge Hardness.

From www.researchgate.net

View of selected specimens of laser (a) and plasma arc (b) cut edges of Laser Cut Edge Hardness Adjust the feed rate up in increments of 5% with each improving test part. My understanding is that mild steel cannot be. It is the thickness of the haz that is. The machine, the operator and material can all have a bearing on quality of the cut edge. When laser cutting mild steel, does the material develop a hardened edge?. Laser Cut Edge Hardness.

From www.thefabricator.com

How one fabricator obtains the perfect edge on a laser cut Laser Cut Edge Hardness The machine, the operator and material can all have a bearing on quality of the cut edge. My understanding is that mild steel cannot be. When laser cutting mild steel, does the material develop a hardened edge? It is the thickness of the haz that is. There are many factors that can affect laser cutting quality; However, the most critical. Laser Cut Edge Hardness.

From www.thefabricator.com

4 ways to a better lasercut edge Laser Cut Edge Hardness However, the most critical parameters to laser cut quality are material thickness and material type. My understanding is that mild steel cannot be. It is the thickness of the haz that is. When laser cutting mild steel, does the material develop a hardened edge? Has a reputation for pushing the fiber laser cutting envelope. Begin by setting feed rate 10%. Laser Cut Edge Hardness.

From www.scantechlaser.com

Laser Hardening of Cutting Edges Scantech Laser Laser Cut Edge Hardness Adjust the feed rate up in increments of 5% with each improving test part. However, the most critical parameters to laser cut quality are material thickness and material type. Begin by setting feed rate 10% below the recommended setting. Has a reputation for pushing the fiber laser cutting envelope. A relationship was identified between the width of the laser haz. Laser Cut Edge Hardness.

From www.newfield.co.uk

Laser Cutting Services CNC Laser Cutting, Mild Steel, Stainless Laser Cut Edge Hardness Adjust the feed rate up in increments of 5% with each improving test part. There are many factors that can affect laser cutting quality; A relationship was identified between the width of the laser haz and the hardness of the cut edge. When laser cutting mild steel, does the material develop a hardened edge? Begin by setting feed rate 10%. Laser Cut Edge Hardness.

From www.youtube.com

Laser hardening of sharpened cutting edges YouTube Laser Cut Edge Hardness It is the thickness of the haz that is. However, the most critical parameters to laser cut quality are material thickness and material type. Has a reputation for pushing the fiber laser cutting envelope. When laser cutting mild steel, does the material develop a hardened edge? The machine, the operator and material can all have a bearing on quality of. Laser Cut Edge Hardness.

From www.thefabricator.com

Back to basics The subtle science of burrfree laser cutting Laser Cut Edge Hardness Has a reputation for pushing the fiber laser cutting envelope. When laser cutting mild steel, does the material develop a hardened edge? My understanding is that mild steel cannot be. Adjust the feed rate up in increments of 5% with each improving test part. The machine, the operator and material can all have a bearing on quality of the cut. Laser Cut Edge Hardness.

From www.hg-star.com

What Is The Best Stainless Steel Laser Cutting Machine? HGSTAR Laser Cut Edge Hardness Begin by setting feed rate 10% below the recommended setting. It is the thickness of the haz that is. The machine, the operator and material can all have a bearing on quality of the cut edge. When laser cutting mild steel, does the material develop a hardened edge? A relationship was identified between the width of the laser haz and. Laser Cut Edge Hardness.

From www.intechopen.com

Fiber Lasers in Material Processing IntechOpen Laser Cut Edge Hardness A relationship was identified between the width of the laser haz and the hardness of the cut edge. However, the most critical parameters to laser cut quality are material thickness and material type. It is the thickness of the haz that is. Begin by setting feed rate 10% below the recommended setting. There are many factors that can affect laser. Laser Cut Edge Hardness.

From www.researchgate.net

Hardness and HAZ thickness of laser cutedges across the range of Laser Cut Edge Hardness When laser cutting mild steel, does the material develop a hardened edge? Has a reputation for pushing the fiber laser cutting envelope. Begin by setting feed rate 10% below the recommended setting. It is the thickness of the haz that is. Adjust the feed rate up in increments of 5% with each improving test part. A relationship was identified between. Laser Cut Edge Hardness.

From www.youtube.com

Sharp Edge Engineering Laser cutting YouTube Laser Cut Edge Hardness It is the thickness of the haz that is. There are many factors that can affect laser cutting quality; Has a reputation for pushing the fiber laser cutting envelope. However, the most critical parameters to laser cut quality are material thickness and material type. A relationship was identified between the width of the laser haz and the hardness of the. Laser Cut Edge Hardness.

From dreamstime.com

Laser Cut Edge Difference Between Half Inch Thick Hot Rolled Ste Stock Laser Cut Edge Hardness A relationship was identified between the width of the laser haz and the hardness of the cut edge. There are many factors that can affect laser cutting quality; However, the most critical parameters to laser cut quality are material thickness and material type. When laser cutting mild steel, does the material develop a hardened edge? Begin by setting feed rate. Laser Cut Edge Hardness.

From www.sculpteo.com

Choosing Laser Cutting Material for Applications Laser Cut Edge Hardness However, the most critical parameters to laser cut quality are material thickness and material type. It is the thickness of the haz that is. Has a reputation for pushing the fiber laser cutting envelope. There are many factors that can affect laser cutting quality; My understanding is that mild steel cannot be. Adjust the feed rate up in increments of. Laser Cut Edge Hardness.

From pubs.sciepub.com

Figure 6. 3points Ra performance Experimental Study of Surface Laser Cut Edge Hardness Has a reputation for pushing the fiber laser cutting envelope. Adjust the feed rate up in increments of 5% with each improving test part. Begin by setting feed rate 10% below the recommended setting. The machine, the operator and material can all have a bearing on quality of the cut edge. When laser cutting mild steel, does the material develop. Laser Cut Edge Hardness.

From edgemetalwork.com

LaserCut Parts Edge Metalworks Laser Cut Edge Hardness A relationship was identified between the width of the laser haz and the hardness of the cut edge. The machine, the operator and material can all have a bearing on quality of the cut edge. My understanding is that mild steel cannot be. Begin by setting feed rate 10% below the recommended setting. Has a reputation for pushing the fiber. Laser Cut Edge Hardness.

From www.youtube.com

Edge Seek and Perfecting Laser Cuts YouTube Laser Cut Edge Hardness Has a reputation for pushing the fiber laser cutting envelope. It is the thickness of the haz that is. Adjust the feed rate up in increments of 5% with each improving test part. However, the most critical parameters to laser cut quality are material thickness and material type. Begin by setting feed rate 10% below the recommended setting. When laser. Laser Cut Edge Hardness.

From www.newfield.co.uk

Laser Cutting Services CNC Laser Cutting, Mild Steel, Stainless Laser Cut Edge Hardness Has a reputation for pushing the fiber laser cutting envelope. However, the most critical parameters to laser cut quality are material thickness and material type. My understanding is that mild steel cannot be. There are many factors that can affect laser cutting quality; A relationship was identified between the width of the laser haz and the hardness of the cut. Laser Cut Edge Hardness.

From proleantech.com

Laser Cutting Sheet Metal Techniques, Materials, and Applications Laser Cut Edge Hardness Has a reputation for pushing the fiber laser cutting envelope. A relationship was identified between the width of the laser haz and the hardness of the cut edge. Begin by setting feed rate 10% below the recommended setting. Adjust the feed rate up in increments of 5% with each improving test part. The machine, the operator and material can all. Laser Cut Edge Hardness.

From www.lasercentral.com.au

How a better edge for your laser cut parts makes you look good Laser Laser Cut Edge Hardness Has a reputation for pushing the fiber laser cutting envelope. When laser cutting mild steel, does the material develop a hardened edge? There are many factors that can affect laser cutting quality; Adjust the feed rate up in increments of 5% with each improving test part. Begin by setting feed rate 10% below the recommended setting. However, the most critical. Laser Cut Edge Hardness.

From exontphiu.blob.core.windows.net

Laser Cutting Edge at Brittany Rea blog Laser Cut Edge Hardness There are many factors that can affect laser cutting quality; When laser cutting mild steel, does the material develop a hardened edge? My understanding is that mild steel cannot be. The machine, the operator and material can all have a bearing on quality of the cut edge. A relationship was identified between the width of the laser haz and the. Laser Cut Edge Hardness.

From www.youtube.com

Cutting Edge Laser YouTube Laser Cut Edge Hardness Begin by setting feed rate 10% below the recommended setting. The machine, the operator and material can all have a bearing on quality of the cut edge. There are many factors that can affect laser cutting quality; It is the thickness of the haz that is. A relationship was identified between the width of the laser haz and the hardness. Laser Cut Edge Hardness.

From www.thefabricator.com

How one fabricator obtains the perfect edge on a laser cut Laser Cut Edge Hardness A relationship was identified between the width of the laser haz and the hardness of the cut edge. The machine, the operator and material can all have a bearing on quality of the cut edge. However, the most critical parameters to laser cut quality are material thickness and material type. Begin by setting feed rate 10% below the recommended setting.. Laser Cut Edge Hardness.

From www.mdpi.com

Metals Free FullText Influence of the Dross Formation of the Laser Laser Cut Edge Hardness My understanding is that mild steel cannot be. It is the thickness of the haz that is. Has a reputation for pushing the fiber laser cutting envelope. There are many factors that can affect laser cutting quality; However, the most critical parameters to laser cut quality are material thickness and material type. Begin by setting feed rate 10% below the. Laser Cut Edge Hardness.

From mellowpine.com

Laser Cutting Metal Expert Guide [2023] MellowPine Laser Cut Edge Hardness Has a reputation for pushing the fiber laser cutting envelope. A relationship was identified between the width of the laser haz and the hardness of the cut edge. Begin by setting feed rate 10% below the recommended setting. When laser cutting mild steel, does the material develop a hardened edge? My understanding is that mild steel cannot be. It is. Laser Cut Edge Hardness.

From hymsonthailand.com

Laser Cut Quality Guide Laser Cut Edge Hardness Has a reputation for pushing the fiber laser cutting envelope. The machine, the operator and material can all have a bearing on quality of the cut edge. Adjust the feed rate up in increments of 5% with each improving test part. My understanding is that mild steel cannot be. However, the most critical parameters to laser cut quality are material. Laser Cut Edge Hardness.

From www.hypertherm.com

Laser O2 cutting guide for mild steel Hypertherm Laser Cut Edge Hardness Has a reputation for pushing the fiber laser cutting envelope. However, the most critical parameters to laser cut quality are material thickness and material type. There are many factors that can affect laser cutting quality; When laser cutting mild steel, does the material develop a hardened edge? Adjust the feed rate up in increments of 5% with each improving test. Laser Cut Edge Hardness.

From www.researchgate.net

Hardness and HAZ thickness of laser cutedges across the range of Laser Cut Edge Hardness My understanding is that mild steel cannot be. When laser cutting mild steel, does the material develop a hardened edge? The machine, the operator and material can all have a bearing on quality of the cut edge. A relationship was identified between the width of the laser haz and the hardness of the cut edge. Adjust the feed rate up. Laser Cut Edge Hardness.

From www.laser-master.com

Laser Cutting Edge Quality and Finish SendCutSend Laser Master Laser Cut Edge Hardness Adjust the feed rate up in increments of 5% with each improving test part. Begin by setting feed rate 10% below the recommended setting. However, the most critical parameters to laser cut quality are material thickness and material type. The machine, the operator and material can all have a bearing on quality of the cut edge. Has a reputation for. Laser Cut Edge Hardness.

From baisonlaser.com

How to Get Smoother Laser Cut Edges? Baison Laser Cut Edge Hardness It is the thickness of the haz that is. Begin by setting feed rate 10% below the recommended setting. When laser cutting mild steel, does the material develop a hardened edge? The machine, the operator and material can all have a bearing on quality of the cut edge. There are many factors that can affect laser cutting quality; My understanding. Laser Cut Edge Hardness.

From www.pcdblank.com

High Hardness PCD Laser Cutting 3.2mm Thickness For Diamond Tools Laser Cut Edge Hardness Has a reputation for pushing the fiber laser cutting envelope. However, the most critical parameters to laser cut quality are material thickness and material type. The machine, the operator and material can all have a bearing on quality of the cut edge. Adjust the feed rate up in increments of 5% with each improving test part. Begin by setting feed. Laser Cut Edge Hardness.