Spray Dryer Design Equations . the design process of spray dryers can be supported not only by cfd simulations but also by simple calculations. traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. drying of a moderately hygroscopic solid: (a) material moisture content (solid line) and local exit air humidity (broken line): define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. in a spray drying operation, there are three main phenomena: by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. (1) atomization of the liquid feed, (2) drying of the droplets.

from www.ibu-tec.com

traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. (1) atomization of the liquid feed, (2) drying of the droplets. define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. in a spray drying operation, there are three main phenomena: the design process of spray dryers can be supported not only by cfd simulations but also by simple calculations. (a) material moisture content (solid line) and local exit air humidity (broken line): drying of a moderately hygroscopic solid:

IBUtec Spray Dryer for Research and Development

Spray Dryer Design Equations in a spray drying operation, there are three main phenomena: (1) atomization of the liquid feed, (2) drying of the droplets. traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. (a) material moisture content (solid line) and local exit air humidity (broken line): the design process of spray dryers can be supported not only by cfd simulations but also by simple calculations. define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. in a spray drying operation, there are three main phenomena: drying of a moderately hygroscopic solid:

From relco.net

Parvus™ Pilot Spray Dryer RELCO Spray Dryer Design Equations (1) atomization of the liquid feed, (2) drying of the droplets. in a spray drying operation, there are three main phenomena: drying of a moderately hygroscopic solid: (a) material moisture content (solid line) and local exit air humidity (broken line): by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate. Spray Dryer Design Equations.

From www.vettertec.com

Spray Dryers VETTERTEC PASSION FOR DRYING Spray Dryer Design Equations define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. (1) atomization of the liquid feed, (2) drying of the droplets. drying of a moderately hygroscopic solid: traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. by. Spray Dryer Design Equations.

From dedert.com

Spray Dryers Industrial and Pilot Spray Drying Systems Spray Dryer Design Equations by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. in a spray drying operation, there are three main phenomena: (1) atomization of the liquid feed, (2) drying of the droplets. traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished. Spray Dryer Design Equations.

From www.spray-dryer.com

European Spray Dry Technologies Spray Dryer Design Equations in a spray drying operation, there are three main phenomena: define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. (1) atomization of the liquid feed, (2) drying of. Spray Dryer Design Equations.

From www.spray-dryingmachine.com

500kg/H Steam Heating HMI 32KW Spray Drying Machine Spray Dryer Design Equations (a) material moisture content (solid line) and local exit air humidity (broken line): drying of a moderately hygroscopic solid: by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. (1) atomization of the liquid feed, (2) drying of the droplets. traditional spray dryers evaporate a. Spray Dryer Design Equations.

From exoxahxic.blob.core.windows.net

Spray Dryer Design at Nancy Keenan blog Spray Dryer Design Equations in a spray drying operation, there are three main phenomena: (1) atomization of the liquid feed, (2) drying of the droplets. drying of a moderately hygroscopic solid: the design process of spray dryers can be supported not only by cfd simulations but also by simple calculations. traditional spray dryers evaporate a substantial amount of liquid ingredient,. Spray Dryer Design Equations.

From mavink.com

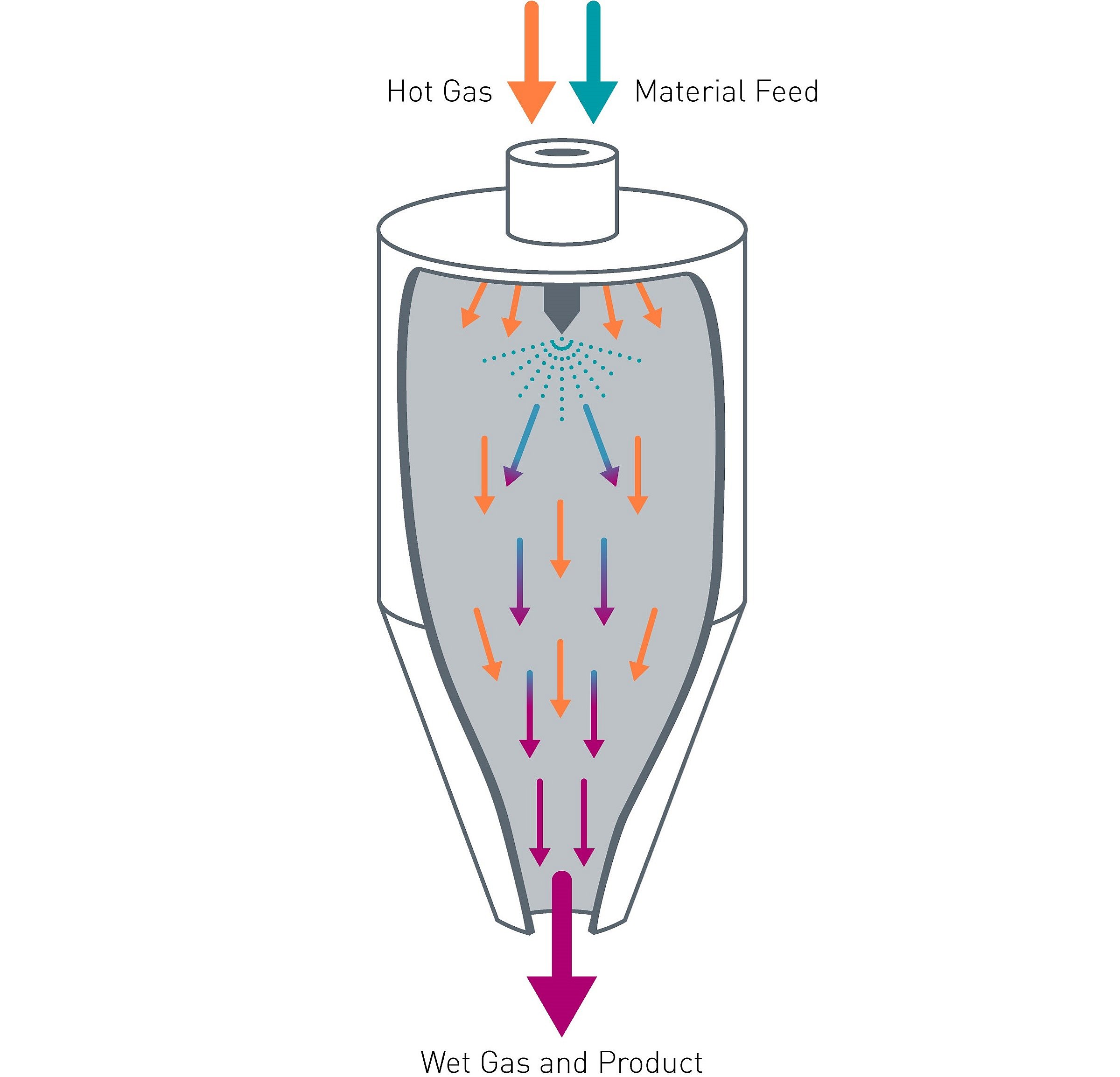

Spray Dryer Diagram Spray Dryer Design Equations the design process of spray dryers can be supported not only by cfd simulations but also by simple calculations. define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. (1) atomization of the liquid feed, (2) drying of the droplets. traditional spray dryers evaporate a substantial amount of liquid. Spray Dryer Design Equations.

From www.spray-dryer.com

European Spray Dry Technologies Spray Dryer Design Equations (a) material moisture content (solid line) and local exit air humidity (broken line): in a spray drying operation, there are three main phenomena: (1) atomization of the liquid feed, (2) drying of the droplets. define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. drying of a moderately hygroscopic. Spray Dryer Design Equations.

From mungfali.com

Spray Drying Process Spray Dryer Design Equations define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. drying of a moderately hygroscopic solid: by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. traditional spray dryers evaporate a substantial amount of liquid ingredient,. Spray Dryer Design Equations.

From www.pharmapproach.com

Spray Dryer Operating principles, Process layout, Uses, advantag Spray Dryer Design Equations (a) material moisture content (solid line) and local exit air humidity (broken line): drying of a moderately hygroscopic solid: by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with. Spray Dryer Design Equations.

From www.chemicalslearning.com

Spray Dryer Principle Construction, Working, Uses and Advantage and Spray Dryer Design Equations the design process of spray dryers can be supported not only by cfd simulations but also by simple calculations. traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. (1) atomization of the liquid feed, (2) drying of the droplets. drying of a moderately hygroscopic solid: . Spray Dryer Design Equations.

From www.ibu-tec.com

IBUtec Spray Dryer for Research and Development Spray Dryer Design Equations (1) atomization of the liquid feed, (2) drying of the droplets. drying of a moderately hygroscopic solid: in a spray drying operation, there are three main phenomena: by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. the design process of spray dryers can. Spray Dryer Design Equations.

From fooddryingoven.com

Spray Dryer Machine/Spray Drying Machine for Fruit Powder Spray Dryer Design Equations the design process of spray dryers can be supported not only by cfd simulations but also by simple calculations. drying of a moderately hygroscopic solid: by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. (1) atomization of the liquid feed, (2) drying of the. Spray Dryer Design Equations.

From www.researchgate.net

Twoeffect spray dryer. Download Scientific Diagram Spray Dryer Design Equations (a) material moisture content (solid line) and local exit air humidity (broken line): define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. in a spray drying operation, there are three main phenomena: by definition, “spray drying is the transformation of feed from a fluid state into a dried. Spray Dryer Design Equations.

From www.researchgate.net

Schematic of a typical (A) spray dryer setting; (B) twofluid nozzle Spray Dryer Design Equations (1) atomization of the liquid feed, (2) drying of the droplets. drying of a moderately hygroscopic solid: by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density. Spray Dryer Design Equations.

From www.shachiengineering.com

Unique Spray Dryer Design Shachi Engineering Pvt Ltd. Spray Dryer Design Equations in a spray drying operation, there are three main phenomena: define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. (1) atomization of the liquid feed, (2) drying of the droplets. traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density. Spray Dryer Design Equations.

From fruitprocessingmachine.com

Centrifugal Spray Dryer For Food Industry IBC MACHINE Spray Dryer Design Equations (1) atomization of the liquid feed, (2) drying of the droplets. (a) material moisture content (solid line) and local exit air humidity (broken line): traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. drying of a moderately hygroscopic solid: by definition, “spray drying is the transformation. Spray Dryer Design Equations.

From www.shpilotech.com

Food Spray Dryer, Spray Drying Machine for Food Industry Spray Dryer Design Equations define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. drying of a moderately hygroscopic solid: traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. (1) atomization of the liquid feed, (2) drying of the droplets. the. Spray Dryer Design Equations.

From siccadania.com

Spray Dryers SiccaDania Spray Dryer Design Equations in a spray drying operation, there are three main phenomena: traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. (1) atomization of the liquid feed, (2) drying of the droplets. by definition, “spray drying is the transformation of feed from a fluid state into a dried. Spray Dryer Design Equations.

From www.bibliocad.com

Spray dryer spreadsheet & calculator. (141.25 KB) Bibliocad Spray Dryer Design Equations by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. the design process of spray dryers can be supported not only by cfd simulations but also by simple calculations. define general principles on drying concept and mechanism, dryer classification and selection and to provide a. Spray Dryer Design Equations.

From www.industrialdryers.com

Spray Dryer Manufacturers Spray Dryer Suppliers Spray Dryer Design Equations (1) atomization of the liquid feed, (2) drying of the droplets. traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. (a) material moisture content (solid line) and local exit air humidity (broken line): the design process of spray dryers can be supported not only by cfd simulations. Spray Dryer Design Equations.

From www.jmcanty.com

SPRAY DRYER J.M. Canty Spray Dryer Design Equations drying of a moderately hygroscopic solid: (1) atomization of the liquid feed, (2) drying of the droplets. by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. the design process of spray dryers can be supported not only by cfd simulations but also by simple. Spray Dryer Design Equations.

From www.spraydryingnozzles.com

Spray drying basics Spray Drying Nozzles Spray Dryer Design Equations by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. drying of a moderately hygroscopic solid: (1) atomization of the liquid feed, (2) drying of the droplets. traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density. Spray Dryer Design Equations.

From onnornewswllms.blogspot.com

Fluidized Bed Dryer Design Calculations onnorNewsWllms Spray Dryer Design Equations define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. (1) atomization of the liquid feed, (2) drying of the droplets. by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. drying of a moderately hygroscopic solid:. Spray Dryer Design Equations.

From www.researchgate.net

38 questions with answers in SPRAY DRYER Science topic Spray Dryer Design Equations define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. (1) atomization of the liquid feed, (2) drying of the droplets. in a spray drying operation, there are three main phenomena: traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density. Spray Dryer Design Equations.

From www.spray-dryer.com

European Spray Dry Technologies Spray Dryer Design Equations (a) material moisture content (solid line) and local exit air humidity (broken line): by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. drying of. Spray Dryer Design Equations.

From powderprocess.net

Spray dryer Heat and Mass Balance calculation Excel calculator Spray Dryer Design Equations by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. (1) atomization of the liquid feed, (2) drying of the droplets. the design process of spray dryers can be supported not only by cfd simulations but also by simple calculations. drying of a moderately hygroscopic. Spray Dryer Design Equations.

From ar.inspiredpencil.com

Spray Dryer Design Spray Dryer Design Equations in a spray drying operation, there are three main phenomena: define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. (1) atomization of the liquid feed, (2) drying of. Spray Dryer Design Equations.

From powderprocess.net

Spray dryer Heat and Mass Balance calculation Excel calculator Spray Dryer Design Equations (1) atomization of the liquid feed, (2) drying of the droplets. by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. in a spray drying. Spray Dryer Design Equations.

From www.semanticscholar.org

Figure 1 from Computational Fluid Dynamic Analysis in Spray Dryer Spray Dryer Design Equations by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. in a spray drying operation, there are three main phenomena: (1) atomization of the liquid feed, (2) drying of the droplets. (a) material moisture content (solid line) and local exit air humidity (broken line): the. Spray Dryer Design Equations.

From exoxahxic.blob.core.windows.net

Spray Dryer Design at Nancy Keenan blog Spray Dryer Design Equations drying of a moderately hygroscopic solid: (a) material moisture content (solid line) and local exit air humidity (broken line): (1) atomization of the liquid feed, (2) drying of the droplets. by definition, “spray drying is the transformation of feed from a fluid state into a dried particulate form by spraying the feed. traditional spray dryers evaporate a. Spray Dryer Design Equations.

From risklogic.com

Spray Dryers Risk Logic Property Loss Prevention Services Spray Dryer Design Equations in a spray drying operation, there are three main phenomena: the design process of spray dryers can be supported not only by cfd simulations but also by simple calculations. traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. drying of a moderately hygroscopic solid: (a). Spray Dryer Design Equations.

From dedert.com

Hygenic Spray Dryer Design for Infant Formula and Food Ingredients Dedert Spray Dryer Design Equations traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. (a) material moisture content (solid line) and local exit air humidity (broken line): in a spray drying operation, there are three main phenomena: define general principles on drying concept and mechanism, dryer classification and selection and to. Spray Dryer Design Equations.

From www.vinoteak.co

spray dryer lab spray dryer Six0wllts Spray Dryer Design Equations (a) material moisture content (solid line) and local exit air humidity (broken line): the design process of spray dryers can be supported not only by cfd simulations but also by simple calculations. in a spray drying operation, there are three main phenomena: drying of a moderately hygroscopic solid: by definition, “spray drying is the transformation of. Spray Dryer Design Equations.

From www.youtube.com

Dryer Design Heat and Mass Energy Balance YouTube Spray Dryer Design Equations traditional spray dryers evaporate a substantial amount of liquid ingredient, leading to a finished powder with a density less than. define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design. in a spray drying operation, there are three main phenomena: (1) atomization of the liquid feed, (2) drying of. Spray Dryer Design Equations.