How To Solder Enamel Coated Wire . Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. some wires have enamel that blocks the ability to solder them.this. to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder perfectly then. Scraping the enamel carefully off with a sharp knife or blade, while. common ways of removing the insulation on enameled wire include: you can use a sharp utility knife or a dedicated wire stripper to carefully scrape off the enamel coating from the ends of the wire you want.

from www.youtube.com

Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder perfectly then. you can use a sharp utility knife or a dedicated wire stripper to carefully scrape off the enamel coating from the ends of the wire you want. some wires have enamel that blocks the ability to solder them.this. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. common ways of removing the insulation on enameled wire include: Scraping the enamel carefully off with a sharp knife or blade, while.

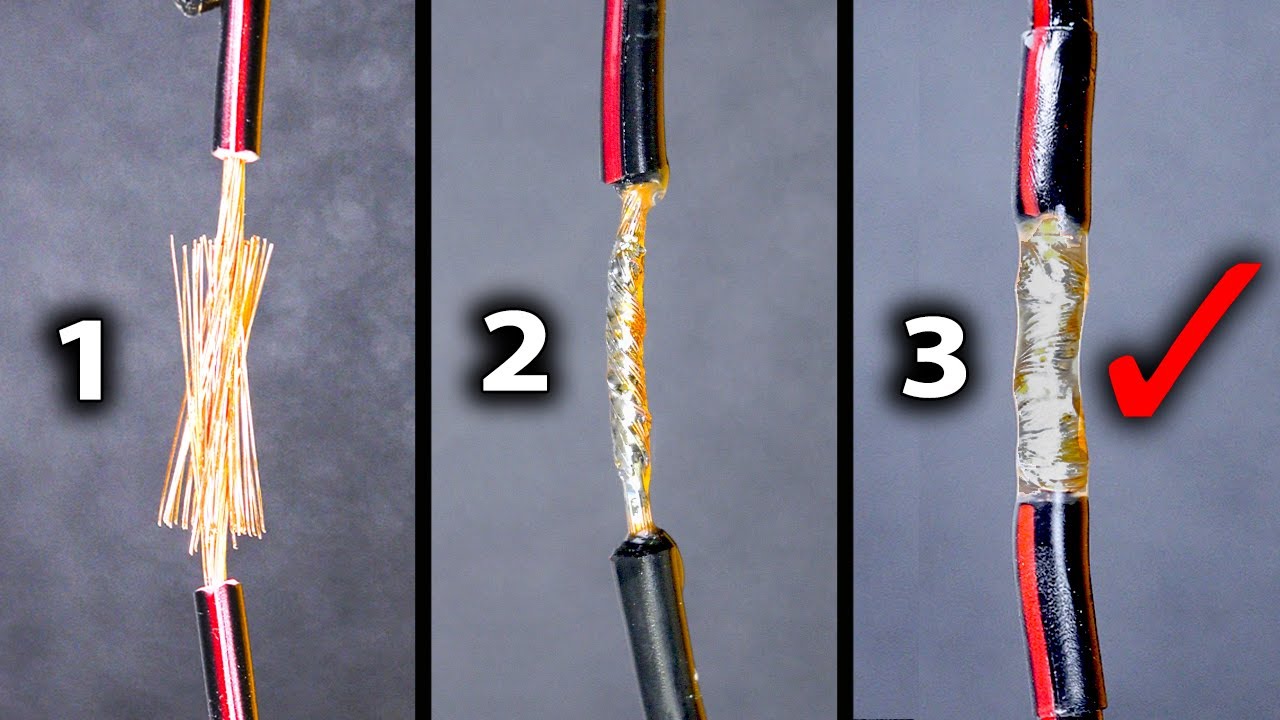

How to SOLDER WIRES TOGETHER PRO TIPS for WATERPROOF CONNECTIONS

How To Solder Enamel Coated Wire Scraping the enamel carefully off with a sharp knife or blade, while. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. some wires have enamel that blocks the ability to solder them.this. common ways of removing the insulation on enameled wire include: to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder perfectly then. Scraping the enamel carefully off with a sharp knife or blade, while. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. you can use a sharp utility knife or a dedicated wire stripper to carefully scrape off the enamel coating from the ends of the wire you want.

From www.ultrafinecopperwire.com

Self Bonding Solderable Enamel Coated Copper Wire 0.012 0.8mm For How To Solder Enamel Coated Wire tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. some wires have enamel that blocks the ability to solder them.this.. How To Solder Enamel Coated Wire.

From sparks.gogo.co.nz

Solderable Enamel Coated Wire, 0.1mm, 8m Length Buy Online From How To Solder Enamel Coated Wire to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder perfectly then. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. Tinning the wire at 400ºc, instead of my. How To Solder Enamel Coated Wire.

From dxoluksth.blob.core.windows.net

How To Solder Small Wire at Margaret Carr blog How To Solder Enamel Coated Wire Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. common ways of removing the insulation on enameled wire include: to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder perfectly then. you can use a sharp utility knife or. How To Solder Enamel Coated Wire.

From www.makerspaces.com

How To Solder A Complete Beginners Guide How To Solder Enamel Coated Wire Scraping the enamel carefully off with a sharp knife or blade, while. common ways of removing the insulation on enameled wire include: some wires have enamel that blocks the ability to solder them.this. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. tldr ⚡ 1) set iron to. How To Solder Enamel Coated Wire.

From dxoctjrco.blob.core.windows.net

Can You Solder Headphone Wire at Shelton Stephenson blog How To Solder Enamel Coated Wire Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder perfectly then. common ways of removing the insulation on enameled wire include: some wires have enamel that blocks the ability. How To Solder Enamel Coated Wire.

From www.hardwaremise.com.my

Enameled Copper Wire Solderable Winding Wire Wire Coil Dawai How To Solder Enamel Coated Wire Scraping the enamel carefully off with a sharp knife or blade, while. you can use a sharp utility knife or a dedicated wire stripper to carefully scrape off the enamel coating from the ends of the wire you want. to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder. How To Solder Enamel Coated Wire.

From www.youtube.com

How to Solder Wires like A Pro Wire Soldering Techniques YouTube How To Solder Enamel Coated Wire common ways of removing the insulation on enameled wire include: tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. . How To Solder Enamel Coated Wire.

From hackaday.com

Iron Tips Soldering Headphones And Enamel Wire Hackaday How To Solder Enamel Coated Wire to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder perfectly then. some wires have enamel that blocks the ability to solder them.this. common ways of removing the insulation on enameled wire include: tldr ⚡ 1) set iron to 400 c 2) get a nice blob of. How To Solder Enamel Coated Wire.

From warwick.ac.uk

Soldering and Lead How To Solder Enamel Coated Wire Scraping the enamel carefully off with a sharp knife or blade, while. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. you can use a sharp utility knife or a dedicated wire stripper to carefully scrape off the enamel coating from the ends of the wire you want. tldr. How To Solder Enamel Coated Wire.

From www.copperenameledwire.com

Self Bonding Soldering Enameled Wire How To Solder Enamel Coated Wire Scraping the enamel carefully off with a sharp knife or blade, while. some wires have enamel that blocks the ability to solder them.this. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. to use simply grip the. How To Solder Enamel Coated Wire.

From www.flyrobo.in

0.1mm Copper Soldering Solder PPA Enameled Wire How To Solder Enamel Coated Wire Scraping the enamel carefully off with a sharp knife or blade, while. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder perfectly then. some wires have enamel that blocks the. How To Solder Enamel Coated Wire.

From www.thespruce.com

How to Solder Wires How To Solder Enamel Coated Wire you can use a sharp utility knife or a dedicated wire stripper to carefully scrape off the enamel coating from the ends of the wire you want. Scraping the enamel carefully off with a sharp knife or blade, while. to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder. How To Solder Enamel Coated Wire.

From www.youtube.com

How To Solder Wires Like A Pro YouTube How To Solder Enamel Coated Wire common ways of removing the insulation on enameled wire include: some wires have enamel that blocks the ability to solder them.this. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to. How To Solder Enamel Coated Wire.

From www.copperenameledwire.com

0.04mm Soldering Enameled Wire Polyesterimide Self Bonding Wire Class 180 How To Solder Enamel Coated Wire tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. you can use a sharp utility knife or a dedicated wire stripper to carefully scrape off the enamel coating from the ends of the wire you want. common. How To Solder Enamel Coated Wire.

From hackaday.com

Iron Tips Soldering Headphones And Enamel Wire Hackaday How To Solder Enamel Coated Wire Scraping the enamel carefully off with a sharp knife or blade, while. some wires have enamel that blocks the ability to solder them.this. common ways of removing the insulation on enameled wire include: you can use a sharp utility knife or a dedicated wire stripper to carefully scrape off the enamel coating from the ends of the. How To Solder Enamel Coated Wire.

From sparks.gogo.co.nz

Solderable Enamel Coated Wire, 0.1mm, 8m Length Buy Online From How To Solder Enamel Coated Wire to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder perfectly then. you can use a sharp utility knife or a dedicated wire stripper to carefully scrape off the enamel coating from the ends of the wire you want. tldr ⚡ 1) set iron to 400 c 2). How To Solder Enamel Coated Wire.

From www.flyrobo.in

0.1mm Copper Soldering Solder PPA Enameled Wire How To Solder Enamel Coated Wire Scraping the enamel carefully off with a sharp knife or blade, while. some wires have enamel that blocks the ability to solder them.this. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. you can use a sharp. How To Solder Enamel Coated Wire.

From dxoafxokf.blob.core.windows.net

How To Solder Wire At Home at Roger Caraway blog How To Solder Enamel Coated Wire Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. you can use a sharp utility knife or a dedicated wire. How To Solder Enamel Coated Wire.

From dxoagolna.blob.core.windows.net

How To Solder A Wire Back On at Debbie Navarro blog How To Solder Enamel Coated Wire you can use a sharp utility knife or a dedicated wire stripper to carefully scrape off the enamel coating from the ends of the wire you want. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. common ways of removing the insulation on enameled wire include: to use. How To Solder Enamel Coated Wire.

From www.youtube.com

How to solder enameled copper wire YouTube How To Solder Enamel Coated Wire Scraping the enamel carefully off with a sharp knife or blade, while. some wires have enamel that blocks the ability to solder them.this. to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder perfectly then. you can use a sharp utility knife or a dedicated wire stripper to. How To Solder Enamel Coated Wire.

From www.ultrafinecopperwire.com

52.5 Awg 0.018mm Soldering Enamel Coated Wire Polyurethane 155 Super Thin How To Solder Enamel Coated Wire to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder perfectly then. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. Scraping the enamel carefully off with a sharp. How To Solder Enamel Coated Wire.

From www.youtube.com

Soldering Wires to Wires Soldering Basics Soldering for Beginners How To Solder Enamel Coated Wire common ways of removing the insulation on enameled wire include: tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. some wires have enamel that blocks the ability to solder them.this. Tinning the wire at 400ºc, instead of. How To Solder Enamel Coated Wire.

From www.pinterest.com

How to Solder Wires Together (Best tips and tricks) Solder Wire How To Solder Enamel Coated Wire Scraping the enamel carefully off with a sharp knife or blade, while. common ways of removing the insulation on enameled wire include: some wires have enamel that blocks the ability to solder them.this. you can use a sharp utility knife or a dedicated wire stripper to carefully scrape off the enamel coating from the ends of the. How To Solder Enamel Coated Wire.

From hackaday.com

Iron Tips Soldering Headphones And Enamel Wire Hackaday How To Solder Enamel Coated Wire Scraping the enamel carefully off with a sharp knife or blade, while. some wires have enamel that blocks the ability to solder them.this. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. to use simply grip the. How To Solder Enamel Coated Wire.

From www.youtube.com

How to SOLDER WIRES TOGETHER PRO TIPS for WATERPROOF CONNECTIONS How To Solder Enamel Coated Wire Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. some wires have enamel that blocks the ability to solder them.this.. How To Solder Enamel Coated Wire.

From www.flyrobo.in

0.1mm Copper Soldering Solder PPA Enameled Wire How To Solder Enamel Coated Wire to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder perfectly then. common ways of removing the insulation on enameled wire include: Scraping the enamel carefully off with a sharp knife or blade, while. some wires have enamel that blocks the ability to solder them.this. tldr ⚡. How To Solder Enamel Coated Wire.

From www.youtube.com

How to Tin Litz Enameled Wire YouTube How To Solder Enamel Coated Wire some wires have enamel that blocks the ability to solder them.this. common ways of removing the insulation on enameled wire include: Scraping the enamel carefully off with a sharp knife or blade, while. you can use a sharp utility knife or a dedicated wire stripper to carefully scrape off the enamel coating from the ends of the. How To Solder Enamel Coated Wire.

From www.youtube.com

SolderJS 135 The BEST Way to Tin Enameled Wire YouTube How To Solder Enamel Coated Wire Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. common ways of removing the insulation on enameled wire include: . How To Solder Enamel Coated Wire.

From www.youtube.com

How To Easily Solder Wires Together(No Soldering Iron) YouTube How To Solder Enamel Coated Wire to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder perfectly then. common ways of removing the insulation on enameled wire include: Scraping the enamel carefully off with a sharp knife or blade, while. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of. How To Solder Enamel Coated Wire.

From www.youtube.com

SolderJS 134 [LIVE] How to Strip and Solder Enameled Wire (See How To Solder Enamel Coated Wire some wires have enamel that blocks the ability to solder them.this. common ways of removing the insulation on enameled wire include: Scraping the enamel carefully off with a sharp knife or blade, while. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. you can use a sharp utility. How To Solder Enamel Coated Wire.

From electronicshacks.com

3 Steps to Solder Wires to Connectors ElectronicsHacks How To Solder Enamel Coated Wire common ways of removing the insulation on enameled wire include: Scraping the enamel carefully off with a sharp knife or blade, while. Tinning the wire at 400ºc, instead of my normal 300ºc, is what worked best for me.⌛⏱️shorter video on. to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to. How To Solder Enamel Coated Wire.

From www.electronicsandyou.com

How to Solder Wires Together Correctly Like a Pro (Easy Tips and Tricks) How To Solder Enamel Coated Wire common ways of removing the insulation on enameled wire include: to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough to solder perfectly then. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools. How To Solder Enamel Coated Wire.

From manualdatacraggier.z21.web.core.windows.net

How To Solder Wiring How To Solder Enamel Coated Wire you can use a sharp utility knife or a dedicated wire stripper to carefully scrape off the enamel coating from the ends of the wire you want. tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. Scraping the. How To Solder Enamel Coated Wire.

From solderingrepair.com

Mastering the Art of Soldering Enameled Wire How To Solder Enamel Coated Wire tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. some wires have enamel that blocks the ability to solder them.this. to use simply grip the wire in the tweezers lightly and pull, it strips the enamel enough. How To Solder Enamel Coated Wire.

From www.supercheapauto.co.nz

How to Solder Wires Wire Joining Supercheap Auto New Zealand How To Solder Enamel Coated Wire some wires have enamel that blocks the ability to solder them.this. common ways of removing the insulation on enameled wire include: tldr ⚡ 1) set iron to 400 c 2) get a nice blob of solder 3) coat wire in flux 4) burn for 2 seconds.👉 tools used in this. Tinning the wire at 400ºc, instead of. How To Solder Enamel Coated Wire.