Most Common Gas For Mig Welding . This gas allows you to get into a spray transfer or pulsed spray transfer. this is a overview of the gas choices for mig welding most metals. However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. when it comes to mig welding, shielding gas is a critical component of doing it properly. When used in small quantities, it can enhance weld penetration and increase the welding speed. the most common gas used for mig welding aluminum is 100% argon. It covers the most common electrodes/wires and what gas to use for. Choose the appropriate gas for optimal weld quality and appearance. for mig welding, use a shielding gas that suits your material. In this article, we’ll hash out the details about shielding. As a shielding gas, argon. 100% argon for aluminum, a 75% argon/25% carbon dioxide mix for mild steel, and a 90% argon/10% carbon dioxide mix for stainless steel. carbon dioxide (co2) is a common example of an active gas used in welding. besides carbon dioxide, argon is one of the most common shielding gases frequently used in mig welding.

from weldingpros.net

besides carbon dioxide, argon is one of the most common shielding gases frequently used in mig welding. As a shielding gas, argon. This gas allows you to get into a spray transfer or pulsed spray transfer. In this article, we’ll hash out the details about shielding. carbon dioxide (co2) is a common example of an active gas used in welding. the most common gas used for mig welding aluminum is 100% argon. this is a overview of the gas choices for mig welding most metals. It covers the most common electrodes/wires and what gas to use for. for mig welding, use a shielding gas that suits your material. 100% argon for aluminum, a 75% argon/25% carbon dioxide mix for mild steel, and a 90% argon/10% carbon dioxide mix for stainless steel.

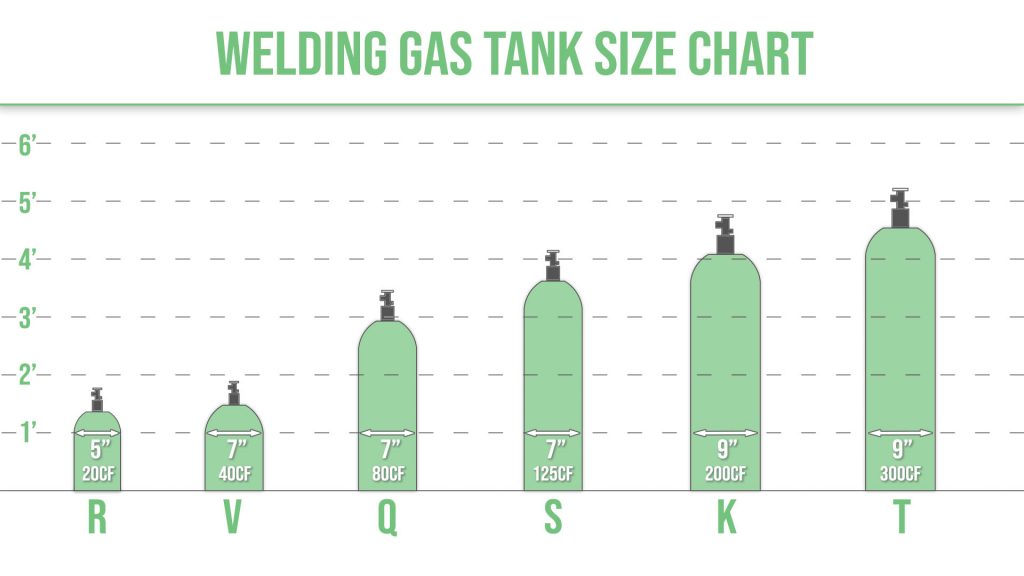

Welding Cylinders Tank Sizes Argon and MIG CO2 Use Time

Most Common Gas For Mig Welding for mig welding, use a shielding gas that suits your material. However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. carbon dioxide (co2) is a common example of an active gas used in welding. when it comes to mig welding, shielding gas is a critical component of doing it properly. In this article, we’ll hash out the details about shielding. besides carbon dioxide, argon is one of the most common shielding gases frequently used in mig welding. 100% argon for aluminum, a 75% argon/25% carbon dioxide mix for mild steel, and a 90% argon/10% carbon dioxide mix for stainless steel. this is a overview of the gas choices for mig welding most metals. It covers the most common electrodes/wires and what gas to use for. for mig welding, use a shielding gas that suits your material. the most common gas used for mig welding aluminum is 100% argon. This gas allows you to get into a spray transfer or pulsed spray transfer. When used in small quantities, it can enhance weld penetration and increase the welding speed. Choose the appropriate gas for optimal weld quality and appearance. As a shielding gas, argon.

From sksgasvalvebugokuho.blogspot.com

Sks Gas Valve What Is The Best Gas For Mig Welding Most Common Gas For Mig Welding It covers the most common electrodes/wires and what gas to use for. However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. In this article, we’ll hash out the details about shielding. the most common gas used for mig welding aluminum is 100% argon. This gas allows you to get into. Most Common Gas For Mig Welding.

From www.codinter.com

TIG vs. MIG Welding Which one to use in every case Codinter Americas Most Common Gas For Mig Welding However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. this is a overview of the gas choices for mig welding most metals. It covers the most common electrodes/wires and what gas to use for. for mig welding, use a shielding gas that suits your material. carbon dioxide (co2). Most Common Gas For Mig Welding.

From weldguru.com

Welding Gases Different Types & Their Uses Weld Guru Most Common Gas For Mig Welding In this article, we’ll hash out the details about shielding. However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. This gas allows you to get into a spray transfer or pulsed spray transfer. this is a overview of the gas choices for mig welding most metals. Choose the appropriate gas. Most Common Gas For Mig Welding.

From weldempire.com

What Should Be the Gas Pressure for MIG Welding? Weld Empire Most Common Gas For Mig Welding As a shielding gas, argon. It covers the most common electrodes/wires and what gas to use for. when it comes to mig welding, shielding gas is a critical component of doing it properly. this is a overview of the gas choices for mig welding most metals. the most common gas used for mig welding aluminum is 100%. Most Common Gas For Mig Welding.

From weldingpros.net

Welding Cylinders Tank Sizes Argon and MIG CO2 Use Time Most Common Gas For Mig Welding besides carbon dioxide, argon is one of the most common shielding gases frequently used in mig welding. In this article, we’ll hash out the details about shielding. 100% argon for aluminum, a 75% argon/25% carbon dioxide mix for mild steel, and a 90% argon/10% carbon dioxide mix for stainless steel. for mig welding, use a shielding gas that. Most Common Gas For Mig Welding.

From welditu.com

What Size Welding Gas Cylinder for MIG or TIG? ArgonCO2 WelditU Most Common Gas For Mig Welding this is a overview of the gas choices for mig welding most metals. This gas allows you to get into a spray transfer or pulsed spray transfer. In this article, we’ll hash out the details about shielding. the most common gas used for mig welding aluminum is 100% argon. when it comes to mig welding, shielding gas. Most Common Gas For Mig Welding.

From www.kapilsteels.com

Best Gas for MIG Welding A Complete Guide Most Common Gas For Mig Welding besides carbon dioxide, argon is one of the most common shielding gases frequently used in mig welding. Choose the appropriate gas for optimal weld quality and appearance. carbon dioxide (co2) is a common example of an active gas used in welding. for mig welding, use a shielding gas that suits your material. It covers the most common. Most Common Gas For Mig Welding.

From weldguru.com

What Size Welding Gas Cylinder for MIG or TIG? Argon & CO2 Weld Guru Most Common Gas For Mig Welding for mig welding, use a shielding gas that suits your material. Choose the appropriate gas for optimal weld quality and appearance. the most common gas used for mig welding aluminum is 100% argon. In this article, we’ll hash out the details about shielding. carbon dioxide (co2) is a common example of an active gas used in welding.. Most Common Gas For Mig Welding.

From blog.thepipingmart.com

MIG Welding vs Gas Welding What's the Difference Most Common Gas For Mig Welding the most common gas used for mig welding aluminum is 100% argon. When used in small quantities, it can enhance weld penetration and increase the welding speed. this is a overview of the gas choices for mig welding most metals. This gas allows you to get into a spray transfer or pulsed spray transfer. for mig welding,. Most Common Gas For Mig Welding.

From weldinganswers.com

Which is the best shielding gas for MIG welding? WELDING ANSWERS Most Common Gas For Mig Welding When used in small quantities, it can enhance weld penetration and increase the welding speed. carbon dioxide (co2) is a common example of an active gas used in welding. besides carbon dioxide, argon is one of the most common shielding gases frequently used in mig welding. Choose the appropriate gas for optimal weld quality and appearance. However, excessive. Most Common Gas For Mig Welding.

From gowelding.org

MIG Welding Gases Choices and Options for Most Metals Most Common Gas For Mig Welding As a shielding gas, argon. carbon dioxide (co2) is a common example of an active gas used in welding. besides carbon dioxide, argon is one of the most common shielding gases frequently used in mig welding. the most common gas used for mig welding aluminum is 100% argon. 100% argon for aluminum, a 75% argon/25% carbon dioxide. Most Common Gas For Mig Welding.

From www.weldingtypes.net

How To Use A Mig Welder Most Common Gas For Mig Welding However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. In this article, we’ll hash out the details about shielding. Choose the appropriate gas for optimal weld quality and appearance. for mig welding, use a shielding gas that suits your material. when it comes to mig welding, shielding gas is. Most Common Gas For Mig Welding.

From analyfe.com

welding gas MIG WELDING GAS OVERVIEW AND CATEGORIES Most Common Gas For Mig Welding Choose the appropriate gas for optimal weld quality and appearance. It covers the most common electrodes/wires and what gas to use for. However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. the most common gas used for mig welding aluminum is 100% argon. for mig welding, use a shielding. Most Common Gas For Mig Welding.

From ind-eng-design.blogspot.com

MIG Welding Working Principle Animation Most Common Gas For Mig Welding However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. carbon dioxide (co2) is a common example of an active gas used in welding. In this article, we’ll hash out the details about shielding. As a shielding gas, argon. for mig welding, use a shielding gas that suits your material.. Most Common Gas For Mig Welding.

From www.fabricatingandmetalworking.com

Fabricating & Metalworking Most Common Gas For Mig Welding 100% argon for aluminum, a 75% argon/25% carbon dioxide mix for mild steel, and a 90% argon/10% carbon dioxide mix for stainless steel. However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. besides carbon dioxide, argon is one of the most common shielding gases frequently used in mig welding. . Most Common Gas For Mig Welding.

From weldingresource.com

What Is The Best Gas For Mig Welding Mild Steel? [Updated On 2023] Most Common Gas For Mig Welding This gas allows you to get into a spray transfer or pulsed spray transfer. However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. As a shielding gas, argon. It covers the most common electrodes/wires and what gas to use for. this is a overview of the gas choices for mig. Most Common Gas For Mig Welding.

From cut-n-weld.co.za

Welding Gases Available in South Africa Most Common Gas For Mig Welding It covers the most common electrodes/wires and what gas to use for. this is a overview of the gas choices for mig welding most metals. for mig welding, use a shielding gas that suits your material. As a shielding gas, argon. when it comes to mig welding, shielding gas is a critical component of doing it properly.. Most Common Gas For Mig Welding.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) Most Common Gas For Mig Welding for mig welding, use a shielding gas that suits your material. this is a overview of the gas choices for mig welding most metals. It covers the most common electrodes/wires and what gas to use for. This gas allows you to get into a spray transfer or pulsed spray transfer. When used in small quantities, it can enhance. Most Common Gas For Mig Welding.

From weldgears.com

What Size Gas Cylinder to Use for MIG Welding? Weld Gears Most Common Gas For Mig Welding However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. besides carbon dioxide, argon is one of the most common shielding gases frequently used in mig welding. When used in small quantities, it can enhance weld penetration and increase the welding speed. As a shielding gas, argon. 100% argon for aluminum,. Most Common Gas For Mig Welding.

From www.youtube.com

Mig Welding Gas Setup Made Simple YouTube Most Common Gas For Mig Welding when it comes to mig welding, shielding gas is a critical component of doing it properly. besides carbon dioxide, argon is one of the most common shielding gases frequently used in mig welding. Choose the appropriate gas for optimal weld quality and appearance. for mig welding, use a shielding gas that suits your material. As a shielding. Most Common Gas For Mig Welding.

From www.museoinclusivo.com

Exploring Gas Options for Aluminum MIG Welding Types, Benefits, and Tips Aluminum Profile Blog Most Common Gas For Mig Welding However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. When used in small quantities, it can enhance weld penetration and increase the welding speed. Choose the appropriate gas for optimal weld quality and appearance. this is a overview of the gas choices for mig welding most metals. when it. Most Common Gas For Mig Welding.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) Most Common Gas For Mig Welding In this article, we’ll hash out the details about shielding. the most common gas used for mig welding aluminum is 100% argon. besides carbon dioxide, argon is one of the most common shielding gases frequently used in mig welding. when it comes to mig welding, shielding gas is a critical component of doing it properly. This gas. Most Common Gas For Mig Welding.

From weldingblos.netlify.app

Principles Of Inert Gas Welding Mig Most Common Gas For Mig Welding As a shielding gas, argon. It covers the most common electrodes/wires and what gas to use for. When used in small quantities, it can enhance weld penetration and increase the welding speed. Choose the appropriate gas for optimal weld quality and appearance. carbon dioxide (co2) is a common example of an active gas used in welding. when it. Most Common Gas For Mig Welding.

From www.cruxweld.com

MIG Welding Shielding Gas Basics CruxWeld Most Common Gas For Mig Welding In this article, we’ll hash out the details about shielding. 100% argon for aluminum, a 75% argon/25% carbon dioxide mix for mild steel, and a 90% argon/10% carbon dioxide mix for stainless steel. carbon dioxide (co2) is a common example of an active gas used in welding. Choose the appropriate gas for optimal weld quality and appearance. this. Most Common Gas For Mig Welding.

From dxomhdzyq.blob.core.windows.net

Mig Welder Argon Gas at Kathleen Derrickson blog Most Common Gas For Mig Welding 100% argon for aluminum, a 75% argon/25% carbon dioxide mix for mild steel, and a 90% argon/10% carbon dioxide mix for stainless steel. Choose the appropriate gas for optimal weld quality and appearance. In this article, we’ll hash out the details about shielding. When used in small quantities, it can enhance weld penetration and increase the welding speed. when. Most Common Gas For Mig Welding.

From blog.thepipingmart.com

Best Gas for MIG Welding Mild Steel Most Common Gas For Mig Welding when it comes to mig welding, shielding gas is a critical component of doing it properly. Choose the appropriate gas for optimal weld quality and appearance. However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. When used in small quantities, it can enhance weld penetration and increase the welding speed.. Most Common Gas For Mig Welding.

From theweldingpro.com

MIG Welding Gas A Comprehensive Guide Most Common Gas For Mig Welding 100% argon for aluminum, a 75% argon/25% carbon dioxide mix for mild steel, and a 90% argon/10% carbon dioxide mix for stainless steel. when it comes to mig welding, shielding gas is a critical component of doing it properly. When used in small quantities, it can enhance weld penetration and increase the welding speed. This gas allows you to. Most Common Gas For Mig Welding.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Torch Repairs & Sales Ltd. Most Common Gas For Mig Welding when it comes to mig welding, shielding gas is a critical component of doing it properly. for mig welding, use a shielding gas that suits your material. the most common gas used for mig welding aluminum is 100% argon. carbon dioxide (co2) is a common example of an active gas used in welding. besides carbon. Most Common Gas For Mig Welding.

From www.perfectwelders.com

How To Optimize MIG Welding Shielding Gas Pressure PERFECT POWER Welders, Welding Wire Most Common Gas For Mig Welding When used in small quantities, it can enhance weld penetration and increase the welding speed. As a shielding gas, argon. In this article, we’ll hash out the details about shielding. This gas allows you to get into a spray transfer or pulsed spray transfer. besides carbon dioxide, argon is one of the most common shielding gases frequently used in. Most Common Gas For Mig Welding.

From prowelderguide.com

Mig Welding Gas Best Types, Guide, TIG and Charts Pro Welder Guide Most Common Gas For Mig Welding for mig welding, use a shielding gas that suits your material. when it comes to mig welding, shielding gas is a critical component of doing it properly. It covers the most common electrodes/wires and what gas to use for. However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. . Most Common Gas For Mig Welding.

From exoahgqnb.blob.core.windows.net

Welding Techniques For Gas at Ashley Weiner blog Most Common Gas For Mig Welding As a shielding gas, argon. the most common gas used for mig welding aluminum is 100% argon. besides carbon dioxide, argon is one of the most common shielding gases frequently used in mig welding. 100% argon for aluminum, a 75% argon/25% carbon dioxide mix for mild steel, and a 90% argon/10% carbon dioxide mix for stainless steel. Choose. Most Common Gas For Mig Welding.

From makemoneywelding.com

Explained Best MIG Welding Shielding Gas To Use Most Common Gas For Mig Welding However, excessive use of active gases can lead to issues such as increased spatter and decreased weld quality. In this article, we’ll hash out the details about shielding. the most common gas used for mig welding aluminum is 100% argon. This gas allows you to get into a spray transfer or pulsed spray transfer. carbon dioxide (co2) is. Most Common Gas For Mig Welding.

From makemoneywelding.com

Explained Best MIG Welding Shielding Gas To Use Most Common Gas For Mig Welding when it comes to mig welding, shielding gas is a critical component of doing it properly. This gas allows you to get into a spray transfer or pulsed spray transfer. besides carbon dioxide, argon is one of the most common shielding gases frequently used in mig welding. Choose the appropriate gas for optimal weld quality and appearance. 100%. Most Common Gas For Mig Welding.

From weldingheadquarters.com

What Is the Best Gas for MIG Welding Mild Steel? Welding Headquarters Most Common Gas For Mig Welding for mig welding, use a shielding gas that suits your material. As a shielding gas, argon. this is a overview of the gas choices for mig welding most metals. It covers the most common electrodes/wires and what gas to use for. However, excessive use of active gases can lead to issues such as increased spatter and decreased weld. Most Common Gas For Mig Welding.

From weldguru.com

MIG vs TIG Welding The Main Differences Weld Guru Most Common Gas For Mig Welding besides carbon dioxide, argon is one of the most common shielding gases frequently used in mig welding. for mig welding, use a shielding gas that suits your material. In this article, we’ll hash out the details about shielding. this is a overview of the gas choices for mig welding most metals. When used in small quantities, it. Most Common Gas For Mig Welding.