Air Tool Pressure Requirements . typically, air tools require psi ranging from 70 to 120. use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. Proper air pressure (psi) the vast. in this brief article, we will focus on the two most important factors in air tool performance: the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). Thus the pressure drop in an installation depends on. Check your tool’s manual for specific requirements. Choosing the correct psi for your air. for air tools, the required psi typically ranges from 70 to 90 psi. your tools’ cfm requirements give you an idea of what you need your air compressor to do, but it’s not enough to.

from blog.spongejet.com

in this brief article, we will focus on the two most important factors in air tool performance: the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). Check your tool’s manual for specific requirements. Thus the pressure drop in an installation depends on. typically, air tools require psi ranging from 70 to 120. Choosing the correct psi for your air. for air tools, the required psi typically ranges from 70 to 90 psi. use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. your tools’ cfm requirements give you an idea of what you need your air compressor to do, but it’s not enough to. Proper air pressure (psi) the vast.

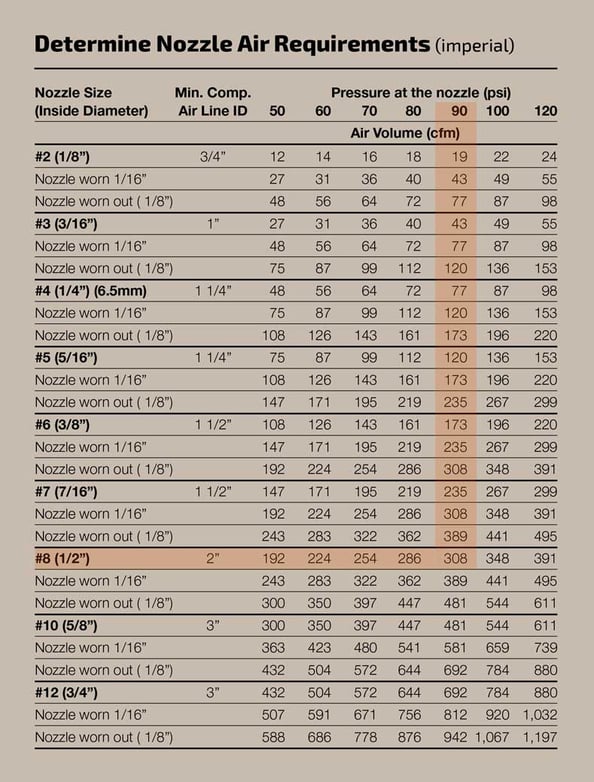

Air Compressor Requirements for Sandblasting

Air Tool Pressure Requirements use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. Proper air pressure (psi) the vast. the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). typically, air tools require psi ranging from 70 to 120. Choosing the correct psi for your air. Thus the pressure drop in an installation depends on. in this brief article, we will focus on the two most important factors in air tool performance: use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. your tools’ cfm requirements give you an idea of what you need your air compressor to do, but it’s not enough to. for air tools, the required psi typically ranges from 70 to 90 psi. Check your tool’s manual for specific requirements.

From airtoolkatsuchiri.blogspot.com

Air Tool Air Tool Pressure Air Tool Pressure Requirements typically, air tools require psi ranging from 70 to 120. the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). for air tools, the required psi typically ranges from 70 to 90 psi. Proper air pressure (psi) the vast. Thus the pressure drop in an installation depends on. Check. Air Tool Pressure Requirements.

From www.milessupply.com

Air Requirement Reference Chart from Miles Supply Air Tool Pressure Requirements typically, air tools require psi ranging from 70 to 120. Thus the pressure drop in an installation depends on. your tools’ cfm requirements give you an idea of what you need your air compressor to do, but it’s not enough to. the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa,. Air Tool Pressure Requirements.

From dengarden.com

How to Use Air Tools and an Air Compressor in Your Dengarden Air Tool Pressure Requirements for air tools, the required psi typically ranges from 70 to 90 psi. Choosing the correct psi for your air. Proper air pressure (psi) the vast. the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). your tools’ cfm requirements give you an idea of what you need your. Air Tool Pressure Requirements.

From www.esmagazine.com

Basics of Pressure & Pressure Measurement Engineered Systems Magazine Air Tool Pressure Requirements Proper air pressure (psi) the vast. for air tools, the required psi typically ranges from 70 to 90 psi. Check your tool’s manual for specific requirements. your tools’ cfm requirements give you an idea of what you need your air compressor to do, but it’s not enough to. typically, air tools require psi ranging from 70 to. Air Tool Pressure Requirements.

From airtoolkatsuchiri.blogspot.com

Air Tool Air Tool Pressure Air Tool Pressure Requirements Choosing the correct psi for your air. in this brief article, we will focus on the two most important factors in air tool performance: Check your tool’s manual for specific requirements. typically, air tools require psi ranging from 70 to 120. use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure. Air Tool Pressure Requirements.

From tendsupplies.com

The Science Behind Pneumatic Air Tools How Do They Work? Tend Air Tool Pressure Requirements for air tools, the required psi typically ranges from 70 to 90 psi. use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. Check your tool’s manual for specific requirements. the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa,. Air Tool Pressure Requirements.

From www.northerntool.com

Milton Air Pressure Gauge 1/4in. NPT, 0160 PSI, Bottom Mount, Model Air Tool Pressure Requirements Thus the pressure drop in an installation depends on. typically, air tools require psi ranging from 70 to 120. use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. for air tools, the required psi typically ranges from 70 to 90 psi. Proper air pressure (psi). Air Tool Pressure Requirements.

From www.milessupply.com

Chart for Compressed Air and Sandblasting Stone Accessories Air Tool Pressure Requirements in this brief article, we will focus on the two most important factors in air tool performance: the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). Thus the pressure drop in an installation depends on. use only clean, dry, regulated compressed air at the rated pressure or within. Air Tool Pressure Requirements.

From www.reddit.com

Paasche 1/10HP, 1/2 CFM Air Compressor r/Tools Air Tool Pressure Requirements Proper air pressure (psi) the vast. for air tools, the required psi typically ranges from 70 to 90 psi. use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. typically, air tools require psi ranging from 70 to 120. Thus the pressure drop in an installation. Air Tool Pressure Requirements.

From dengarden.com

How to Use Air Tools and an Air Compressor in Your Dengarden Air Tool Pressure Requirements Proper air pressure (psi) the vast. Thus the pressure drop in an installation depends on. in this brief article, we will focus on the two most important factors in air tool performance: use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. for air tools, the. Air Tool Pressure Requirements.

From www.setra.com

Room Pressure Guidelines in Healthcare Air Tool Pressure Requirements typically, air tools require psi ranging from 70 to 120. your tools’ cfm requirements give you an idea of what you need your air compressor to do, but it’s not enough to. Choosing the correct psi for your air. for air tools, the required psi typically ranges from 70 to 90 psi. use only clean, dry,. Air Tool Pressure Requirements.

From airtoolkatsuchiri.blogspot.com

Air Tool Air Tool Cfm Requirements Air Tool Pressure Requirements typically, air tools require psi ranging from 70 to 120. Thus the pressure drop in an installation depends on. in this brief article, we will focus on the two most important factors in air tool performance: for air tools, the required psi typically ranges from 70 to 90 psi. your tools’ cfm requirements give you an. Air Tool Pressure Requirements.

From www.linquip.com

What Tools Are Used to Measure Air Pressure? A Comprehensive Guide Air Tool Pressure Requirements Proper air pressure (psi) the vast. the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. your tools’ cfm requirements give you an idea of what you need. Air Tool Pressure Requirements.

From okigihan.blogspot.kr

Aircraft systems Pressurized Aircraft Air Tool Pressure Requirements Check your tool’s manual for specific requirements. Thus the pressure drop in an installation depends on. use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. Choosing the correct psi for your air. in this brief article, we will focus on the two most important factors in. Air Tool Pressure Requirements.

From www.scribd.com

Air Pressure Table PDF Air Tool Pressure Requirements the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). Proper air pressure (psi) the vast. your tools’ cfm requirements give you an idea of what you need your air compressor to do, but it’s not enough to. for air tools, the required psi typically ranges from 70 to. Air Tool Pressure Requirements.

From www.scribd.com

Pressure Test Requirements Charts PDF Air Tool Pressure Requirements use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. Thus the pressure drop in an installation depends on. Choosing the correct psi for your air. in this brief article, we will focus on the two most important factors in air tool performance: the air consumption. Air Tool Pressure Requirements.

From aircompressor50.wordpress.com

Selecting the Right Air Compressor for Your Air Tool Air Compressor Air Tool Pressure Requirements for air tools, the required psi typically ranges from 70 to 90 psi. typically, air tools require psi ranging from 70 to 120. the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). in this brief article, we will focus on the two most important factors in air. Air Tool Pressure Requirements.

From www.compressorpros.com

Sizing Guide Air Tool Pressure Requirements Proper air pressure (psi) the vast. your tools’ cfm requirements give you an idea of what you need your air compressor to do, but it’s not enough to. the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). Thus the pressure drop in an installation depends on. typically, air. Air Tool Pressure Requirements.

From dxobgtlpw.blob.core.windows.net

Air Hose Pressure Regulator at Cheri Larson blog Air Tool Pressure Requirements Thus the pressure drop in an installation depends on. typically, air tools require psi ranging from 70 to 120. Choosing the correct psi for your air. use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. Check your tool’s manual for specific requirements. for air tools,. Air Tool Pressure Requirements.

From www.youtube.com

HVAC Clean room air flow calculation for desired pressurized room YouTube Air Tool Pressure Requirements in this brief article, we will focus on the two most important factors in air tool performance: your tools’ cfm requirements give you an idea of what you need your air compressor to do, but it’s not enough to. Choosing the correct psi for your air. Proper air pressure (psi) the vast. for air tools, the required. Air Tool Pressure Requirements.

From www.walmart.com

Spray Tool Pressure Regulating Gauge LCD Digital Display Air Pressure Air Tool Pressure Requirements use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). your tools’ cfm requirements give you an idea of what you need your air compressor to do, but. Air Tool Pressure Requirements.

From airtoolkatsuchiri.blogspot.com

Air Tool Air Tool Requirements Air Tool Pressure Requirements typically, air tools require psi ranging from 70 to 120. Check your tool’s manual for specific requirements. use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. in this brief article, we will focus on the two most important factors in air tool performance: Proper air. Air Tool Pressure Requirements.

From airtoolkatsuchiri.blogspot.com

Air Tool Air Tool Cfm Requirements Air Tool Pressure Requirements in this brief article, we will focus on the two most important factors in air tool performance: the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). Thus the pressure drop in an installation depends on. for air tools, the required psi typically ranges from 70 to 90 psi.. Air Tool Pressure Requirements.

From amtechdiy.com

77pc air tool kit Amtech Air Tool Pressure Requirements Choosing the correct psi for your air. your tools’ cfm requirements give you an idea of what you need your air compressor to do, but it’s not enough to. use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. typically, air tools require psi ranging from. Air Tool Pressure Requirements.

From www.familyhandyman.com

Pro's Guide to Air Compressor Upgrades and Attachments Family Handyman Air Tool Pressure Requirements Choosing the correct psi for your air. in this brief article, we will focus on the two most important factors in air tool performance: your tools’ cfm requirements give you an idea of what you need your air compressor to do, but it’s not enough to. Proper air pressure (psi) the vast. Thus the pressure drop in an. Air Tool Pressure Requirements.

From www.engineeringtoolbox.com

Compressed Air Pipe Line Pressure Loss Online Calculator with Air Tool Pressure Requirements in this brief article, we will focus on the two most important factors in air tool performance: Check your tool’s manual for specific requirements. Proper air pressure (psi) the vast. typically, air tools require psi ranging from 70 to 120. the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2. Air Tool Pressure Requirements.

From sandblastingmachines.com

Understanding Sandblasting Compressor Size Requirements Sandblasting Air Tool Pressure Requirements in this brief article, we will focus on the two most important factors in air tool performance: Proper air pressure (psi) the vast. your tools’ cfm requirements give you an idea of what you need your air compressor to do, but it’s not enough to. Check your tool’s manual for specific requirements. the air consumption is based. Air Tool Pressure Requirements.

From bddrill.us

Air Requirements Black Diamond Drilling USA Air Tool Pressure Requirements Check your tool’s manual for specific requirements. Thus the pressure drop in an installation depends on. in this brief article, we will focus on the two most important factors in air tool performance: Choosing the correct psi for your air. the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar).. Air Tool Pressure Requirements.

From www.kennametal.com

How to Choose the Right Blast Nozzle Kennametal Air Tool Pressure Requirements Thus the pressure drop in an installation depends on. in this brief article, we will focus on the two most important factors in air tool performance: the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). Proper air pressure (psi) the vast. Choosing the correct psi for your air. . Air Tool Pressure Requirements.

From compactequip.com

Air Tools And Where There Are Air Tools, There Are Diesel Air Air Tool Pressure Requirements Proper air pressure (psi) the vast. Thus the pressure drop in an installation depends on. your tools’ cfm requirements give you an idea of what you need your air compressor to do, but it’s not enough to. Check your tool’s manual for specific requirements. use only clean, dry, regulated compressed air at the rated pressure or within the. Air Tool Pressure Requirements.

From blog.spongejet.com

Air Compressor Requirements for Sandblasting Air Tool Pressure Requirements typically, air tools require psi ranging from 70 to 120. use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. Check your tool’s manual for specific requirements. the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). Proper. Air Tool Pressure Requirements.

From www.aliexpress.com

PneumaticImpactSmallWrench12PneumaticGunAirPressureWrench Air Tool Pressure Requirements typically, air tools require psi ranging from 70 to 120. use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on the. the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). Check your tool’s manual for specific requirements. Proper. Air Tool Pressure Requirements.

From www.scribd.com

Air Tool Consumption Chart Drill Elevator Air Tool Pressure Requirements Choosing the correct psi for your air. for air tools, the required psi typically ranges from 70 to 90 psi. in this brief article, we will focus on the two most important factors in air tool performance: use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on. Air Tool Pressure Requirements.

From thesprucetools.com

What Size Air Compressor Do I Need for Air Tools? (With CFM Chart) Air Tool Pressure Requirements for air tools, the required psi typically ranges from 70 to 90 psi. your tools’ cfm requirements give you an idea of what you need your air compressor to do, but it’s not enough to. the air consumption is based on commonly used working pressure of approximately 90 psi (620 kpa, 6.2 bar). Proper air pressure (psi). Air Tool Pressure Requirements.

From ricksfreeautorepairadvice.com

AC pressure gauge readings — Ricks Free Auto Repair Advice Ricks Free Air Tool Pressure Requirements Check your tool’s manual for specific requirements. in this brief article, we will focus on the two most important factors in air tool performance: for air tools, the required psi typically ranges from 70 to 90 psi. typically, air tools require psi ranging from 70 to 120. your tools’ cfm requirements give you an idea of. Air Tool Pressure Requirements.