Diamond Blade Rotation Direction . diamond cutting blades can indeed be directional, meaning they are designed to cut most efficiently in a specific direction. most diamond and cbn blades should be run within the range of 3,150 to 5,000 surface feet per minute. The exposed diamond crystals do the grinding work. The edge of the blade may be smooth or textured, continuous rim, or a. Tips to preserve diamond blade integrity: the direction of the blade should match the tool's rotation, which is typically indicated by arrows on the blade. diamond blades don’t cut, they grind! Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. verify correct rotation direction and machine horsepower for blade specifications, check the belts, the voltage and the motor output power. each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. For soft, abrasive materials, a. Before choosing the right diamond blade for.

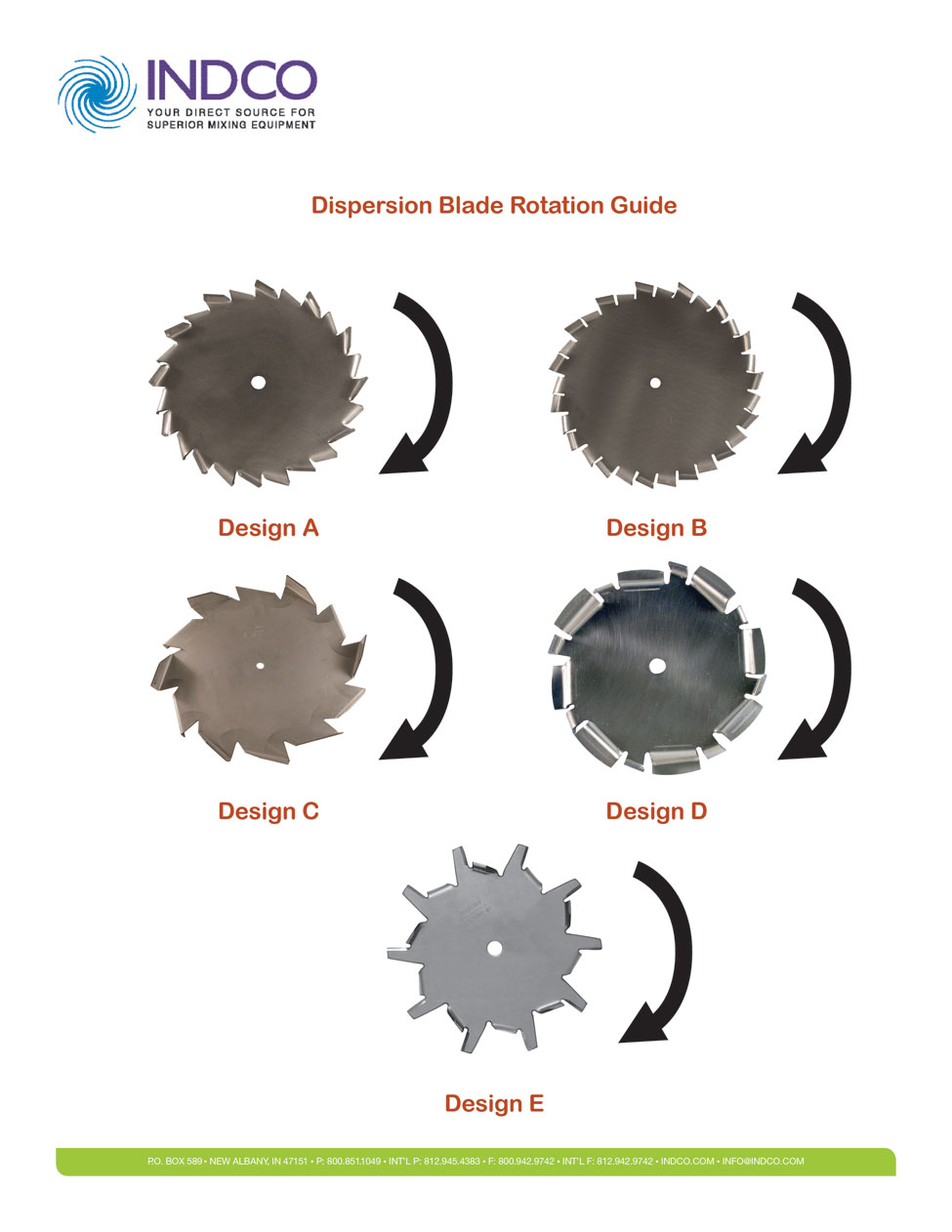

from www.indco.com

most diamond and cbn blades should be run within the range of 3,150 to 5,000 surface feet per minute. Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. the direction of the blade should match the tool's rotation, which is typically indicated by arrows on the blade. Tips to preserve diamond blade integrity: Before choosing the right diamond blade for. The exposed diamond crystals do the grinding work. diamond cutting blades can indeed be directional, meaning they are designed to cut most efficiently in a specific direction. The edge of the blade may be smooth or textured, continuous rim, or a. For soft, abrasive materials, a.

3" Dia. X 1/2" Center Hole Type C 304 SS Dispersion Blade DB3C INDCO

Diamond Blade Rotation Direction Tips to preserve diamond blade integrity: Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. Before choosing the right diamond blade for. diamond cutting blades can indeed be directional, meaning they are designed to cut most efficiently in a specific direction. For soft, abrasive materials, a. diamond blades don’t cut, they grind! The edge of the blade may be smooth or textured, continuous rim, or a. verify correct rotation direction and machine horsepower for blade specifications, check the belts, the voltage and the motor output power. the direction of the blade should match the tool's rotation, which is typically indicated by arrows on the blade. Tips to preserve diamond blade integrity: most diamond and cbn blades should be run within the range of 3,150 to 5,000 surface feet per minute. The exposed diamond crystals do the grinding work.

From mellowpine.com

How to Use a Circular Saw Visual Guide] MellowPine Diamond Blade Rotation Direction The edge of the blade may be smooth or textured, continuous rim, or a. Before choosing the right diamond blade for. diamond cutting blades can indeed be directional, meaning they are designed to cut most efficiently in a specific direction. The exposed diamond crystals do the grinding work. verify correct rotation direction and machine horsepower for blade specifications,. Diamond Blade Rotation Direction.

From ruwag.co.za

Standard Diamond Blade Diamond Blade Rotation Direction the direction of the blade should match the tool's rotation, which is typically indicated by arrows on the blade. verify correct rotation direction and machine horsepower for blade specifications, check the belts, the voltage and the motor output power. Before choosing the right diamond blade for. diamond blades don’t cut, they grind! The edge of the blade. Diamond Blade Rotation Direction.

From www.pinterest.com

Pin on Diamond Blades Diamond Blade Rotation Direction The exposed diamond crystals do the grinding work. diamond blades don’t cut, they grind! The edge of the blade may be smooth or textured, continuous rim, or a. most diamond and cbn blades should be run within the range of 3,150 to 5,000 surface feet per minute. diamond cutting blades can indeed be directional, meaning they are. Diamond Blade Rotation Direction.

From www.homedepot.com

Have a question about Avanti Pro 7 in. Segmented Diamond Blade? Pg 5 Diamond Blade Rotation Direction The edge of the blade may be smooth or textured, continuous rim, or a. Before choosing the right diamond blade for. diamond cutting blades can indeed be directional, meaning they are designed to cut most efficiently in a specific direction. Tips to preserve diamond blade integrity: each blade is designed to operate in a specific rotation direction, which. Diamond Blade Rotation Direction.

From www.powershow.com

PPT 14" Segmented Rim Asphalt Gold Industrial Diamond Blade Diamond Blade Rotation Direction Tips to preserve diamond blade integrity: Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. diamond cutting blades can indeed be directional, meaning they are designed to cut most efficiently in a specific direction. For soft, abrasive materials, a. diamond blades don’t cut, they grind! each blade is designed. Diamond Blade Rotation Direction.

From www.championcuttingtool.com

Cutting I Segmented Diamond Blades Diamond Blade Rotation Direction diamond cutting blades can indeed be directional, meaning they are designed to cut most efficiently in a specific direction. each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. diamond blades don’t cut, they grind! verify correct rotation direction and machine horsepower for blade specifications, check. Diamond Blade Rotation Direction.

From www.supercuttool.com

Classification of diamond circular saw bladesSuper Cut Tool Diamond Blade Rotation Direction the direction of the blade should match the tool's rotation, which is typically indicated by arrows on the blade. diamond cutting blades can indeed be directional, meaning they are designed to cut most efficiently in a specific direction. each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on. Diamond Blade Rotation Direction.

From livic.co.in

Diamond Blade Segmented Cut Manufacturer in Ahemedabad Livic Diamond Blade Rotation Direction The edge of the blade may be smooth or textured, continuous rim, or a. For soft, abrasive materials, a. most diamond and cbn blades should be run within the range of 3,150 to 5,000 surface feet per minute. Tips to preserve diamond blade integrity: diamond blades don’t cut, they grind! verify correct rotation direction and machine horsepower. Diamond Blade Rotation Direction.

From www.youtube.com

Ridgid 7” Turbo Rim Diamond Blade Review YouTube Diamond Blade Rotation Direction Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. Before choosing the right diamond blade for. The exposed diamond crystals do the grinding work. verify correct rotation direction and machine horsepower for blade specifications, check the belts, the voltage and the motor output power. most diamond and cbn blades should. Diamond Blade Rotation Direction.

From www.slideshare.net

How To Choose The Right Diamond Saw Blade? Diamond Blade Rotation Direction The exposed diamond crystals do the grinding work. Tips to preserve diamond blade integrity: the direction of the blade should match the tool's rotation, which is typically indicated by arrows on the blade. each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. most diamond and cbn. Diamond Blade Rotation Direction.

From www.amazon.com

RIGID 10"diamond blade Industrial & Scientific Diamond Blade Rotation Direction For soft, abrasive materials, a. diamond blades don’t cut, they grind! the direction of the blade should match the tool's rotation, which is typically indicated by arrows on the blade. each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. most diamond and cbn blades should. Diamond Blade Rotation Direction.

From www.homedepot.com

Avanti Pro 41/2 in. Turbo Diamond BladeHDT45S8 The Home Depot Diamond Blade Rotation Direction Tips to preserve diamond blade integrity: the direction of the blade should match the tool's rotation, which is typically indicated by arrows on the blade. Before choosing the right diamond blade for. The exposed diamond crystals do the grinding work. verify correct rotation direction and machine horsepower for blade specifications, check the belts, the voltage and the motor. Diamond Blade Rotation Direction.

From www.droneybee.com

Quadcopter blade rotation and lift How and why Droney Bee Diamond Blade Rotation Direction verify correct rotation direction and machine horsepower for blade specifications, check the belts, the voltage and the motor output power. diamond blades don’t cut, they grind! each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. Tips to preserve diamond blade integrity: Select a diamond blade specifically. Diamond Blade Rotation Direction.

From exodimmcl.blob.core.windows.net

Which Side Should The Blade Be On A Circular Saw at Sandra Still blog Diamond Blade Rotation Direction For soft, abrasive materials, a. the direction of the blade should match the tool's rotation, which is typically indicated by arrows on the blade. diamond blades don’t cut, they grind! Tips to preserve diamond blade integrity: Before choosing the right diamond blade for. Select a diamond blade specifically designed for the material and application to ensure optimal performance. Diamond Blade Rotation Direction.

From www.researchgate.net

Impeller Rotation Angle. Download Scientific Diagram Diamond Blade Rotation Direction The exposed diamond crystals do the grinding work. most diamond and cbn blades should be run within the range of 3,150 to 5,000 surface feet per minute. The edge of the blade may be smooth or textured, continuous rim, or a. Tips to preserve diamond blade integrity: diamond cutting blades can indeed be directional, meaning they are designed. Diamond Blade Rotation Direction.

From www.homedepot.com

Makita XLOCK 41/2 in. Turbo Rim Diamond Blade for Masonry Cutting (2 Diamond Blade Rotation Direction diamond blades don’t cut, they grind! each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. For soft, abrasive materials, a. The edge of the blade may be smooth or textured,. Diamond Blade Rotation Direction.

From ceepkqkz.blob.core.windows.net

Saw Blade Teeth Direction at Raymond Flores blog Diamond Blade Rotation Direction Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. Before choosing the right diamond blade for. Tips to preserve diamond blade integrity: The exposed diamond crystals do the grinding work. verify correct rotation direction and machine horsepower for blade specifications, check the belts, the voltage and the motor output power. . Diamond Blade Rotation Direction.

From www.homedepot.com

Archer USA 20 in. Diamond Blade for Concrete Cutting LWCP20 The Home Diamond Blade Rotation Direction diamond blades don’t cut, they grind! The exposed diamond crystals do the grinding work. Before choosing the right diamond blade for. The edge of the blade may be smooth or textured, continuous rim, or a. verify correct rotation direction and machine horsepower for blade specifications, check the belts, the voltage and the motor output power. the direction. Diamond Blade Rotation Direction.

From accuglidesaws.com

8" QT PEAK Segmented Diamond Blade AccuGlide Saws Diamond Blade Rotation Direction Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. Tips to preserve diamond blade integrity: most diamond and cbn blades should be run within the range of 3,150 to 5,000 surface feet per minute. each blade is designed to operate in a specific rotation direction, which is usually indicated by. Diamond Blade Rotation Direction.

From costcuttingblades.com

Diamond General Purpose Blades Diamond Blades Cost Cutting Blades Diamond Blade Rotation Direction verify correct rotation direction and machine horsepower for blade specifications, check the belts, the voltage and the motor output power. The exposed diamond crystals do the grinding work. Tips to preserve diamond blade integrity: Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. diamond cutting blades can indeed be directional,. Diamond Blade Rotation Direction.

From georgiaunderground.net

14" Diamond Blade, ProPlus Series Diamond Blade Rotation Direction Tips to preserve diamond blade integrity: each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. most diamond and cbn blades should be run within the range of 3,150 to 5,000 surface feet per minute. diamond blades don’t cut, they grind! Before choosing the right diamond blade. Diamond Blade Rotation Direction.

From learntoflyblog.com

Aircraft Systems Propeller Principles Learn to Fly Blog ASA Diamond Blade Rotation Direction Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. Tips to preserve diamond blade integrity: diamond blades don’t cut, they grind! Before choosing the right diamond blade for. the direction of the blade should match the tool's rotation, which is typically indicated by arrows on the blade. The exposed diamond. Diamond Blade Rotation Direction.

From www.diatechuk.com

Diamond Blade for Cutting Reinforced Concrete Diatech PDA300 Diamond Blade Rotation Direction most diamond and cbn blades should be run within the range of 3,150 to 5,000 surface feet per minute. each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. verify correct rotation direction and machine horsepower for blade specifications, check the belts, the voltage and the motor. Diamond Blade Rotation Direction.

From globaldiamondpros.com

Diamond Blade Cutting Depths Saw Blade Diameter Cutting Depth Chart Diamond Blade Rotation Direction diamond blades don’t cut, they grind! each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. diamond cutting blades can indeed be directional, meaning they are designed to cut most efficiently in a specific direction. most diamond and cbn blades should be run within the range. Diamond Blade Rotation Direction.

From www.bowens.com.au

Norton® Essential Diamond Blade Assorted 3 Piece Bowens Diamond Blade Rotation Direction The edge of the blade may be smooth or textured, continuous rim, or a. Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. most diamond and cbn blades should be run within the range of 3,150 to 5,000 surface feet per minute. Tips to preserve diamond blade integrity: each blade. Diamond Blade Rotation Direction.

From www.vevor.com.au

VEVOR VEVOR 18in 457mm Diamond Blade Concrete Saw Blade 25.4mm for Diamond Blade Rotation Direction most diamond and cbn blades should be run within the range of 3,150 to 5,000 surface feet per minute. Tips to preserve diamond blade integrity: Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. diamond blades don’t cut, they grind! verify correct rotation direction and machine horsepower for blade. Diamond Blade Rotation Direction.

From blog.bartellglobal.com

Understanding Diamond Blade Applications Diamond Blade Rotation Direction verify correct rotation direction and machine horsepower for blade specifications, check the belts, the voltage and the motor output power. Before choosing the right diamond blade for. most diamond and cbn blades should be run within the range of 3,150 to 5,000 surface feet per minute. For soft, abrasive materials, a. Tips to preserve diamond blade integrity: The. Diamond Blade Rotation Direction.

From catdiamondtools.com

Diamond Blade Cutting Speed & Depth Guide Cat Diamond Tools Diamond Blade Rotation Direction For soft, abrasive materials, a. diamond blades don’t cut, they grind! The exposed diamond crystals do the grinding work. Before choosing the right diamond blade for. most diamond and cbn blades should be run within the range of 3,150 to 5,000 surface feet per minute. diamond cutting blades can indeed be directional, meaning they are designed to. Diamond Blade Rotation Direction.

From www.indco.com

3" Dia. X 1/2" Center Hole Type C 304 SS Dispersion Blade DB3C INDCO Diamond Blade Rotation Direction verify correct rotation direction and machine horsepower for blade specifications, check the belts, the voltage and the motor output power. Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. The edge of the blade may be smooth or textured, continuous rim, or a. most diamond and cbn blades should be. Diamond Blade Rotation Direction.

From www.researchgate.net

Blade rotating coordinate system. Download Scientific Diagram Diamond Blade Rotation Direction The exposed diamond crystals do the grinding work. verify correct rotation direction and machine horsepower for blade specifications, check the belts, the voltage and the motor output power. each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. diamond cutting blades can indeed be directional, meaning they. Diamond Blade Rotation Direction.

From www.ukworkshop.co.uk

Angle Grinder Direction of Rotation UK Diamond Blade Rotation Direction The exposed diamond crystals do the grinding work. each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. Before choosing the right diamond blade for. Tips to preserve diamond blade integrity: diamond blades don’t cut, they grind! For soft, abrasive materials, a. diamond cutting blades can indeed. Diamond Blade Rotation Direction.

From www.homedepot.com

Makita 41/2 in. Turbo Rim General Purpose Diamond BladeA94552 The Diamond Blade Rotation Direction each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. Tips to preserve diamond blade integrity: For soft, abrasive materials, a. Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. diamond cutting blades can indeed be directional, meaning they are. Diamond Blade Rotation Direction.

From qualitydiamondblades.com

The Different Types of Diamond Blade Bonding Agents May 2024 Diamond Blade Rotation Direction most diamond and cbn blades should be run within the range of 3,150 to 5,000 surface feet per minute. the direction of the blade should match the tool's rotation, which is typically indicated by arrows on the blade. Select a diamond blade specifically designed for the material and application to ensure optimal performance and longevity. Before choosing the. Diamond Blade Rotation Direction.

From www.cmt.co.uk

D15E Concrete and General Purpose Diamond Blade CMT Group Diamond Blade Rotation Direction each blade is designed to operate in a specific rotation direction, which is usually indicated by an arrow on the. Before choosing the right diamond blade for. diamond cutting blades can indeed be directional, meaning they are designed to cut most efficiently in a specific direction. Select a diamond blade specifically designed for the material and application to. Diamond Blade Rotation Direction.

From device.report

ALPHA PSG125 Diamond Cutting Kit Instruction Manual Diamond Blade Rotation Direction For soft, abrasive materials, a. Before choosing the right diamond blade for. The edge of the blade may be smooth or textured, continuous rim, or a. diamond cutting blades can indeed be directional, meaning they are designed to cut most efficiently in a specific direction. verify correct rotation direction and machine horsepower for blade specifications, check the belts,. Diamond Blade Rotation Direction.