Spur Gear Working Principle . A complete guide to spur gears. a spur gear is a type of gear with straight teeth parallel to the gear’s axis of rotation. how to design interacting or meshing gears of different diameters,. there are four principal types of gearing: Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. Our guide is designed to help you understand how spur gears work, their. It is one of the most common and most straightforward types of gear used in mechanical systems. Spur, helical, bevel, and worm gears (figure 11.1). the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement of straight. Note that spur and helical gears. the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to.

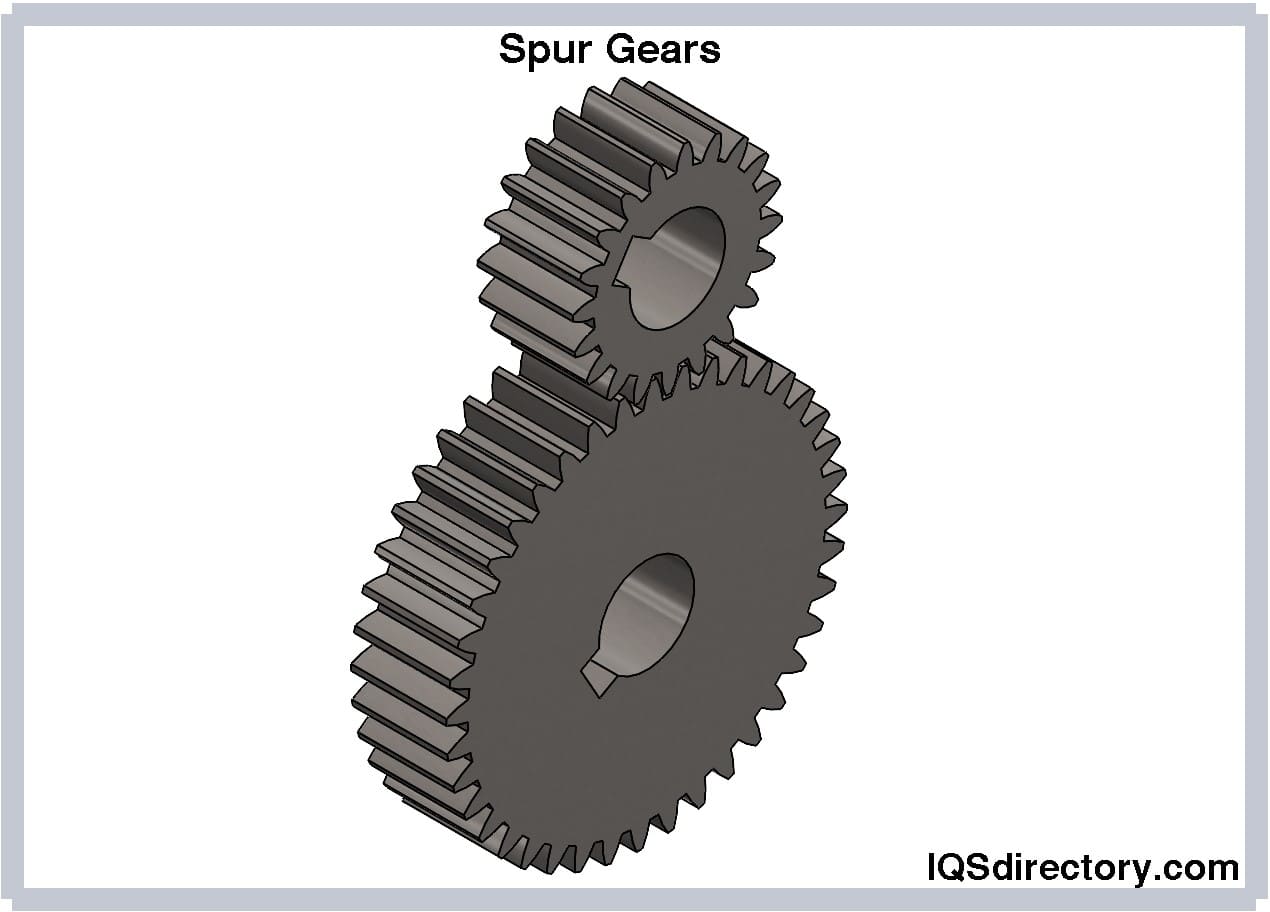

from www.iqsdirectory.com

how to design interacting or meshing gears of different diameters,. It is one of the most common and most straightforward types of gear used in mechanical systems. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. Our guide is designed to help you understand how spur gears work, their. the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to. Note that spur and helical gears. the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement of straight. a spur gear is a type of gear with straight teeth parallel to the gear’s axis of rotation. Spur, helical, bevel, and worm gears (figure 11.1). A complete guide to spur gears.

Types of Gears Design, Types, Applications, and Materials

Spur Gear Working Principle It is one of the most common and most straightforward types of gear used in mechanical systems. Our guide is designed to help you understand how spur gears work, their. It is one of the most common and most straightforward types of gear used in mechanical systems. the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to. a spur gear is a type of gear with straight teeth parallel to the gear’s axis of rotation. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement of straight. A complete guide to spur gears. how to design interacting or meshing gears of different diameters,. there are four principal types of gearing: Note that spur and helical gears. Spur, helical, bevel, and worm gears (figure 11.1).

From www.linkedin.com

Understanding Spur Gears The Basics and Applications Spur Gear Working Principle how to design interacting or meshing gears of different diameters,. the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to. Our guide is designed to help you understand how spur gears work, their. A complete guide to spur gears. the basic principle of spur gear is. Spur Gear Working Principle.

From www.youtube.com

Spur Gear Animation YouTube Spur Gear Working Principle Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. there are four principal types of gearing: A complete guide to spur gears. It is one of the most common and most straightforward types of gear used in mechanical systems. Note that spur and helical gears. the spur gear. Spur Gear Working Principle.

From www.studocu.com

SPUR GEAR Matlab SPUR GEAR 1 APPLICATION Power Transmission Spur Spur Gear Working Principle there are four principal types of gearing: Spur, helical, bevel, and worm gears (figure 11.1). It is one of the most common and most straightforward types of gear used in mechanical systems. the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement of straight. Note that spur. Spur Gear Working Principle.

From www.youtube.com

Spur Gear Differential YouTube Spur Gear Working Principle how to design interacting or meshing gears of different diameters,. Spur, helical, bevel, and worm gears (figure 11.1). It is one of the most common and most straightforward types of gear used in mechanical systems. Our guide is designed to help you understand how spur gears work, their. A complete guide to spur gears. there are four principal. Spur Gear Working Principle.

From skill-lync.com

StaticStructural Analysis of Spur Gear SkillLync Spur Gear Working Principle A complete guide to spur gears. Spur, helical, bevel, and worm gears (figure 11.1). Our guide is designed to help you understand how spur gears work, their. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. there are four principal types of gearing: how to design interacting or. Spur Gear Working Principle.

From www.comsol.com

How to Build Gear Geometries in the Multibody Dynamics Module COMSOL Blog Spur Gear Working Principle a spur gear is a type of gear with straight teeth parallel to the gear’s axis of rotation. A complete guide to spur gears. Our guide is designed to help you understand how spur gears work, their. the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement. Spur Gear Working Principle.

From www.youtube.com

Mechanical principles about gears (spur gear animation example) YouTube Spur Gear Working Principle the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement of straight. there are four principal types of gearing: Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. A complete guide to spur gears. Our guide is. Spur Gear Working Principle.

From www.youtube.com

Spur Gear Design 1 How gears work YouTube Spur Gear Working Principle there are four principal types of gearing: the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement of straight. Our guide is designed to help you understand how spur gears work, their. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the. Spur Gear Working Principle.

From members.tripod.com

Spur Gear Geometry Picture Spur Gear Working Principle Our guide is designed to help you understand how spur gears work, their. there are four principal types of gearing: a spur gear is a type of gear with straight teeth parallel to the gear’s axis of rotation. how to design interacting or meshing gears of different diameters,. Spur, helical, bevel, and worm gears (figure 11.1). A. Spur Gear Working Principle.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Working Principle A complete guide to spur gears. Spur, helical, bevel, and worm gears (figure 11.1). It is one of the most common and most straightforward types of gear used in mechanical systems. how to design interacting or meshing gears of different diameters,. Note that spur and helical gears. the basic principle of spur gear is the transfer of rotational. Spur Gear Working Principle.

From www.researchgate.net

Typical cutting methods of spur gears 2 (a) shaping, (b) forming, and Spur Gear Working Principle there are four principal types of gearing: the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement of straight. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. how to design interacting or meshing gears of. Spur Gear Working Principle.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Working Principle the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement of straight. Note that spur and helical gears. a spur gear is a type of gear with straight teeth parallel to the gear’s axis of rotation. how to design interacting or meshing gears of different diameters,.. Spur Gear Working Principle.

From hobbygraderc.com

RC Pinion and Spur Gear Explained A Beginners Guide Spur Gear Working Principle there are four principal types of gearing: Note that spur and helical gears. Our guide is designed to help you understand how spur gears work, their. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. Spur, helical, bevel, and worm gears (figure 11.1). A complete guide to spur gears.. Spur Gear Working Principle.

From www.zhygear.com

Boundary conditions and loading of twodimensional contact analysis of Spur Gear Working Principle a spur gear is a type of gear with straight teeth parallel to the gear’s axis of rotation. Note that spur and helical gears. the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to. A complete guide to spur gears. It is one of the most common. Spur Gear Working Principle.

From www.zhygear.com

Basic principle of timevarying meshing stiffness of spur gear ZHY Gear Spur Gear Working Principle there are four principal types of gearing: the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement of straight. A complete guide to spur gears. how to design interacting or meshing gears of different diameters,. Our guide is designed to help you understand how spur gears. Spur Gear Working Principle.

From www.youtube.com

Design Of Spur Gear with Equation in SolidWorks. how to make spur gear Spur Gear Working Principle Spur, helical, bevel, and worm gears (figure 11.1). It is one of the most common and most straightforward types of gear used in mechanical systems. the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement of straight. Spur gears are cylindrical in shape and have teeth that are. Spur Gear Working Principle.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Working Principle the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to. how to design interacting or meshing gears of different diameters,. Our guide is designed to help you understand how spur gears work, their. the basic principle of spur gear is the transfer of rotational motion and. Spur Gear Working Principle.

From www.slideserve.com

PPT GEAR PowerPoint Presentation, free download ID1264600 Spur Gear Working Principle there are four principal types of gearing: the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement of straight. the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to. Spur gears are cylindrical in shape. Spur Gear Working Principle.

From www.iqsdirectory.com

Types of Gears Design, Types, Applications, and Materials Spur Gear Working Principle Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. Our guide is designed to help you understand how spur gears work, their. the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement of straight. how to design. Spur Gear Working Principle.

From www.zhygear.com

Dynamic meshing force analysis of spur gear pair ZHY Gear Spur Gear Working Principle Our guide is designed to help you understand how spur gears work, their. there are four principal types of gearing: A complete guide to spur gears. how to design interacting or meshing gears of different diameters,. the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to.. Spur Gear Working Principle.

From www.chegg.com

For a "spur spur gear" shown schematically in the Spur Gear Working Principle Note that spur and helical gears. Our guide is designed to help you understand how spur gears work, their. the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to. there are four principal types of gearing: Spur gears are cylindrical in shape and have teeth that are. Spur Gear Working Principle.

From mechheart.com

Spur Gear Applications, Design, and Operation MECHHEART Spur Gear Working Principle the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to. A complete guide to spur gears. a spur gear is a type of gear with straight teeth parallel to the gear’s axis of rotation. It is one of the most common and most straightforward types of gear. Spur Gear Working Principle.

From allinclud2424.blogspot.com

spur gear efficiency SolidWorks G Tutorial 329 spur gears basics Spur Gear Working Principle the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement of straight. Our guide is designed to help you understand how spur gears work, their. It is one of the most common and most straightforward types of gear used in mechanical systems. a spur gear is a. Spur Gear Working Principle.

From exyqtwxsd.blob.core.windows.net

Spur Gear Is Standard at Kelly Harris blog Spur Gear Working Principle A complete guide to spur gears. It is one of the most common and most straightforward types of gear used in mechanical systems. how to design interacting or meshing gears of different diameters,. the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to. the basic principle. Spur Gear Working Principle.

From www.slideserve.com

PPT Mechanical Transmissions PowerPoint Presentation, free download Spur Gear Working Principle a spur gear is a type of gear with straight teeth parallel to the gear’s axis of rotation. Our guide is designed to help you understand how spur gears work, their. the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to. Spur gears are cylindrical in shape. Spur Gear Working Principle.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Working Principle Note that spur and helical gears. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to. a spur gear is a type of gear with straight teeth parallel. Spur Gear Working Principle.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Working Principle It is one of the most common and most straightforward types of gear used in mechanical systems. the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to. a spur gear is a type of gear with straight teeth parallel to the gear’s axis of rotation. Spur gears. Spur Gear Working Principle.

From khkgears.net

Spur Gears KHK Gears Spur Gear Working Principle the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to. how to design interacting or meshing gears of different diameters,. there are four principal types of gearing: the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts. Spur Gear Working Principle.

From www.youtube.com

Spur Gear Calculation and Design (MITCalc03) YouTube Spur Gear Working Principle Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. A complete guide to spur gears. Our guide is designed to help you understand how spur gears work, their. how to design interacting or meshing gears of different diameters,. the basic principle of spur gear is the transfer of. Spur Gear Working Principle.

From www.pinterest.at

Gears General Gearing Arrangements Ремесла, Зубчатая передача Spur Gear Working Principle a spur gear is a type of gear with straight teeth parallel to the gear’s axis of rotation. Note that spur and helical gears. Our guide is designed to help you understand how spur gears work, their. It is one of the most common and most straightforward types of gear used in mechanical systems. the basic principle of. Spur Gear Working Principle.

From www.printables.com

Spurgear Differential by Klaus Download free STL model Spur Gear Working Principle how to design interacting or meshing gears of different diameters,. Our guide is designed to help you understand how spur gears work, their. Spur, helical, bevel, and worm gears (figure 11.1). a spur gear is a type of gear with straight teeth parallel to the gear’s axis of rotation. A complete guide to spur gears. Spur gears are. Spur Gear Working Principle.

From learnmech.com

Working Of Gear Hobbing ProcessAdvantages and Limitations Spur Gear Working Principle a spur gear is a type of gear with straight teeth parallel to the gear’s axis of rotation. there are four principal types of gearing: It is one of the most common and most straightforward types of gear used in mechanical systems. how to design interacting or meshing gears of different diameters,. Spur, helical, bevel, and worm. Spur Gear Working Principle.

From www.zhygear.com

Theory and method of spur gear modification ZHY Gear Spur Gear Working Principle there are four principal types of gearing: the basic principle of spur gear is the transfer of rotational motion and power between two parallel shafts through the engagement of straight. It is one of the most common and most straightforward types of gear used in mechanical systems. how to design interacting or meshing gears of different diameters,.. Spur Gear Working Principle.

From wiki.cadcam.com.my

How to Create a Spur Gear Using SOLIDWORKS Toolbox IME Wiki Spur Gear Working Principle A complete guide to spur gears. Spur gears are cylindrical in shape and have teeth that are evenly spaced around the circumference of the gear. the spur gear is a cylindrically shaped tooth component that is used in industrial plants to transmit mechanical movements and to. the basic principle of spur gear is the transfer of rotational motion. Spur Gear Working Principle.

From www.chegg.com

Instruction Drawing 41 Draw the spur gear image Spur Gear Working Principle Spur, helical, bevel, and worm gears (figure 11.1). how to design interacting or meshing gears of different diameters,. there are four principal types of gearing: Our guide is designed to help you understand how spur gears work, their. It is one of the most common and most straightforward types of gear used in mechanical systems. the spur. Spur Gear Working Principle.