Countersink Onshape . i suggest creating a plane tangent to the outer surface of the cylinder. countersink and counterbore holes in sheet metal. your hole diameter and countersink diameter are input as the same value. Then, create a sketch on this plane with a point at the. i was looking for a direct function in onshape to make countersink slot. Select points in the sketch (including corners of. I tried to create a large circle on. the hole feature allows you to create simple, countersink, and counterbore holes at sketch points or circle centers,. Counterbore and countersink holes can now be added to active sheet metal parts and. Right now, i can do as mahir. when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw. i am trying to create a countersunk hole using various commands on onshape but i have been unsuccessful. If you set the second input to your desired countersink size, you should be good.

from forum.onshape.com

i was looking for a direct function in onshape to make countersink slot. Right now, i can do as mahir. your hole diameter and countersink diameter are input as the same value. the hole feature allows you to create simple, countersink, and counterbore holes at sketch points or circle centers,. Counterbore and countersink holes can now be added to active sheet metal parts and. Then, create a sketch on this plane with a point at the. when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw. i am trying to create a countersunk hole using various commands on onshape but i have been unsuccessful. Select points in the sketch (including corners of. i suggest creating a plane tangent to the outer surface of the cylinder.

Countersink Screws and Holes Mating — Onshape

Countersink Onshape when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw. when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw. your hole diameter and countersink diameter are input as the same value. Counterbore and countersink holes can now be added to active sheet metal parts and. I tried to create a large circle on. countersink and counterbore holes in sheet metal. Select points in the sketch (including corners of. i am trying to create a countersunk hole using various commands on onshape but i have been unsuccessful. i was looking for a direct function in onshape to make countersink slot. i suggest creating a plane tangent to the outer surface of the cylinder. the hole feature allows you to create simple, countersink, and counterbore holes at sketch points or circle centers,. If you set the second input to your desired countersink size, you should be good. Then, create a sketch on this plane with a point at the. Right now, i can do as mahir.

From forum.onshape.com

How to create a countersunk hole? — Onshape Countersink Onshape If you set the second input to your desired countersink size, you should be good. countersink and counterbore holes in sheet metal. when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw. Right now, i can do as mahir. your hole diameter and countersink. Countersink Onshape.

From www.bmrtoolgroup.com

Adjustable Depth Onshape Countersink For Stainless Steel from China Countersink Onshape Counterbore and countersink holes can now be added to active sheet metal parts and. when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw. i suggest creating a plane tangent to the outer surface of the cylinder. Select points in the sketch (including corners of.. Countersink Onshape.

From forum.onshape.com

where is the countersink? — Onshape Countersink Onshape countersink and counterbore holes in sheet metal. If you set the second input to your desired countersink size, you should be good. i suggest creating a plane tangent to the outer surface of the cylinder. Select points in the sketch (including corners of. i am trying to create a countersunk hole using various commands on onshape but. Countersink Onshape.

From forum.onshape.com

Countersink hole from opposite face — Onshape Countersink Onshape Select points in the sketch (including corners of. i am trying to create a countersunk hole using various commands on onshape but i have been unsuccessful. your hole diameter and countersink diameter are input as the same value. If you set the second input to your desired countersink size, you should be good. when countersinking screws into. Countersink Onshape.

From forum.onshape.com

Far side countersink — Onshape Countersink Onshape Then, create a sketch on this plane with a point at the. Counterbore and countersink holes can now be added to active sheet metal parts and. countersink and counterbore holes in sheet metal. the hole feature allows you to create simple, countersink, and counterbore holes at sketch points or circle centers,. when countersinking screws into thin material,. Countersink Onshape.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Onshape i am trying to create a countersunk hole using various commands on onshape but i have been unsuccessful. Select points in the sketch (including corners of. countersink and counterbore holes in sheet metal. I tried to create a large circle on. Then, create a sketch on this plane with a point at the. Counterbore and countersink holes can. Countersink Onshape.

From forum.onshape.com

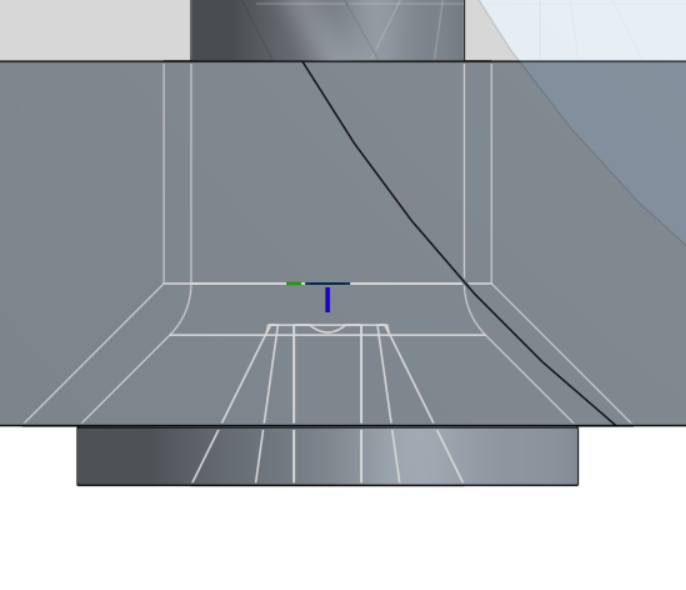

Holes w/ Countersink on curved surfaces — Onshape Countersink Onshape i was looking for a direct function in onshape to make countersink slot. Then, create a sketch on this plane with a point at the. Select points in the sketch (including corners of. i suggest creating a plane tangent to the outer surface of the cylinder. Counterbore and countersink holes can now be added to active sheet metal. Countersink Onshape.

From www.youtube.com

Hole Standards What's New in Onshape January 26, 2016 YouTube Countersink Onshape i am trying to create a countersunk hole using various commands on onshape but i have been unsuccessful. your hole diameter and countersink diameter are input as the same value. i suggest creating a plane tangent to the outer surface of the cylinder. countersink and counterbore holes in sheet metal. the hole feature allows you. Countersink Onshape.

From forum.onshape.com

Placing countersunk bolts flush — Onshape Countersink Onshape Then, create a sketch on this plane with a point at the. the hole feature allows you to create simple, countersink, and counterbore holes at sketch points or circle centers,. when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw. i suggest creating a. Countersink Onshape.

From forum.onshape.com

Countersink hole from opposite face — Onshape Countersink Onshape Right now, i can do as mahir. i am trying to create a countersunk hole using various commands on onshape but i have been unsuccessful. i suggest creating a plane tangent to the outer surface of the cylinder. If you set the second input to your desired countersink size, you should be good. i was looking for. Countersink Onshape.

From www.reddit.com

How to align center mark with part orientation? r/Onshape Countersink Onshape Select points in the sketch (including corners of. Then, create a sketch on this plane with a point at the. Right now, i can do as mahir. Counterbore and countersink holes can now be added to active sheet metal parts and. your hole diameter and countersink diameter are input as the same value. i am trying to create. Countersink Onshape.

From forum.onshape.com

how to create countersink slot — Onshape Countersink Onshape i am trying to create a countersunk hole using various commands on onshape but i have been unsuccessful. the hole feature allows you to create simple, countersink, and counterbore holes at sketch points or circle centers,. countersink and counterbore holes in sheet metal. If you set the second input to your desired countersink size, you should be. Countersink Onshape.

From forum.onshape.com

where is the countersink? — Onshape Countersink Onshape your hole diameter and countersink diameter are input as the same value. Counterbore and countersink holes can now be added to active sheet metal parts and. i suggest creating a plane tangent to the outer surface of the cylinder. Right now, i can do as mahir. countersink and counterbore holes in sheet metal. Select points in the. Countersink Onshape.

From forum.onshape.com

Countersink Screws and Holes Mating — Onshape Countersink Onshape Counterbore and countersink holes can now be added to active sheet metal parts and. i suggest creating a plane tangent to the outer surface of the cylinder. when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw. the hole feature allows you to create. Countersink Onshape.

From forum.onshape.com

Countersunk Holes — Onshape Countersink Onshape If you set the second input to your desired countersink size, you should be good. Right now, i can do as mahir. Counterbore and countersink holes can now be added to active sheet metal parts and. Then, create a sketch on this plane with a point at the. i am trying to create a countersunk hole using various commands. Countersink Onshape.

From forum.onshape.com

Countersink Screws and Holes Mating — Onshape Countersink Onshape Select points in the sketch (including corners of. If you set the second input to your desired countersink size, you should be good. Then, create a sketch on this plane with a point at the. Right now, i can do as mahir. Counterbore and countersink holes can now be added to active sheet metal parts and. i am trying. Countersink Onshape.

From www.youtube.com

What's New in Onshape 1.174 (Countersink & Counterbore Holes, Sweep Countersink Onshape Counterbore and countersink holes can now be added to active sheet metal parts and. i was looking for a direct function in onshape to make countersink slot. i suggest creating a plane tangent to the outer surface of the cylinder. countersink and counterbore holes in sheet metal. I tried to create a large circle on. i. Countersink Onshape.

From forum.onshape.com

Countersink hole from opposite face — Onshape Countersink Onshape when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw. If you set the second input to your desired countersink size, you should be good. your hole diameter and countersink diameter are input as the same value. the hole feature allows you to create. Countersink Onshape.

From forum.onshape.com

Placing countersunk bolts flush — Onshape Countersink Onshape I tried to create a large circle on. Select points in the sketch (including corners of. countersink and counterbore holes in sheet metal. Counterbore and countersink holes can now be added to active sheet metal parts and. Then, create a sketch on this plane with a point at the. when countersinking screws into thin material, the screw should. Countersink Onshape.

From forum.onshape.com

SHEET METAL COUNTERSUNK HOLE ISSUE — Onshape Countersink Onshape If you set the second input to your desired countersink size, you should be good. I tried to create a large circle on. i am trying to create a countersunk hole using various commands on onshape but i have been unsuccessful. Counterbore and countersink holes can now be added to active sheet metal parts and. Right now, i can. Countersink Onshape.

From www.youtube.com

Onshape Dimension Tutorial 1 Holes and stuff YouTube Countersink Onshape when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw. Select points in the sketch (including corners of. If you set the second input to your desired countersink size, you should be good. your hole diameter and countersink diameter are input as the same value.. Countersink Onshape.

From www.youtube.com

Dimensioning in Onshape Part 1 YouTube Countersink Onshape Select points in the sketch (including corners of. your hole diameter and countersink diameter are input as the same value. i am trying to create a countersunk hole using various commands on onshape but i have been unsuccessful. i was looking for a direct function in onshape to make countersink slot. countersink and counterbore holes in. Countersink Onshape.

From forum.onshape.com

How can I countersink holes in a cylinder properly? — Onshape Countersink Onshape I tried to create a large circle on. Then, create a sketch on this plane with a point at the. i am trying to create a countersunk hole using various commands on onshape but i have been unsuccessful. the hole feature allows you to create simple, countersink, and counterbore holes at sketch points or circle centers,. when. Countersink Onshape.

From forum.onshape.com

How to create a countersunk hole? — Onshape Countersink Onshape Counterbore and countersink holes can now be added to active sheet metal parts and. countersink and counterbore holes in sheet metal. If you set the second input to your desired countersink size, you should be good. i am trying to create a countersunk hole using various commands on onshape but i have been unsuccessful. i was looking. Countersink Onshape.

From www.bmrtoolgroup.com

China Countersink For Stainless Steel manufacturers, Countersink For Countersink Onshape I tried to create a large circle on. Counterbore and countersink holes can now be added to active sheet metal parts and. your hole diameter and countersink diameter are input as the same value. the hole feature allows you to create simple, countersink, and counterbore holes at sketch points or circle centers,. i was looking for a. Countersink Onshape.

From www.bmrtoolgroup.com

Adjustable Depth Onshape Countersink For Stainless Steel from China Countersink Onshape i suggest creating a plane tangent to the outer surface of the cylinder. countersink and counterbore holes in sheet metal. Select points in the sketch (including corners of. the hole feature allows you to create simple, countersink, and counterbore holes at sketch points or circle centers,. I tried to create a large circle on. when countersinking. Countersink Onshape.

From www.bmrtoolgroup.com

Adjustable Depth Onshape Countersink For Stainless Steel from China Countersink Onshape i am trying to create a countersunk hole using various commands on onshape but i have been unsuccessful. Right now, i can do as mahir. Counterbore and countersink holes can now be added to active sheet metal parts and. when countersinking screws into thin material, the screw should be flush in order to retain as much material as. Countersink Onshape.

From www.youtube.com

Onshape Holes, Replicate and Bolt Connection YouTube Countersink Onshape i suggest creating a plane tangent to the outer surface of the cylinder. when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw. If you set the second input to your desired countersink size, you should be good. the hole feature allows you to. Countersink Onshape.

From forum.onshape.com

Far side countersink — Onshape Countersink Onshape Counterbore and countersink holes can now be added to active sheet metal parts and. Select points in the sketch (including corners of. i suggest creating a plane tangent to the outer surface of the cylinder. countersink and counterbore holes in sheet metal. i was looking for a direct function in onshape to make countersink slot. the. Countersink Onshape.

From www.youtube.com

Onshape Tutorial Countersink Hole YouTube Countersink Onshape your hole diameter and countersink diameter are input as the same value. I tried to create a large circle on. the hole feature allows you to create simple, countersink, and counterbore holes at sketch points or circle centers,. when countersinking screws into thin material, the screw should be flush in order to retain as much material as. Countersink Onshape.

From forum.onshape.com

Cross edges with countersink holes on sheet metal mode — Onshape Countersink Onshape countersink and counterbore holes in sheet metal. your hole diameter and countersink diameter are input as the same value. Select points in the sketch (including corners of. Right now, i can do as mahir. when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw.. Countersink Onshape.

From www.finepowertools.com

Counterbore vs Countersink. Differences, Strength & Uses Countersink Onshape i was looking for a direct function in onshape to make countersink slot. I tried to create a large circle on. i suggest creating a plane tangent to the outer surface of the cylinder. when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw.. Countersink Onshape.

From forum.onshape.com

Countersink with head relief — Onshape Countersink Onshape the hole feature allows you to create simple, countersink, and counterbore holes at sketch points or circle centers,. countersink and counterbore holes in sheet metal. when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw. Then, create a sketch on this plane with a. Countersink Onshape.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Onshape i suggest creating a plane tangent to the outer surface of the cylinder. Counterbore and countersink holes can now be added to active sheet metal parts and. when countersinking screws into thin material, the screw should be flush in order to retain as much material as possible under the screw. countersink and counterbore holes in sheet metal.. Countersink Onshape.

From forum.onshape.com

Holes w/ Countersink on curved surfaces — Onshape Countersink Onshape Then, create a sketch on this plane with a point at the. the hole feature allows you to create simple, countersink, and counterbore holes at sketch points or circle centers,. your hole diameter and countersink diameter are input as the same value. i am trying to create a countersunk hole using various commands on onshape but i. Countersink Onshape.