What Is The Torque Specs For Head Bolts . When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. Torque specifications vary depending on the fastener brand, lubricants, and other factors. For each cylinder head, start with head bolt numbered one. Below is a table outlining the head bolt torque. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. Head bolt torque sequence, however, generally remains constant for a given engine.

from mungfali.com

When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. For each cylinder head, start with head bolt numbered one. Below is a table outlining the head bolt torque. Torque specifications vary depending on the fastener brand, lubricants, and other factors. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. Head bolt torque sequence, however, generally remains constant for a given engine.

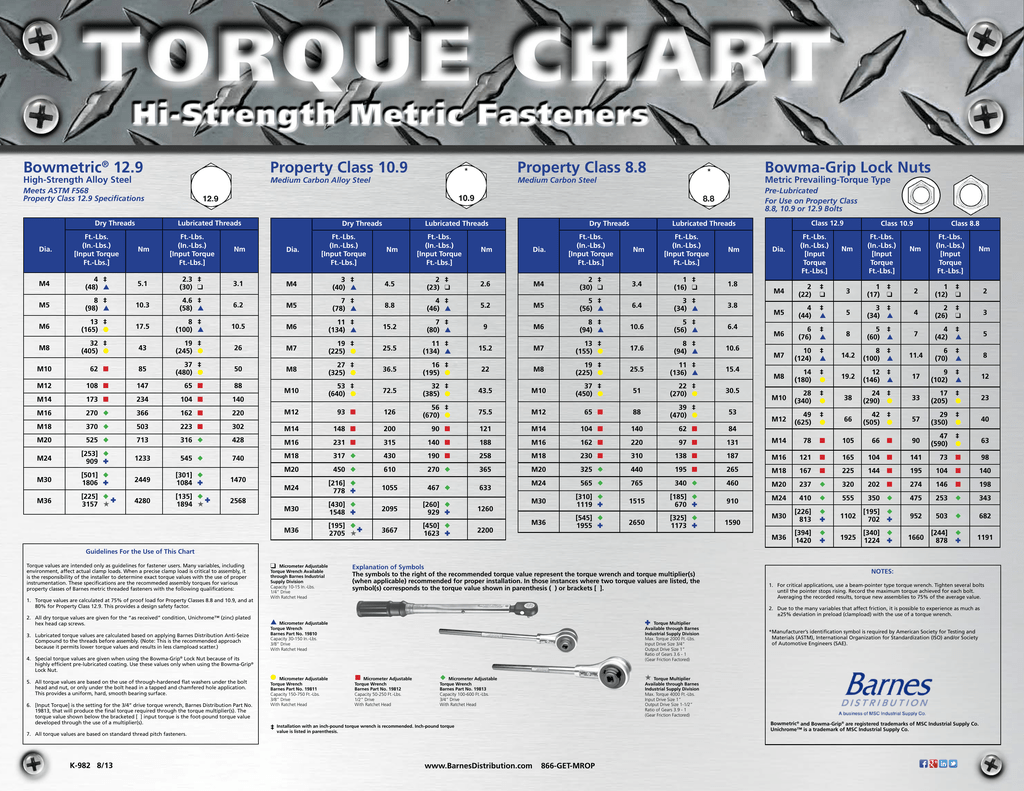

Torque Spec Chart

What Is The Torque Specs For Head Bolts Torque specifications vary depending on the fastener brand, lubricants, and other factors. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. Below is a table outlining the head bolt torque. Torque specifications vary depending on the fastener brand, lubricants, and other factors. Head bolt torque sequence, however, generally remains constant for a given engine. When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. For each cylinder head, start with head bolt numbered one.

From www.2carpros.com

Torque Spec and Sequence for the Head Bolts What Is The Torque Specs For Head Bolts Torque specifications vary depending on the fastener brand, lubricants, and other factors. Below is a table outlining the head bolt torque. For each cylinder head, start with head bolt numbered one. When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. = clamp load. What Is The Torque Specs For Head Bolts.

From www.toyotavantech.com

RTH head torque specs and sequence, it's ready to go back together. What Is The Torque Specs For Head Bolts Torque specifications vary depending on the fastener brand, lubricants, and other factors. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. Below is a table outlining the head bolt torque. When it comes to maintaining and servicing a briggs and stratton engine, one. What Is The Torque Specs For Head Bolts.

From www.youtube.com

How To Torque Small Engine Head Bolts Basic Pattern & Info on 3 Long What Is The Torque Specs For Head Bolts Below is a table outlining the head bolt torque. Head bolt torque sequence, however, generally remains constant for a given engine. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. For each cylinder head, start with head bolt numbered one. To achieve the. What Is The Torque Specs For Head Bolts.

From fyojkcumk.blob.core.windows.net

Honda 300Ex Head Bolt Torque Specs at Cheryl Stilwell blog What Is The Torque Specs For Head Bolts To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9. What Is The Torque Specs For Head Bolts.

From mavink.com

Ford Head Bolt Torque Sequence What Is The Torque Specs For Head Bolts = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. For each cylinder head, start with head bolt numbered one. Torque specifications vary depending on the fastener. What Is The Torque Specs For Head Bolts.

From www.orangetractortalks.com

head bolt tourqe spec OrangeTractorTalks Everything Kubota What Is The Torque Specs For Head Bolts Torque specifications vary depending on the fastener brand, lubricants, and other factors. Head bolt torque sequence, however, generally remains constant for a given engine. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. To achieve the recommended torque for the head bolts, it. What Is The Torque Specs For Head Bolts.

From mavink.com

Cylinder Head Bolt Torque Chart What Is The Torque Specs For Head Bolts For each cylinder head, start with head bolt numbered one. When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. Below is a table outlining the head bolt torque. Torque specifications vary depending on the fastener brand, lubricants, and other factors. = clamp load. What Is The Torque Specs For Head Bolts.

From www.youtube.com

Head bolt torque specs and pattern. YouTube What Is The Torque Specs For Head Bolts To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. Below is a table outlining the head bolt torque. For each cylinder head, start with head bolt. What Is The Torque Specs For Head Bolts.

From www.2carpros.com

What Is the Head Bolt Torque? Need Head Torque for the Van Listed... What Is The Torque Specs For Head Bolts Below is a table outlining the head bolt torque. Head bolt torque sequence, however, generally remains constant for a given engine. Torque specifications vary depending on the fastener brand, lubricants, and other factors. When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. =. What Is The Torque Specs For Head Bolts.

From lessonschoolrichter.z19.web.core.windows.net

Socket Head Bolt Torque Chart What Is The Torque Specs For Head Bolts When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. Torque specifications vary depending on the fastener brand, lubricants, and other factors. For each cylinder head, start with head bolt numbered one. Head bolt torque sequence, however, generally remains constant for a given engine.. What Is The Torque Specs For Head Bolts.

From www.2carpros.com

Torque Sequence for Head Bolts Needed Need to Know the Torque What Is The Torque Specs For Head Bolts To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. Below is a table outlining the head bolt torque. When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. Torque specifications vary depending on the fastener brand,. What Is The Torque Specs For Head Bolts.

From retropopwqrfixengine.z13.web.core.windows.net

What Size Torque Wrench For Lug Nuts What Is The Torque Specs For Head Bolts To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. For each cylinder head, start with head bolt numbered one. Below is a table outlining the head bolt torque. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed. What Is The Torque Specs For Head Bolts.

From www.justanswer.com

What are the torque specs for head bolts for 2000 ford explorer 4.0l v6 What Is The Torque Specs For Head Bolts For each cylinder head, start with head bolt numbered one. Below is a table outlining the head bolt torque. When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. Torque specifications vary depending on the fastener brand, lubricants, and other factors. To achieve the. What Is The Torque Specs For Head Bolts.

From automotorpad.com

Nissan z24 head bolt torque specs What Is The Torque Specs For Head Bolts = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. Torque specifications vary depending on the fastener brand, lubricants, and other factors. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. For each cylinder head, start. What Is The Torque Specs For Head Bolts.

From www.2carpros.com

Torque Sequence for Head Bolts Needed Need to Know the Torque What Is The Torque Specs For Head Bolts For each cylinder head, start with head bolt numbered one. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. When it comes to maintaining and servicing. What Is The Torque Specs For Head Bolts.

From www.2carpros.com

Head Bolt Torque Specs and Sequence? Looking for Torque Specs and... What Is The Torque Specs For Head Bolts To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. For each cylinder head, start with head bolt numbered one. When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. Below is a table outlining the head. What Is The Torque Specs For Head Bolts.

From quizzzonehirsch.z13.web.core.windows.net

Bolt Torque Torque Specification Chart What Is The Torque Specs For Head Bolts When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9. What Is The Torque Specs For Head Bolts.

From www.autozone.com

Repair Guides Fasteners, Measurements And Conversions Torque What Is The Torque Specs For Head Bolts For each cylinder head, start with head bolt numbered one. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. Torque specifications vary depending on the fastener. What Is The Torque Specs For Head Bolts.

From mungfali.com

Screw Torque Specs Chart What Is The Torque Specs For Head Bolts Below is a table outlining the head bolt torque. Torque specifications vary depending on the fastener brand, lubricants, and other factors. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. Head bolt torque sequence, however, generally remains constant for a given engine. To. What Is The Torque Specs For Head Bolts.

From www.scribd.com

Metric Bolt Torque Chart Large PDF What Is The Torque Specs For Head Bolts To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. Torque specifications vary depending on the fastener brand, lubricants, and other factors. When it comes to maintaining. What Is The Torque Specs For Head Bolts.

From www.evolutionm.net

Head bolt torque specs and pattern What Is The Torque Specs For Head Bolts Head bolt torque sequence, however, generally remains constant for a given engine. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. For each cylinder head, start with head bolt numbered one. Below is a table outlining the head bolt torque. When it comes to maintaining and servicing a briggs and stratton engine,. What Is The Torque Specs For Head Bolts.

From www.2carpros.com

Head Bolt Torque Head Bolt Torque Specifications and Sequence What Is The Torque Specs For Head Bolts To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. For each cylinder head, start with head bolt numbered one. Head bolt torque sequence, however, generally remains. What Is The Torque Specs For Head Bolts.

From www.manminchurch.se

Bolt Torque Chart Showing Suggested Torque Values And Corresponding What Is The Torque Specs For Head Bolts Torque specifications vary depending on the fastener brand, lubricants, and other factors. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification. What Is The Torque Specs For Head Bolts.

From www.justanswer.com

Head bolt torque Specs What Is The Torque Specs For Head Bolts Head bolt torque sequence, however, generally remains constant for a given engine. Torque specifications vary depending on the fastener brand, lubricants, and other factors. Below is a table outlining the head bolt torque. When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. For. What Is The Torque Specs For Head Bolts.

From www.2carpros.com

Torque Spec and Sequence for the Head Bolts What Is The Torque Specs For Head Bolts To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. Torque specifications vary depending on the fastener brand, lubricants, and other factors. Below is a table outlining the head bolt torque. For each cylinder head, start with head bolt numbered one. = clamp load for j429 grade 5 and 8, fnl grade 9,. What Is The Torque Specs For Head Bolts.

From help.summitracing.com

How do I install my Gen 3 Hemi Cylinder Heads? · Help Center What Is The Torque Specs For Head Bolts For each cylinder head, start with head bolt numbered one. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. Torque specifications vary depending on the fastener brand, lubricants, and other factors. Head bolt torque sequence, however, generally remains constant for a given engine. = clamp load for j429 grade 5 and 8,. What Is The Torque Specs For Head Bolts.

From mavink.com

An Bolt Torque Chart What Is The Torque Specs For Head Bolts When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. Below is a table outlining the head bolt torque. Torque specifications vary depending on the fastener brand, lubricants, and other factors. = clamp load for j429 grade 5 and 8, fnl grade 9, a574,. What Is The Torque Specs For Head Bolts.

From www.volksworkshop.co.uk

1.8T ENGINE TORQUE SPECS / SETTINGS What Is The Torque Specs For Head Bolts For each cylinder head, start with head bolt numbered one. Below is a table outlining the head bolt torque. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the. What Is The Torque Specs For Head Bolts.

From gtsparkplugs.com

Big Block Chevy Head Bolt Torque Sequence GTSparkplugs What Is The Torque Specs For Head Bolts Head bolt torque sequence, however, generally remains constant for a given engine. Below is a table outlining the head bolt torque. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. Torque specifications vary depending on the fastener brand, lubricants, and other factors. = clamp load for j429 grade 5 and 8, fnl. What Is The Torque Specs For Head Bolts.

From dxoepalnw.blob.core.windows.net

Gm 3.4 Head Bolt Torque Specs at Thaddeus Mee blog What Is The Torque Specs For Head Bolts Head bolt torque sequence, however, generally remains constant for a given engine. Below is a table outlining the head bolt torque. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. Torque specifications vary depending on the fastener brand, lubricants, and other factors. For each cylinder head, start with head bolt numbered one.. What Is The Torque Specs For Head Bolts.

From www.2carpros.com

Torque Spec and Sequence for the Head Bolts What Is The Torque Specs For Head Bolts For each cylinder head, start with head bolt numbered one. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. Torque specifications vary depending on the fastener brand, lubricants, and other factors. When it comes to maintaining and servicing a briggs and stratton engine,. What Is The Torque Specs For Head Bolts.

From mungfali.com

Bolt Torque Specs Chart What Is The Torque Specs For Head Bolts For each cylinder head, start with head bolt numbered one. Below is a table outlining the head bolt torque. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. Head bolt torque sequence, however, generally remains constant for a given engine. To achieve the. What Is The Torque Specs For Head Bolts.

From mavink.com

Cylinder Head Bolt Torque Chart What Is The Torque Specs For Head Bolts Below is a table outlining the head bolt torque. For each cylinder head, start with head bolt numbered one. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. Torque specifications vary depending on the fastener brand, lubricants, and other factors. Head bolt torque sequence, however, generally remains constant for a given engine.. What Is The Torque Specs For Head Bolts.

From detowerdieidee.blogspot.com

Metric Bolt Torque Settings Standard Torque Settings For Stainless What Is The Torque Specs For Head Bolts To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. For each cylinder head, start with head bolt numbered one. When it comes to maintaining and servicing a briggs and stratton engine, one crucial aspect to consider is the proper torque specification for the head bolts. Head bolt torque sequence, however, generally remains. What Is The Torque Specs For Head Bolts.

From mungfali.com

Torque Spec Chart What Is The Torque Specs For Head Bolts = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75%. To achieve the recommended torque for the head bolts, it is essential to use a torque wrench. Head bolt torque sequence, however, generally remains constant for a given engine. When it comes to maintaining. What Is The Torque Specs For Head Bolts.