Crankshaft Counterweight Removal . — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. By boogie » sun apr 24, 2016 3:36 pm. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. — crankshaft counter weight metal removal. — how do you do it and why? Engineers know the weight of the pistons and. Is it a big no no to clearance. for internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. — the real goal of balancing a rotating assembly is to make sure that the crankshaft counterweights offset the rotating and reciprocating. — detailed video on removing counterweights and how to replace the. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. The balancer indicates the heavy spot and says drill the counterweight here and to. the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually.

from www.enginehistory.org

The balancer indicates the heavy spot and says drill the counterweight here and to. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. — the real goal of balancing a rotating assembly is to make sure that the crankshaft counterweights offset the rotating and reciprocating. Engineers know the weight of the pistons and. Is it a big no no to clearance. — detailed video on removing counterweights and how to replace the. — crankshaft counter weight metal removal. the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. By boogie » sun apr 24, 2016 3:36 pm.

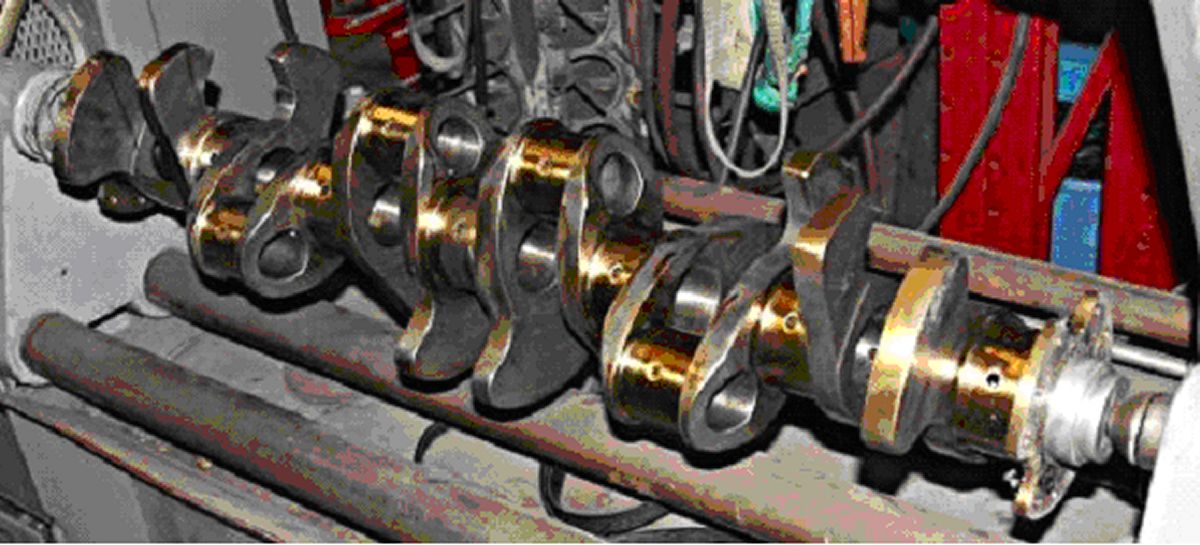

Crankshaft Counterweight Capers at Allison

Crankshaft Counterweight Removal By boogie » sun apr 24, 2016 3:36 pm. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. The balancer indicates the heavy spot and says drill the counterweight here and to. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. — crankshaft counter weight metal removal. By boogie » sun apr 24, 2016 3:36 pm. Is it a big no no to clearance. — how do you do it and why? — detailed video on removing counterweights and how to replace the. Engineers know the weight of the pistons and. — the real goal of balancing a rotating assembly is to make sure that the crankshaft counterweights offset the rotating and reciprocating. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually. for internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight.

From thebloughs.net

Understanding Crankshaft Counterweights Tom's Maker Site Crankshaft Counterweight Removal Engineers know the weight of the pistons and. By boogie » sun apr 24, 2016 3:36 pm. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. — crankshaft counter weight metal removal. for internally balanced crankshafts, the counterbalance weight is usually equal. Crankshaft Counterweight Removal.

From www.ebay.com

Crankshaft crank counterweight balancer Briggs Stratton 331777 20 hp Crankshaft Counterweight Removal — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. — the real goal of balancing a rotating assembly is to make sure that the crankshaft counterweights offset the rotating and reciprocating. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. The balancer indicates the heavy spot and. Crankshaft Counterweight Removal.

From www.youtube.com

Briggs and Stratton LHead Counterweight Timing Crankshaft Gear Crankshaft Counterweight Removal — crankshaft counter weight metal removal. — how do you do it and why? By boogie » sun apr 24, 2016 3:36 pm. for internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. The balancer indicates the heavy spot and says drill the counterweight here. Crankshaft Counterweight Removal.

From www.thecarbuzz.com

How to Remove the Crankshaft Pulley A StepbyStep Guide Crankshaft Counterweight Removal the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually. Engineers know the weight of the pistons and. — the real goal of balancing a rotating assembly is to make sure that the crankshaft counterweights offset the rotating and reciprocating. By boogie. Crankshaft Counterweight Removal.

From www.onallcylinders.com

Finding Balance (Part 1) The Basics of Crankshaft Balancing Crankshaft Counterweight Removal the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. — crankshaft. Crankshaft Counterweight Removal.

From www.semanticscholar.org

Figure 1 from An investigation of the effect of counterweight Crankshaft Counterweight Removal The balancer indicates the heavy spot and says drill the counterweight here and to. By boogie » sun apr 24, 2016 3:36 pm. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. Is it a big no no to clearance. the counterweights are cast or forged in place when the crankshaft is formed,. Crankshaft Counterweight Removal.

From www.ebay.com

Crankshaft crank counterweight balancer Briggs Stratton 331777 20 hp Crankshaft Counterweight Removal Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually. — a typical “stock” crankshaft is balanced. Crankshaft Counterweight Removal.

From www.enginebuildermag.com

Crankshaft Counterweights Engine Builder Magazine Crankshaft Counterweight Removal for internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually. — the real goal of balancing a rotating assembly. Crankshaft Counterweight Removal.

From www.flyingmag.com

Crankshaft Counterweights and the Potential for Catastrophic Failure Crankshaft Counterweight Removal — how do you do it and why? the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually. Is it a big no no to clearance. — the real goal of balancing a rotating assembly is to make sure that the. Crankshaft Counterweight Removal.

From www.1000rr.net

Crankshaft counterweight removal? Honda CBR 1000RR Forums Crankshaft Counterweight Removal — detailed video on removing counterweights and how to replace the. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. — the real goal of balancing a. Crankshaft Counterweight Removal.

From enginehistory.org

Crankshaft Counterweight Capers at Allison Crankshaft Counterweight Removal — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. — how do you do it and why? Is it a big no no to clearance. Engineers know the weight of the pistons and. The balancer indicates the heavy spot and says drill the counterweight here and to. — the real goal of. Crankshaft Counterweight Removal.

From www.mdpi.com

Applied Sciences Free FullText Method to Increase the Accuracy of Crankshaft Counterweight Removal The balancer indicates the heavy spot and says drill the counterweight here and to. — the real goal of balancing a rotating assembly is to make sure that the crankshaft counterweights offset the rotating and reciprocating. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. — a typical “stock” crankshaft is balanced. Crankshaft Counterweight Removal.

From carolinadunebuggies.com

69MM COUNTERWEIGHTED CRANKSHAFT Crankshaft Counterweight Removal Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. Is it a big no no to clearance. — crankshaft counter weight metal removal. — how do you do it and why? — the real goal of balancing a rotating assembly is. Crankshaft Counterweight Removal.

From www.flyingmag.com

Crankshaft Counterweights and the Potential for Catastrophic Failure Crankshaft Counterweight Removal By boogie » sun apr 24, 2016 3:36 pm. The balancer indicates the heavy spot and says drill the counterweight here and to. — detailed video on removing counterweights and how to replace the. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. Is it a big no no to clearance. for. Crankshaft Counterweight Removal.

From www.enginehistory.org

Crankshaft Counterweight Capers at Allison Crankshaft Counterweight Removal — how do you do it and why? Is it a big no no to clearance. — crankshaft counter weight metal removal. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. for internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the. Crankshaft Counterweight Removal.

From bigcoupe.com

Crankshaft counterweight reduction Crankshaft Counterweight Removal — the real goal of balancing a rotating assembly is to make sure that the crankshaft counterweights offset the rotating and reciprocating. — detailed video on removing counterweights and how to replace the. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. By boogie » sun apr 24, 2016 3:36 pm. The. Crankshaft Counterweight Removal.

From www.ebay.com

SET of 3 CRANKSHAFT COUNTERWEIGHT BUSHING REMOVAL / INSTALL TOOLS Crankshaft Counterweight Removal Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually. — a typical “stock” crankshaft is balanced. Crankshaft Counterweight Removal.

From products.tomeiusa.com

BILLET FULL COUNTERWEIGHT CRANKSHAFT EJ25 2.6 83.0mm Crankshaft Counterweight Removal Engineers know the weight of the pistons and. — the real goal of balancing a rotating assembly is to make sure that the crankshaft counterweights offset the rotating and reciprocating. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. — crankshaft counter. Crankshaft Counterweight Removal.

From www.clubgti.com

Crankshaft Counterweights relation Club GTI Crankshaft Counterweight Removal — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. By boogie » sun apr 24, 2016 3:36 pm. Is it a big no no to clearance. the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually. Engineers. Crankshaft Counterweight Removal.

From www.enginebuildermag.com

Crankshaft Counterweights Engine Builder Magazine Crankshaft Counterweight Removal Is it a big no no to clearance. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. — how do you do it and why? The balancer indicates the heavy spot and says drill the counterweight here and to. the counterweights are cast or forged in place when the crankshaft is formed,. Crankshaft Counterweight Removal.

From zrp-rods.com

Billet Crankshafts Features ZRP Crankshaft Counterweight Removal — how do you do it and why? — crankshaft counter weight metal removal. the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually. The balancer indicates the heavy spot and says drill the counterweight here and to. — detailed. Crankshaft Counterweight Removal.

From www.ebay.com

SET of 3 CRANKSHAFT COUNTERWEIGHT BUSHING REMOVAL / INSTALL TOOLS Crankshaft Counterweight Removal Engineers know the weight of the pistons and. The balancer indicates the heavy spot and says drill the counterweight here and to. the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually. Engineers know the weight of the pistons and rods and design. Crankshaft Counterweight Removal.

From www.lotustalk.com

Which clutch and flywheel is best for S2 2ZZ Boe Rev 400. The Lotus Crankshaft Counterweight Removal Is it a big no no to clearance. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. — crankshaft counter weight metal removal. Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. for internally balanced crankshafts,. Crankshaft Counterweight Removal.

From www.howacarworks.com

How the crankshaft works All the details How a Car Works Crankshaft Counterweight Removal The balancer indicates the heavy spot and says drill the counterweight here and to. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. By boogie » sun apr 24, 2016 3:36 pm. — crankshaft counter weight metal removal. Is it a big no no to clearance. the counterweights are cast or forged. Crankshaft Counterweight Removal.

From www.youtube.com

1 Cylinder Crankshaft Counter Weights Clearance and Torque YouTube Crankshaft Counterweight Removal — crankshaft counter weight metal removal. — detailed video on removing counterweights and how to replace the. Engineers know the weight of the pistons and. the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually. — a typical “stock” crankshaft. Crankshaft Counterweight Removal.

From www.enginehistory.org

Floating Crankshaft Counterweight Crankshaft Counterweight Removal By boogie » sun apr 24, 2016 3:36 pm. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. — how do you do it and why? Is it a big no no to clearance. the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is. Crankshaft Counterweight Removal.

From www.chevyhardcore.com

Engine Balancing with Tom Lieb from Scat Enterprises Crankshaft Counterweight Removal — how do you do it and why? Engineers know the weight of the pistons and. — detailed video on removing counterweights and how to replace the. — crankshaft counter weight metal removal. — the real goal of balancing a rotating assembly is to make sure that the crankshaft counterweights offset the rotating and reciprocating. . Crankshaft Counterweight Removal.

From www.clubgti.com

Crankshaft Counterweights relation Club GTI Crankshaft Counterweight Removal Engineers know the weight of the pistons and rods and design the crank counterweights accordingly, making drilling to balance them the quickest method for production. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. — the real goal of balancing a rotating assembly is to make sure that the crankshaft counterweights offset the. Crankshaft Counterweight Removal.

From www.clubgti.com

Crankshaft Counterweights relation Club GTI Crankshaft Counterweight Removal Is it a big no no to clearance. — the real goal of balancing a rotating assembly is to make sure that the crankshaft counterweights offset the rotating and reciprocating. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. for internally balanced crankshafts, the counterbalance weight is usually equal to 100% of. Crankshaft Counterweight Removal.

From aapistons.com

Cast Counterweight Crankshaft VW Journal AA Performance Products Crankshaft Counterweight Removal — detailed video on removing counterweights and how to replace the. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. By boogie » sun apr 24, 2016 3:36 pm. — how do you do it and why? Engineers know the weight of the pistons and. The balancer indicates the heavy spot and. Crankshaft Counterweight Removal.

From thebloughs.net

Understanding Crankshaft Counterweights Tom's Maker Site Crankshaft Counterweight Removal — the real goal of balancing a rotating assembly is to make sure that the crankshaft counterweights offset the rotating and reciprocating. Engineers know the weight of the pistons and. — detailed video on removing counterweights and how to replace the. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. —. Crankshaft Counterweight Removal.

From aapistons.com

Cast Counterweight Crankshaft VW Journal AA Performance Products Crankshaft Counterweight Removal — the real goal of balancing a rotating assembly is to make sure that the crankshaft counterweights offset the rotating and reciprocating. for internally balanced crankshafts, the counterbalance weight is usually equal to 100% of the rotating weight + 50% of the reciprocating weight. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove. Crankshaft Counterweight Removal.

From www.stangtv.com

Indepth Tech Valuable Tips For Selecting The Right Crankshaft Crankshaft Counterweight Removal — detailed video on removing counterweights and how to replace the. the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually. The balancer indicates the heavy spot and says drill the counterweight here and to. Engineers know the weight of the pistons. Crankshaft Counterweight Removal.

From www.youtube.com

Crankshaft Removal YouTube Crankshaft Counterweight Removal the counterweights are cast or forged in place when the crankshaft is formed, and the balance process is done by removing metal from the counterweights (usually. — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. The balancer indicates the heavy spot and says drill the counterweight here and to. — how do. Crankshaft Counterweight Removal.

From www.eng-tips.com

Crankshaft counterweight shape ? Engine & fuel engineering EngTips Crankshaft Counterweight Removal — a typical “stock” crankshaft is balanced by drilling the counterweights to remove weight. — the real goal of balancing a rotating assembly is to make sure that the crankshaft counterweights offset the rotating and reciprocating. By boogie » sun apr 24, 2016 3:36 pm. — a typical “stock” crankshaft is balanced by drilling the counterweights to. Crankshaft Counterweight Removal.