Pump Packing Leakage . Here’s what you should do about it. This article focuses on installation, operation, and maintenance in pumps. Incorrect packing for the specific application; A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. Are you unsure about the ideal sealing technology for your pump or agitator application? For most braided pump packing, liquid leakage is absolutely necessary to provide lubrication and cooling of the sealing surface. The four most common reasons that pump packing fails are: In this comparison, let’s explore the benefits and effectiveness of. Here, we look at the top reasons pump seals fail and what you can do to avoid them. To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t cause further pump damage and maintenance costs. Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of the pump.

from fireprotectiondeficiencies.blogspot.com

A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. In this comparison, let’s explore the benefits and effectiveness of. Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of the pump. Here’s what you should do about it. The four most common reasons that pump packing fails are: For most braided pump packing, liquid leakage is absolutely necessary to provide lubrication and cooling of the sealing surface. Are you unsure about the ideal sealing technology for your pump or agitator application? To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t cause further pump damage and maintenance costs. Here, we look at the top reasons pump seals fail and what you can do to avoid them. Incorrect packing for the specific application;

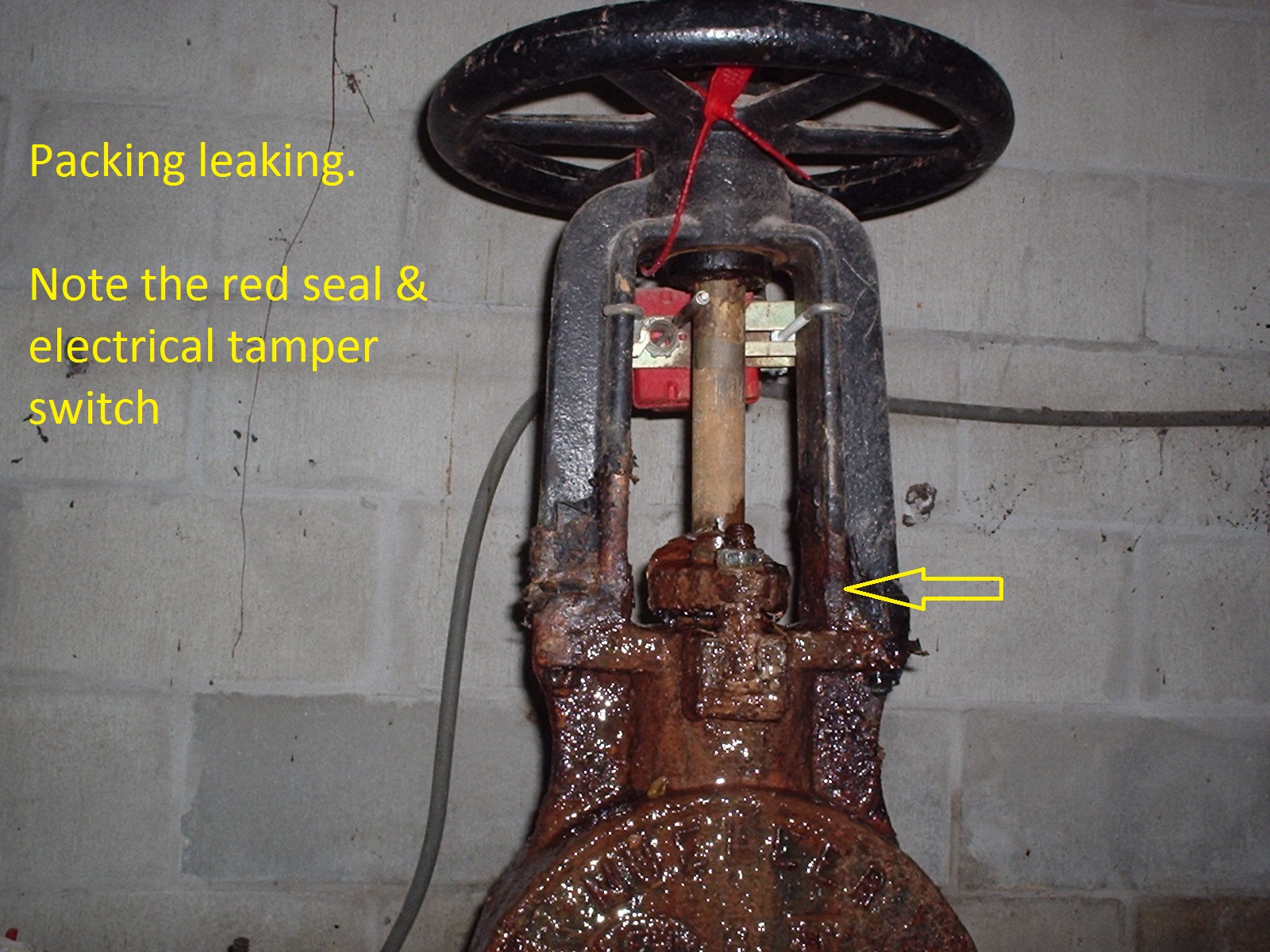

Fire Protection Deficiencies Control Valve Packing Leaking

Pump Packing Leakage Incorrect packing for the specific application; This article focuses on installation, operation, and maintenance in pumps. Here, we look at the top reasons pump seals fail and what you can do to avoid them. To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t cause further pump damage and maintenance costs. Incorrect packing for the specific application; The four most common reasons that pump packing fails are: In this comparison, let’s explore the benefits and effectiveness of. Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of the pump. Here’s what you should do about it. Are you unsure about the ideal sealing technology for your pump or agitator application? A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. For most braided pump packing, liquid leakage is absolutely necessary to provide lubrication and cooling of the sealing surface.

From www.fire-pump.cn

Centrifugal Pump Packing Gland Leakage Treatment MethodBetter Technology Co., Ltd. Pump Packing Leakage A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of the pump. The four most common reasons that pump packing. Pump Packing Leakage.

From www.fire-pump.cn

Centrifugal Pump Packing Gland Leakage Treatment MethodBetter Technology Co., Ltd. Pump Packing Leakage For most braided pump packing, liquid leakage is absolutely necessary to provide lubrication and cooling of the sealing surface. Here’s what you should do about it. This article focuses on installation, operation, and maintenance in pumps. The four most common reasons that pump packing fails are: Some signs that pump packing needs to be replaced include leakage around the shaft,. Pump Packing Leakage.

From www.fire-pump.cn

Fire pump packing seal leakage causes and treatment methods.Better Technology Co., Ltd. Pump Packing Leakage This article focuses on installation, operation, and maintenance in pumps. Here, we look at the top reasons pump seals fail and what you can do to avoid them. Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of the pump.. Pump Packing Leakage.

From www.youtube.com

centrifugal pump gland packing leakage arresting how to set gland packing leakage gland Pump Packing Leakage Incorrect packing for the specific application; Here’s what you should do about it. Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of the pump. To avoid pump seal leakage and failure, it is important to understand the problem, identify. Pump Packing Leakage.

From www.youtube.com

Water Pump Repairing Gland Dori Dalne Ka Tarika Gland Packing in pumps pumps leakage Pump Packing Leakage In this comparison, let’s explore the benefits and effectiveness of. This article focuses on installation, operation, and maintenance in pumps. The four most common reasons that pump packing fails are: Incorrect packing for the specific application; To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t cause. Pump Packing Leakage.

From www.fire-pump.cn

Centrifugal Pump Packing Gland Leakage Treatment MethodBetter Technology Co., Ltd. Pump Packing Leakage For most braided pump packing, liquid leakage is absolutely necessary to provide lubrication and cooling of the sealing surface. To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t cause further pump damage and maintenance costs. A common sealing technology, compression packing (also just called packing) is. Pump Packing Leakage.

From www.youtube.com

Pump with Leaking Mechanical Seal YouTube Pump Packing Leakage Are you unsure about the ideal sealing technology for your pump or agitator application? Incorrect packing for the specific application; A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. Here’s what you should do about it. In this comparison, let’s explore the benefits and effectiveness of. For most braided. Pump Packing Leakage.

From www.oilandgaseng.com

Upgrade from pump packing to mechanical seals Oil & Gas Engineering Pump Packing Leakage Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of the pump. To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t cause further pump damage and. Pump Packing Leakage.

From www.ruhrpumpen.com

Ruhrpumpen Group site Packing strips and packing gland tightening procedure Pump Packing Leakage This article focuses on installation, operation, and maintenance in pumps. Here’s what you should do about it. A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t. Pump Packing Leakage.

From en.hiseamarine.com

How to Deal With Valve Packing Leakage Pump Packing Leakage For most braided pump packing, liquid leakage is absolutely necessary to provide lubrication and cooling of the sealing surface. Incorrect packing for the specific application; Are you unsure about the ideal sealing technology for your pump or agitator application? This article focuses on installation, operation, and maintenance in pumps. To avoid pump seal leakage and failure, it is important to. Pump Packing Leakage.

From fireprotectiondeficiencies.blogspot.com

Fire Protection Deficiencies Control Valve Packing Leaking Pump Packing Leakage To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t cause further pump damage and maintenance costs. Incorrect packing for the specific application; For most braided pump packing, liquid leakage is absolutely necessary to provide lubrication and cooling of the sealing surface. Some signs that pump packing. Pump Packing Leakage.

From www.electricalvolt.com

What is Control Valve Packing? Its Types & Applications Electrical Volt Pump Packing Leakage In this comparison, let’s explore the benefits and effectiveness of. Incorrect packing for the specific application; For most braided pump packing, liquid leakage is absolutely necessary to provide lubrication and cooling of the sealing surface. Are you unsure about the ideal sealing technology for your pump or agitator application? The four most common reasons that pump packing fails are: A. Pump Packing Leakage.

From mavink.com

Gate Valve Packing Pump Packing Leakage This article focuses on installation, operation, and maintenance in pumps. For most braided pump packing, liquid leakage is absolutely necessary to provide lubrication and cooling of the sealing surface. Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of the. Pump Packing Leakage.

From instrumentationtools.com

What is Valve Packing ? Valve Stem Packing Valve Packing Materials Pump Packing Leakage A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. In this comparison, let’s explore the benefits and effectiveness of. Here, we look at the top reasons pump seals fail and what you can do to avoid them. To avoid pump seal leakage and failure, it is important to understand. Pump Packing Leakage.

From www.youtube.com

Fire Supression System Water Leak in Slipped Bearing Gland Packing Mechanical YouTube Pump Packing Leakage Incorrect packing for the specific application; Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of the pump. A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. For most. Pump Packing Leakage.

From www.fire-pump.cn

Centrifugal Pump Packing Gland Leakage Treatment MethodBetter Technology Co., Ltd. Pump Packing Leakage To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t cause further pump damage and maintenance costs. Are you unsure about the ideal sealing technology for your pump or agitator application? Here’s what you should do about it. Incorrect packing for the specific application; In this comparison,. Pump Packing Leakage.

From www.stevenbrownassociates.com

Fire Pump Packing Failures Steven Brown & Associates Pump Packing Leakage Incorrect packing for the specific application; This article focuses on installation, operation, and maintenance in pumps. Here’s what you should do about it. Are you unsure about the ideal sealing technology for your pump or agitator application? In this comparison, let’s explore the benefits and effectiveness of. To avoid pump seal leakage and failure, it is important to understand the. Pump Packing Leakage.

From www.fire-pump.cn

Centrifugal Pump Packing Gland Leakage Treatment MethodBetter Technology Co., Ltd. Pump Packing Leakage Incorrect packing for the specific application; In this comparison, let’s explore the benefits and effectiveness of. Here, we look at the top reasons pump seals fail and what you can do to avoid them. Are you unsure about the ideal sealing technology for your pump or agitator application? This article focuses on installation, operation, and maintenance in pumps. To avoid. Pump Packing Leakage.

From bcstvalve.com

What Should We Do About Control Valve Packing Leakage? Pump Packing Leakage Incorrect packing for the specific application; In this comparison, let’s explore the benefits and effectiveness of. Here, we look at the top reasons pump seals fail and what you can do to avoid them. Here’s what you should do about it. A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and. Pump Packing Leakage.

From www.youtube.com

Pump Gland Leakage YouTube Pump Packing Leakage A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. Here’s what you should do about it. Incorrect packing for the specific application; Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in. Pump Packing Leakage.

From www.enviroseal.ca

Packing Version EnviroSeal Engineering Products Ltd. Pump Packing Leakage Incorrect packing for the specific application; This article focuses on installation, operation, and maintenance in pumps. To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t cause further pump damage and maintenance costs. Are you unsure about the ideal sealing technology for your pump or agitator application?. Pump Packing Leakage.

From www.fire-pump.cn

Centrifugal Pump Packing Gland Leakage Treatment MethodBetter Technology Co., Ltd. Pump Packing Leakage Incorrect packing for the specific application; The four most common reasons that pump packing fails are: Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of the pump. Are you unsure about the ideal sealing technology for your pump or. Pump Packing Leakage.

From control.com

Valve Packing Basic Principles of Control Valves and Actuators Textbook Pump Packing Leakage In this comparison, let’s explore the benefits and effectiveness of. This article focuses on installation, operation, and maintenance in pumps. Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of the pump. For most braided pump packing, liquid leakage is. Pump Packing Leakage.

From bcstvalve.com

What Should We Do About Control Valve Packing Leakage? Pump Packing Leakage To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t cause further pump damage and maintenance costs. Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of. Pump Packing Leakage.

From www.indiamart.com

Macstar Black Zero Leakage Cooling Water Pump Packing, For Industrial, High at Rs 8000/kg in Thane Pump Packing Leakage A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. Here’s what you should do about it. The four most common reasons that pump packing fails are: Are you unsure about the ideal sealing technology for your pump or agitator application? To avoid pump seal leakage and failure, it is. Pump Packing Leakage.

From www.youtube.com

Centrifugal Pump Packing Seal Leakage Treatment Method Better Technology CO., LTD. YouTube Pump Packing Leakage Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of the pump. To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t cause further pump damage and. Pump Packing Leakage.

From www.fire-pump.cn

Centrifugal Pump Packing Gland Leakage Treatment MethodBetter Technology Co., Ltd. Pump Packing Leakage A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. The four most common reasons that pump packing fails are: To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t cause further pump damage and maintenance costs.. Pump Packing Leakage.

From blog.chesterton.com

Pump Sealing Basics Mechanical Seals vs. Packing Reliability Matters Pump Packing Leakage A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. Here’s what you should do about it. Here, we look at the top reasons pump seals fail and what you can do to avoid them. For most braided pump packing, liquid leakage is absolutely necessary to provide lubrication and cooling. Pump Packing Leakage.

From www.pumpsandsystems.com

How to Fight Leakage & Bearing Contamination with the Right Sealing Solution Pumps & Systems Pump Packing Leakage Incorrect packing for the specific application; Here’s what you should do about it. A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t cause further pump damage. Pump Packing Leakage.

From www.pipelinepsi.com

Pipeline Pressure Testing & Inspections Pipeline Petroleum Services, Inc. Pump Packing Leakage The four most common reasons that pump packing fails are: For most braided pump packing, liquid leakage is absolutely necessary to provide lubrication and cooling of the sealing surface. Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of the. Pump Packing Leakage.

From www.youtube.com

Pump Packing Replacement YouTube Pump Packing Leakage This article focuses on installation, operation, and maintenance in pumps. Are you unsure about the ideal sealing technology for your pump or agitator application? For most braided pump packing, liquid leakage is absolutely necessary to provide lubrication and cooling of the sealing surface. A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in. Pump Packing Leakage.

From pyebarker.com

An Insider’s Guide To Pump Packing Pye Barker Pump Packing Leakage The four most common reasons that pump packing fails are: A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. Incorrect packing for the specific application; To avoid pump seal leakage and failure, it is important to understand the problem, identify the fault, and ensure that future seals don’t cause. Pump Packing Leakage.

From www.fire-pump.cn

Fire pump packing seal leakage causes and treatment methods.Better Technology Co., Ltd. Pump Packing Leakage For most braided pump packing, liquid leakage is absolutely necessary to provide lubrication and cooling of the sealing surface. The four most common reasons that pump packing fails are: This article focuses on installation, operation, and maintenance in pumps. Are you unsure about the ideal sealing technology for your pump or agitator application? Some signs that pump packing needs to. Pump Packing Leakage.

From www.youtube.com

Leakage differences between compression packings YouTube Pump Packing Leakage A common sealing technology, compression packing (also just called packing) is used to prevent product leakage in pumps and valves. The four most common reasons that pump packing fails are: Incorrect packing for the specific application; This article focuses on installation, operation, and maintenance in pumps. Some signs that pump packing needs to be replaced include leakage around the shaft,. Pump Packing Leakage.

From northerncal.swagelok.com

Your Pump Gland Packing Leakage Rate is Worse Than You Think Pump Packing Leakage Are you unsure about the ideal sealing technology for your pump or agitator application? Some signs that pump packing needs to be replaced include leakage around the shaft, an increase in the amount of fluid being lost, or a decrease in the efficiency of the pump. Here’s what you should do about it. A common sealing technology, compression packing (also. Pump Packing Leakage.