What Is Pad Printing Process . at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché or base. Pad printing ensures decoration that is durable and highly repeatable for mass production. pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. It is an ideal process for products across numerous industries. The offset printing process requires the. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components.

from packagingguruji.com

pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. Pad printing ensures decoration that is durable and highly repeatable for mass production. The offset printing process requires the. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. It is an ideal process for products across numerous industries. pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché or base.

Know how Pad Printing Process PackagingGURUji

What Is Pad Printing Process at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. It is an ideal process for products across numerous industries. pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché or base. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. Pad printing ensures decoration that is durable and highly repeatable for mass production. The offset printing process requires the.

From www.epfl.ch

Compliant electrodes by padprinting ‒ LMTS ‐ EPFL What Is Pad Printing Process pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché or base. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a. What Is Pad Printing Process.

From www.printinginternational.com

What is pad printing? A step by step guide print specialist C. Luca What Is Pad Printing Process pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. It is an ideal process for products across numerous industries. pad printing uses flexible silicon to transfer ink to a. What Is Pad Printing Process.

From www.tamponprint.co.rs

TAMPON PRINT 014 D.O.O. FAQ Basic overview of pad printing process What Is Pad Printing Process at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. The offset printing process requires the. pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. Pad printing ensures decoration that is durable and highly repeatable for mass production. pad. What Is Pad Printing Process.

From www.slideshare.net

Pad Printing Technology What Is Pad Printing Process pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. Pad printing ensures decoration that is durable and highly repeatable for mass production. It is an ideal process for products across. What Is Pad Printing Process.

From www.signshop.com

Personalization and Pad Printing Sign Builder Illustrated, The HowTo What Is Pad Printing Process at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. It is an ideal process for products across numerous industries. pad printing, also called tampography or tampo. What Is Pad Printing Process.

From www.digitalgpoint.com

The Basics of Pad Printing A Comprehensive Guide DigitalGpoint What Is Pad Printing Process pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. The offset printing process requires the. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. Pad printing ensures decoration that is durable and highly repeatable for mass production. pad. What Is Pad Printing Process.

From packagingguruji.com

Know how Pad Printing Process PackagingGURUji What Is Pad Printing Process at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. The offset printing process requires the. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. pad printing uses flexible silicon to transfer ink to a workpiece. What Is Pad Printing Process.

From www.unipipes.com

Pad Printing The Process, its Advantages, and Applications What Is Pad Printing Process The offset printing process requires the. It is an ideal process for products across numerous industries. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. Pad printing ensures decoration that. What Is Pad Printing Process.

From www.youtube.com

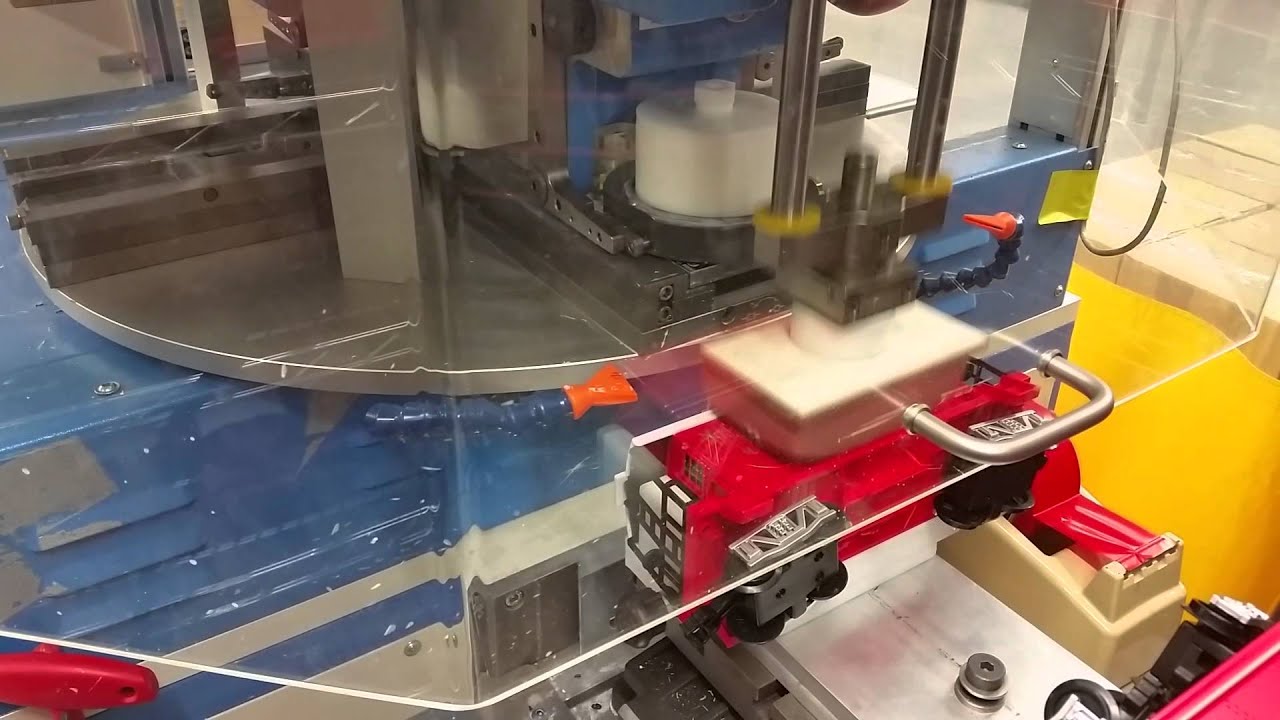

How to Pad Print a quick overview of the Pad Printing Process. YouTube What Is Pad Printing Process Pad printing ensures decoration that is durable and highly repeatable for mass production. It is an ideal process for products across numerous industries. The offset printing process requires the. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. pad printing uses flexible silicon to transfer ink to. What Is Pad Printing Process.

From www.unipipes.com

Pad Printing The Process, its Advantages, and Applications What Is Pad Printing Process pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. The offset printing process requires the. Pad printing ensures decoration that is durable and highly repeatable for mass production. It is an ideal process for products across numerous industries. pad printing uses flexible silicon to transfer ink to. What Is Pad Printing Process.

From proprinterhub.medium.com

What is Pad Printing? Complete Pad Printing Process Pro Printer Hub What Is Pad Printing Process at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. The offset printing process requires the. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. Pad printing ensures decoration that is durable and highly repeatable for mass. What Is Pad Printing Process.

From www.mdpi.com

Sensors Free FullText PadPrinting as a Fabrication Process for What Is Pad Printing Process at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché. What Is Pad Printing Process.

From www.ioniser-pro.co.uk

Pad Printing Ioniser Pro What Is Pad Printing Process Pad printing ensures decoration that is durable and highly repeatable for mass production. pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. at its core, pad printing is a. What Is Pad Printing Process.

From itwtranstech.com

What Is Pad Printing ITW Trans Tech What Is Pad Printing Process pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. Pad printing ensures decoration that is durable and highly repeatable for mass production. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. The offset printing process requires the. It is. What Is Pad Printing Process.

From thesourcer.com

What is Pad Printing? The Sourcer What Is Pad Printing Process Pad printing ensures decoration that is durable and highly repeatable for mass production. The offset printing process requires the. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d. What Is Pad Printing Process.

From www.researchgate.net

Schematic of pad printing process Download Scientific Diagram What Is Pad Printing Process pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. The offset printing process requires the. pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché or base. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d. What Is Pad Printing Process.

From www.madearia.com

Pad Printing Finish Process, Types, Benefits and Uses What Is Pad Printing Process at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché or base. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of. What Is Pad Printing Process.

From pad-printing.com

Guide To Pad Printing Pad Printing Technology What Is Pad Printing Process at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. The offset printing process requires the. It is an ideal process for products across numerous industries. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. pad. What Is Pad Printing Process.

From jetprintapp.com

What Is Pad Printing Pad Printing 101 What Is Pad Printing Process at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché or base. The offset printing process requires the. It is an ideal process for products across numerous industries. pad printing. What Is Pad Printing Process.

From www.unipipes.com

Pad Printing The Process, its Advantages, and Applications What Is Pad Printing Process pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. It is an ideal process for products across numerous industries. pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. The offset printing process requires the. Pad printing ensures decoration that. What Is Pad Printing Process.

From www.unipipes.com

Pad Printing The Process, its Advantages, and Applications What Is Pad Printing Process pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché. What Is Pad Printing Process.

From www.rapiddirect.com

Pad Printing Know Its Process and Advantages rapiddirect What Is Pad Printing Process It is an ideal process for products across numerous industries. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. Pad printing ensures decoration that is durable and. What Is Pad Printing Process.

From padprinting.in

Pad Printing Machine Buyer's Guide • Careprint Mumbai What Is Pad Printing Process pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché or base. Pad printing ensures decoration that is durable and highly repeatable for mass production. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. It is an ideal process for. What Is Pad Printing Process.

From www.poradora.com

Printing poradora What Is Pad Printing Process The offset printing process requires the. pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. Pad printing ensures decoration that is durable and highly repeatable for mass production. pad. What Is Pad Printing Process.

From www.youtube.com

Pad Printing Process on Garments YouTube What Is Pad Printing Process pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché or base. pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. It is an ideal process for products across numerous industries. The offset printing process requires the. at its core, pad printing. What Is Pad Printing Process.

From www.sunrise-metal.com

Pad Printing 6 Things About Pad Printing Sunrise Metal What Is Pad Printing Process It is an ideal process for products across numerous industries. The offset printing process requires the. Pad printing ensures decoration that is durable and highly repeatable for mass production. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. pad printing, also called tampography or tampo printing, is. What Is Pad Printing Process.

From www.manufacturingguide.com

Pad printing Find suppliers, processes & material What Is Pad Printing Process Pad printing ensures decoration that is durable and highly repeatable for mass production. The offset printing process requires the. pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché or base. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components.. What Is Pad Printing Process.

From jmproto.com

Pad Printing Process Principles, Practical Tips and Applications Jmproto What Is Pad Printing Process The offset printing process requires the. It is an ideal process for products across numerous industries. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. Pad printing ensures decoration that is durable and highly repeatable for mass production. pad printing, also called tampography or tampo printing, is. What Is Pad Printing Process.

From padprinting.in

Learn Pad Printing Process • 100+Articles SchoolCarePrint What Is Pad Printing Process It is an ideal process for products across numerous industries. Pad printing ensures decoration that is durable and highly repeatable for mass production. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a. What Is Pad Printing Process.

From padprinting.in

Learn Pad Printing Process • 100+Articles SchoolCarePrint What Is Pad Printing Process It is an ideal process for products across numerous industries. pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché or base. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. The offset printing process requires the. pad printing. What Is Pad Printing Process.

From www.unipipes.com

Pad Printing The Process, its Advantages, and Applications What Is Pad Printing Process The offset printing process requires the. It is an ideal process for products across numerous industries. pad printing, also called tampography or tampo printing, is an indirect offset (gravure) printing process where a. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. pad printing technology offers. What Is Pad Printing Process.

From www.sunrise-metal.com

Pad Printing 6 Things About Pad Printing Sunrise Metal What Is Pad Printing Process at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. The offset printing process requires the. pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché or base. pad printing, also called tampography or tampo printing, is an indirect offset. What Is Pad Printing Process.

From www.inksandmore.co.uk

What is Pad Printing? A Guide for Beginners Inks and More What Is Pad Printing Process pad printing uses flexible silicon to transfer ink to a workpiece or product from an etched cliché or base. at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. It is an ideal process for products across numerous industries. Pad printing ensures decoration that is durable and highly. What Is Pad Printing Process.

From tagless.inkcups.com

Is Pad Printing Right for Your Business? Inkcups Tagless Systems What Is Pad Printing Process at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. The offset printing process requires the. Pad printing ensures decoration that is durable and highly repeatable for mass production. It is an ideal process for products across numerous industries. pad printing, also called tampography or tampo printing, is. What Is Pad Printing Process.

From digitalchowder.com

What Is A Pad Printer And How Can It Help Your Home Business? What Is Pad Printing Process at its core, pad printing is a uniquely adaptable printing process that transfers a 2d image onto a 3d object. It is an ideal process for products across numerous industries. pad printing technology offers pad printing, laser marking, screen printing, and hot/foil stamping for a wide array of electronic components. pad printing, also called tampography or tampo. What Is Pad Printing Process.