Corner Joint Welding Uses . They will form an l shape because the ends of. The resulting materials form an l shape. They are commonly used in the construction and automotive industries, as well as for fabricating storage tanks and pressure vessels. A corner joint is any joint in welding where two pieces of material are joined at a right angle. It is an easy to assemble joint, the. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. To make a corner joint, a welder must bond two metal pieces. But those metals do not form a t shape, unlike a tee joint. Experienced welders know that many techniques are similar in the way they look when the weld is complete and in terms of the positioning of the material. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’.

from engineeringexploration.com

But those metals do not form a t shape, unlike a tee joint. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. Experienced welders know that many techniques are similar in the way they look when the weld is complete and in terms of the positioning of the material. It is an easy to assemble joint, the. They are commonly used in the construction and automotive industries, as well as for fabricating storage tanks and pressure vessels. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. A corner joint is any joint in welding where two pieces of material are joined at a right angle. The resulting materials form an l shape. They will form an l shape because the ends of. To make a corner joint, a welder must bond two metal pieces.

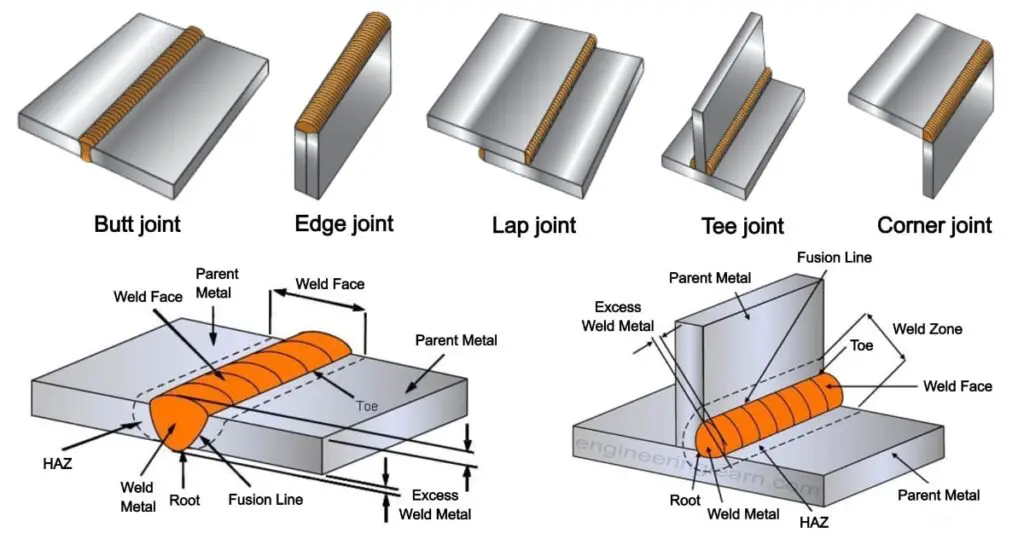

The 5 Types of Welding Joints, pros, cons, and their uses (In Details

Corner Joint Welding Uses Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. They will form an l shape because the ends of. A corner joint is any joint in welding where two pieces of material are joined at a right angle. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. They are commonly used in the construction and automotive industries, as well as for fabricating storage tanks and pressure vessels. To make a corner joint, a welder must bond two metal pieces. The resulting materials form an l shape. Experienced welders know that many techniques are similar in the way they look when the weld is complete and in terms of the positioning of the material. But those metals do not form a t shape, unlike a tee joint. It is an easy to assemble joint, the.

From www.youtube.com

Basic Stick welding, Corner Joint Welding for Beginners YouTube Corner Joint Welding Uses A corner joint is any joint in welding where two pieces of material are joined at a right angle. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. It is an easy to assemble joint, the. They are commonly used in the construction and automotive. Corner Joint Welding Uses.

From www.youtube.com

Mig welding outside corner joints YouTube Corner Joint Welding Uses The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. But those metals do not form a t shape, unlike a tee joint. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle. Corner Joint Welding Uses.

From weldinglogic.com

Corner Joint Weld Corner Joint Welding Symbol Strength Types & More Corner Joint Welding Uses Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. But those metals do not form a t shape, unlike a tee joint. To make a corner joint, a welder must bond two metal pieces. They will form an l shape because the ends of. The. Corner Joint Welding Uses.

From weldingclarity.com

Welding Joints 5 Types and Tips for TopQuality Results Corner Joint Welding Uses A corner joint is any joint in welding where two pieces of material are joined at a right angle. To make a corner joint, a welder must bond two metal pieces. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. They are commonly used in. Corner Joint Welding Uses.

From www.youtube.com

How to Weld Corner Joints YouTube Corner Joint Welding Uses Experienced welders know that many techniques are similar in the way they look when the weld is complete and in terms of the positioning of the material. The resulting materials form an l shape. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. They are. Corner Joint Welding Uses.

From www.grainews.ca

How to weld corner joints Grainews Corner Joint Welding Uses Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. They will form an l shape because the ends of. It is an easy to assemble joint, the. A corner joint is any joint in welding where two pieces of material are joined at a right. Corner Joint Welding Uses.

From weldingclarity.com

Corner Joint Welding Definition, Types and Easy Tips Corner Joint Welding Uses Experienced welders know that many techniques are similar in the way they look when the weld is complete and in terms of the positioning of the material. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. But those metals do not form a. Corner Joint Welding Uses.

From www.mig-welding.co.uk

TIG Tutorial Outside Corner Weld Corner Joint Welding Uses A corner joint is any joint in welding where two pieces of material are joined at a right angle. It is an easy to assemble joint, the. But those metals do not form a t shape, unlike a tee joint. They will form an l shape because the ends of. Corner joint welds are a type of butt weld that. Corner Joint Welding Uses.

From www.weldingis.com

Types Of Welding Joints Design and Welding Symbols Corner Joint Welding Uses The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. Experienced welders know that many techniques are similar in the way they look when the weld is complete and in terms of the positioning of the material. But those metals do not form a. Corner Joint Welding Uses.

From engineeringdiscoveries.com

Different Types Of Welding Joints Engineering Discoveries Corner Joint Welding Uses Experienced welders know that many techniques are similar in the way they look when the weld is complete and in terms of the positioning of the material. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. They will form an l shape because. Corner Joint Welding Uses.

From www.youtube.com

MIG Welding Outside Corner Joints Part 1 of 3 Carbon Steel MIG Corner Joint Welding Uses They are commonly used in the construction and automotive industries, as well as for fabricating storage tanks and pressure vessels. The resulting materials form an l shape. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. But those metals do not form a. Corner Joint Welding Uses.

From mewelding.com

Corner Joint Welding All You Need To Know Corner Joint Welding Uses The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. They will form an l shape because the ends of. Experienced welders know that many techniques are similar in the way they look when the weld is complete and in terms of the positioning. Corner Joint Welding Uses.

From blog.red-d-arc.com

Corner Joint Welds Types, Procedures, Tips & More RedDArc Corner Joint Welding Uses They are commonly used in the construction and automotive industries, as well as for fabricating storage tanks and pressure vessels. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. A corner joint is any joint in welding where two pieces of material are joined at. Corner Joint Welding Uses.

From weldingclarity.com

Corner Joint Welding Definition, Types and Easy Tips Corner Joint Welding Uses To make a corner joint, a welder must bond two metal pieces. They will form an l shape because the ends of. They are commonly used in the construction and automotive industries, as well as for fabricating storage tanks and pressure vessels. It is an easy to assemble joint, the. Experienced welders know that many techniques are similar in the. Corner Joint Welding Uses.

From welderslab.com

What Are the 5 Basic Types of Welding Joints A Beginner's Guide Corner Joint Welding Uses To make a corner joint, a welder must bond two metal pieces. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. Experienced welders know that many techniques are similar in the way they look when the weld is complete and in terms of the positioning. Corner Joint Welding Uses.

From weldinglogic.com

Corner Joint Weld Corner Joint Welding Symbol Strength Types & More Corner Joint Welding Uses Experienced welders know that many techniques are similar in the way they look when the weld is complete and in terms of the positioning of the material. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. But those metals do not form a. Corner Joint Welding Uses.

From www.reddit.com

How to make/ Welding perfectly sharp corner? r/Welding Corner Joint Welding Uses To make a corner joint, a welder must bond two metal pieces. The resulting materials form an l shape. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. They are commonly used in the construction and automotive industries, as well as for fabricating storage tanks. Corner Joint Welding Uses.

From blog.thepipingmart.com

Advantages and Disadvantages of Corner Joint Welding Corner Joint Welding Uses Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. They are commonly used in the construction and automotive industries, as well as for fabricating storage tanks and pressure vessels. But those metals do not form a t shape, unlike a tee joint. A corner joint. Corner Joint Welding Uses.

From engineeringexploration.com

The 5 Types of Welding Joints, pros, cons, and their uses (In Details Corner Joint Welding Uses But those metals do not form a t shape, unlike a tee joint. The resulting materials form an l shape. They will form an l shape because the ends of. They are commonly used in the construction and automotive industries, as well as for fabricating storage tanks and pressure vessels. A corner joint is any joint in welding where two. Corner Joint Welding Uses.

From weldingclarity.com

Corner Joint Welding Definition, Types and Easy Tips Corner Joint Welding Uses The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. They are commonly used in the construction and automotive industries, as well as for fabricating storage tanks and pressure vessels. But those metals do not form a t shape, unlike a tee joint. Experienced. Corner Joint Welding Uses.

From blog.thepipingmart.com

What is Corner Joint Weld? Uses and Working Corner Joint Welding Uses To make a corner joint, a welder must bond two metal pieces. But those metals do not form a t shape, unlike a tee joint. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. A corner joint is any joint in welding where. Corner Joint Welding Uses.

From www.grainews.ca

How to weld corner joints Grainews Corner Joint Welding Uses It is an easy to assemble joint, the. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. They are commonly used in the construction and automotive industries, as well as for fabricating storage tanks and pressure vessels. Corner joint welds are a type. Corner Joint Welding Uses.

From www.theengineerspost.com

Types of Welding Joints (Explained in detail) Pictures PDF Corner Joint Welding Uses A corner joint is any joint in welding where two pieces of material are joined at a right angle. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. It is an easy to assemble joint, the. Experienced welders know that many techniques are similar in. Corner Joint Welding Uses.

From www.grainews.ca

How to weld corner joints Grainews Corner Joint Welding Uses It is an easy to assemble joint, the. They will form an l shape because the ends of. A corner joint is any joint in welding where two pieces of material are joined at a right angle. To make a corner joint, a welder must bond two metal pieces. The resulting materials form an l shape. They are commonly used. Corner Joint Welding Uses.

From www.grainews.ca

How to weld corner joints Grainews Corner Joint Welding Uses They are commonly used in the construction and automotive industries, as well as for fabricating storage tanks and pressure vessels. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. Experienced welders know that many techniques are similar in the way they look when the weld. Corner Joint Welding Uses.

From www.youtube.com

How to make square tubing miter joint Welding Steel tube corner joint Corner Joint Welding Uses It is an easy to assemble joint, the. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. To make a corner joint, a welder must bond two metal pieces. They are commonly used in the construction and automotive industries, as well as for fabricating storage. Corner Joint Welding Uses.

From weldingtroop.com

5 Types of Welding Joints and Their Use Complete Guide Corner Joint Welding Uses To make a corner joint, a welder must bond two metal pieces. They are commonly used in the construction and automotive industries, as well as for fabricating storage tanks and pressure vessels. They will form an l shape because the ends of. Corner joint welds are a type of butt weld that is used to join two pieces of metal. Corner Joint Welding Uses.

From www.artofit.org

Types of welding joints explained in detail pictures pdf Artofit Corner Joint Welding Uses To make a corner joint, a welder must bond two metal pieces. Experienced welders know that many techniques are similar in the way they look when the weld is complete and in terms of the positioning of the material. A corner joint is any joint in welding where two pieces of material are joined at a right angle. It is. Corner Joint Welding Uses.

From welderslab.com

What Are the 5 Basic Types of Welding Joints A Beginner's Guide Corner Joint Welding Uses But those metals do not form a t shape, unlike a tee joint. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. They are commonly used in the construction and automotive industries, as well as for fabricating storage tanks and pressure vessels. The corner joint. Corner Joint Welding Uses.

From tigbrush.com

Various Types of Welding Joints and Their Uses TIG Brush Corner Joint Welding Uses It is an easy to assemble joint, the. The resulting materials form an l shape. To make a corner joint, a welder must bond two metal pieces. Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. But those metals do not form a t shape,. Corner Joint Welding Uses.

From www.youtube.com

Tips for TIG Welding Outside Corner Joints YouTube Corner Joint Welding Uses Corner joint welds are a type of butt weld that is used to join two pieces of metal at an angle of 90 degrees. They will form an l shape because the ends of. A corner joint is any joint in welding where two pieces of material are joined at a right angle. To make a corner joint, a welder. Corner Joint Welding Uses.

From www.onestopndt.com

An ultimate Guide to Weld Joints OnestopNDT Corner Joint Welding Uses A corner joint is any joint in welding where two pieces of material are joined at a right angle. They will form an l shape because the ends of. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. It is an easy to. Corner Joint Welding Uses.

From tigbrush.com

Various Types of Welding Joints and Their Uses TIG Brush Corner Joint Welding Uses They will form an l shape because the ends of. The resulting materials form an l shape. The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘l’. A corner joint is any joint in welding where two pieces of material are joined at a. Corner Joint Welding Uses.

From eziil.com

Welding Joint Types Butt, T, Edge, Lap, Corner Corner Joint Welding Uses They will form an l shape because the ends of. But those metals do not form a t shape, unlike a tee joint. The resulting materials form an l shape. Experienced welders know that many techniques are similar in the way they look when the weld is complete and in terms of the positioning of the material. Corner joint welds. Corner Joint Welding Uses.

From tomwelding.com

Understanding Welding Joint Types and Their Applications Tom Welding Corner Joint Welding Uses To make a corner joint, a welder must bond two metal pieces. The resulting materials form an l shape. They will form an l shape because the ends of. Experienced welders know that many techniques are similar in the way they look when the weld is complete and in terms of the positioning of the material. The corner joint welding. Corner Joint Welding Uses.