Blind Hole Anodising . unless they are affected by an airlock, blind holes or deep bores will generally anodise well. Through holes (th on drawing at right) will hardcoat evenly up to twice the length of the diameter (x). — small, tapped, blind holes can be a problem. Due to surface tension of the solutions, these parts can be very difficult. — anodizing may be simply classified as type ii or sulfuric anodize, or type ill, commonly called hard anodize. Blind holes (bh on drawing at right) will only hardcoat to a depth equal to the diameter of the hole (x=y). Alloy 2024 may have a max. — we can successfully process the anodising of blind holes and along the inside of tubes to a depth of equal to 10. Coating thickness, color and alloys. the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. How to anodize aluminum parts? — watch out for uncleaned swarf on blind holes, fingerprints on surfaces (avoid handling parts with bare hands!), and oil residue from the manufacturing process. The anodize solution is heavier than water. blind holes oriented upside down will form an air pocket and little or no anodize will form. — hardcoat blind holes or through holes.

from aluconsult.com

Coating thickness, color and alloys. Electroplating however has a limited. Alloy 2024 may have a max. The anodize solution is heavier than water. Blind holes (bh on drawing at right) will only hardcoat to a depth equal to the diameter of the hole (x=y). the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. Due to surface tension of the solutions, these parts can be very difficult. How to anodize aluminum parts? — we can successfully process the anodising of blind holes and along the inside of tubes to a depth of equal to 10. blind holes oriented upside down will form an air pocket and little or no anodize will form.

How to Anodize Aluminum Type II Anodizing for Beginners AluConsult

Blind Hole Anodising — anodizing may be simply classified as type ii or sulfuric anodize, or type ill, commonly called hard anodize. the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. unless they are affected by an airlock, blind holes or deep bores will generally anodise well. Blind holes (bh on drawing at right) will only hardcoat to a depth equal to the diameter of the hole (x=y). Due to surface tension of the solutions, these parts can be very difficult. The anodize solution is heavier than water. — anodizing may be simply classified as type ii or sulfuric anodize, or type ill, commonly called hard anodize. — small, tapped, blind holes can be a problem. Electroplating however has a limited. blind holes oriented upside down will form an air pocket and little or no anodize will form. Through holes (th on drawing at right) will hardcoat evenly up to twice the length of the diameter (x). Coating thickness, color and alloys. How to anodize aluminum parts? — hardcoat blind holes or through holes. Alloy 2024 may have a max. — we can successfully process the anodising of blind holes and along the inside of tubes to a depth of equal to 10.

From www.researchgate.net

Fast hole EDM drilling models of blindhole stage and breakthroughhole Blind Hole Anodising the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. Coating thickness, color and alloys. — we can successfully process the anodising of blind holes and along the inside of tubes to a depth of equal to 10. How to anodize aluminum parts? blind holes oriented upside down will. Blind Hole Anodising.

From www.nexflow.com

Blind Hole Cleaning System Nex Flow Air Products Blind Hole Anodising the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. Electroplating however has a limited. — we can successfully process the anodising of blind holes and along the inside of tubes to a depth of equal to 10. Due to surface tension of the solutions, these parts can be very. Blind Hole Anodising.

From www.sansmachining.com

Understanding Blind Holes in Machining SANS Blind Hole Anodising Blind holes (bh on drawing at right) will only hardcoat to a depth equal to the diameter of the hole (x=y). — hardcoat blind holes or through holes. — anodizing may be simply classified as type ii or sulfuric anodize, or type ill, commonly called hard anodize. — watch out for uncleaned swarf on blind holes, fingerprints. Blind Hole Anodising.

From www.youtube.com

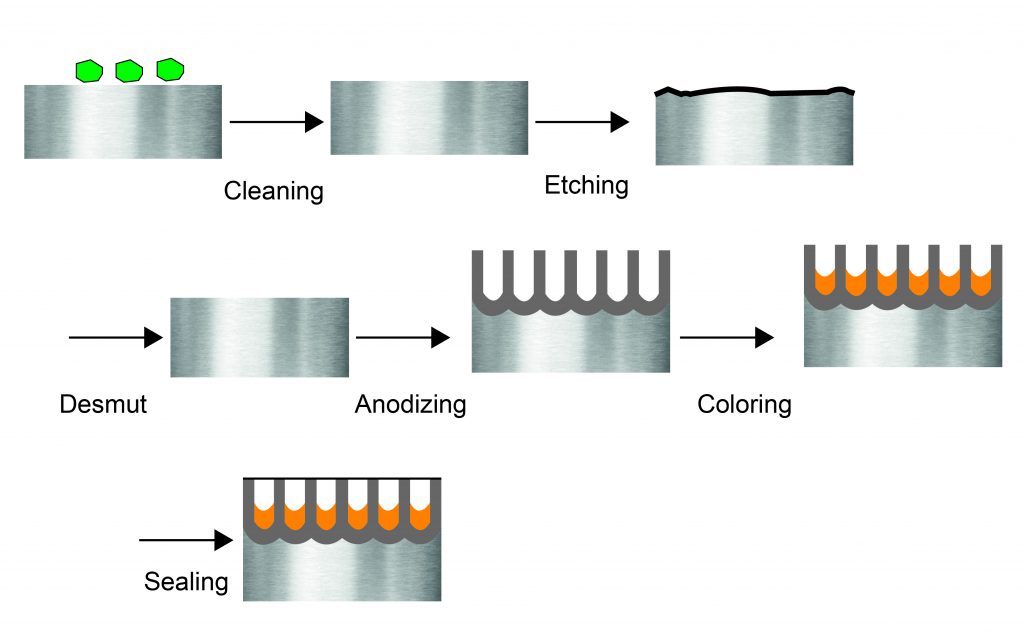

Basic Steps in Anodizing How to Anodize Episode 4 YouTube Blind Hole Anodising Electroplating however has a limited. — we can successfully process the anodising of blind holes and along the inside of tubes to a depth of equal to 10. the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. The anodize solution is heavier than water. — watch out for. Blind Hole Anodising.

From www.researchgate.net

Drilling process (a) blind holes (b) through holes [10]. Download Blind Hole Anodising blind holes oriented upside down will form an air pocket and little or no anodize will form. the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. unless they are affected by an airlock, blind holes or deep bores will generally anodise well. — watch out for uncleaned. Blind Hole Anodising.

From www.homenish.com

How to Hang Blinds Without Drilling Holes Homenish Blind Hole Anodising — watch out for uncleaned swarf on blind holes, fingerprints on surfaces (avoid handling parts with bare hands!), and oil residue from the manufacturing process. Due to surface tension of the solutions, these parts can be very difficult. — hardcoat blind holes or through holes. blind holes oriented upside down will form an air pocket and little. Blind Hole Anodising.

From at-machining.com

The Engineer's Guide to Blind Holes in Machining ATMachining Blind Hole Anodising — watch out for uncleaned swarf on blind holes, fingerprints on surfaces (avoid handling parts with bare hands!), and oil residue from the manufacturing process. — we can successfully process the anodising of blind holes and along the inside of tubes to a depth of equal to 10. The anodize solution is heavier than water. — small,. Blind Hole Anodising.

From wheelsadviser.com

How To Mark Blind Holes For Drilling? Blind Hole Anodising Due to surface tension of the solutions, these parts can be very difficult. Electroplating however has a limited. the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. Coating thickness, color and alloys. Alloy 2024 may have a max. blind holes oriented upside down will form an air pocket and. Blind Hole Anodising.

From www.m2prototype.com

Blind Holes During Aluminum Parts Anodizing Blind Hole Anodising Through holes (th on drawing at right) will hardcoat evenly up to twice the length of the diameter (x). — we can successfully process the anodising of blind holes and along the inside of tubes to a depth of equal to 10. — watch out for uncleaned swarf on blind holes, fingerprints on surfaces (avoid handling parts with. Blind Hole Anodising.

From threadingtoolsguide.com

Difference between through hole and blind hole on threadingtools giude Blind Hole Anodising Alloy 2024 may have a max. Coating thickness, color and alloys. The anodize solution is heavier than water. — hardcoat blind holes or through holes. Blind holes (bh on drawing at right) will only hardcoat to a depth equal to the diameter of the hole (x=y). unless they are affected by an airlock, blind holes or deep bores. Blind Hole Anodising.

From toolsweek.com

How to Mark Blind Holes for Drilling (10 Expert Methods) Blind Hole Anodising blind holes oriented upside down will form an air pocket and little or no anodize will form. — we can successfully process the anodising of blind holes and along the inside of tubes to a depth of equal to 10. Through holes (th on drawing at right) will hardcoat evenly up to twice the length of the diameter. Blind Hole Anodising.

From engineersbible.com

Types of Holes The Complete Guide The Engineer's Bible Blind Hole Anodising — hardcoat blind holes or through holes. — small, tapped, blind holes can be a problem. Due to surface tension of the solutions, these parts can be very difficult. unless they are affected by an airlock, blind holes or deep bores will generally anodise well. Alloy 2024 may have a max. — anodizing may be simply. Blind Hole Anodising.

From www.youtube.com

Blind Hole Burnishing Tool YouTube Blind Hole Anodising — anodizing may be simply classified as type ii or sulfuric anodize, or type ill, commonly called hard anodize. Blind holes (bh on drawing at right) will only hardcoat to a depth equal to the diameter of the hole (x=y). — watch out for uncleaned swarf on blind holes, fingerprints on surfaces (avoid handling parts with bare hands!),. Blind Hole Anodising.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? Blind Hole Anodising the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. How to anodize aluminum parts? — small, tapped, blind holes can be a problem. Alloy 2024 may have a max. — anodizing may be simply classified as type ii or sulfuric anodize, or type ill, commonly called hard anodize.. Blind Hole Anodising.

From aluconsult.com

How to Anodize Aluminum Type II Anodizing for Beginners AluConsult Blind Hole Anodising The anodize solution is heavier than water. — we can successfully process the anodising of blind holes and along the inside of tubes to a depth of equal to 10. Electroplating however has a limited. Coating thickness, color and alloys. Alloy 2024 may have a max. — hardcoat blind holes or through holes. — small, tapped, blind. Blind Hole Anodising.

From zenith-ultrasonics.com

Cleaning Blind Holes Zenith Ultrasonics Blind Hole Anodising Blind holes (bh on drawing at right) will only hardcoat to a depth equal to the diameter of the hole (x=y). — hardcoat blind holes or through holes. How to anodize aluminum parts? — small, tapped, blind holes can be a problem. — we can successfully process the anodising of blind holes and along the inside of. Blind Hole Anodising.

From www.m2prototype.com

Blind Holes During Aluminum Parts Anodizing Blind Hole Anodising blind holes oriented upside down will form an air pocket and little or no anodize will form. the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. — hardcoat blind holes or through holes. Alloy 2024 may have a max. Blind holes (bh on drawing at right) will only. Blind Hole Anodising.

From www.researchgate.net

Drilling process (a) blind holes (b) through holes [10]. Download Blind Hole Anodising the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. — small, tapped, blind holes can be a problem. Through holes (th on drawing at right) will hardcoat evenly up to twice the length of the diameter (x). — anodizing may be simply classified as type ii or sulfuric. Blind Hole Anodising.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? Blind Hole Anodising unless they are affected by an airlock, blind holes or deep bores will generally anodise well. the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. — watch out for uncleaned swarf on blind holes, fingerprints on surfaces (avoid handling parts with bare hands!), and oil residue from the. Blind Hole Anodising.

From www.youtube.com

MAKE A BLIND HOLE BEARING PULLER // BEARING PULLER DIY YouTube Blind Hole Anodising Electroplating however has a limited. Due to surface tension of the solutions, these parts can be very difficult. Through holes (th on drawing at right) will hardcoat evenly up to twice the length of the diameter (x). — hardcoat blind holes or through holes. Alloy 2024 may have a max. — anodizing may be simply classified as type. Blind Hole Anodising.

From www.machinistguides.com

Guide to Holes on Blueprints [Types, Symbols & Features] Machinist Guides Blind Hole Anodising Alloy 2024 may have a max. The anodize solution is heavier than water. Through holes (th on drawing at right) will hardcoat evenly up to twice the length of the diameter (x). Electroplating however has a limited. unless they are affected by an airlock, blind holes or deep bores will generally anodise well. Coating thickness, color and alloys. Blind. Blind Hole Anodising.

From www.cutwel.co.uk

How to select the correct tap for your job Cutwel Ltd Blind Hole Anodising Through holes (th on drawing at right) will hardcoat evenly up to twice the length of the diameter (x). — anodizing may be simply classified as type ii or sulfuric anodize, or type ill, commonly called hard anodize. — watch out for uncleaned swarf on blind holes, fingerprints on surfaces (avoid handling parts with bare hands!), and oil. Blind Hole Anodising.

From www.fittings-it.com

Blind Hole CT Fittings S.r.l. Blind Hole Anodising — small, tapped, blind holes can be a problem. How to anodize aluminum parts? — watch out for uncleaned swarf on blind holes, fingerprints on surfaces (avoid handling parts with bare hands!), and oil residue from the manufacturing process. Blind holes (bh on drawing at right) will only hardcoat to a depth equal to the diameter of the. Blind Hole Anodising.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? Blind Hole Anodising — small, tapped, blind holes can be a problem. Due to surface tension of the solutions, these parts can be very difficult. How to anodize aluminum parts? Alloy 2024 may have a max. — we can successfully process the anodising of blind holes and along the inside of tubes to a depth of equal to 10. Coating thickness,. Blind Hole Anodising.

From www.pinterest.com

Product Overview Blind Hole Cleaning System Blow dirt, chip and debris Blind Hole Anodising unless they are affected by an airlock, blind holes or deep bores will generally anodise well. — anodizing may be simply classified as type ii or sulfuric anodize, or type ill, commonly called hard anodize. Due to surface tension of the solutions, these parts can be very difficult. The anodize solution is heavier than water. — watch. Blind Hole Anodising.

From www.youtube.com

[EN] FAQ 003120 How can I create a blind hole in a solid? YouTube Blind Hole Anodising Due to surface tension of the solutions, these parts can be very difficult. the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. Through holes (th on drawing at right) will hardcoat evenly up to twice the length of the diameter (x). — anodizing may be simply classified as type. Blind Hole Anodising.

From www.blindster.com

Blinds with Holes Vs. No Holes/Routeless Blinds Blindster Blog Blind Hole Anodising Alloy 2024 may have a max. The anodize solution is heavier than water. the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. Due to surface tension of the solutions, these parts can be very difficult. blind holes oriented upside down will form an air pocket and little or no. Blind Hole Anodising.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? Blind Hole Anodising unless they are affected by an airlock, blind holes or deep bores will generally anodise well. Due to surface tension of the solutions, these parts can be very difficult. How to anodize aluminum parts? Electroplating however has a limited. The anodize solution is heavier than water. blind holes oriented upside down will form an air pocket and little. Blind Hole Anodising.

From www.youtube.com

Asher Spiro thumb hole anodizing (Mako) YouTube Blind Hole Anodising Due to surface tension of the solutions, these parts can be very difficult. the aluminum anodizing and hardcoating processes are described with a design guide for coating thickness, threads and holes. — anodizing may be simply classified as type ii or sulfuric anodize, or type ill, commonly called hard anodize. unless they are affected by an airlock,. Blind Hole Anodising.

From rifleshooter.com

Gunsmithing basics Tapping a blind hole Blind Hole Anodising unless they are affected by an airlock, blind holes or deep bores will generally anodise well. Blind holes (bh on drawing at right) will only hardcoat to a depth equal to the diameter of the hole (x=y). The anodize solution is heavier than water. the aluminum anodizing and hardcoating processes are described with a design guide for coating. Blind Hole Anodising.

From www.slideserve.com

PPT Chapter 10 cont. PowerPoint Presentation, free download ID1984589 Blind Hole Anodising — watch out for uncleaned swarf on blind holes, fingerprints on surfaces (avoid handling parts with bare hands!), and oil residue from the manufacturing process. Alloy 2024 may have a max. — hardcoat blind holes or through holes. Due to surface tension of the solutions, these parts can be very difficult. — we can successfully process the. Blind Hole Anodising.

From threadingtoolsguide.com

Difference between through hole and blind hole on threadingtools giude Blind Hole Anodising — small, tapped, blind holes can be a problem. Through holes (th on drawing at right) will hardcoat evenly up to twice the length of the diameter (x). — watch out for uncleaned swarf on blind holes, fingerprints on surfaces (avoid handling parts with bare hands!), and oil residue from the manufacturing process. Alloy 2024 may have a. Blind Hole Anodising.

From www.linkedin.com

The difference between "countersunk hole, through hole, blind hole" Blind Hole Anodising — watch out for uncleaned swarf on blind holes, fingerprints on surfaces (avoid handling parts with bare hands!), and oil residue from the manufacturing process. The anodize solution is heavier than water. Due to surface tension of the solutions, these parts can be very difficult. — we can successfully process the anodising of blind holes and along the. Blind Hole Anodising.

From toolsmechanism.com

How to Mark Blind Holes for Drilling? Tools Mechanism Blind Hole Anodising Coating thickness, color and alloys. Electroplating however has a limited. — watch out for uncleaned swarf on blind holes, fingerprints on surfaces (avoid handling parts with bare hands!), and oil residue from the manufacturing process. — hardcoat blind holes or through holes. The anodize solution is heavier than water. blind holes oriented upside down will form an. Blind Hole Anodising.

From recoildaily.com

Tapping a blind hole Recoil Daily Blind Hole Anodising unless they are affected by an airlock, blind holes or deep bores will generally anodise well. — small, tapped, blind holes can be a problem. Due to surface tension of the solutions, these parts can be very difficult. How to anodize aluminum parts? Electroplating however has a limited. blind holes oriented upside down will form an air. Blind Hole Anodising.