Aluminum Rod Manufacturing Process . aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous rolling. aluminum rod production process as follows: aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. Extrusion is used to form. The multiple drawing processes result in. cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter.

from www.aluminum-furnace.com

The multiple drawing processes result in. Extrusion is used to form. aluminum rod production process as follows: Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous rolling. when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn.

Horizontal Continuous Casting MachineAluminum/Copper RodHTGP

Aluminum Rod Manufacturing Process aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous rolling. aluminum rod production process as follows: aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. Extrusion is used to form. when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. The multiple drawing processes result in.

From cokroaminotofarzan.blogspot.com

Casting In Manufacturing Process Aluminum Rod Manufacturing Process aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. Extrusion is used to form. aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. The multiple drawing processes result in. cold drawn (cf) aluminum rod is produced through a cold drawing. Aluminum Rod Manufacturing Process.

From www.ssspradman.com

Wire Rod Mill SSS PRADMAN Aluminum Rod Manufacturing Process aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. aluminum rod production process as follows: Extrusion is used to form. The multiple drawing processes result in. when. Aluminum Rod Manufacturing Process.

From peterhurst.z13.web.core.windows.net

Tig Aluminum Filler Rod Chart Aluminum Rod Manufacturing Process cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. Extrusion is used to form. when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. aluminum rod production process as follows: aluminum rod. Aluminum Rod Manufacturing Process.

From www.aluminum-furnace.com

Horizontal Continuous Casting MachineAluminum/Copper RodHTGP Aluminum Rod Manufacturing Process aluminum rod production process as follows: when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. Extrusion is used to form. Aluminum ingot →. Aluminum Rod Manufacturing Process.

From www.youtube.com

Aluminum rod manufacturing YouTube Aluminum Rod Manufacturing Process aluminum rod production process as follows: The multiple drawing processes result in. cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. when strength and precision are needed,. Aluminum Rod Manufacturing Process.

From www.solaracks.com

Aluminum production process China Solaracks Aluminum Rod Manufacturing Process aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous rolling. aluminum rod production process as follows: when strength and precision are needed, aluminum can be forged by compressing the metal between dies. Aluminum Rod Manufacturing Process.

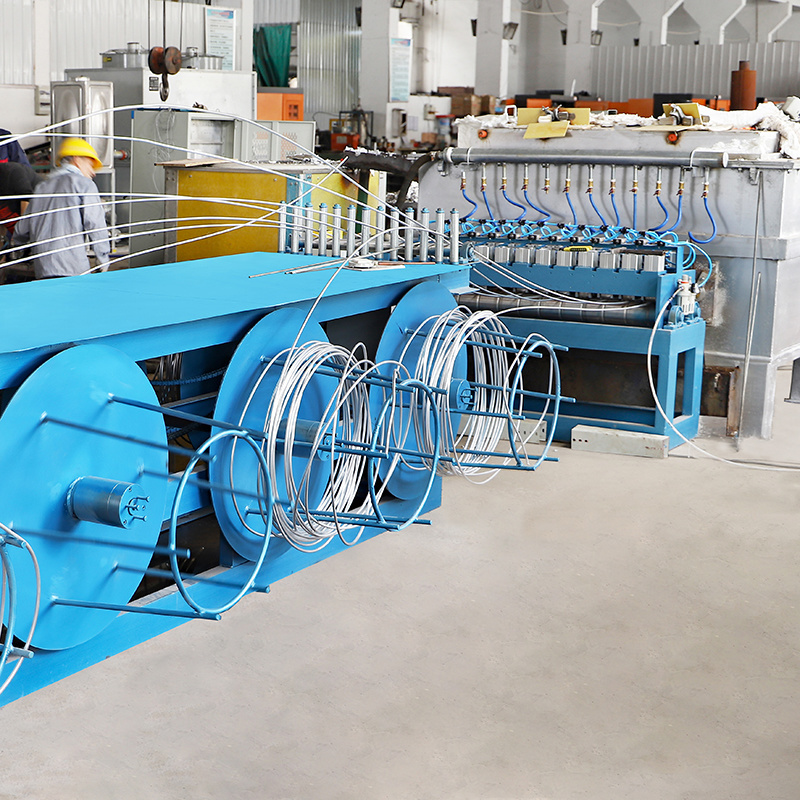

From www.itm-co.eu

Rod Breakdown Machines Our Products ITM SRL Aluminum Rod Manufacturing Process Extrusion is used to form. Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous rolling. aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the. Aluminum Rod Manufacturing Process.

From www.pmar.com.my

Press Metal Aluminium Rods Sdn. Bhd. (formerly known as Leader Aluminum Rod Manufacturing Process cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. Extrusion is used to form. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. aluminum rod production process as follows: aluminum rod continuous casting and rolling is. Aluminum Rod Manufacturing Process.

From www.chegg.com

Solved In a manufacturing process, long aluminum rods of Aluminum Rod Manufacturing Process cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous rolling. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. aluminum. Aluminum Rod Manufacturing Process.

From www.chegg.com

Solved In a manufacturing process, long aluminum rods of Aluminum Rod Manufacturing Process when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. Extrusion is used to form. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. Aluminum ingot → melting furnace → holding furnace → continuous casting machine. Aluminum Rod Manufacturing Process.

From keski.condesan-ecoandes.org

aluminium extrusion process flow chart Keski Aluminum Rod Manufacturing Process aluminum rod production process as follows: Extrusion is used to form. cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous rolling. The multiple drawing processes result in. when strength. Aluminum Rod Manufacturing Process.

From www.zenoindustry.com

China Custom Aluminum Rod Continuous Casting and Rolling Production Aluminum Rod Manufacturing Process aluminum rod production process as follows: aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. Extrusion is used to form. Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous rolling. cold drawn (cf) aluminum rod is produced through a cold drawing. Aluminum Rod Manufacturing Process.

From www.chalcoaluminum.com

Precision Ground Aluminum Rod Bar Chalco Aluminum Aluminum Rod Manufacturing Process aluminum rod production process as follows: aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. cold drawn (cf) aluminum rod is produced through a. Aluminum Rod Manufacturing Process.

From www.pmar.com.my

Press Metal Aluminium Rods Sdn. Bhd. (formerly known as Leader Aluminum Rod Manufacturing Process aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid. Aluminum Rod Manufacturing Process.

From www.chegg.com

Solved In a manufacturing process, long aluminum rods of Aluminum Rod Manufacturing Process when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. Extrusion is used to form. aluminum rod production process as follows: aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. cold drawn (cf) aluminum rod. Aluminum Rod Manufacturing Process.

From www.youtube.com

Aluminium rod continuous casting and rolling mill YouTube Aluminum Rod Manufacturing Process The multiple drawing processes result in. aluminum rod production process as follows: Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous rolling. Extrusion is used to form. aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. aluminum rods production process can. Aluminum Rod Manufacturing Process.

From www.slideshare.net

Aluminium productionprocess Aluminum Rod Manufacturing Process cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. The multiple drawing processes result in. when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. Aluminum ingot → melting furnace → holding furnace →. Aluminum Rod Manufacturing Process.

From www.aluminiumceramicfiber.com

How does Aluminum Rods Produce? Aluminum Rod Manufacturing Process when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous rolling. The multiple drawing processes result in. cold drawn (cf) aluminum rod is produced through a cold drawing. Aluminum Rod Manufacturing Process.

From www.youtube.com

11 1xxx,3xxx,4xxx,6xxx series Aluminum alloy Rod CCR Line YouTube Aluminum Rod Manufacturing Process aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. Extrusion is used to form. when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. The multiple drawing processes result in. aluminum rod production process as follows:. Aluminum Rod Manufacturing Process.

From www.chegg.com

Solved 3. In a manufacturing process, long aluminum rods of Aluminum Rod Manufacturing Process The multiple drawing processes result in. Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous rolling. when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. aluminum rod production process as follows: Extrusion is used to form.. Aluminum Rod Manufacturing Process.

From ionthis.com

Aluminum Extrusion Process & Heat Sinks Explained Ionthis Inc Aluminum Rod Manufacturing Process cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. The multiple drawing processes result in. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. aluminum rod production process as follows: when strength and precision are needed,. Aluminum Rod Manufacturing Process.

From www.youtube.com

ALUMINIUM EXTRUSION Production Facility , How it's Made, Aluminium Aluminum Rod Manufacturing Process cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. The multiple drawing processes result in. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic. Aluminum Rod Manufacturing Process.

From hoohaco.en.made-in-china.com

Ce/ISO Aluminum Rod Breakdown Line Manufacturing Machine China Cable Aluminum Rod Manufacturing Process Extrusion is used to form. The multiple drawing processes result in. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. Aluminum ingot → melting furnace → holding furnace → continuous casting machine. Aluminum Rod Manufacturing Process.

From www.youtube.com

How to make aluminum alloy rods for conductors?Aluminium rod Aluminum Rod Manufacturing Process cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. Extrusion is used to form. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. aluminum rod continuous casting and rolling is a continuous production technology in which the. Aluminum Rod Manufacturing Process.

From www.savemyexams.co.uk

Extraction of Aluminium from Bauxite (9.3.3) CIE IGCSE Chemistry Aluminum Rod Manufacturing Process aluminum rod production process as follows: aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. The multiple drawing processes result in. Extrusion is used to form. cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. aluminum rods. Aluminum Rod Manufacturing Process.

From www.spacedaily.com

A new manufacturing process for aluminum alloys Aluminum Rod Manufacturing Process aluminum rod production process as follows: when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. Aluminum ingot → melting furnace → holding furnace. Aluminum Rod Manufacturing Process.

From pearlitesteel.com

Stainless Steel Pipe and Tube Manufacturing Process Aluminum Rod Manufacturing Process Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous rolling. aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. aluminum rod production process as follows: Extrusion is used to form. when strength and precision are needed, aluminum can be forged by. Aluminum Rod Manufacturing Process.

From www.answersarena.com

[Solved] In a manufacturing process, long aluminum rods o Aluminum Rod Manufacturing Process Extrusion is used to form. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. aluminum rod production process as follows: when strength and precision are needed, aluminum can be forged by compressing the metal between dies to produce parts such as racecar wheels. cold drawn (cf) aluminum. Aluminum Rod Manufacturing Process.

From www.pnnl.gov

A New Manufacturing Process for Aluminum Alloys News Release PNNL Aluminum Rod Manufacturing Process The multiple drawing processes result in. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous. Aluminum Rod Manufacturing Process.

From www.dreamstime.com

The Aluminium Production Process. Vector Illustration Stock Vector Aluminum Rod Manufacturing Process cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. The multiple drawing processes result in. aluminum rod production process as follows: Aluminum ingot → melting furnace → holding. Aluminum Rod Manufacturing Process.

From www.al-furnace.com

Aluminum Rod Continuous Casting and Rolling Line_Products_XinTer Aluminum Rod Manufacturing Process aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. Aluminum ingot. Aluminum Rod Manufacturing Process.

From tutorbin.com

Solved In a manufacturing process, long aluminum rods of square cross Aluminum Rod Manufacturing Process aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. Extrusion is used to form. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. The multiple drawing processes result in. Aluminum ingot → melting furnace → holding furnace → continuous casting machine. Aluminum Rod Manufacturing Process.

From helecu.com

Metal Forming Basic, Types , Diagram , Classification Learn Aluminum Rod Manufacturing Process aluminum rod continuous casting and rolling is a continuous production technology in which the aluminum liquid is. The multiple drawing processes result in. Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous rolling. cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve. Aluminum Rod Manufacturing Process.

From www.aluminiumstrip-hm.com

Production flow chart of aluminum strip aluminium strip,aluminium Aluminum Rod Manufacturing Process aluminum rod production process as follows: Extrusion is used to form. The multiple drawing processes result in. aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. cold drawn (cf) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. aluminum. Aluminum Rod Manufacturing Process.

From www.pmar.com.my

Press Metal Aluminium Rods Sdn. Bhd. (formerly known as Leader Aluminum Rod Manufacturing Process aluminum rods production process can be divided into several different processes namely extrusion, rolling and coiling, or drawn. Extrusion is used to form. The multiple drawing processes result in. Aluminum ingot → melting furnace → holding furnace → continuous casting machine → hydraulic shears → continuous rolling. when strength and precision are needed, aluminum can be forged by. Aluminum Rod Manufacturing Process.