Rubber In Balls . Due to their form and. when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. Our rubber balls feature excellent elasticity and withstand both compression and atmospheric conditions. commonly used in molding applications such as injection molding and extrusion, these foaming agents reduce weight, warpage, and. natural rubber offers numerous advantages when used in the production of balls: Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms of gameplay and product development. how it's made: Being a renewable resource, natural rubber has a minimal environmental impact compared to synthetic alternatives. Natural rubber decomposes over time, reducing waste and pollution. rubber balls are used as seals in pumps and check valves. They are also commonly used inside of vibrating sifters to help clean.

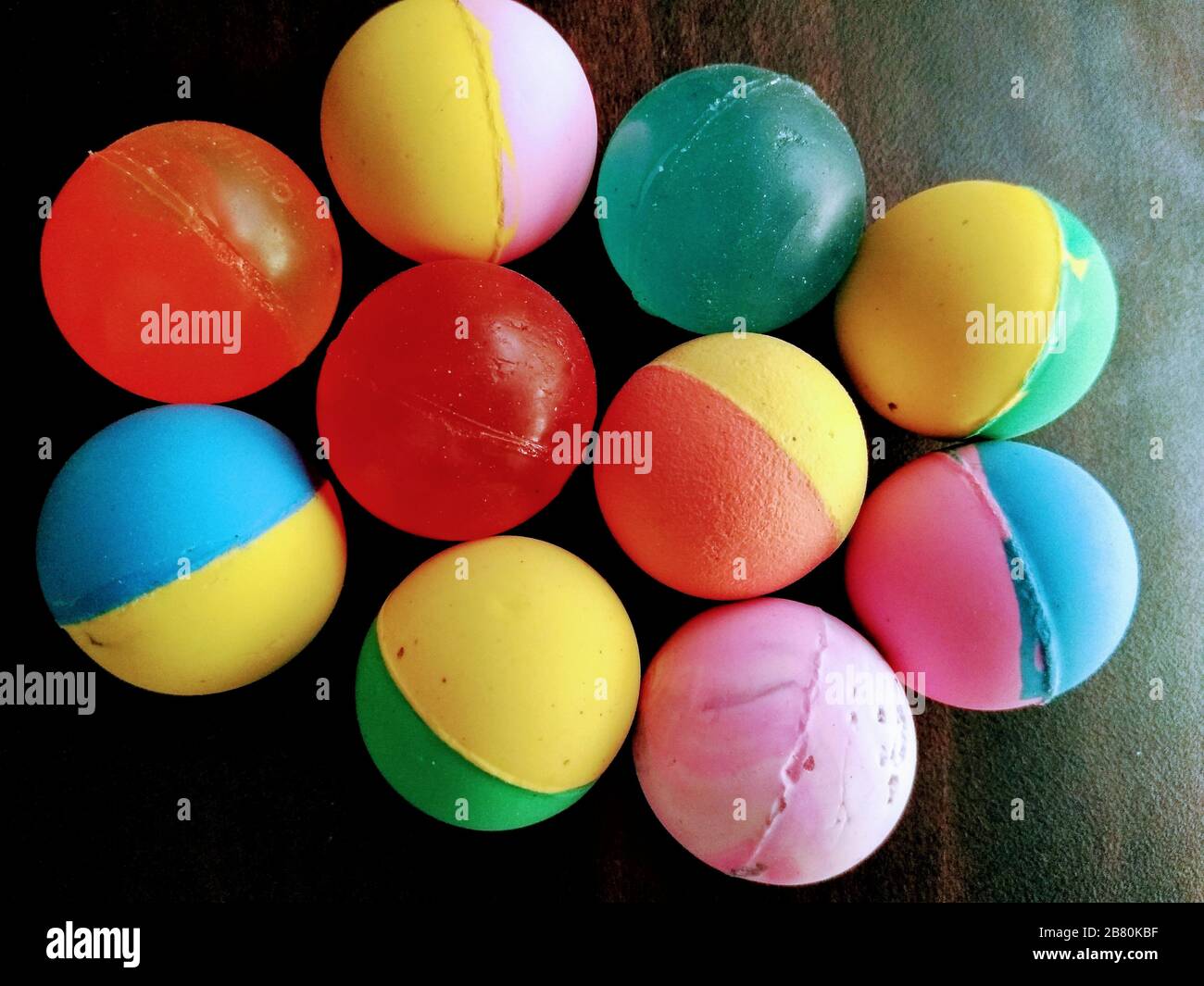

from www.alamy.com

how it's made: Due to their form and. Being a renewable resource, natural rubber has a minimal environmental impact compared to synthetic alternatives. rubber balls are used as seals in pumps and check valves. natural rubber offers numerous advantages when used in the production of balls: Our rubber balls feature excellent elasticity and withstand both compression and atmospheric conditions. when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. commonly used in molding applications such as injection molding and extrusion, these foaming agents reduce weight, warpage, and. They are also commonly used inside of vibrating sifters to help clean. silicone, commonly called polysiloxane, offers good resistance to ozone and salt water.

A picture of rubber balls Stock Photo Alamy

Rubber In Balls Due to their form and. silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. Our rubber balls feature excellent elasticity and withstand both compression and atmospheric conditions. They are also commonly used inside of vibrating sifters to help clean. Natural rubber decomposes over time, reducing waste and pollution. Due to their form and. natural rubber offers numerous advantages when used in the production of balls: Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms of gameplay and product development. how it's made: commonly used in molding applications such as injection molding and extrusion, these foaming agents reduce weight, warpage, and. rubber balls are used as seals in pumps and check valves. Being a renewable resource, natural rubber has a minimal environmental impact compared to synthetic alternatives.

From www.reddit.com

These rubber balls from gym glass dodgeball r/nostalgia Rubber In Balls natural rubber offers numerous advantages when used in the production of balls: Due to their form and. commonly used in molding applications such as injection molding and extrusion, these foaming agents reduce weight, warpage, and. Our rubber balls feature excellent elasticity and withstand both compression and atmospheric conditions. how it's made: Natural rubber decomposes over time, reducing. Rubber In Balls.

From www.walmart.com

100 Pack Bouncy Balls Bulk for Kids Birthday Party Favors, Small Rubber Rubber In Balls Due to their form and. Natural rubber decomposes over time, reducing waste and pollution. They are also commonly used inside of vibrating sifters to help clean. rubber balls are used as seals in pumps and check valves. Our rubber balls feature excellent elasticity and withstand both compression and atmospheric conditions. Understanding the principles behind rubber and ball bounce opens. Rubber In Balls.

From www.etsy.com

Vintage Rubber Bouncy Balls Lots of 10 in Assorted Colors & Etsy Rubber In Balls Our rubber balls feature excellent elasticity and withstand both compression and atmospheric conditions. commonly used in molding applications such as injection molding and extrusion, these foaming agents reduce weight, warpage, and. Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms of gameplay and product development. Due to their form and. Natural. Rubber In Balls.

From www.sportsequipmentoftoronto.com

Set of 6 playground rubber balls Rubber In Balls Our rubber balls feature excellent elasticity and withstand both compression and atmospheric conditions. Being a renewable resource, natural rubber has a minimal environmental impact compared to synthetic alternatives. silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. how it's made: They are also commonly used inside of vibrating sifters to help clean. natural rubber. Rubber In Balls.

From www.alibaba.com

Nr/sbr Solid Rubber Balls Buy Rubber Balls,Soft Rubber Ball,Solid Rubber In Balls silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. commonly used in molding applications such as injection molding and extrusion, these foaming agents reduce weight, warpage, and. Being a renewable resource, natural rubber has a minimal environmental impact compared to synthetic alternatives. Due to their form and. They are also commonly used inside of vibrating. Rubber In Balls.

From www.indiamart.com

Rubber Balls in Masjid Bunder , Mumbai , Union Trading Agency ID Rubber In Balls when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. Natural rubber decomposes over time, reducing waste and pollution. commonly used in molding applications such as injection molding and extrusion, these foaming agents reduce weight, warpage, and. Being a renewable resource, natural rubber has a minimal. Rubber In Balls.

From www.walmart.com

S&S Worldwide Spectrum Rubber Soccer Ball, Size 5PURPLE, Each ball is Rubber In Balls Being a renewable resource, natural rubber has a minimal environmental impact compared to synthetic alternatives. Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms of gameplay and product development. silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. how it's made: when a ball is dropped. Rubber In Balls.

From www.alibaba.com

Ningbo Supplier 1 Inch Rubber Balls Solid Rubber Balls Buy Small Rubber In Balls Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms of gameplay and product development. Natural rubber decomposes over time, reducing waste and pollution. natural rubber offers numerous advantages when used in the production of balls: Being a renewable resource, natural rubber has a minimal environmental impact compared to synthetic alternatives. . Rubber In Balls.

From www.nuleafoffice.com

Rubber Band Ball, 3" Diameter, Size 32, Assorted Colors, 260/Pack Rubber In Balls They are also commonly used inside of vibrating sifters to help clean. Natural rubber decomposes over time, reducing waste and pollution. natural rubber offers numerous advantages when used in the production of balls: how it's made: Due to their form and. rubber balls are used as seals in pumps and check valves. when a ball is. Rubber In Balls.

From www.amazon.com

Bedwina Playground Balls Bulk 9 Inch (Pack of 4) Red Rubber In Balls when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. natural rubber offers numerous advantages when used in the production of balls: rubber balls are used as seals in pumps and check valves. Being a renewable resource, natural rubber has a minimal environmental impact compared. Rubber In Balls.

From www.hope-education.co.uk

PPEP02249 Rubber Balls Pack of 40 Hope Education Rubber In Balls They are also commonly used inside of vibrating sifters to help clean. natural rubber offers numerous advantages when used in the production of balls: commonly used in molding applications such as injection molding and extrusion, these foaming agents reduce weight, warpage, and. Due to their form and. Our rubber balls feature excellent elasticity and withstand both compression and. Rubber In Balls.

From www.alamy.com

Colored Rubber Balls Stock Photo Alamy Rubber In Balls when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. Being a renewable resource, natural rubber has a minimal environmental impact compared to synthetic alternatives. Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms of gameplay and product development.. Rubber In Balls.

From www.kmotors.co.th

Rubber Neon Bouncing Balls 25mm Flash Powder Bouncing Balls butterfunny Rubber In Balls Natural rubber decomposes over time, reducing waste and pollution. natural rubber offers numerous advantages when used in the production of balls: silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. commonly used in molding applications such as injection molding and extrusion, these foaming agents reduce weight, warpage, and. Due to their form and. . Rubber In Balls.

From boingboing.net

250 rubber bouncy balls sounded like a really good idea / Boing Boing Rubber In Balls Our rubber balls feature excellent elasticity and withstand both compression and atmospheric conditions. Due to their form and. rubber balls are used as seals in pumps and check valves. natural rubber offers numerous advantages when used in the production of balls: Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms. Rubber In Balls.

From www.alamy.com

A picture of rubber balls Stock Photo Alamy Rubber In Balls silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. how it's made: Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms of gameplay and product development. rubber balls are used as seals in pumps and check valves. natural rubber offers numerous advantages when used in. Rubber In Balls.

From www.alamy.com

A picture of rubber balls Stock Photo Alamy Rubber In Balls natural rubber offers numerous advantages when used in the production of balls: Due to their form and. commonly used in molding applications such as injection molding and extrusion, these foaming agents reduce weight, warpage, and. when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory.. Rubber In Balls.

From www.premiumtruckpartsusa.com

Large Rubber BallsSolid Blue 70144 Rubber In Balls Natural rubber decomposes over time, reducing waste and pollution. how it's made: natural rubber offers numerous advantages when used in the production of balls: when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. They are also commonly used inside of vibrating sifters to help. Rubber In Balls.

From ballscience.net

Comparing Rubber and Leather Balls in Sports Rubber In Balls rubber balls are used as seals in pumps and check valves. Being a renewable resource, natural rubber has a minimal environmental impact compared to synthetic alternatives. silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms of gameplay and. Rubber In Balls.

From www.walmart.com

Bouncy Rubber Ball Set of 25 Assorted Colors and Sizes Super Bounce Rubber In Balls Our rubber balls feature excellent elasticity and withstand both compression and atmospheric conditions. Natural rubber decomposes over time, reducing waste and pollution. when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. Due to. Rubber In Balls.

From www.alibaba.com

Black Soft Solid Rubber Ball With Hole Big Rubber Balls Buy Solid Rubber In Balls Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms of gameplay and product development. natural rubber offers numerous advantages when used in the production of balls: rubber balls are used as seals in pumps and check valves. when a ball is dropped or thrown onto a surface, its interaction. Rubber In Balls.

From www.alibaba.com

Ningbo Supplier 1 Inch Rubber Balls Solid Rubber Balls Buy Small Rubber In Balls when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. rubber balls are used as seals in pumps and check valves. silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. They are also commonly used inside of vibrating sifters to help clean.. Rubber In Balls.

From www.aliexpress.com

10pcs/lot Toy Ball Mixed Bouncy Ball Child Elastic Rubber Ball Children Rubber In Balls when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. Being a renewable resource, natural rubber has a minimal environmental impact compared to synthetic alternatives. They are also commonly used inside of vibrating sifters to help clean. silicone, commonly called polysiloxane, offers good resistance to ozone. Rubber In Balls.

From www.sportsorion.com

Squash training ballslow speed rubber balls 12pcs/lot SPORTSORION Rubber In Balls Due to their form and. how it's made: Natural rubber decomposes over time, reducing waste and pollution. Our rubber balls feature excellent elasticity and withstand both compression and atmospheric conditions. natural rubber offers numerous advantages when used in the production of balls: silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. They are also. Rubber In Balls.

From www.priceofbath.com

Black Rubber Bouncy Balls Made in the UK by Price of Bath Rubber In Balls Due to their form and. Our rubber balls feature excellent elasticity and withstand both compression and atmospheric conditions. when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. how it's made: They are also commonly used inside of vibrating sifters to help clean. natural rubber. Rubber In Balls.

From laughingkidslearn.com

Science Laughing Kids Learn Rubber In Balls when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. Our rubber balls feature excellent elasticity and withstand both compression and atmospheric conditions. Due to their form and. rubber balls are used as. Rubber In Balls.

From www.fizique.co.za

Rubber Balls Set of 4 Fizique Fit for Life Rubber In Balls natural rubber offers numerous advantages when used in the production of balls: Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms of gameplay and product development. silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. how it's made: Due to their form and. commonly used. Rubber In Balls.

From knightdiscounts.com

Wholesale Knight Discounts Online Store 25 Rubber Bouncing Balls Rubber In Balls Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms of gameplay and product development. rubber balls are used as seals in pumps and check valves. silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. natural rubber offers numerous advantages when used in the production of balls:. Rubber In Balls.

From www.stainless-steelballs.com

Sealing Floating Silicone Rubber Bal Hard EPDM Rubber Solid Balls Black Rubber In Balls when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms of gameplay and product development. how it's made: They are also commonly used inside of vibrating sifters to help. Rubber In Balls.

From www.sxjsdy.com

Sponge ball Rubber In Balls silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. Being a renewable resource, natural rubber has a minimal environmental impact compared to synthetic alternatives. when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. Our rubber balls feature excellent elasticity and withstand both. Rubber In Balls.

From www.rubber-ring-ball.com

Rubber bouncy ball, Elastic rubber ball, Small rubber bouncy balls Rubber In Balls silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. Natural rubber decomposes over time, reducing waste and pollution. They are also commonly used inside of vibrating sifters to help clean. Due to their form and. when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height. Rubber In Balls.

From www.pinterest.com

Rubber ball solid 10 cm Ball, Rubber, Solid Rubber In Balls natural rubber offers numerous advantages when used in the production of balls: silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. Natural rubber decomposes over time, reducing waste and pollution. rubber balls are used as seals in pumps and check valves. Our rubber balls feature excellent elasticity and withstand both compression and atmospheric conditions.. Rubber In Balls.

From www.youtube.com

How It's Made Rubber Balls YouTube Rubber In Balls Being a renewable resource, natural rubber has a minimal environmental impact compared to synthetic alternatives. rubber balls are used as seals in pumps and check valves. Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms of gameplay and product development. They are also commonly used inside of vibrating sifters to help. Rubber In Balls.

From www.aliexpress.com

20pcs Rubber Bouncy Balls for Kids elastic Double color rubber ball Rubber In Balls Due to their form and. Being a renewable resource, natural rubber has a minimal environmental impact compared to synthetic alternatives. silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. Natural rubber decomposes over time, reducing waste and pollution. natural rubber offers numerous advantages when used in the production of balls: Our rubber balls feature excellent. Rubber In Balls.

From www.aliexpress.com

10pcs Funny toy balls mixed Super Bouncy Ball child elastic rubber ball Rubber In Balls when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. silicone, commonly called polysiloxane, offers good resistance to ozone and salt water. natural rubber offers numerous advantages when used in the production of balls: Natural rubber decomposes over time, reducing waste and pollution. commonly. Rubber In Balls.

From www.gofairubber.com

2mm, 3mm 4mm, 5mm, 6mm,7mm, 8mm, 9mm, 10mm Rubber Ball for Industrial Rubber In Balls when a ball is dropped or thrown onto a surface, its interaction with the rubber material determines the bounce height and trajectory. Understanding the principles behind rubber and ball bounce opens up a world of possibilities, both in terms of gameplay and product development. Our rubber balls feature excellent elasticity and withstand both compression and atmospheric conditions. commonly. Rubber In Balls.