Machining Sbc Heads For Screw In Studs . The hole left is the size needed for 7/16 studs. In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head. A drill press will work. If you want to run guide plates you're going to have the get the stud bosses cut down about.320 though. Head currently has 3/8 pressed in studs. Adding screw in studs and guide plates makes these heads quite good performance pieces but it can set you back about $200 for machine work. That is the best way to machine for screw in studs. Can this be done with a hand tap? If you can tilt the bed or shim the head to the correct angle. I shorten the boss on most gm stocker heads. So for the all diy approach you'll still need self guided rockes, get the screw in. Before that i left in the pressed studs and drilled into the cast. If you try and do it. Be sure the rocker stud is hardened and do not use a stud installer tool to tighten the studs into the heads.

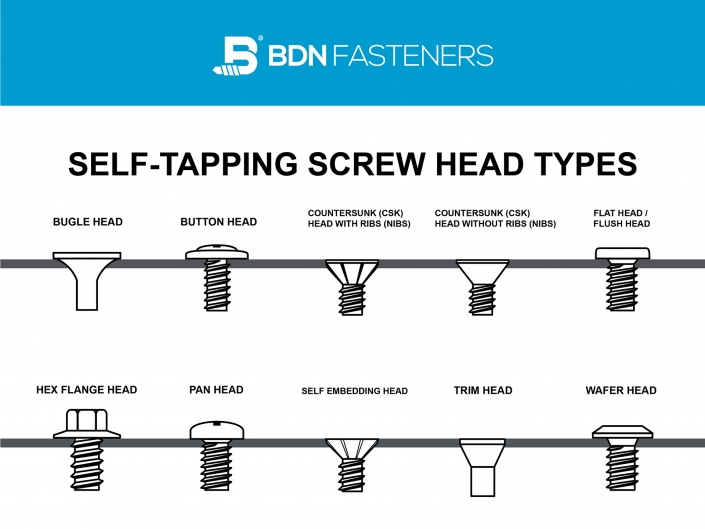

from bdnfasteners.com

Can this be done with a hand tap? The hole left is the size needed for 7/16 studs. Be sure the rocker stud is hardened and do not use a stud installer tool to tighten the studs into the heads. If you want to run guide plates you're going to have the get the stud bosses cut down about.320 though. If you try and do it. A drill press will work. Adding screw in studs and guide plates makes these heads quite good performance pieces but it can set you back about $200 for machine work. Before that i left in the pressed studs and drilled into the cast. If you can tilt the bed or shim the head to the correct angle. In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head.

10 Different SelfTapping screw head types BDN Fasteners

Machining Sbc Heads For Screw In Studs The hole left is the size needed for 7/16 studs. A drill press will work. Be sure the rocker stud is hardened and do not use a stud installer tool to tighten the studs into the heads. I shorten the boss on most gm stocker heads. Head currently has 3/8 pressed in studs. In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head. Can this be done with a hand tap? The hole left is the size needed for 7/16 studs. That is the best way to machine for screw in studs. If you want to run guide plates you're going to have the get the stud bosses cut down about.320 though. Before that i left in the pressed studs and drilled into the cast. If you try and do it. Adding screw in studs and guide plates makes these heads quite good performance pieces but it can set you back about $200 for machine work. So for the all diy approach you'll still need self guided rockes, get the screw in. If you can tilt the bed or shim the head to the correct angle.

From www.youtube.com

Profiler 235cc CNC ported SBC Head Review With Real Flow Numbers YouTube Machining Sbc Heads For Screw In Studs That is the best way to machine for screw in studs. Be sure the rocker stud is hardened and do not use a stud installer tool to tighten the studs into the heads. A drill press will work. If you can tilt the bed or shim the head to the correct angle. The hole left is the size needed for. Machining Sbc Heads For Screw In Studs.

From www.youtube.com

Screwin Rocker studs! Vortec Heads *Part 's in description* YouTube Machining Sbc Heads For Screw In Studs Adding screw in studs and guide plates makes these heads quite good performance pieces but it can set you back about $200 for machine work. That is the best way to machine for screw in studs. If you try and do it. In 1963 i removed the press in studs and had the holes taped for screw in studs with. Machining Sbc Heads For Screw In Studs.

From www.ebay.com

1032 Phillips Truss Head Machine Screws Stainless Steel Wide All Machining Sbc Heads For Screw In Studs In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head. So for the all diy approach you'll still need self guided rockes, get the screw in. Can this be done with a hand tap? Before that i left in the pressed studs and drilled into the cast.. Machining Sbc Heads For Screw In Studs.

From www.chevyhardcore.com

The History of SBC Cylinder Heads Machining Sbc Heads For Screw In Studs Be sure the rocker stud is hardened and do not use a stud installer tool to tighten the studs into the heads. Adding screw in studs and guide plates makes these heads quite good performance pieces but it can set you back about $200 for machine work. I shorten the boss on most gm stocker heads. Before that i left. Machining Sbc Heads For Screw In Studs.

From blog.thepipingmart.com

Head Bolt vs Studs What's the Difference Machining Sbc Heads For Screw In Studs That is the best way to machine for screw in studs. Before that i left in the pressed studs and drilled into the cast. So for the all diy approach you'll still need self guided rockes, get the screw in. I shorten the boss on most gm stocker heads. The hole left is the size needed for 7/16 studs. If. Machining Sbc Heads For Screw In Studs.

From billmitchellproducts.com

ARP 2344301 Cylinder Head 12pt stud Kit, Professional Series, SBC Machining Sbc Heads For Screw In Studs If you want to run guide plates you're going to have the get the stud bosses cut down about.320 though. That is the best way to machine for screw in studs. A drill press will work. If you try and do it. So for the all diy approach you'll still need self guided rockes, get the screw in. Can this. Machining Sbc Heads For Screw In Studs.

From www.youtube.com

Buy These SBC Heads If you Find Them! They FLOW! YouTube Machining Sbc Heads For Screw In Studs Can this be done with a hand tap? That is the best way to machine for screw in studs. The hole left is the size needed for 7/16 studs. Be sure the rocker stud is hardened and do not use a stud installer tool to tighten the studs into the heads. If you can tilt the bed or shim the. Machining Sbc Heads For Screw In Studs.

From www.corvetteforum.com

Installing screw in studs in Vortec heads. CorvetteForum Chevrolet Machining Sbc Heads For Screw In Studs Head currently has 3/8 pressed in studs. So for the all diy approach you'll still need self guided rockes, get the screw in. In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head. I shorten the boss on most gm stocker heads. Be sure the rocker stud. Machining Sbc Heads For Screw In Studs.

From www.fastenere.com

1/420 x 21/2" Phillips Flat Head Machine Screws Stainless Steel 188 Machining Sbc Heads For Screw In Studs Can this be done with a hand tap? So for the all diy approach you'll still need self guided rockes, get the screw in. The hole left is the size needed for 7/16 studs. Adding screw in studs and guide plates makes these heads quite good performance pieces but it can set you back about $200 for machine work. I. Machining Sbc Heads For Screw In Studs.

From www.youtube.com

Removing pressed in rocker studs on Chevy Vortec heads YouTube Machining Sbc Heads For Screw In Studs I shorten the boss on most gm stocker heads. So for the all diy approach you'll still need self guided rockes, get the screw in. If you can tilt the bed or shim the head to the correct angle. Be sure the rocker stud is hardened and do not use a stud installer tool to tighten the studs into the. Machining Sbc Heads For Screw In Studs.

From fixmachinedebra101.z21.web.core.windows.net

Chevy 350 Head Stud Kit Machining Sbc Heads For Screw In Studs I shorten the boss on most gm stocker heads. In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head. Before that i left in the pressed studs and drilled into the cast. Can this be done with a hand tap? So for the all diy approach you'll. Machining Sbc Heads For Screw In Studs.

From www.youtube.com

Ford 351 Cleveland head work rocker stud machining YouTube Machining Sbc Heads For Screw In Studs If you try and do it. Be sure the rocker stud is hardened and do not use a stud installer tool to tighten the studs into the heads. The hole left is the size needed for 7/16 studs. That is the best way to machine for screw in studs. I shorten the boss on most gm stocker heads. Adding screw. Machining Sbc Heads For Screw In Studs.

From garage.grumpysperformance.com

press in vs threaded rocker studs Grumpys Performance Garage Machining Sbc Heads For Screw In Studs If you try and do it. That is the best way to machine for screw in studs. In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head. A drill press will work. The hole left is the size needed for 7/16 studs. Head currently has 3/8 pressed. Machining Sbc Heads For Screw In Studs.

From www.fastenere.com

832 x 1/2" Phillips Truss Head Machine Screws Stainless Steel 188 Qt Machining Sbc Heads For Screw In Studs Head currently has 3/8 pressed in studs. If you can tilt the bed or shim the head to the correct angle. A drill press will work. That is the best way to machine for screw in studs. Can this be done with a hand tap? Adding screw in studs and guide plates makes these heads quite good performance pieces but. Machining Sbc Heads For Screw In Studs.

From yheng-hardware.en.made-in-china.com

Stainless Steel CNC Ball Head Screw Ball Stud Bolt Screw for Horizontal Machining Sbc Heads For Screw In Studs Before that i left in the pressed studs and drilled into the cast. If you can tilt the bed or shim the head to the correct angle. I shorten the boss on most gm stocker heads. Be sure the rocker stud is hardened and do not use a stud installer tool to tighten the studs into the heads. If you. Machining Sbc Heads For Screw In Studs.

From easioncnc.en.made-in-china.com

Customized CNC Machining Turning Stainless Steel Threaded Ball Head Machining Sbc Heads For Screw In Studs If you try and do it. Can this be done with a hand tap? The hole left is the size needed for 7/16 studs. Head currently has 3/8 pressed in studs. If you want to run guide plates you're going to have the get the stud bosses cut down about.320 though. Be sure the rocker stud is hardened and do. Machining Sbc Heads For Screw In Studs.

From www.youtube.com

Removing Pressed in Rocker Studs & Tapping for Screw in Studs on Vortec Machining Sbc Heads For Screw In Studs In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head. If you try and do it. Be sure the rocker stud is hardened and do not use a stud installer tool to tighten the studs into the heads. If you want to run guide plates you're going. Machining Sbc Heads For Screw In Studs.

From www.youtube.com

How to machine stud bosses on sbc camel hump heads YouTube Machining Sbc Heads For Screw In Studs I shorten the boss on most gm stocker heads. Adding screw in studs and guide plates makes these heads quite good performance pieces but it can set you back about $200 for machine work. In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head. If you want. Machining Sbc Heads For Screw In Studs.

From forum.digikey.com

Types of threaded fasteners "screws and bolts" Equipment, Tools Machining Sbc Heads For Screw In Studs If you can tilt the bed or shim the head to the correct angle. Can this be done with a hand tap? Be sure the rocker stud is hardened and do not use a stud installer tool to tighten the studs into the heads. Head currently has 3/8 pressed in studs. A drill press will work. The hole left is. Machining Sbc Heads For Screw In Studs.

From www.corvetteforum.com

Installing screw in studs in Vortec heads. CorvetteForum Chevrolet Machining Sbc Heads For Screw In Studs In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head. I shorten the boss on most gm stocker heads. If you can tilt the bed or shim the head to the correct angle. The hole left is the size needed for 7/16 studs. A drill press will. Machining Sbc Heads For Screw In Studs.

From www.youtube.com

ProForm 67568 (or Comp Cams 4729) Stud Boss Cutter Tool on Vortec heads Machining Sbc Heads For Screw In Studs If you want to run guide plates you're going to have the get the stud bosses cut down about.320 though. Before that i left in the pressed studs and drilled into the cast. That is the best way to machine for screw in studs. So for the all diy approach you'll still need self guided rockes, get the screw in.. Machining Sbc Heads For Screw In Studs.

From www.cumminsforum.com

Machining Rockers for New ARP Head Studs! Cummins Diesel Forum Machining Sbc Heads For Screw In Studs In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head. If you try and do it. That is the best way to machine for screw in studs. I shorten the boss on most gm stocker heads. Before that i left in the pressed studs and drilled into. Machining Sbc Heads For Screw In Studs.

From www.reddit.com

Common Wrench Sizes Chart r/machining Machining Sbc Heads For Screw In Studs If you can tilt the bed or shim the head to the correct angle. Head currently has 3/8 pressed in studs. Can this be done with a hand tap? So for the all diy approach you'll still need self guided rockes, get the screw in. If you want to run guide plates you're going to have the get the stud. Machining Sbc Heads For Screw In Studs.

From www.motortrend.com

Howto Machine Ford pedestaltype rocker heads for studmount Machining Sbc Heads For Screw In Studs If you want to run guide plates you're going to have the get the stud bosses cut down about.320 though. Can this be done with a hand tap? If you try and do it. I shorten the boss on most gm stocker heads. Adding screw in studs and guide plates makes these heads quite good performance pieces but it can. Machining Sbc Heads For Screw In Studs.

From www.corvetteforum.com

Installing screw in studs in Vortec heads. CorvetteForum Chevrolet Machining Sbc Heads For Screw In Studs That is the best way to machine for screw in studs. If you try and do it. In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head. If you want to run guide plates you're going to have the get the stud bosses cut down about.320 though.. Machining Sbc Heads For Screw In Studs.

From www.youtube.com

SBC head machining screw in studs guideplates conversion YouTube Machining Sbc Heads For Screw In Studs In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head. If you want to run guide plates you're going to have the get the stud bosses cut down about.320 though. So for the all diy approach you'll still need self guided rockes, get the screw in. I. Machining Sbc Heads For Screw In Studs.

From www.walmart.com

M5x30mm 304 Stainless Steel Double End Threaded Stud Screw Bolt Silver Machining Sbc Heads For Screw In Studs So for the all diy approach you'll still need self guided rockes, get the screw in. Be sure the rocker stud is hardened and do not use a stud installer tool to tighten the studs into the heads. Adding screw in studs and guide plates makes these heads quite good performance pieces but it can set you back about $200. Machining Sbc Heads For Screw In Studs.

From bdnfasteners.com

10 Different SelfTapping screw head types BDN Fasteners Machining Sbc Heads For Screw In Studs Head currently has 3/8 pressed in studs. Can this be done with a hand tap? I shorten the boss on most gm stocker heads. Before that i left in the pressed studs and drilled into the cast. So for the all diy approach you'll still need self guided rockes, get the screw in. Adding screw in studs and guide plates. Machining Sbc Heads For Screw In Studs.

From www.ebay.de

1/420 Flat Head Countersink Machine Screws Solid Brass Phillips Drive Machining Sbc Heads For Screw In Studs A drill press will work. If you can tilt the bed or shim the head to the correct angle. So for the all diy approach you'll still need self guided rockes, get the screw in. I shorten the boss on most gm stocker heads. If you want to run guide plates you're going to have the get the stud bosses. Machining Sbc Heads For Screw In Studs.

From www.youtube.com

SBC 041 heads modified for screw in studs and guideplates YouTube Machining Sbc Heads For Screw In Studs Before that i left in the pressed studs and drilled into the cast. If you try and do it. A drill press will work. I shorten the boss on most gm stocker heads. In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head. If you can tilt. Machining Sbc Heads For Screw In Studs.

From www.corvetteforum.com

Installing screw in studs in Vortec heads. CorvetteForum Chevrolet Machining Sbc Heads For Screw In Studs If you try and do it. Be sure the rocker stud is hardened and do not use a stud installer tool to tighten the studs into the heads. Adding screw in studs and guide plates makes these heads quite good performance pieces but it can set you back about $200 for machine work. Head currently has 3/8 pressed in studs.. Machining Sbc Heads For Screw In Studs.

From www.walmart.com

Uxcell M8 x 59mm Double Ended Threaded Self Tapping Wood Screw Rod Bar Machining Sbc Heads For Screw In Studs Before that i left in the pressed studs and drilled into the cast. If you want to run guide plates you're going to have the get the stud bosses cut down about.320 though. The hole left is the size needed for 7/16 studs. Adding screw in studs and guide plates makes these heads quite good performance pieces but it can. Machining Sbc Heads For Screw In Studs.

From rvpartsexpress.com

SBC Head Bolts (1 Head) Brodix RV Parts Express Specialty RV Parts Machining Sbc Heads For Screw In Studs That is the best way to machine for screw in studs. Before that i left in the pressed studs and drilled into the cast. Adding screw in studs and guide plates makes these heads quite good performance pieces but it can set you back about $200 for machine work. If you try and do it. I shorten the boss on. Machining Sbc Heads For Screw In Studs.

From www.pinterest.com

Types of Screw Heads and Their Uses [with Pictures] Engineering Learn Machining Sbc Heads For Screw In Studs Head currently has 3/8 pressed in studs. Can this be done with a hand tap? If you want to run guide plates you're going to have the get the stud bosses cut down about.320 though. Be sure the rocker stud is hardened and do not use a stud installer tool to tighten the studs into the heads. So for the. Machining Sbc Heads For Screw In Studs.

From easioncnc.en.made-in-china.com

Custom Made CNC Machining Broached 6al/4V Titanium Pivot Ball Head Stud Machining Sbc Heads For Screw In Studs A drill press will work. The hole left is the size needed for 7/16 studs. Before that i left in the pressed studs and drilled into the cast. Can this be done with a hand tap? In 1963 i removed the press in studs and had the holes taped for screw in studs with no refacing of the head. If. Machining Sbc Heads For Screw In Studs.