Material Management Lean Manufacturing . Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process improvement. There are 5 principles of lean manufacturing. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Let’s delve into the five.

from www.wallstreetmojo.com

At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. There are 5 principles of lean manufacturing. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process improvement. Let’s delve into the five. Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence.

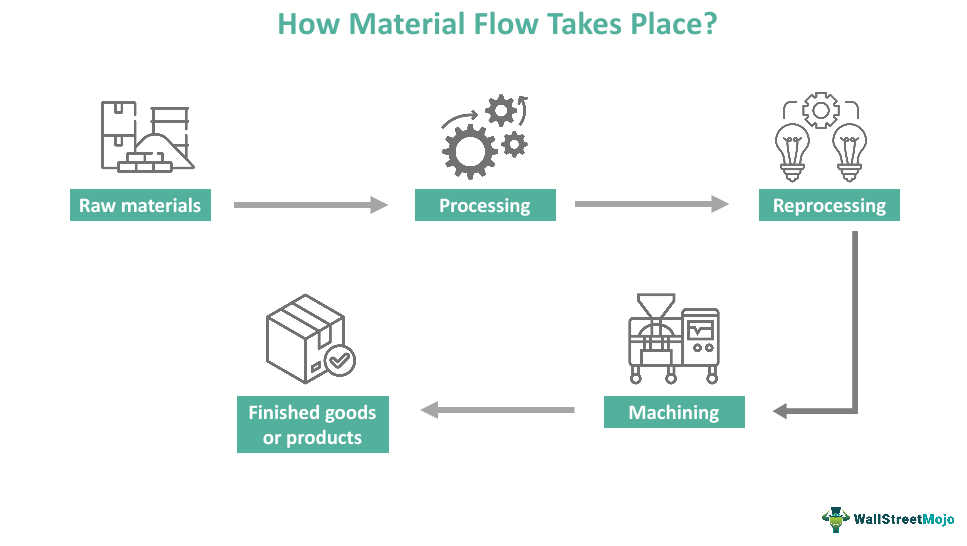

Material Flow What Is It, Types, Examples, Importance

Material Management Lean Manufacturing Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process improvement. At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Let’s delve into the five. There are 5 principles of lean manufacturing. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for.

From www.conceptdraw.com

Lean Manufacturing Diagrams Value Stream Mapping Software Material Management Lean Manufacturing Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process improvement. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for.. Material Management Lean Manufacturing.

From www.leansixsigmadefinition.com

6 M’s Lean Manufacturing and Six Sigma Definitions Material Management Lean Manufacturing Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. Lean manufacturing. Material Management Lean Manufacturing.

From www.wallstreetmojo.com

Material Flow What Is It, Types, Examples, Importance Material Management Lean Manufacturing Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process improvement. Lean manufacturing, an approach that. Material Management Lean Manufacturing.

From www.researchgate.net

Elements and tools of lean manufacturing, Singh et al. (2018 Material Management Lean Manufacturing Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. Let’s delve into the five. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Lean manufacturing. Material Management Lean Manufacturing.

From ar.inspiredpencil.com

Lean Manufacturing 5s Material Management Lean Manufacturing Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. There are 5 principles of lean manufacturing. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in. Material Management Lean Manufacturing.

From leanfactories.com

Lean Manufacturing Training Materials Lean Factories Material Management Lean Manufacturing Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. Let’s delve into the five. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process improvement. Explore the six tried and tested lean manufacturing techniques which act as game. Material Management Lean Manufacturing.

From mungfali.com

Lean 8 Wastes Chart Material Management Lean Manufacturing Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. Lean manufacturing. Material Management Lean Manufacturing.

From www.amalo-recrutement.fr

LEAN manufacturing Qu'estce que le lean manufacturing Material Management Lean Manufacturing Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. There are 5 principles of lean manufacturing. Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Let’s delve into the five. At its core, lean manufacturing is focused on improving efficiency while. Material Management Lean Manufacturing.

From www.slideserve.com

PPT LEAN Product Development practices PowerPoint Presentation, free Material Management Lean Manufacturing Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. Lean. Material Management Lean Manufacturing.

From www.reliableplant.com

Kaizen Explained Reliable Plant Material Management Lean Manufacturing Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process improvement. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. There are 5 principles of lean manufacturing. Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting. Material Management Lean Manufacturing.

From www.youtube.com

What is Kanban? Kanban Visual Systems Explained in 4 stages Easily Material Management Lean Manufacturing Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. There are 5 principles of lean manufacturing. At its core, lean manufacturing is focused on improving efficiency while. Material Management Lean Manufacturing.

From www.gkdaring.com

7 Waste of Lean Manufacturing Material Management Lean Manufacturing Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Let’s delve into the five. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking. Material Management Lean Manufacturing.

From www.marketing91.com

Materials Management Definition, Types, Benefits, and Objectives Material Management Lean Manufacturing Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process improvement. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Lean manufacturing is a. Material Management Lean Manufacturing.

From medium.com

Designing a manufacturing System through Lean Layouts and Cellular Material Management Lean Manufacturing Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. There are 5. Material Management Lean Manufacturing.

From ottomotors.com

Efficient Lineside Delivery in the Era of Lean Manufacturing Material Management Lean Manufacturing Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for.. Material Management Lean Manufacturing.

From www.slideserve.com

PPT Lean Production System PowerPoint Presentation, free download Material Management Lean Manufacturing Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Let’s delve into the five. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process improvement.. Material Management Lean Manufacturing.

From solutionbuggy.blogspot.com

Lean manufacturing effectiveness by reduction of waste SolutionBuggy Material Management Lean Manufacturing At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Let’s delve into the five. Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Lean manufacturing, an. Material Management Lean Manufacturing.

From www.planettogether.com

7 Types of Waste in Lean Manufacturing Material Management Lean Manufacturing Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process improvement. At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Lean manufacturing. Material Management Lean Manufacturing.

From www.imcosoftware.com

The Importance of Lean Material Management IMCO Software Material Management Lean Manufacturing Let’s delve into the five. At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Lean manufacturing. Material Management Lean Manufacturing.

From www.leansixsigmadefinition.com

Fishbone Diagram Lean Manufacturing and Six Sigma Definitions Material Management Lean Manufacturing Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Let’s delve into the five. Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. There are 5. Material Management Lean Manufacturing.

From www.youtube.com

Materials Management Functions and Objectives of Material Management Material Management Lean Manufacturing Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process improvement. There are 5 principles of lean manufacturing. At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which.. Material Management Lean Manufacturing.

From tinhocvanphongs.com

Lean Manufacturing Kanban kanban card tin hoc van phong Material Management Lean Manufacturing Let’s delve into the five. Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. There are 5 principles of lean manufacturing. At its core, lean manufacturing is focused. Material Management Lean Manufacturing.

From leanfactories.com

Lean Manufacturing Training Materials Lean Factories Material Management Lean Manufacturing At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process improvement. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. Explore the. Material Management Lean Manufacturing.

From leanmanufacturingtools.org

Lean Manufacturing definition What is Lean Material Management Lean Manufacturing Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. There. Material Management Lean Manufacturing.

From accendoreliability.com

Design for Lean Material Management Lean Manufacturing At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Let’s delve into the five. Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process improvement. There. Material Management Lean Manufacturing.

From www.quality-assurance-solutions.com

7 Wastes of Lean Material Management Lean Manufacturing There are 5 principles of lean manufacturing. Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. At its core, lean manufacturing is focused on improving efficiency while reducing. Material Management Lean Manufacturing.

From www.conceptdraw.com

Lean Manufacturing Diagrams Value Stream Mapping Software Material Management Lean Manufacturing Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. There are 5 principles of lean manufacturing. Let’s delve into the five. Lean manufacturing is a production system that. Material Management Lean Manufacturing.

From mavink.com

Lean Manufacturing Process Flow Chart Material Management Lean Manufacturing Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. There are 5 principles of lean manufacturing. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point. Material Management Lean Manufacturing.

From leanmanufacturingtools.org

Lean Manufacturing Tools, Principles, Implementation Material Management Lean Manufacturing Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. Lean manufacturing is a methodology. Material Management Lean Manufacturing.

From www.vecteezy.com

8 Wastes of lean manufacturing infographic presentation template with Material Management Lean Manufacturing Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process. Material Management Lean Manufacturing.

From www.leanmanufacturinghoy.com

Lean Manufacturing. Los 8 grandes despilfarros (mudas) de tu empresa Material Management Lean Manufacturing At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. Let’s delve into. Material Management Lean Manufacturing.

From www.dsidirect.com

Lean Principles for Materials Management DSI Direct Material Management Lean Manufacturing Let’s delve into the five. At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. There are 5 principles of lean manufacturing. Explore the six tried and tested lean manufacturing techniques which act as game. Material Management Lean Manufacturing.

From hubpages.com

Lean Manufacturing Tools HubPages Material Management Lean Manufacturing Lean manufacturing is a framework focused on optimizing production processes based on essential principles guiding organizations toward excellence. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. At its core, lean manufacturing is focused on improving efficiency while reducing waste, both of which. Let’s delve into the five. Lean manufacturing, an. Material Management Lean Manufacturing.

From techqualitypedia.com

Lean Manufacturing Lean Principles Lean 5S Material Management Lean Manufacturing Lean manufacturing, an approach that depends greatly on flexibility and workplace organization, is an excellent starting point for companies. Lean manufacturing is a production system that focuses on reducing waste, creating customer value and seeking continuous process improvement. Let’s delve into the five. Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material. Material Management Lean Manufacturing.

From www.scribd.com

Implementing a Methodology to Define Management Objectives and Material Management Lean Manufacturing Explore the six tried and tested lean manufacturing techniques which act as game changers in optimizing material flow. Lean manufacturing is a methodology that can help streamline and improve manufacturing processes or other services in order to provide enhanced benefits for. There are 5 principles of lean manufacturing. Lean manufacturing is a production system that focuses on reducing waste, creating. Material Management Lean Manufacturing.