Solder Mask Cleaning . Epoxy solder masks typically offer. For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals used during manufacturing and service. Uv curable solder mask is useful for creating own pcbs, since you can expose it through film with solder mask layer and wash out uncured areas afterwards. Several safe and reliable ways exist to remove solder masks from the circuit board surface. You'll want to agitate the pcb by shaking it back and forth in the container. Grinding, scraping, milling, microblasting, and chemical stripping are the most. Then, use a paper towel to scrub away any remaining. To improve soldermask adhesion and prevent related problems, consider these solutions: On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects.

from circuits-diy.com

Grinding, scraping, milling, microblasting, and chemical stripping are the most. For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. Uv curable solder mask is useful for creating own pcbs, since you can expose it through film with solder mask layer and wash out uncured areas afterwards. On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. Epoxy solder masks typically offer. You'll want to agitate the pcb by shaking it back and forth in the container. Then, use a paper towel to scrub away any remaining. Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals used during manufacturing and service. To improve soldermask adhesion and prevent related problems, consider these solutions: Several safe and reliable ways exist to remove solder masks from the circuit board surface.

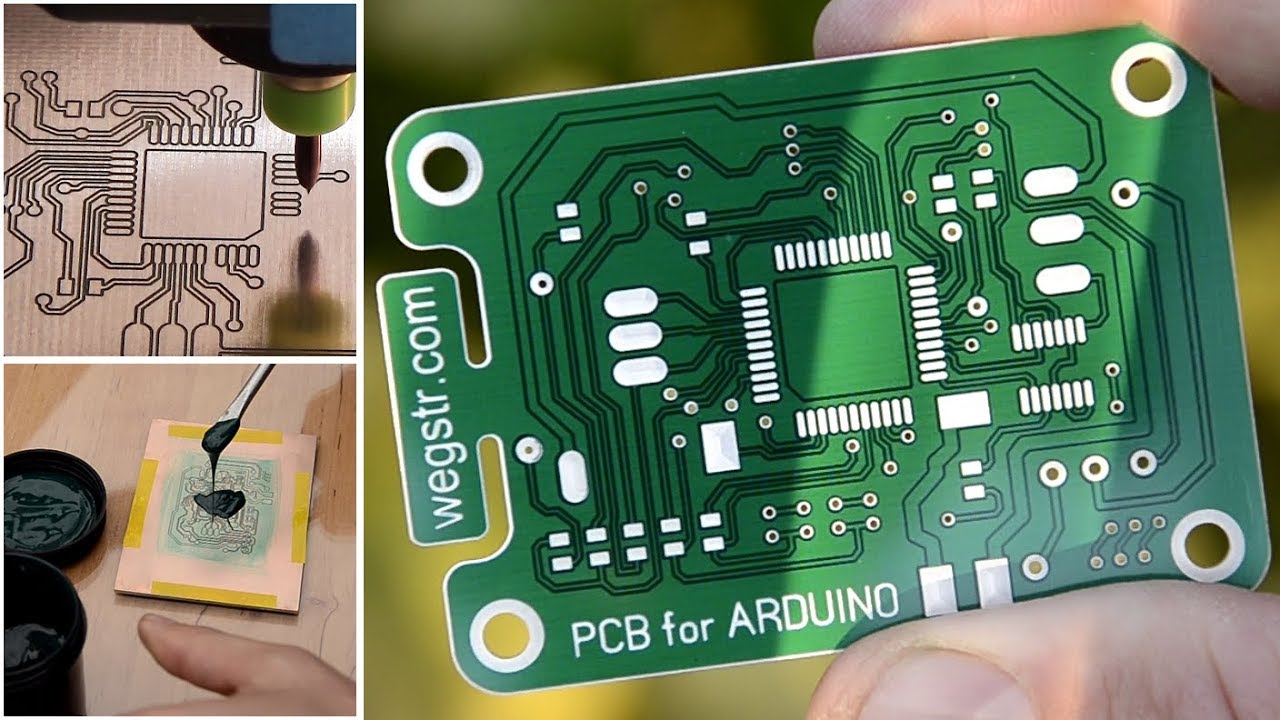

PCB Manufacturing Process A Complete Guide For Beginners

Solder Mask Cleaning Uv curable solder mask is useful for creating own pcbs, since you can expose it through film with solder mask layer and wash out uncured areas afterwards. Epoxy solder masks typically offer. You'll want to agitate the pcb by shaking it back and forth in the container. On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. Then, use a paper towel to scrub away any remaining. Grinding, scraping, milling, microblasting, and chemical stripping are the most. Several safe and reliable ways exist to remove solder masks from the circuit board surface. Uv curable solder mask is useful for creating own pcbs, since you can expose it through film with solder mask layer and wash out uncured areas afterwards. Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals used during manufacturing and service. For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. To improve soldermask adhesion and prevent related problems, consider these solutions:

From www.pcbacleaningmachine.com

PCB green mask ink special cleaning machine Naco3 liquid cleaning Solder Mask Cleaning You'll want to agitate the pcb by shaking it back and forth in the container. To improve soldermask adhesion and prevent related problems, consider these solutions: Then, use a paper towel to scrub away any remaining. Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals used during manufacturing and service. Grinding, scraping,. Solder Mask Cleaning.

From www.alibaba.com

Wondermask Water Washable Solder Mask 2205g Us Brand Noncorrosive Solder Mask Cleaning For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. Grinding, scraping, milling, microblasting, and chemical stripping are the most. On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. Uv curable solder mask is useful for creating own pcbs, since you. Solder Mask Cleaning.

From jensenglobal.com

Solder Mask System Jensen Global Solder Mask Cleaning To improve soldermask adhesion and prevent related problems, consider these solutions: Grinding, scraping, milling, microblasting, and chemical stripping are the most. Then, use a paper towel to scrub away any remaining. You'll want to agitate the pcb by shaking it back and forth in the container. Uv curable solder mask is useful for creating own pcbs, since you can expose. Solder Mask Cleaning.

From www.techspray.com

WonderMASK PX Peelable Solder Mask Techspray Solder Mask Cleaning Several safe and reliable ways exist to remove solder masks from the circuit board surface. For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. Look for a mask that can withstand. Solder Mask Cleaning.

From www.techspray.com

Techform TC533 Peelable Solder Mask Techspray Solder Mask Cleaning On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. You'll want to agitate the pcb by shaking it back and forth in the container. Several safe and reliable ways exist to remove solder masks from the circuit board surface. Look for a mask that can withstand exposure to. Solder Mask Cleaning.

From www.assemcorp.com

LDM Solder Mask AssemCorp Solder Mask Cleaning You'll want to agitate the pcb by shaking it back and forth in the container. Epoxy solder masks typically offer. On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. Uv curable solder mask is useful for creating own pcbs, since you can expose it through film with solder. Solder Mask Cleaning.

From www.chiptronics.com.my

Chemask Peelable Solder Mask Chiptronics (M) Sdn. Bhd. Solder Mask Cleaning Epoxy solder masks typically offer. Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals used during manufacturing and service. Several safe and reliable ways exist to remove solder masks from the circuit board surface. On occasion, solder mask will need to be removed from a printed circuit board in situations such as. Solder Mask Cleaning.

From asia.techspray.com

WonderMASK WSOL Washable Solder Mask Techspray Asia / Australia Solder Mask Cleaning Then, use a paper towel to scrub away any remaining. To improve soldermask adhesion and prevent related problems, consider these solutions: Several safe and reliable ways exist to remove solder masks from the circuit board surface. Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals used during manufacturing and service. For a. Solder Mask Cleaning.

From www.nextpcb.com

White Solder Mask NextPCB Solder Mask Cleaning You'll want to agitate the pcb by shaking it back and forth in the container. On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. Grinding, scraping, milling, microblasting, and chemical stripping are the most. Look for a mask that can withstand exposure to solder flux, solvents for cleaning,. Solder Mask Cleaning.

From www.elepcb.com

PCB Manufacturing Process A StepbyStep Guide ELEPCB Solder Mask Cleaning Then, use a paper towel to scrub away any remaining. You'll want to agitate the pcb by shaking it back and forth in the container. For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. Uv curable solder mask is useful for creating own pcbs, since you can expose it through film with. Solder Mask Cleaning.

From www.solder.net

Solder Mask Repair and Coating Services at BEST Inc Solder Mask Cleaning For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. Uv curable solder mask is useful for creating own pcbs, since you can expose it through film with solder mask layer and wash out uncured areas afterwards. Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other. Solder Mask Cleaning.

From www.techspray.com

How To Use Spot Mask for Wave Soldering & Conformal Coating Techspray Solder Mask Cleaning To improve soldermask adhesion and prevent related problems, consider these solutions: Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals used during manufacturing and service. Then, use a paper towel to scrub away any remaining. Several safe and reliable ways exist to remove solder masks from the circuit board surface. Grinding, scraping,. Solder Mask Cleaning.

From www.circuits-diy.com

PCB Solder Mask What is it & Why do you need it? Solder Mask Cleaning Several safe and reliable ways exist to remove solder masks from the circuit board surface. Grinding, scraping, milling, microblasting, and chemical stripping are the most. Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals used during manufacturing and service. Epoxy solder masks typically offer. You'll want to agitate the pcb by shaking. Solder Mask Cleaning.

From reversepcb.com

About Solder Mask All You Need to Know Solder Mask Cleaning Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals used during manufacturing and service. Epoxy solder masks typically offer. Grinding, scraping, milling, microblasting, and chemical stripping are the most. For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. You'll want to agitate the pcb. Solder Mask Cleaning.

From www.aimsolder.com

FluxCrazed Solder Mask AIM Solder Solder Mask Cleaning Uv curable solder mask is useful for creating own pcbs, since you can expose it through film with solder mask layer and wash out uncured areas afterwards. Grinding, scraping, milling, microblasting, and chemical stripping are the most. On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. You'll want. Solder Mask Cleaning.

From www.youtube.com

Ecospray manuale Solder mask spray YouTube Solder Mask Cleaning Epoxy solder masks typically offer. Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals used during manufacturing and service. To improve soldermask adhesion and prevent related problems, consider these solutions: For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. You'll want to agitate the. Solder Mask Cleaning.

From circuits-diy.com

PCB Manufacturing Process A Complete Guide For Beginners Solder Mask Cleaning On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. You'll want to agitate the pcb by shaking it back and forth in the container. Grinding, scraping, milling, microblasting, and chemical stripping are the most. Look for a mask that can withstand exposure to solder flux, solvents for cleaning,. Solder Mask Cleaning.

From pcbassemblymanufacturing.com

Solder mask on the PCB surface Solder Mask Cleaning Several safe and reliable ways exist to remove solder masks from the circuit board surface. Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals used during manufacturing and service. You'll want to agitate the pcb by shaking it back and forth in the container. To improve soldermask adhesion and prevent related problems,. Solder Mask Cleaning.

From www.protoexpress.com

What is Solder Mask Layer? Sierra Circuits Solder Mask Cleaning Grinding, scraping, milling, microblasting, and chemical stripping are the most. For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. Then, use a paper towel to scrub away any remaining. Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals used during manufacturing and service. Uv. Solder Mask Cleaning.

From www.nextpcb.com

Solder Mask Material Everything You Need to Know NextPCB Solder Mask Cleaning Several safe and reliable ways exist to remove solder masks from the circuit board surface. On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. To improve soldermask adhesion and prevent related problems, consider these solutions: Then, use a paper towel to scrub away any remaining. Look for a. Solder Mask Cleaning.

From www.tequipment.net

Techspray 2211G Wondermask Peelable Solder Mask, 1 Gal TEquipment Solder Mask Cleaning Uv curable solder mask is useful for creating own pcbs, since you can expose it through film with solder mask layer and wash out uncured areas afterwards. For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. Epoxy solder masks typically offer. On occasion, solder mask will need to be removed from a. Solder Mask Cleaning.

From www.chiptronics.com.my

Chemask Peelable Solder Mask Chiptronics (M) Sdn. Bhd. Solder Mask Cleaning Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals used during manufacturing and service. Then, use a paper towel to scrub away any remaining. Epoxy solder masks typically offer. You'll want to agitate the pcb by shaking it back and forth in the container. To improve soldermask adhesion and prevent related problems,. Solder Mask Cleaning.

From www.alibaba.com

Wondermask Wa Washable Solder Mask 2206g 1 Gallon Us Brand Non Solder Mask Cleaning To improve soldermask adhesion and prevent related problems, consider these solutions: You'll want to agitate the pcb by shaking it back and forth in the container. Then, use a paper towel to scrub away any remaining. Uv curable solder mask is useful for creating own pcbs, since you can expose it through film with solder mask layer and wash out. Solder Mask Cleaning.

From www.youtube.com

Make a PCB Solder Mask with LPKF ProMask YouTube Solder Mask Cleaning You'll want to agitate the pcb by shaking it back and forth in the container. Then, use a paper towel to scrub away any remaining. Several safe and reliable ways exist to remove solder masks from the circuit board surface. On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing. Solder Mask Cleaning.

From www.techsprayeu.com

How To Use Spot Mask for Wave Soldering & Conformal Coating Techspray Solder Mask Cleaning Epoxy solder masks typically offer. On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. To improve soldermask adhesion and prevent related problems, consider these solutions: Then, use a paper towel to scrub away any remaining. You'll want to agitate the pcb by shaking it back and forth in. Solder Mask Cleaning.

From www.chemtronics.com

Chemtronics Solder Mask Products Chemtronics Solder Mask Cleaning Several safe and reliable ways exist to remove solder masks from the circuit board surface. To improve soldermask adhesion and prevent related problems, consider these solutions: For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals. Solder Mask Cleaning.

From learn.adafruit.com

Overview How To Solder Mask PCBs Adafruit Learning System Solder Mask Cleaning To improve soldermask adhesion and prevent related problems, consider these solutions: You'll want to agitate the pcb by shaking it back and forth in the container. For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. Then, use a paper towel to scrub away any remaining. On occasion, solder mask will need to. Solder Mask Cleaning.

From www.linkedin.com

What is Peelable Solder Mask? Solder Mask Cleaning On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. Epoxy solder masks typically offer. Grinding, scraping, milling, microblasting, and chemical stripping are the most. You'll want to agitate the pcb by shaking it back and forth in the container. Then, use a paper towel to scrub away any. Solder Mask Cleaning.

From www.pcbaaa.com

PCB solder mask an ultimate guide for beginners IBE Electronics Solder Mask Cleaning For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. You'll want to agitate the pcb by shaking it back and forth in the container. To improve soldermask adhesion and prevent related problems, consider these solutions: Uv curable solder mask is useful for creating own pcbs, since you can expose it through film. Solder Mask Cleaning.

From www.youtube.com

PCB Solder Mask Removal Sandpaper 2 YouTube Solder Mask Cleaning Uv curable solder mask is useful for creating own pcbs, since you can expose it through film with solder mask layer and wash out uncured areas afterwards. On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. Look for a mask that can withstand exposure to solder flux, solvents. Solder Mask Cleaning.

From www.flickr.com

Removing solder mask Cleaning the corrosion on traces unde… Flickr Solder Mask Cleaning Uv curable solder mask is useful for creating own pcbs, since you can expose it through film with solder mask layer and wash out uncured areas afterwards. Grinding, scraping, milling, microblasting, and chemical stripping are the most. Look for a mask that can withstand exposure to solder flux, solvents for cleaning, and other chemicals used during manufacturing and service. Several. Solder Mask Cleaning.

From www.pcbaaa.com

PCB solder mask an ultimate guide for beginners IBE Electronics Solder Mask Cleaning To improve soldermask adhesion and prevent related problems, consider these solutions: For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. Uv curable solder mask is useful for creating own pcbs, since you can expose it through film with solder mask layer and wash out uncured areas afterwards. Grinding, scraping, milling, microblasting, and. Solder Mask Cleaning.

From www.youtube.com

How to remowe green solder mask easy with caustic soda! YouTube Solder Mask Cleaning On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. You'll want to agitate the pcb by shaking it back and forth in the container. Then, use a paper towel to scrub away any remaining. Epoxy solder masks typically offer. Several safe and reliable ways exist to remove solder. Solder Mask Cleaning.

From www.protoexpress.com

6 Common Solder Mask Errors in PCBs Sierra Circuits Solder Mask Cleaning On occasion, solder mask will need to be removed from a printed circuit board in situations such as board manufacturing defects. To improve soldermask adhesion and prevent related problems, consider these solutions: For a solder mask to adhere properly, the pcb surface must be clean and free of contaminants. Uv curable solder mask is useful for creating own pcbs, since. Solder Mask Cleaning.