Steel Angles In Bending . Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. This article describes the verification of steel members subject to shear, bending moments and axial forces. A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the included die angle to provide the needed. Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. The member must provide adequate compression, tension, bending. Bending is commonly used to describe the process for a tighter radius bend, whereas. The bending angle is the beginning angle to which the operator overbends so that the metal springs back to the desired bent angle.

from eziil.com

Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. The bending angle is the beginning angle to which the operator overbends so that the metal springs back to the desired bent angle. Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the included die angle to provide the needed. Bending is commonly used to describe the process for a tighter radius bend, whereas. This article describes the verification of steel members subject to shear, bending moments and axial forces. The member must provide adequate compression, tension, bending.

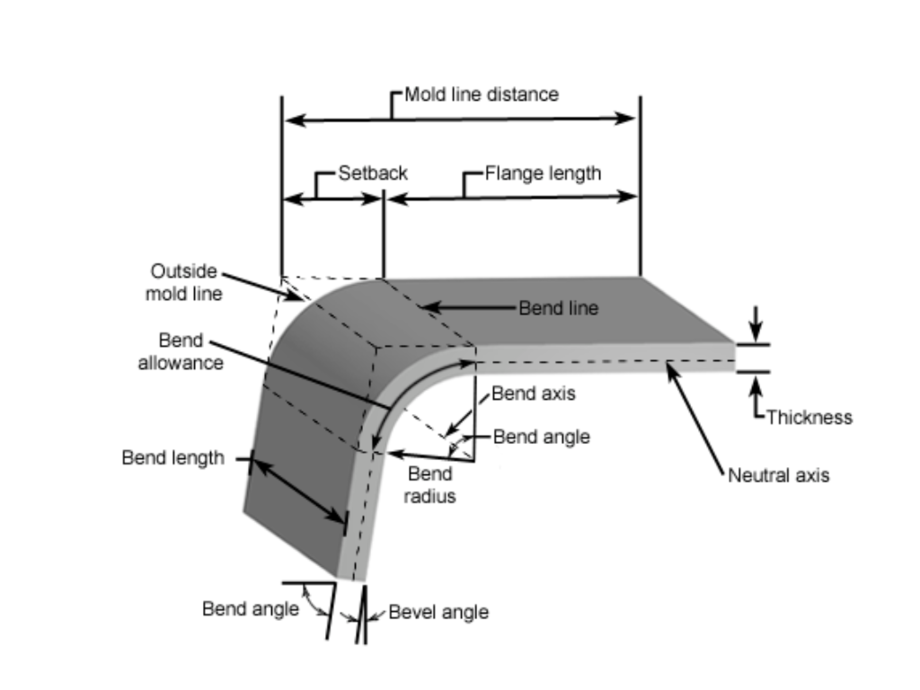

Sheet Metal Bend Radius Full Guide Chart

Steel Angles In Bending This article describes the verification of steel members subject to shear, bending moments and axial forces. The member must provide adequate compression, tension, bending. The bending angle is the beginning angle to which the operator overbends so that the metal springs back to the desired bent angle. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. This article describes the verification of steel members subject to shear, bending moments and axial forces. Bending is commonly used to describe the process for a tighter radius bend, whereas. A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the included die angle to provide the needed.

From a1roll.com

Angle Bending A1 Roll Company Steel Angles In Bending Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. The bending angle is the beginning angle to which the operator overbends so that the metal springs back to the desired bent angle. This article describes the verification of steel members subject to shear, bending moments and axial. Steel Angles In Bending.

From www.damatech.com

Hardox Bending Damatech Steel Angles In Bending Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. The member must provide adequate compression, tension, bending. A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the included die angle to provide the. Steel Angles In Bending.

From www.excelcalcs.com

Single Angle Bending with Torsion Steel Angles In Bending Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. This article describes the verification of steel members subject to shear, bending moments and axial forces. The bending angle is the beginning angle to which the operator overbends so that the metal springs back to the desired bent angle. Bend allowance (ba) ba. Steel Angles In Bending.

From www.appliedalloys.com.au

Standard Pipe Bends Dimensions Applied Alloys International Steel Angles In Bending The member must provide adequate compression, tension, bending. A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the included die angle to provide the needed. The bending angle is the beginning angle to which the operator overbends so that the metal. Steel Angles In Bending.

From www.youtube.com

Roll Bending of Steel Angle YouTube Steel Angles In Bending Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. This article describes the verification of steel members subject to shear, bending moments and axial forces. Bending is commonly used to describe the process for a tighter radius bend, whereas. The bending angle is the beginning angle to which the operator overbends so. Steel Angles In Bending.

From reganindustrial.com

Customized Angled Bar Bending Philippines Steel Angles In Bending Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. Bending is commonly used to describe the process for a tighter radius bend, whereas. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. The member must provide adequate compression, tension,. Steel Angles In Bending.

From marlynsanville.blogspot.com

How To Bend Angle Iron Into A Circle 1 Learn how to perfect each Steel Angles In Bending The bending angle is the beginning angle to which the operator overbends so that the metal springs back to the desired bent angle. The member must provide adequate compression, tension, bending. Bending is commonly used to describe the process for a tighter radius bend, whereas. Bending/rolling steel is the process of curving a steel member to a specified radius and. Steel Angles In Bending.

From www.maxweiss.com

Wide Flange Beam Bending, Rolling & Forming Structural Steel Bending Steel Angles In Bending The member must provide adequate compression, tension, bending. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. The bending angle is the beginning angle to which the operator overbends so that the metal springs back to the desired bent angle. Bending/rolling steel is the process of curving. Steel Angles In Bending.

From www.nssco.com

Structural Steel Angles North Shore Steel Steel Angles In Bending This article describes the verification of steel members subject to shear, bending moments and axial forces. A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the included die angle to provide the needed. The member must provide adequate compression, tension, bending.. Steel Angles In Bending.

From www.slideserve.com

PPT Design of Bending Members in Steel PowerPoint Presentation ID Steel Angles In Bending The member must provide adequate compression, tension, bending. Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. Bending is commonly used to describe the process for a tighter radius bend, whereas. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always. Steel Angles In Bending.

From heckmannbuildingprods.com

Bent Plate Professional Construction Masonry Tools Steel Angles In Bending Bending is commonly used to describe the process for a tighter radius bend, whereas. Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the. Steel Angles In Bending.

From www.protocase.co.uk

Sheet Metal Bending Tolerances Steel Angles In Bending Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the included die angle to provide the needed. Bending is commonly used to describe the. Steel Angles In Bending.

From dailycivil.com

How To Calculate Bend Deduction Length Of Bar Steel Angles In Bending The bending angle is the beginning angle to which the operator overbends so that the metal springs back to the desired bent angle. Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is. Steel Angles In Bending.

From www.smlease.com

Sheet Metal Bending Operation Types Methods and applications Steel Angles In Bending Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. The bending angle is the beginning angle to which the operator overbends so that the metal springs back to the desired bent angle. The member must provide adequate compression, tension, bending. Bending is commonly used to describe the. Steel Angles In Bending.

From metalmaq.shop

Metal sheet bending table Steel Angles In Bending A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the included die angle to provide the needed. This article describes the verification of steel members subject to shear, bending moments and axial forces. Bend allowance (ba) ba = [ (0.017453 ×. Steel Angles In Bending.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Steel Angles In Bending Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. This article describes the verification of steel members subject to shear, bending moments and axial forces. A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s. Steel Angles In Bending.

From www.lscmetalfab.com

Angle Bending Angle Rolling Steel Angles In Bending Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. The member must provide adequate compression, tension, bending. This article describes the verification of steel members subject to shear, bending moments and axial forces. Bending is commonly used to describe the process for a tighter radius bend, whereas.. Steel Angles In Bending.

From blog.projectmaterials.com

AISC/EN RSA Steel Angles for Structural Applications • Projectmaterials Steel Angles In Bending Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. Bending is commonly used to describe the process for a tighter radius bend, whereas. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. The bending angle is the beginning angle. Steel Angles In Bending.

From www.smlease.com

Sheet Metal KFactor, Bend Allowance and Flat Length Calculations Steel Angles In Bending This article describes the verification of steel members subject to shear, bending moments and axial forces. Bending is commonly used to describe the process for a tighter radius bend, whereas. Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. The bending angle is the beginning angle to which the operator overbends so. Steel Angles In Bending.

From www.merchantsfabrication.com

bending Archives Merchants Fabrication, Inc Steel Angles In Bending Bending is commonly used to describe the process for a tighter radius bend, whereas. This article describes the verification of steel members subject to shear, bending moments and axial forces. The bending angle is the beginning angle to which the operator overbends so that the metal springs back to the desired bent angle. Bend allowance (ba) ba = [ (0.017453. Steel Angles In Bending.

From www.pinterest.com

Angle Bending Chicago Metal Rolled Products Mechanical Design Steel Angles In Bending The member must provide adequate compression, tension, bending. The bending angle is the beginning angle to which the operator overbends so that the metal springs back to the desired bent angle. Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. A certain sheet metal workpiece may have, say, 2 degrees of springback,. Steel Angles In Bending.

From longero.com

Angle Iron Bending & Rolling Steel Angles In Bending Bending is commonly used to describe the process for a tighter radius bend, whereas. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. The member must provide adequate compression, tension, bending. A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a. Steel Angles In Bending.

From www.eng-tips.com

Steel Angle Bending/Splitting Structural engineering general Steel Angles In Bending Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. This article describes the verification of steel members subject to shear, bending moments and axial forces. The bending angle is the. Steel Angles In Bending.

From steelfabservices.com.au

Steel Angles Everything You Need To Know Steel Angles In Bending Bending is commonly used to describe the process for a tighter radius bend, whereas. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. This article describes the verification of steel members subject to shear, bending moments and axial forces. The member must provide adequate compression, tension, bending.. Steel Angles In Bending.

From www.pinterest.com

Bend, Iron, Easy, Steel Steel Angles In Bending This article describes the verification of steel members subject to shear, bending moments and axial forces. A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the included die angle to provide the needed. The member must provide adequate compression, tension, bending.. Steel Angles In Bending.

From www.nssco.com

Structural Steel Angles North Shore Steel Steel Angles In Bending Bending is commonly used to describe the process for a tighter radius bend, whereas. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. The member must provide adequate compression, tension,. Steel Angles In Bending.

From www.thefabricator.com

Precision sheet metal bending and the V groove Steel Angles In Bending A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the included die angle to provide the needed. Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. The member must provide adequate compression, tension,. Steel Angles In Bending.

From steelfabservices.com.au

Steel Angles Everything You Need To Know Steel Angles In Bending Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. The bending angle is the beginning angle to which the operator overbends so that the metal springs back to the desired bent angle. The member must provide adequate compression, tension, bending. This article describes the verification of steel members subject to shear, bending. Steel Angles In Bending.

From www.semanticscholar.org

[PDF] Bearing, Shear, and Torsion Capacities of Steel Angle Sections Steel Angles In Bending Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the included die angle to provide the needed. The member must provide adequate compression, tension,. Steel Angles In Bending.

From a1roll.com

Angle Bending A1 Roll Company Steel Angles In Bending A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the included die angle to provide the needed. The member must provide adequate compression, tension, bending. The bending angle is the beginning angle to which the operator overbends so that the metal. Steel Angles In Bending.

From www.komaspec.com

An Engineers’ Guide to Sheet Metal Bending & Laser Cutting Komaspec Steel Angles In Bending The bending angle is the beginning angle to which the operator overbends so that the metal springs back to the desired bent angle. A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the included die angle to provide the needed. Bending. Steel Angles In Bending.

From inchbyinch.de

INCH Technical English pictorial bending & drawing (sheet metal) Steel Angles In Bending The member must provide adequate compression, tension, bending. This article describes the verification of steel members subject to shear, bending moments and axial forces. Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. The bending angle is the beginning angle to which the operator overbends so that the metal springs back to. Steel Angles In Bending.

From www.mech4study.com

Different Sheet Metal Bending Process mech4study Steel Angles In Bending Bending is commonly used to describe the process for a tighter radius bend, whereas. This article describes the verification of steel members subject to shear, bending moments and axial forces. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. The member must provide adequate compression, tension, bending.. Steel Angles In Bending.

From www.eng-tips.com

Steel Angle Bending/Splitting Structural engineering general Steel Angles In Bending Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle. Steel Angles In Bending.

From marlynsanville.blogspot.com

How To Bend Angle Iron Into A Circle 1 Learn how to perfect each Steel Angles In Bending A certain sheet metal workpiece may have, say, 2 degrees of springback, so you need a punch with minimum included angle that’s at least 2 degrees less than the included die angle to provide the needed. Bending is commonly used to describe the process for a tighter radius bend, whereas. The bending angle is the beginning angle to which the. Steel Angles In Bending.