Tap Vs Rigid Tap . As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used before the tap starts to cut. Tapping tools are divided into four types: What are the advantages of rigid tapping? Straight flute tap, spiral point tap, spiral fuse tap, and forming tap. Produces internal threads in holes. Chips are produced and must be removed. High quality rigid holders cost less than high quality tension compression holders. Rigid tapping is the second most common method of tapping on the mill. Prepares the hole for tapping by creating the right size for the tap to enter and cut threads. Which type you use depends on what type of hole you want to thread, blind hole or. Tapping cuts material away from the hole, which generates chips that must be evacuated. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle.

from www.promaxxtool.com

Tapping cuts material away from the hole, which generates chips that must be evacuated. What are the advantages of rigid tapping? Produces internal threads in holes. Tapping tools are divided into four types: Prepares the hole for tapping by creating the right size for the tap to enter and cut threads. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. High quality rigid holders cost less than high quality tension compression holders. Rigid tapping is the second most common method of tapping on the mill. Which type you use depends on what type of hole you want to thread, blind hole or. As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used before the tap starts to cut.

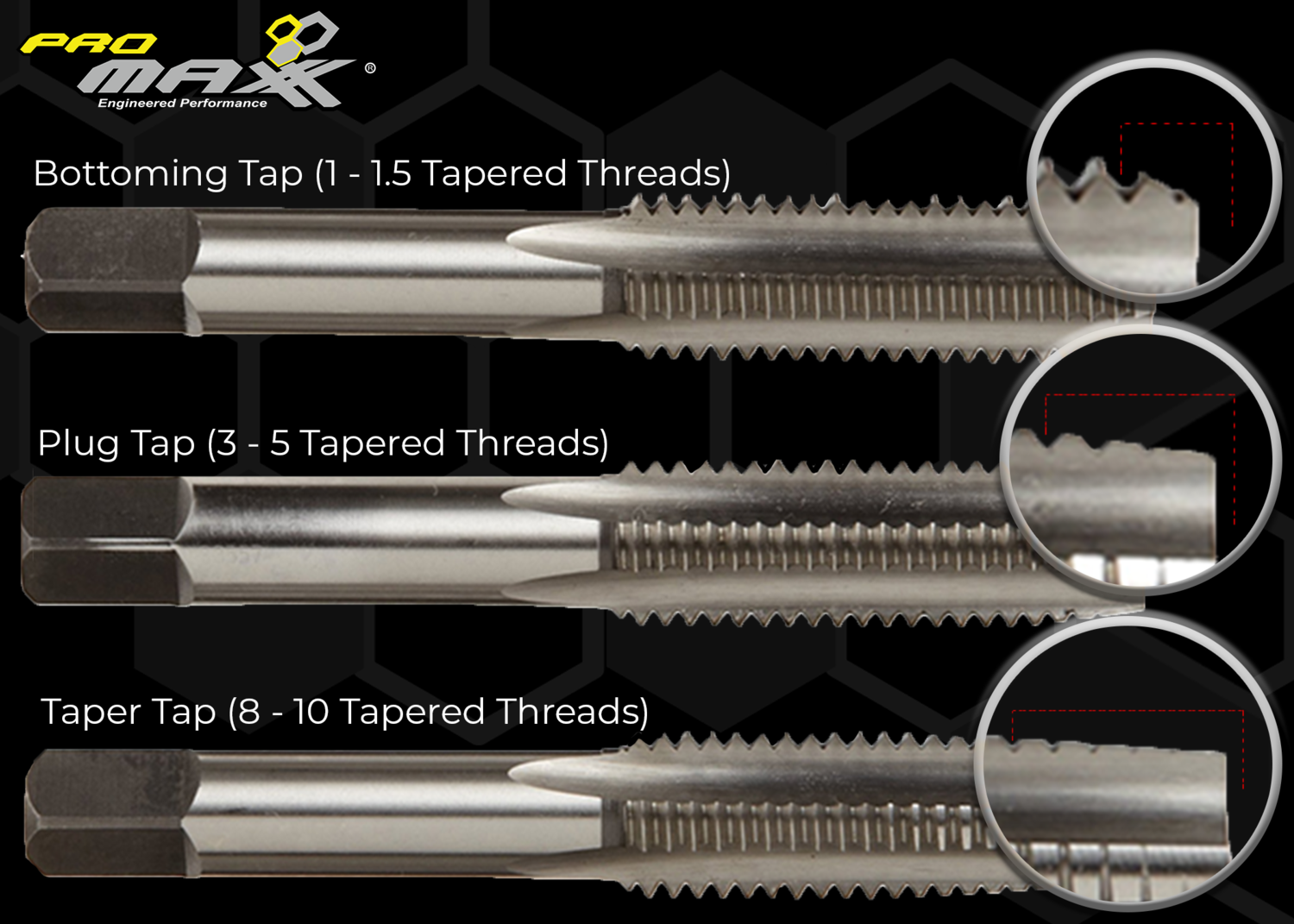

Different Types of Taps and When to Use Them ProMAXX Tool

Tap Vs Rigid Tap High quality rigid holders cost less than high quality tension compression holders. As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used before the tap starts to cut. Tapping tools are divided into four types: Which type you use depends on what type of hole you want to thread, blind hole or. Produces internal threads in holes. What are the advantages of rigid tapping? Straight flute tap, spiral point tap, spiral fuse tap, and forming tap. Chips are produced and must be removed. High quality rigid holders cost less than high quality tension compression holders. Prepares the hole for tapping by creating the right size for the tap to enter and cut threads. Tapping cuts material away from the hole, which generates chips that must be evacuated. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. Rigid tapping is the second most common method of tapping on the mill.

From www.cncmasters.com

Rigid Tapping AddOn for CNC Milling Machines CNC Masters Tap Vs Rigid Tap Which type you use depends on what type of hole you want to thread, blind hole or. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. Straight flute tap, spiral point tap, spiral fuse tap, and forming tap. High quality rigid holders cost less than high quality tension compression holders. As a. Tap Vs Rigid Tap.

From www.youtube.com

constant speed vs rigid tapping YouTube Tap Vs Rigid Tap Which type you use depends on what type of hole you want to thread, blind hole or. Straight flute tap, spiral point tap, spiral fuse tap, and forming tap. High quality rigid holders cost less than high quality tension compression holders. Prepares the hole for tapping by creating the right size for the tap to enter and cut threads. Chips. Tap Vs Rigid Tap.

From www.youtube.com

Rigid Tap YouTube Tap Vs Rigid Tap Chips are produced and must be removed. What are the advantages of rigid tapping? Straight flute tap, spiral point tap, spiral fuse tap, and forming tap. Produces internal threads in holes. Rigid tapping is the second most common method of tapping on the mill. Tapping cuts material away from the hole, which generates chips that must be evacuated. Prepares the. Tap Vs Rigid Tap.

From www.kroger.com

Ridgid Tap,1/4 NPT E5113 E5113, 1 Kroger Tap Vs Rigid Tap Straight flute tap, spiral point tap, spiral fuse tap, and forming tap. Chips are produced and must be removed. Tapping cuts material away from the hole, which generates chips that must be evacuated. Tapping tools are divided into four types: Rigid tapping is the second most common method of tapping on the mill. High quality rigid holders cost less than. Tap Vs Rigid Tap.

From breakingfreemediation.com

Thread Chaser vs Tap A Difference Guide Breaking Free Mediation Tap Vs Rigid Tap Rigid tapping is the second most common method of tapping on the mill. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used before the tap starts. Tap Vs Rigid Tap.

From www.youtube.com

Tap typesTaper, Plug, Bottoming YouTube Tap Vs Rigid Tap Straight flute tap, spiral point tap, spiral fuse tap, and forming tap. Prepares the hole for tapping by creating the right size for the tap to enter and cut threads. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. High quality rigid holders cost less than high quality tension compression holders. Produces. Tap Vs Rigid Tap.

From einvoice.fpt.com.vn

A Complete Guide On Types Of Taps For Threading WayKen, 45 OFF Tap Vs Rigid Tap Chips are produced and must be removed. Rigid tapping is the second most common method of tapping on the mill. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. Tapping tools are divided into four types: High quality rigid holders cost less than high quality tension compression holders. As a tap becomes. Tap Vs Rigid Tap.

From martinsupply.com

Cut Taps vs. Roll Taps What is the difference? Martin Supply Tap Vs Rigid Tap Tapping tools are divided into four types: Chips are produced and must be removed. High quality rigid holders cost less than high quality tension compression holders. What are the advantages of rigid tapping? Rigid tapping is the second most common method of tapping on the mill. With this technique the tap is clamped in the spindle and threaded into the. Tap Vs Rigid Tap.

From www.youtube.com

TAP DIFFERENCE BETWEEN CUT & ROLL TAP in hindi YouTube Tap Vs Rigid Tap As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used before the tap starts to cut. Tapping tools are divided into four types: Produces internal threads in holes. Which type you use depends on what type of hole you want to thread, blind hole. Tap Vs Rigid Tap.

From dropbymyhouse.com

Faucet vs Tap Tap Vs Rigid Tap Which type you use depends on what type of hole you want to thread, blind hole or. Tapping tools are divided into four types: Rigid tapping is the second most common method of tapping on the mill. What are the advantages of rigid tapping? High quality rigid holders cost less than high quality tension compression holders. Straight flute tap, spiral. Tap Vs Rigid Tap.

From lessonlangdonslurp.z21.web.core.windows.net

Salt Water Vs Tap Water Project Class 12 Tap Vs Rigid Tap Straight flute tap, spiral point tap, spiral fuse tap, and forming tap. Rigid tapping is the second most common method of tapping on the mill. Which type you use depends on what type of hole you want to thread, blind hole or. High quality rigid holders cost less than high quality tension compression holders. As a tap becomes dull, the. Tap Vs Rigid Tap.

From www.walmart.com

Ridgid Tap, 1/2 Npt E5115 E5115 Tap Vs Rigid Tap With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. Chips are produced and must be removed. Straight flute tap, spiral point tap, spiral fuse tap, and forming tap. Produces internal threads in holes. Rigid tapping is the second most common method of tapping on the mill. Which type you use depends on. Tap Vs Rigid Tap.

From www.youtube.com

Rigid Tap Existing Holes VF2SSYT & Renishaw Probe YouTube Tap Vs Rigid Tap What are the advantages of rigid tapping? Tapping cuts material away from the hole, which generates chips that must be evacuated. High quality rigid holders cost less than high quality tension compression holders. Prepares the hole for tapping by creating the right size for the tap to enter and cut threads. Straight flute tap, spiral point tap, spiral fuse tap,. Tap Vs Rigid Tap.

From www.mrkitchenfaucets.com

Faucets Vs. Taps Which One Is Right For You? Mr. Kitchen Faucets Tap Vs Rigid Tap What are the advantages of rigid tapping? As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used before the tap starts to cut. Rigid tapping is the second most common method of tapping on the mill. Produces internal threads in holes. Which type you. Tap Vs Rigid Tap.

From www.cutwel.co.uk

Roll Tapping vs Conventional (Cut) Tapping Cutwel Ltd Tap Vs Rigid Tap Prepares the hole for tapping by creating the right size for the tap to enter and cut threads. What are the advantages of rigid tapping? Rigid tapping is the second most common method of tapping on the mill. Which type you use depends on what type of hole you want to thread, blind hole or. Chips are produced and must. Tap Vs Rigid Tap.

From www.youtube.com

Rigid tap done! YouTube Tap Vs Rigid Tap As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used before the tap starts to cut. Prepares the hole for tapping by creating the right size for the tap to enter and cut threads. High quality rigid holders cost less than high quality tension. Tap Vs Rigid Tap.

From www.youtube.com

Mach3 Rigid Tap YouTube Tap Vs Rigid Tap Tapping cuts material away from the hole, which generates chips that must be evacuated. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. What are the advantages of rigid tapping? Rigid tapping is the second most common method of tapping on the mill. Which type you use depends on what type of. Tap Vs Rigid Tap.

From www.optcuttingtools.com

News The classification of Taps requires reasonable selection to Tap Vs Rigid Tap High quality rigid holders cost less than high quality tension compression holders. Chips are produced and must be removed. Tapping tools are divided into four types: Prepares the hole for tapping by creating the right size for the tap to enter and cut threads. Tapping cuts material away from the hole, which generates chips that must be evacuated. Which type. Tap Vs Rigid Tap.

From www.cutwel.co.uk

Roll Tapping vs Conventional (Cut) Tapping Cutwel Ltd Tap Vs Rigid Tap Produces internal threads in holes. As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used before the tap starts to cut. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. What are the advantages of rigid. Tap Vs Rigid Tap.

From www.carbideanddiamondtooling.com

ER20 Rigid Tap Collets 1/8 5/32 7/32 5/16 7/16 1/2 Inch Tap Size ID 17921 Tap Vs Rigid Tap What are the advantages of rigid tapping? Rigid tapping is the second most common method of tapping on the mill. Chips are produced and must be removed. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. Tapping tools are divided into four types: Which type you use depends on what type of. Tap Vs Rigid Tap.

From eezee.com.my

Ridgid Tap 1 "Npt E5117 35840 Eezee Tap Vs Rigid Tap Rigid tapping is the second most common method of tapping on the mill. Tapping cuts material away from the hole, which generates chips that must be evacuated. What are the advantages of rigid tapping? As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used. Tap Vs Rigid Tap.

From www.grainger.com

RIDGID, Tap, 1/4 NPT E5113 25XC73E5113 Grainger Tap Vs Rigid Tap High quality rigid holders cost less than high quality tension compression holders. Prepares the hole for tapping by creating the right size for the tap to enter and cut threads. As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used before the tap starts. Tap Vs Rigid Tap.

From www.tmsmith.com

Tap Holders Standard & Custom Tap Holders TM Smith Tool Tap Vs Rigid Tap High quality rigid holders cost less than high quality tension compression holders. Rigid tapping is the second most common method of tapping on the mill. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. Produces internal threads in holes. Which type you use depends on what type of hole you want to. Tap Vs Rigid Tap.

From www.youtube.com

Hand tap VS Machine tap YouTube Tap Vs Rigid Tap Tapping cuts material away from the hole, which generates chips that must be evacuated. High quality rigid holders cost less than high quality tension compression holders. Rigid tapping is the second most common method of tapping on the mill. Prepares the hole for tapping by creating the right size for the tap to enter and cut threads. Chips are produced. Tap Vs Rigid Tap.

From www.lazada.co.id

RIDGID 35815 Hand Tap 1/8" Npt E5112 E5112 Handtap Pipe Tap Ridgid Ori Tap Vs Rigid Tap Which type you use depends on what type of hole you want to thread, blind hole or. Tapping tools are divided into four types: Chips are produced and must be removed. As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used before the tap. Tap Vs Rigid Tap.

From www.classiccarrestorationclub.com

Cutting Threads An Introduction to Using a Tap to Thread Bolt Holes Tap Vs Rigid Tap Rigid tapping is the second most common method of tapping on the mill. High quality rigid holders cost less than high quality tension compression holders. As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used before the tap starts to cut. Straight flute tap,. Tap Vs Rigid Tap.

From www.jarviscuttingtools.com

Forming Taps Jarvis Cutting Tools Tap Vs Rigid Tap Straight flute tap, spiral point tap, spiral fuse tap, and forming tap. Rigid tapping is the second most common method of tapping on the mill. Tapping tools are divided into four types: Produces internal threads in holes. High quality rigid holders cost less than high quality tension compression holders. Prepares the hole for tapping by creating the right size for. Tap Vs Rigid Tap.

From www.velosolar.com

Line Side Tap vs. Load Side Tap Everything You Need To Know Tap Vs Rigid Tap Produces internal threads in holes. High quality rigid holders cost less than high quality tension compression holders. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used. Tap Vs Rigid Tap.

From www.promaxxtool.com

Different Types of Taps and When to Use Them ProMAXX Tool Tap Vs Rigid Tap Chips are produced and must be removed. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. Rigid tapping is the second most common method of tapping on the mill. Straight flute tap, spiral point tap, spiral fuse tap, and forming tap. Prepares the hole for tapping by creating the right size for. Tap Vs Rigid Tap.

From techniks.fotcnc.com

CAT 50 Rigid Tap 1 1 Rigid Tap Holders Rigid Tap Holders Tap Vs Rigid Tap Produces internal threads in holes. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. Tapping tools are divided into four types: As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used before the tap starts to. Tap Vs Rigid Tap.

From www.machinemfg.com

Tapping Types, Selection, and Skills Explained MachineMFG Tap Vs Rigid Tap Prepares the hole for tapping by creating the right size for the tap to enter and cut threads. High quality rigid holders cost less than high quality tension compression holders. Chips are produced and must be removed. Tapping cuts material away from the hole, which generates chips that must be evacuated. Which type you use depends on what type of. Tap Vs Rigid Tap.

From www.kroger.com

Ridgid Tap, 1/2 Npt E5115 E5115, 1 Kroger Tap Vs Rigid Tap Tapping cuts material away from the hole, which generates chips that must be evacuated. Prepares the hole for tapping by creating the right size for the tap to enter and cut threads. Which type you use depends on what type of hole you want to thread, blind hole or. What are the advantages of rigid tapping? High quality rigid holders. Tap Vs Rigid Tap.

From wiredatathinngk.z21.web.core.windows.net

Standard Metric Tap Sizes Tap Vs Rigid Tap Chips are produced and must be removed. As a tap becomes dull, the pressure needed to start the tap into the hole increases, and more compression stroke within the tap driver is used before the tap starts to cut. Rigid tapping is the second most common method of tapping on the mill. Straight flute tap, spiral point tap, spiral fuse. Tap Vs Rigid Tap.

From www.jarviscuttingtools.com

Cutting Taps vs. Forming Taps Difference Jarvis Tap Vs Rigid Tap Straight flute tap, spiral point tap, spiral fuse tap, and forming tap. Prepares the hole for tapping by creating the right size for the tap to enter and cut threads. Rigid tapping is the second most common method of tapping on the mill. Which type you use depends on what type of hole you want to thread, blind hole or.. Tap Vs Rigid Tap.

From www.carbideanddiamondtooling.com

ER32 Rigid Tap Collets M3 M27 Metric Tap Size ID 17929 Tap Vs Rigid Tap Rigid tapping is the second most common method of tapping on the mill. Produces internal threads in holes. With this technique the tap is clamped in the spindle and threaded into the workpiece under spindle. What are the advantages of rigid tapping? Prepares the hole for tapping by creating the right size for the tap to enter and cut threads.. Tap Vs Rigid Tap.