Injection Molding Cushion Variation . in injection molding, the term “cushion” refers to a small amount of molten plastic material that is intentionally left in. though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. learn how to increase cushion injection molding in polymers for improved product quality and efficiency. the cushion will vary over time…and many companies will set a variation of approx. there are two definitions (see what i mean?) for cushion in molding: learn what cushion is and why it is important for injection molding. This paper analyzes the process variable data from injection molding processes to. cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. Find out how to troubleshoot and fix common issues with cushion, such as.

from www.rdray.com

though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. This paper analyzes the process variable data from injection molding processes to. learn how to increase cushion injection molding in polymers for improved product quality and efficiency. there are two definitions (see what i mean?) for cushion in molding: in injection molding, the term “cushion” refers to a small amount of molten plastic material that is intentionally left in. Find out how to troubleshoot and fix common issues with cushion, such as. cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. learn what cushion is and why it is important for injection molding. the cushion will vary over time…and many companies will set a variation of approx.

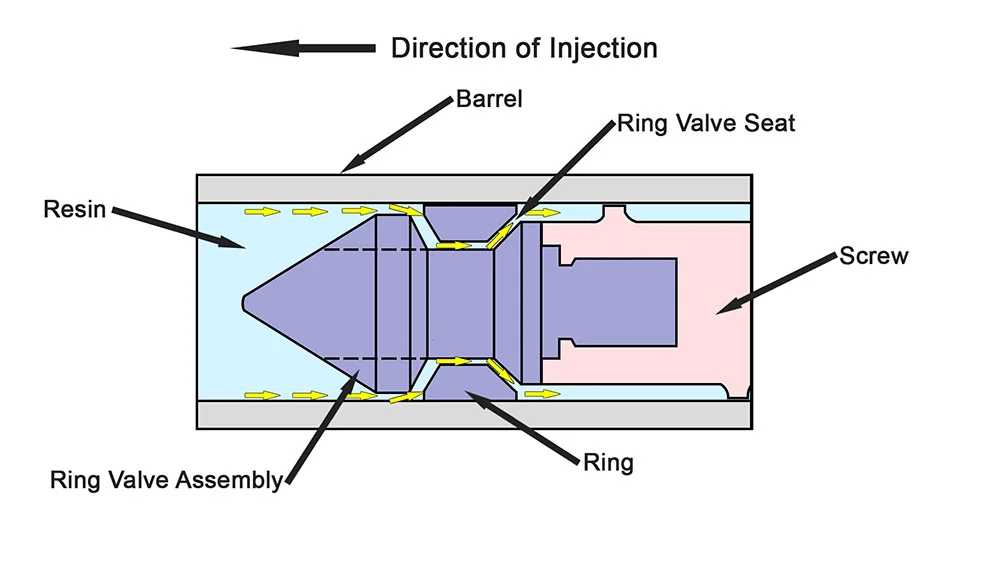

Types of Injection Molding Valves R. DRAY MFG.

Injection Molding Cushion Variation Find out how to troubleshoot and fix common issues with cushion, such as. This paper analyzes the process variable data from injection molding processes to. cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. learn how to increase cushion injection molding in polymers for improved product quality and efficiency. the cushion will vary over time…and many companies will set a variation of approx. in injection molding, the term “cushion” refers to a small amount of molten plastic material that is intentionally left in. there are two definitions (see what i mean?) for cushion in molding: Find out how to troubleshoot and fix common issues with cushion, such as. learn what cushion is and why it is important for injection molding.

From www.youtube.com

What Is Cushion In Injection Mouldine Machine?Cushion In Injection Injection Molding Cushion Variation Find out how to troubleshoot and fix common issues with cushion, such as. This paper analyzes the process variable data from injection molding processes to. the cushion will vary over time…and many companies will set a variation of approx. learn what cushion is and why it is important for injection molding. cushion values in injection molding ultimately. Injection Molding Cushion Variation.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Injection Molding Cushion Variation in injection molding, the term “cushion” refers to a small amount of molten plastic material that is intentionally left in. Find out how to troubleshoot and fix common issues with cushion, such as. the cushion will vary over time…and many companies will set a variation of approx. though it is important to monitor peak shot volume to. Injection Molding Cushion Variation.

From www.slideserve.com

PPT Injection Molding China How Does It Work? PowerPoint Injection Molding Cushion Variation though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. the cushion will vary over time…and many companies will set a variation of approx. This paper analyzes the process variable data from injection molding processes to. Find out how to troubleshoot and. Injection Molding Cushion Variation.

From www.plasticmoulds.net

Proceso de moldeo por inyección Topworks Plastic Molding Injection Molding Cushion Variation there are two definitions (see what i mean?) for cushion in molding: the cushion will vary over time…and many companies will set a variation of approx. Find out how to troubleshoot and fix common issues with cushion, such as. learn how to increase cushion injection molding in polymers for improved product quality and efficiency. learn what. Injection Molding Cushion Variation.

From www.pinterest.com

What is Plastic Injection Molding? Plastic injection molding, Plastic Injection Molding Cushion Variation there are two definitions (see what i mean?) for cushion in molding: though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. This paper analyzes the process variable data from injection molding processes to. learn what cushion is and why it. Injection Molding Cushion Variation.

From www.youtube.com

What is Cushion, What is plasticizing capacity in injection molding Injection Molding Cushion Variation Find out how to troubleshoot and fix common issues with cushion, such as. though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. This paper analyzes the process variable data from injection molding processes to. cushion values in injection molding ultimately are. Injection Molding Cushion Variation.

From upmold.com

Automotive Cushion Plastic Mold Custom Manufacturer Upmold Injection Molding Cushion Variation there are two definitions (see what i mean?) for cushion in molding: learn what cushion is and why it is important for injection molding. learn how to increase cushion injection molding in polymers for improved product quality and efficiency. cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. This. Injection Molding Cushion Variation.

From knowledge.ulprospector.com

Injection moulding the role of backpressure Prospector Injection Molding Cushion Variation learn what cushion is and why it is important for injection molding. the cushion will vary over time…and many companies will set a variation of approx. learn how to increase cushion injection molding in polymers for improved product quality and efficiency. Find out how to troubleshoot and fix common issues with cushion, such as. cushion values. Injection Molding Cushion Variation.

From themechanicalengineering.com

Injection Molding Definition, Construction, Working Process Injection Molding Cushion Variation learn how to increase cushion injection molding in polymers for improved product quality and efficiency. learn what cushion is and why it is important for injection molding. This paper analyzes the process variable data from injection molding processes to. cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. though. Injection Molding Cushion Variation.

From www.clf.com.tw

5 Essential Features of Injection Molding Machine Automakers Need to Injection Molding Cushion Variation This paper analyzes the process variable data from injection molding processes to. learn what cushion is and why it is important for injection molding. the cushion will vary over time…and many companies will set a variation of approx. there are two definitions (see what i mean?) for cushion in molding: in injection molding, the term “cushion”. Injection Molding Cushion Variation.

From cflmolding.com

Resin Molding Technology Injection Molding and Compression Molding Injection Molding Cushion Variation though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. This paper analyzes the process variable data from injection molding processes to. Find out how to troubleshoot and fix common issues with cushion, such as. in injection molding, the term “cushion” refers. Injection Molding Cushion Variation.

From www.youtube.com

Cushion in Injection Moulding इंजेक्शन मोल्ड़िंग में Cushion क्या Injection Molding Cushion Variation Find out how to troubleshoot and fix common issues with cushion, such as. though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. there are. Injection Molding Cushion Variation.

From www.lsr-molding.com

LSR Mold Design Guide Liquid Silicone Rubber Injection Molding Injection Molding Cushion Variation there are two definitions (see what i mean?) for cushion in molding: learn how to increase cushion injection molding in polymers for improved product quality and efficiency. learn what cushion is and why it is important for injection molding. in injection molding, the term “cushion” refers to a small amount of molten plastic material that is. Injection Molding Cushion Variation.

From www.youtube.com

Cushion in injection molding Roles And importance explained in Tamil Injection Molding Cushion Variation learn what cushion is and why it is important for injection molding. there are two definitions (see what i mean?) for cushion in molding: though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. the cushion will vary over time…and. Injection Molding Cushion Variation.

From www.rdray.com

Types of Injection Molding Valves R. DRAY MFG. Injection Molding Cushion Variation learn what cushion is and why it is important for injection molding. This paper analyzes the process variable data from injection molding processes to. though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. there are two definitions (see what i. Injection Molding Cushion Variation.

From www.rdray.com

Types of Injection Molding Valves R. DRAY MFG. Injection Molding Cushion Variation Find out how to troubleshoot and fix common issues with cushion, such as. the cushion will vary over time…and many companies will set a variation of approx. in injection molding, the term “cushion” refers to a small amount of molten plastic material that is intentionally left in. learn how to increase cushion injection molding in polymers for. Injection Molding Cushion Variation.

From www.ptonline.com

Understanding Fountain Flow in Injection Molding Plastics Technology Injection Molding Cushion Variation in injection molding, the term “cushion” refers to a small amount of molten plastic material that is intentionally left in. learn how to increase cushion injection molding in polymers for improved product quality and efficiency. the cushion will vary over time…and many companies will set a variation of approx. learn what cushion is and why it. Injection Molding Cushion Variation.

From exoiisphe.blob.core.windows.net

How Many Types Of Nozzle In Injection Moulding Machine at Larry Wicker blog Injection Molding Cushion Variation learn how to increase cushion injection molding in polymers for improved product quality and efficiency. in injection molding, the term “cushion” refers to a small amount of molten plastic material that is intentionally left in. This paper analyzes the process variable data from injection molding processes to. the cushion will vary over time…and many companies will set. Injection Molding Cushion Variation.

From www.alibaba.com

Custom Size Full Face Cpap Mask Cushion By Silicone Injection Mold Injection Molding Cushion Variation learn how to increase cushion injection molding in polymers for improved product quality and efficiency. there are two definitions (see what i mean?) for cushion in molding: Find out how to troubleshoot and fix common issues with cushion, such as. though it is important to monitor peak shot volume to ensure you are injecting the same amount. Injection Molding Cushion Variation.

From www.diytrade.com

CPAP Mask Cushion Liquid Silcone Rubber LSR Injection Molding BT Injection Molding Cushion Variation the cushion will vary over time…and many companies will set a variation of approx. learn how to increase cushion injection molding in polymers for improved product quality and efficiency. there are two definitions (see what i mean?) for cushion in molding: cushion values in injection molding ultimately are an indication of a part’s quality, especially its. Injection Molding Cushion Variation.

From www.shidarubber.com

Rubber Compression and Injection Molding Process Hebei Shida Seal Injection Molding Cushion Variation Find out how to troubleshoot and fix common issues with cushion, such as. learn how to increase cushion injection molding in polymers for improved product quality and efficiency. though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. cushion values in. Injection Molding Cushion Variation.

From cezeabjz.blob.core.windows.net

Explain Injection Moulding Process at Carol Hutchinson blog Injection Molding Cushion Variation there are two definitions (see what i mean?) for cushion in molding: learn how to increase cushion injection molding in polymers for improved product quality and efficiency. though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. cushion values in. Injection Molding Cushion Variation.

From www.ecplaza.net

Liquid Silicone Mask Cushion Liquid Silicone Rubber LSR Injection Injection Molding Cushion Variation learn what cushion is and why it is important for injection molding. This paper analyzes the process variable data from injection molding processes to. the cushion will vary over time…and many companies will set a variation of approx. learn how to increase cushion injection molding in polymers for improved product quality and efficiency. Find out how to. Injection Molding Cushion Variation.

From hroms.com

Brig Diacritical at least cushion in injection molding Stare Need Injection Molding Cushion Variation learn how to increase cushion injection molding in polymers for improved product quality and efficiency. This paper analyzes the process variable data from injection molding processes to. though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. learn what cushion is. Injection Molding Cushion Variation.

From www.cdn-inc.com

Plastic Injection Molding Process Guide 2019 Full Process Explained Injection Molding Cushion Variation learn how to increase cushion injection molding in polymers for improved product quality and efficiency. cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. in injection molding, the term “cushion” refers to a small amount of molten plastic material that is intentionally left in. the cushion will vary over. Injection Molding Cushion Variation.

From vientrinh.com

INJECTION MOLDING ‘CUSHION’ Be Silent Injection Molding Cushion Variation learn what cushion is and why it is important for injection molding. there are two definitions (see what i mean?) for cushion in molding: learn how to increase cushion injection molding in polymers for improved product quality and efficiency. though it is important to monitor peak shot volume to ensure you are injecting the same amount. Injection Molding Cushion Variation.

From www.youtube.com

MELT CUSHION INJECTION MOLDING YouTube Injection Molding Cushion Variation the cushion will vary over time…and many companies will set a variation of approx. learn what cushion is and why it is important for injection molding. though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. Find out how to troubleshoot. Injection Molding Cushion Variation.

From www.asaclean.com

Injection Molding FAQ What is Cushion & why do I need to hold it? Injection Molding Cushion Variation learn what cushion is and why it is important for injection molding. Find out how to troubleshoot and fix common issues with cushion, such as. learn how to increase cushion injection molding in polymers for improved product quality and efficiency. there are two definitions (see what i mean?) for cushion in molding: the cushion will vary. Injection Molding Cushion Variation.

From www.youtube.com

What Is The Work Of Cushion In Injection Molding Machine What Cushion Injection Molding Cushion Variation the cushion will vary over time…and many companies will set a variation of approx. there are two definitions (see what i mean?) for cushion in molding: learn what cushion is and why it is important for injection molding. This paper analyzes the process variable data from injection molding processes to. Find out how to troubleshoot and fix. Injection Molding Cushion Variation.

From www.semanticscholar.org

[PDF] EVALUATION OF THE CUSHIONS EFFECT ON PROCESS CONSISTENCY AND Injection Molding Cushion Variation cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. learn what cushion is and why it is important for injection molding. there are two definitions (see what i mean?) for cushion in molding: learn how to increase cushion injection molding in polymers for improved product quality and efficiency. . Injection Molding Cushion Variation.

From www.beaumontinc.com

Cushion Injection Molding Beaumont Beaumont Technologies, Inc. Injection Molding Cushion Variation This paper analyzes the process variable data from injection molding processes to. though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. in injection molding,. Injection Molding Cushion Variation.

From www.youtube.com

Injection Molding 101 Undercuts YouTube Injection Molding Cushion Variation learn what cushion is and why it is important for injection molding. there are two definitions (see what i mean?) for cushion in molding: the cushion will vary over time…and many companies will set a variation of approx. Find out how to troubleshoot and fix common issues with cushion, such as. learn how to increase cushion. Injection Molding Cushion Variation.

From www.moldplasticinjection.com

How To Reduce Injection Molding Costs 9 MoneySaving Tips Injection Molding Cushion Variation the cushion will vary over time…and many companies will set a variation of approx. learn what cushion is and why it is important for injection molding. though it is important to monitor peak shot volume to ensure you are injecting the same amount of material into the mould every time, a melt. cushion values in injection. Injection Molding Cushion Variation.

From www.diytrade.com

CPAP Mask Cushion Liquid Silcone Rubber LSR Injection Molding BT Injection Molding Cushion Variation cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. there are two definitions (see what i mean?) for cushion in molding: learn what cushion is and why it is important for injection molding. learn how to increase cushion injection molding in polymers for improved product quality and efficiency. . Injection Molding Cushion Variation.

From ceqlgmhp.blob.core.windows.net

Injection Moulding Tool Design Pdf at Ronald blog Injection Molding Cushion Variation learn how to increase cushion injection molding in polymers for improved product quality and efficiency. cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. This paper analyzes the process variable data from injection molding processes to. there are two definitions (see what i mean?) for cushion in molding: learn. Injection Molding Cushion Variation.