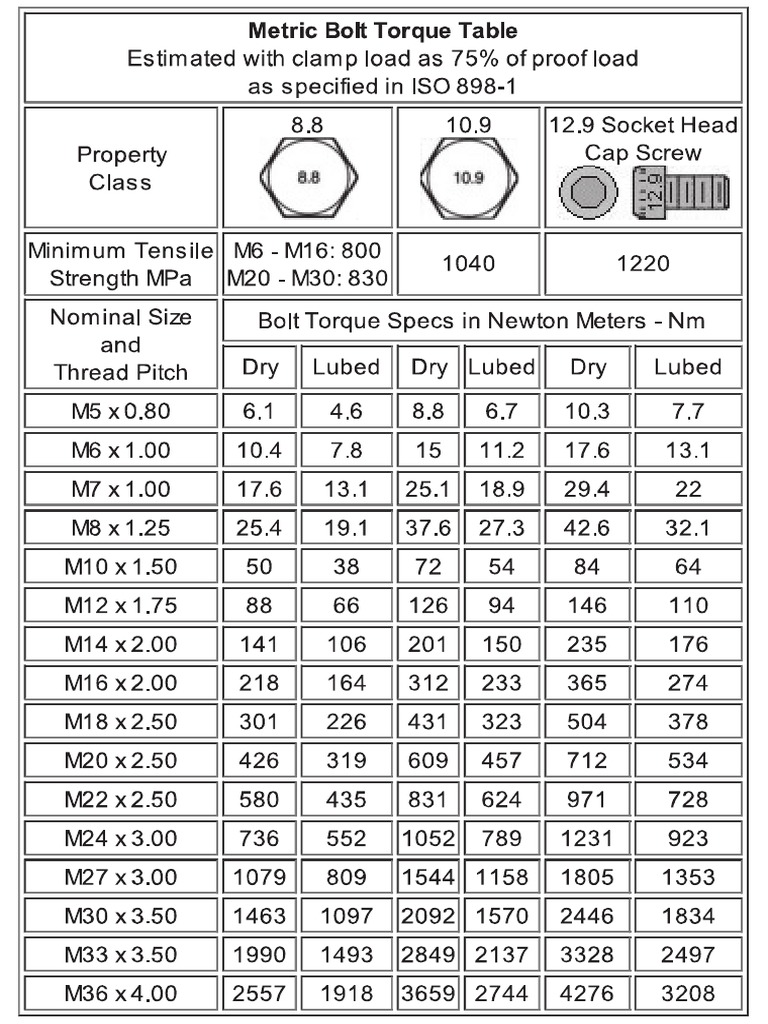

Bolt Torque Chart Grade 5 . These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. In practice, there are many factors that affect permissible torque including bolt type, thread. Grade 2, 5, and 8 values are for plated bolts. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are. The bolt’s class indicates its material strength, with higher. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. The size column also includes the thread count. Identify the grade, size, and thread density of your.

from templates.esad.edu.br

The size column also includes the thread count. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. Grade 2, 5, and 8 values are for plated bolts. Identify the grade, size, and thread density of your. In practice, there are many factors that affect permissible torque including bolt type, thread. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. The bolt’s class indicates its material strength, with higher. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are.

Printable Bolt Torque Chart

Bolt Torque Chart Grade 5 In practice, there are many factors that affect permissible torque including bolt type, thread. The bolt’s class indicates its material strength, with higher. Grade 2, 5, and 8 values are for plated bolts. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. In practice, there are many factors that affect permissible torque including bolt type, thread. The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. Identify the grade, size, and thread density of your. The size column also includes the thread count. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are.

From www.sampletemplates.com

FREE 7+ Sample Bolt Torque Chart Templates in PDF, Word Bolt Torque Chart Grade 5 = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are. The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. Grade 2, 5, and 8 values are for plated bolts. In practice, there are many factors that affect. Bolt Torque Chart Grade 5.

From elchoroukhost.net

Standard Metric Bolt Torque Table Elcho Table Bolt Torque Chart Grade 5 The size column also includes the thread count. Identify the grade, size, and thread density of your. In practice, there are many factors that affect permissible torque including bolt type, thread. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. = clamp load for j429 grade. Bolt Torque Chart Grade 5.

From www.sampletemplates.com

FREE 7+ Sample Bolt Torque Chart Templates in PDF, Word Bolt Torque Chart Grade 5 The bolt’s class indicates its material strength, with higher. Identify the grade, size, and thread density of your. The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. Grade 2, 5, and 8 values are for plated bolts. The size column also includes the thread count. In practice, there are many. Bolt Torque Chart Grade 5.

From mungfali.com

ISO Metric Bolt Torque Chart Bolt Torque Chart Grade 5 Identify the grade, size, and thread density of your. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are. The size column also includes the thread count. The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. In. Bolt Torque Chart Grade 5.

From www.scribd.com

Bolt Torque Chart Screw Applied And Interdisciplinary Physics Bolt Torque Chart Grade 5 Identify the grade, size, and thread density of your. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. Grade 2, 5, and 8 values are for plated bolts. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts. Bolt Torque Chart Grade 5.

From mavink.com

Metric Fastener Torque Chart Bolt Torque Chart Grade 5 The size column also includes the thread count. The bolt’s class indicates its material strength, with higher. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9,. Bolt Torque Chart Grade 5.

From bceweb.org

Torque Chart For Grade 5 Bolts A Visual Reference of Charts Chart Master Bolt Torque Chart Grade 5 The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The size column also includes the thread count. The bolt’s class indicates its material strength, with higher. The torque values. Bolt Torque Chart Grade 5.

From www.autozone.com

Repair Guides Fasteners, Measurements And Conversions Measuring Bolt Torque Chart Grade 5 The bolt’s class indicates its material strength, with higher. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The charts below show. Bolt Torque Chart Grade 5.

From studykuhn.z19.web.core.windows.net

Bolt Torque Spec Chart Bolt Torque Chart Grade 5 The size column also includes the thread count. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. The bolt’s class indicates its material strength, with higher.. Bolt Torque Chart Grade 5.

From templates.esad.edu.br

Printable Bolt Torque Chart Bolt Torque Chart Grade 5 The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. Grade 2, 5, and 8 values are for plated bolts. The size column also includes the thread count. Identify the grade, size, and thread density of your. The bolt’s class indicates its material strength, with higher. In practice, there are many factors that. Bolt Torque Chart Grade 5.

From mavink.com

Astm A325 Bolt Torque Chart Bolt Torque Chart Grade 5 The bolt’s class indicates its material strength, with higher. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. Grade 2, 5, and 8 values are for plated bolts. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes.. Bolt Torque Chart Grade 5.

From www.scribd.com

Bolt Bolt Torque Chart Screw Mechanical Engineering Bolt Torque Chart Grade 5 These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. The size column also includes the thread count. The torque values can only be achieved if nut (or tapped hole). Bolt Torque Chart Grade 5.

From workshopsrgopalan5v1.z21.web.core.windows.net

Sae Grade 5 Bolt Torque Chart Bolt Torque Chart Grade 5 The bolt’s class indicates its material strength, with higher. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The charts below show. Bolt Torque Chart Grade 5.

From mungfali.com

ISO Metric Bolt Torque Chart Bolt Torque Chart Grade 5 In practice, there are many factors that affect permissible torque including bolt type, thread. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry. Bolt Torque Chart Grade 5.

From dockskaapnews.blogspot.com

Standard Bolt Torque Chart / Fastener Torque Specifications Bolts Bolt Torque Chart Grade 5 Grade 2, 5, and 8 values are for plated bolts. The bolt’s class indicates its material strength, with higher. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. Identify the grade, size, and thread density of your. The charts below show the ideal tightening torque for. Bolt Torque Chart Grade 5.

From mavink.com

Printable Bolt Grade Chart Bolt Torque Chart Grade 5 = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are. Grade 2, 5, and 8 values are for plated bolts. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. In practice, there. Bolt Torque Chart Grade 5.

From www.repairengineering.com

Bolt Torque Chart Bolt Torque Chart Grade 5 The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. The size column also includes the thread count. In practice, there are many factors that affect permissible torque including bolt type, thread. Identify the grade, size, and thread density of your. These metric bolt torque charts show the ideal tightening torque. Bolt Torque Chart Grade 5.

From templates.esad.edu.br

Printable Bolt Torque Chart Bolt Torque Chart Grade 5 The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. The size column also includes the thread count. Identify the grade, size, and thread density of your. These metric bolt torque charts show the. Bolt Torque Chart Grade 5.

From floorjacked.com

SAE Bolt Torque Chart Grade 2, Grade 5, Grade 8 Floorjacked Bolt Torque Chart Grade 5 In practice, there are many factors that affect permissible torque including bolt type, thread. The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. Grade 2, 5, and 8 values are for plated bolts. Identify the grade, size, and thread density of your. The size column also includes the thread count.. Bolt Torque Chart Grade 5.

From mungfali.com

Bolt Torque Specs Chart Bolt Torque Chart Grade 5 The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. In practice, there are many factors that affect permissible torque including bolt type, thread. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. Grade 2, 5,. Bolt Torque Chart Grade 5.

From bceweb.org

Metric Bolt Torque Chart Into Aluminum A Visual Reference of Charts Bolt Torque Chart Grade 5 These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The bolt’s class indicates its material strength, with higher. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. The size column also. Bolt Torque Chart Grade 5.

From materialsven.z13.web.core.windows.net

Printable Bolt Torque Chart Bolt Torque Chart Grade 5 Identify the grade, size, and thread density of your. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. Grade 2, 5, and 8 values are for plated bolts. The bolt’s class indicates its material strength, with higher. The torque values can only be achieved if nut. Bolt Torque Chart Grade 5.

From repairfixmenyeid50.z4.web.core.windows.net

Sae Grade 5 Bolt Torque Chart Bolt Torque Chart Grade 5 The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. The bolt’s class indicates its material strength, with higher. Grade 2, 5, and 8 values are for plated bolts. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes.. Bolt Torque Chart Grade 5.

From www.sampletemplates.com

FREE 7+ Sample Bolt Torque Chart Templates in PDF, Word Bolt Torque Chart Grade 5 Grade 2, 5, and 8 values are for plated bolts. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The torque values can. Bolt Torque Chart Grade 5.

From mavink.com

Metric Bolt Torque Guide Bolt Torque Chart Grade 5 The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. The size column also includes the thread count. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are. The torque values can only be achieved if nut (or. Bolt Torque Chart Grade 5.

From www.formsbirds.com

Metric Torque Values Chart Free Download Bolt Torque Chart Grade 5 These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The bolt’s class indicates its material strength, with higher. Identify the grade, size, and thread density of your. In practice, there are many factors that affect permissible torque including bolt type, thread. The charts below show the. Bolt Torque Chart Grade 5.

From www.bustinyournuts.com

Torque Charts Industrial Bolting and Torque Tools Bolt Torque Chart Grade 5 These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. In practice, there are many factors that affect permissible torque including bolt type, thread. The size column also. Bolt Torque Chart Grade 5.

From www.teambuick.com

Bolt Torque Chart, Team Buick Bolt Torque Chart Grade 5 In practice, there are many factors that affect permissible torque including bolt type, thread. The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are. The charts below show. Bolt Torque Chart Grade 5.

From dockskaapnews.blogspot.com

Standard Bolt Torque Chart / Fastener Torque Specifications Bolts Bolt Torque Chart Grade 5 The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. In practice, there are many factors that affect permissible torque including bolt type, thread. The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. = clamp load for j429 grade 5 and 8, fnl. Bolt Torque Chart Grade 5.

From www.sampletemplates.com

FREE 7+ Sample Bolt Torque Chart Templates in PDF, Word Bolt Torque Chart Grade 5 = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are. Grade 2, 5, and 8 values are for plated bolts. The bolt’s class indicates its material strength, with higher. The size column also includes the thread count. The charts below show the ideal tightening torque for each. Bolt Torque Chart Grade 5.

From www.bustinyournuts.com

Torque Charts Industrial Bolting and Torque Tools Bolt Torque Chart Grade 5 The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. The size column also includes the thread count. The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. Identify the grade, size, and thread density of your. In practice, there are many factors that. Bolt Torque Chart Grade 5.

From garagefixcononena.z13.web.core.windows.net

Sae Grade 5 Bolt Torque Chart Bolt Torque Chart Grade 5 The values in this torque chart refer to sae grade 2, sae grade 5, and sae grade 8 bolts. Grade 2, 5, and 8 values are for plated bolts. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are. These metric bolt torque charts show the ideal. Bolt Torque Chart Grade 5.

From wtbmotorsports.co.uk

Motorsport Metric Bolt Torque Specification Chart WTB Motorsports Bolt Torque Chart Grade 5 Grade 2, 5, and 8 values are for plated bolts. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. The charts below. Bolt Torque Chart Grade 5.

From workshopsrgopalan5v1.z21.web.core.windows.net

Sae Grade 5 Bolt Torque Chart Bolt Torque Chart Grade 5 The bolt’s class indicates its material strength, with higher. Identify the grade, size, and thread density of your. The size column also includes the thread count. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9. Bolt Torque Chart Grade 5.

From ricksfreeautorepairadvice.com

Bolt Grade Chart — Ricks Free Auto Repair Advice Ricks Free Auto Repair Bolt Torque Chart Grade 5 The size column also includes the thread count. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The bolt’s class indicates its material strength, with higher. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal. Bolt Torque Chart Grade 5.