Spur Gear Efficiency Calculation . (inch units applicable for constants) spur gear design calculator. An outline design procedure for a worm and wheel gear set using the agma equations is: Define the number of starts. In the following pages we analyze the influence of a few parameters concerning gear efficiency. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Define the center distance, c. The output power is the (input. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data.

from present5.com

Define the number of starts. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. (inch units applicable for constants) spur gear design calculator. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Define the center distance, c. An outline design procedure for a worm and wheel gear set using the agma equations is: Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). The output power is the (input. In the following pages we analyze the influence of a few parameters concerning gear efficiency.

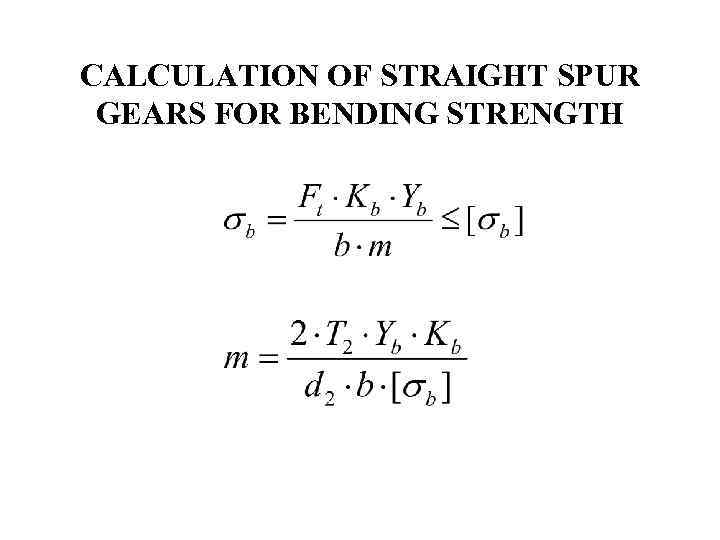

CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH

Spur Gear Efficiency Calculation Define the center distance, c. In the following pages we analyze the influence of a few parameters concerning gear efficiency. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Define the center distance, c. (inch units applicable for constants) spur gear design calculator. An outline design procedure for a worm and wheel gear set using the agma equations is: The output power is the (input. Define the number of starts. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %.

From lesamiesdemayalabeille.blogspot.com

Spur Gear Formula Spur Gear Design Project lesamiesdemayalabeille Spur Gear Efficiency Calculation 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. An outline design procedure for a worm and wheel gear set using the agma equations is: Define the number of starts. Define the center distance, c. The output power is the (input. Gear dimensions are determined in accordance with their specifications, such as module (m),. Spur Gear Efficiency Calculation.

From www.youtube.com

Spur Gear Calculation and Design (MITCalc03) YouTube Spur Gear Efficiency Calculation 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Define the center distance, c. An outline design procedure for a worm and wheel gear set using the agma equations is: In the following pages we. Spur Gear Efficiency Calculation.

From present5.com

CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH Spur Gear Efficiency Calculation An outline design procedure for a worm and wheel gear set using the agma equations is: In the following pages we analyze the influence of a few parameters concerning gear efficiency. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Define the number of starts. Gear dimensions are determined in. Spur Gear Efficiency Calculation.

From kktechnicalinfo.blogspot.com

Engineeringtechnicalinfo Calculation of Gear Dimensions Spur Gear Efficiency Calculation (inch units applicable for constants) spur gear design calculator. Define the center distance, c. In the following pages we analyze the influence of a few parameters concerning gear efficiency. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. 40 rows spur gear design formula for geometry, pitch, tooth clearance and. Spur Gear Efficiency Calculation.

From www.youtube.com

Spur gear calculation, Design Details Spur Gear Formula spur gear Spur Gear Efficiency Calculation The output power is the (input. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. (inch units applicable for constants) spur gear design calculator. Define the center distance, c. Define the number of starts. An. Spur Gear Efficiency Calculation.

From mikemajorsdds.com

Câine Cheie Miere helical gear efficiency calculation Nutriție escalada Spur Gear Efficiency Calculation The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. The output power is the (input. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). An outline design procedure for a worm and wheel gear set. Spur Gear Efficiency Calculation.

From present5.com

CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH Spur Gear Efficiency Calculation In the following pages we analyze the influence of a few parameters concerning gear efficiency. Define the center distance, c. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). The efficiency of a gear system is simple calculated as the [output shaft power /input shaft. Spur Gear Efficiency Calculation.

From www.slideserve.com

PPT Blueprint Reading for the Machine Trades, Sixth Edition Unit 15 Spur Gear Efficiency Calculation The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Define the number of starts. Define the center distance, c. (inch units applicable for constants) spur gear design calculator. The output power is the (input. In the following pages we analyze the influence of a few parameters concerning gear efficiency. 40. Spur Gear Efficiency Calculation.

From www.semanticscholar.org

[PDF] An Experimental Investigation of Spur Gear Efficiency Semantic Spur Gear Efficiency Calculation In the following pages we analyze the influence of a few parameters concerning gear efficiency. An outline design procedure for a worm and wheel gear set using the agma equations is: Define the center distance, c. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The output power is the (input. The efficiency of. Spur Gear Efficiency Calculation.

From present5.com

CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH Spur Gear Efficiency Calculation The output power is the (input. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. An outline design procedure for a worm and wheel gear set using the agma equations is: In the following pages we analyze the influence of a few parameters concerning gear efficiency. Define the number of. Spur Gear Efficiency Calculation.

From www.michiganmech.com

How to Calculate Module of Spur Gear Spur Gear Efficiency Calculation (inch units applicable for constants) spur gear design calculator. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The output power is the (input. In the following pages we analyze the influence of a few parameters concerning gear efficiency. The efficiency of a gear system is simple calculated as the [output shaft power /input. Spur Gear Efficiency Calculation.

From present5.com

CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH Spur Gear Efficiency Calculation 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Define the center distance, c. (inch units applicable for constants) spur gear design calculator. An outline design procedure for a worm and wheel gear set using the agma equations is: Gear dimensions are determined in accordance with their specifications, such as module (m), number of. Spur Gear Efficiency Calculation.

From khkgears.net

Bending Strength of Spur and Helical Gears KHK Gears Spur Gear Efficiency Calculation 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. (inch units applicable for constants) spur gear design calculator. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. In the following pages we analyze the influence of a few parameters concerning gear efficiency. An outline. Spur Gear Efficiency Calculation.

From giohkfgxm.blob.core.windows.net

The Spur Gear Efficiency at Erin Tookes blog Spur Gear Efficiency Calculation The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Define the number of starts. In the following pages we analyze the influence of a few parameters. Spur Gear Efficiency Calculation.

From khkgears.net

Surface Durability of Spur and Helical Gears KHK Gears Spur Gear Efficiency Calculation 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. In the following pages we analyze the influence of a few parameters concerning gear efficiency. Define the center distance, c. (inch units applicable for constants) spur gear design calculator. Define the number of starts. The efficiency of a gear system is simple calculated as the. Spur Gear Efficiency Calculation.

From allinclud2424.blogspot.com

spur gear efficiency SolidWorks G Tutorial 329 spur gears basics Spur Gear Efficiency Calculation The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. (inch units applicable for constants) spur gear design calculator. In the following pages we analyze the influence of a few parameters concerning gear efficiency. An outline design procedure for a worm and wheel gear set using the agma equations is: Define. Spur Gear Efficiency Calculation.

From www.slideserve.com

PPT How to Choose the Right Spur Gears for Your Vehicle PowerPoint Spur Gear Efficiency Calculation Define the number of starts. (inch units applicable for constants) spur gear design calculator. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Define the center. Spur Gear Efficiency Calculation.

From www.mdpi.com

A Numerical Analysis of Hybrid Spur Gears with Asymmetric Teeth Stress Spur Gear Efficiency Calculation Define the number of starts. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. An outline design procedure for a worm and wheel gear set using. Spur Gear Efficiency Calculation.

From www.slideserve.com

PPT Force Analysis Spur Gears PowerPoint Presentation, free Spur Gear Efficiency Calculation 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Define the center distance, c. (inch units applicable for constants) spur gear design calculator. The output power is the (input. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). An. Spur Gear Efficiency Calculation.

From www.engineersedge.com

AGMA Spur Gear Profile Calculator Spread Sheet Spur Gear Efficiency Calculation The output power is the (input. (inch units applicable for constants) spur gear design calculator. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). An outline design procedure for a worm and wheel gear set using the agma equations is: Define the center distance, c.. Spur Gear Efficiency Calculation.

From 193.2.78.197

A New Calculation Method for Instantaneous Efficiency and Torque Spur Gear Efficiency Calculation Define the number of starts. An outline design procedure for a worm and wheel gear set using the agma equations is: 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Define the center distance, c. (inch units applicable for constants) spur gear design calculator. The output power is the (input. Gear dimensions are determined. Spur Gear Efficiency Calculation.

From mechanicaltopdc.blogspot.com

Spur Gear Design Spur Gear Efficiency Calculation Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Define the number of starts. An outline design procedure for a worm and wheel gear set using the agma equations is: 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data.. Spur Gear Efficiency Calculation.

From khkgears.net

Gear Forces KHK Gears Spur Gear Efficiency Calculation The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). An outline. Spur Gear Efficiency Calculation.

From www.youtube.com

Gear velocity ratio for Simple and Compound Gear train. Reduction or Spur Gear Efficiency Calculation 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. (inch units applicable for constants) spur gear design calculator. Define the number of starts. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). An outline design procedure for a worm. Spur Gear Efficiency Calculation.

From www.youtube.com

CALCULATION RACK AND SPUR GEAR EXCEL FORMULA YouTube Spur Gear Efficiency Calculation Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Define the number of starts. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Define the center distance, c. An outline design procedure for a worm. Spur Gear Efficiency Calculation.

From present5.com

CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH FORCES Spur Gear Efficiency Calculation The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. The output power is the (input. Define the number of starts. Define the center distance, c. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. In the following pages we analyze the influence of a. Spur Gear Efficiency Calculation.

From kktechnicalinfo.blogspot.com

Engineeringtechnicalinfo Calculation of Gear Dimensions Spur Gear Efficiency Calculation 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. In the following pages we analyze the influence of a few parameters concerning gear efficiency. The output power is the (input. An outline design procedure for a worm and wheel gear set using the agma equations is: Define the number of starts. (inch units applicable. Spur Gear Efficiency Calculation.

From www.zhygear.com

Verification of calculation accuracy of spur gear stiffness model ZHY Spur Gear Efficiency Calculation Define the center distance, c. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. An outline design procedure for a worm and wheel gear set using the agma equations is: In the following pages we analyze the influence of a few parameters concerning gear efficiency. (inch units applicable for constants). Spur Gear Efficiency Calculation.

From evolventdesign.com

Spur Gear Calculator Hub Evolvent Design Spur Gear Efficiency Calculation An outline design procedure for a worm and wheel gear set using the agma equations is: The output power is the (input. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Define the number of starts. In the following pages we analyze the influence of. Spur Gear Efficiency Calculation.

From www.chegg.com

Solved Given two sets of spur gears, calculate the gear Spur Gear Efficiency Calculation Define the number of starts. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. The output power is the (input. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). 40 rows spur gear design formula. Spur Gear Efficiency Calculation.

From us.misumi-ec.com

Center to Center Spacing for Shafts with Spur Gears MISUMI Mech Lab Blog Spur Gear Efficiency Calculation Define the center distance, c. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). An outline design procedure for a worm and wheel gear set using the agma equations is: The efficiency of a gear system is simple calculated as the [output shaft power /input. Spur Gear Efficiency Calculation.

From evolventdesign.com

Spur Gear Calculator Hub Evolvent Design Spur Gear Efficiency Calculation The output power is the (input. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). (inch units applicable for constants) spur gear design calculator. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. In the following pages we analyze. Spur Gear Efficiency Calculation.

From www.extrica.com

An improved mesh stiffness calculation model of spur gear pair under Spur Gear Efficiency Calculation (inch units applicable for constants) spur gear design calculator. Define the number of starts. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. In the following pages we analyze the influence of a few parameters concerning gear efficiency. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft. Spur Gear Efficiency Calculation.

From www.mechanicdrive.com

Spur gear calculation Spur Gear Efficiency Calculation (inch units applicable for constants) spur gear design calculator. In the following pages we analyze the influence of a few parameters concerning gear efficiency. Define the number of starts. Define the center distance, c. An outline design procedure for a worm and wheel gear set using the agma equations is: Gear dimensions are determined in accordance with their specifications, such. Spur Gear Efficiency Calculation.

From www.engineersedge.com

Spur Gear Design Tool Calculator Spur Gear Efficiency Calculation Define the number of starts. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Define the center distance, c. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). In the following pages we analyze the influence of a few. Spur Gear Efficiency Calculation.