Etching For Penetrant Inspection . One of the most critical steps in the penetrant inspection process is preparing the part for inspection. The surface must be free of oil,. Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can be. If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. Due to this the parts must be etched prior to the dye penetrant testing process. One of the most critical steps of a liquid penetrant inspection is the surface preparation. All coatings, such as paints,. The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component.

from www.testrade.co.uk

The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. The surface must be free of oil,. If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. One of the most critical steps of a liquid penetrant inspection is the surface preparation. One of the most critical steps in the penetrant inspection process is preparing the part for inspection. All coatings, such as paints,. Due to this the parts must be etched prior to the dye penetrant testing process. Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can be.

INSPECTION LINE

Etching For Penetrant Inspection If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. All coatings, such as paints,. The surface must be free of oil,. One of the most critical steps in the penetrant inspection process is preparing the part for inspection. The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can be. Due to this the parts must be etched prior to the dye penetrant testing process. One of the most critical steps of a liquid penetrant inspection is the surface preparation.

From www.testrade.co.uk

INSPECTION LINE Etching For Penetrant Inspection One of the most critical steps in the penetrant inspection process is preparing the part for inspection. If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. All coatings, such as paints,. Due to this the parts must be etched prior to the dye penetrant testing process. One of the. Etching For Penetrant Inspection.

From www.ndtgroup.co.uk

Dye Inspection NDT Group Etching For Penetrant Inspection If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. All coatings, such as paints,. One of the most critical steps in the penetrant inspection process is preparing the part for inspection. Due to this the parts must be etched prior to the dye penetrant testing process. Penetrant inspection should. Etching For Penetrant Inspection.

From magnaflux.com

The Ultimate Guide to Visible Dye Testing Etching For Penetrant Inspection If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. The surface must be free of oil,. One of the most critical steps of a liquid penetrant inspection is the surface preparation. All coatings, such as paints,. One of the most critical steps in the penetrant inspection process is preparing. Etching For Penetrant Inspection.

From www.testrade.co.uk

INSPECTION LINE Etching For Penetrant Inspection One of the most critical steps of a liquid penetrant inspection is the surface preparation. All coatings, such as paints,. The surface must be free of oil,. Due to this the parts must be etched prior to the dye penetrant testing process. If material smearing is a problem, an etching process can be used to remove the smeared material prior. Etching For Penetrant Inspection.

From www.researchgate.net

inspection process. Download Scientific Diagram Etching For Penetrant Inspection If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. One of the most critical steps in the penetrant inspection process is preparing. Etching For Penetrant Inspection.

From www.eminspection.co.uk

Inspection and Equipment EM Inspection Co Ltd Etching For Penetrant Inspection Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can be. Due to this the parts must be etched prior to the dye penetrant testing process. One of the most critical steps of a liquid penetrant inspection is the surface preparation. The surface must be free of oil,. All coatings, such as. Etching For Penetrant Inspection.

From www.scribd.com

ASTM E14172013Standard Practice for Liquid Testing Etching For Penetrant Inspection Due to this the parts must be etched prior to the dye penetrant testing process. The surface must be free of oil,. One of the most critical steps in the penetrant inspection process is preparing the part for inspection. If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. The. Etching For Penetrant Inspection.

From www.onestopndt.com

Liquid Testing OnestopNDT Etching For Penetrant Inspection One of the most critical steps in the penetrant inspection process is preparing the part for inspection. One of the most critical steps of a liquid penetrant inspection is the surface preparation. The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. If. Etching For Penetrant Inspection.

From www.txndt.com

When Is Liquid Testing the Best Method? TXNDT Etching For Penetrant Inspection Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can be. All coatings, such as paints,. One of the most critical steps in the penetrant inspection process is preparing the part for inspection. Due to this the parts must be etched prior to the dye penetrant testing process. The surface must be. Etching For Penetrant Inspection.

From weldinspectionservices.com

Dye Inspection Weld Inspection Services LLC Etching For Penetrant Inspection Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can be. All coatings, such as paints,. The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. The surface must be free of oil,. If material. Etching For Penetrant Inspection.

From www.onestopndt.com

Liquid Testing Basics, Usage, and Benefits Etching For Penetrant Inspection One of the most critical steps in the penetrant inspection process is preparing the part for inspection. All coatings, such as paints,. The surface must be free of oil,. One of the most critical steps of a liquid penetrant inspection is the surface preparation. The process of etching is a chemical operation using a suitable chemical to remove a pre. Etching For Penetrant Inspection.

From incertec.com

ASTM E1417 Fluorescent Dye & NDT Liquid Testing Etching For Penetrant Inspection If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can be. The surface must be free of oil,. Due to this the parts must be etched prior to the dye penetrant testing. Etching For Penetrant Inspection.

From www.twi-global.com

What is Liquid Testing? (Definition, Advantages and Examples Etching For Penetrant Inspection The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. All coatings, such as paints,. The surface must be free of oil,. Due. Etching For Penetrant Inspection.

From www.aerospaceplating.com

Sunvair Aerospace Group Certifications Etching For Penetrant Inspection The surface must be free of oil,. If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can be. The process of etching is a chemical operation using a suitable chemical to remove. Etching For Penetrant Inspection.

From pdfslide.net

(PDF) Process Specification for Pickling, Etching, and Descaling Etching For Penetrant Inspection Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can be. If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. The surface must be free of oil,. One of the most critical steps in the penetrant inspection process is preparing the. Etching For Penetrant Inspection.

From www.norwoodmedical.com

Florescent Inspection (FPI) Norwood Medical Etching For Penetrant Inspection Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can be. The surface must be free of oil,. One of the most critical steps of a liquid penetrant inspection is the surface preparation. If material smearing is a problem, an etching process can be used to remove the smeared material prior to. Etching For Penetrant Inspection.

From www.youtube.com

Testing (PT) NDT Inspection Technique YouTube Etching For Penetrant Inspection All coatings, such as paints,. If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. The surface must be free of oil,. One of the most critical steps in the penetrant inspection process is preparing the part for inspection. One of the most critical steps of a liquid penetrant inspection. Etching For Penetrant Inspection.

From www.youtube.com

Elite NDT visible liquid inspection YouTube Etching For Penetrant Inspection The surface must be free of oil,. Due to this the parts must be etched prior to the dye penetrant testing process. The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. One of the most critical steps of a liquid penetrant inspection. Etching For Penetrant Inspection.

From www.testrade.co.uk

INSPECTION LINE Etching For Penetrant Inspection The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. One of the most critical steps in the penetrant inspection process is preparing the part for inspection. All coatings, such as paints,. If material smearing is a problem, an etching process can be. Etching For Penetrant Inspection.

From notionpress.com

Testing Principles, Techniques, Applications, and Interview Q&A Etching For Penetrant Inspection If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. One of the most critical steps in the penetrant inspection process is preparing the part for inspection. The surface must be free of oil,. One of the most critical steps of a liquid penetrant inspection is the surface preparation. All. Etching For Penetrant Inspection.

From www.iacsltd.co.uk

Dye Inspection IACS Etching For Penetrant Inspection Due to this the parts must be etched prior to the dye penetrant testing process. All coatings, such as paints,. If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. One of the most critical steps of a liquid penetrant inspection is the surface preparation. Penetrant inspection should take place. Etching For Penetrant Inspection.

From rslndt.com

Dye Inspection (DPI) RSL Etching For Penetrant Inspection All coatings, such as paints,. One of the most critical steps in the penetrant inspection process is preparing the part for inspection. If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. One of the most critical steps of a liquid penetrant inspection is the surface preparation. Due to this. Etching For Penetrant Inspection.

From axisndt.co.uk

Liquid Inspection — Axis Etching For Penetrant Inspection The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. The surface must be free of oil,. If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. One of the most critical steps. Etching For Penetrant Inspection.

From whatispiping.com

Dye Test Definition, Principles, Procedure, Standards Etching For Penetrant Inspection One of the most critical steps of a liquid penetrant inspection is the surface preparation. The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can. Etching For Penetrant Inspection.

From www.onestopndt.com

Liquid Testing OnestopNDT Etching For Penetrant Inspection One of the most critical steps in the penetrant inspection process is preparing the part for inspection. All coatings, such as paints,. If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. The surface must be free of oil,. One of the most critical steps of a liquid penetrant inspection. Etching For Penetrant Inspection.

From apiexam.com

Liquid examination BOK API 653 An explanation Apiexam Etching For Penetrant Inspection The surface must be free of oil,. Due to this the parts must be etched prior to the dye penetrant testing process. If material smearing is a problem, an etching process can be used to remove the smeared material prior to inspection. One of the most critical steps of a liquid penetrant inspection is the surface preparation. The process of. Etching For Penetrant Inspection.

From pdfslide.net

(PDF) Process Specification for Pickling, Etching, and Descaling Etching For Penetrant Inspection One of the most critical steps of a liquid penetrant inspection is the surface preparation. Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can be. The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the. Etching For Penetrant Inspection.

From www.triquestndt.com

Liquid Testing Etching For Penetrant Inspection The surface must be free of oil,. One of the most critical steps in the penetrant inspection process is preparing the part for inspection. All coatings, such as paints,. The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. Penetrant inspection should take. Etching For Penetrant Inspection.

From onlinendts.com

ASNT Level III Liquid Testing Exam Preparatory Course Etching For Penetrant Inspection Due to this the parts must be etched prior to the dye penetrant testing process. One of the most critical steps in the penetrant inspection process is preparing the part for inspection. The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. The. Etching For Penetrant Inspection.

From www.youtube.com

Knowledge Floater "Dye Testing" YouTube Etching For Penetrant Inspection Due to this the parts must be etched prior to the dye penetrant testing process. Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can be. The surface must be free of oil,. One of the most critical steps of a liquid penetrant inspection is the surface preparation. The process of etching. Etching For Penetrant Inspection.

From www.techman-head.com

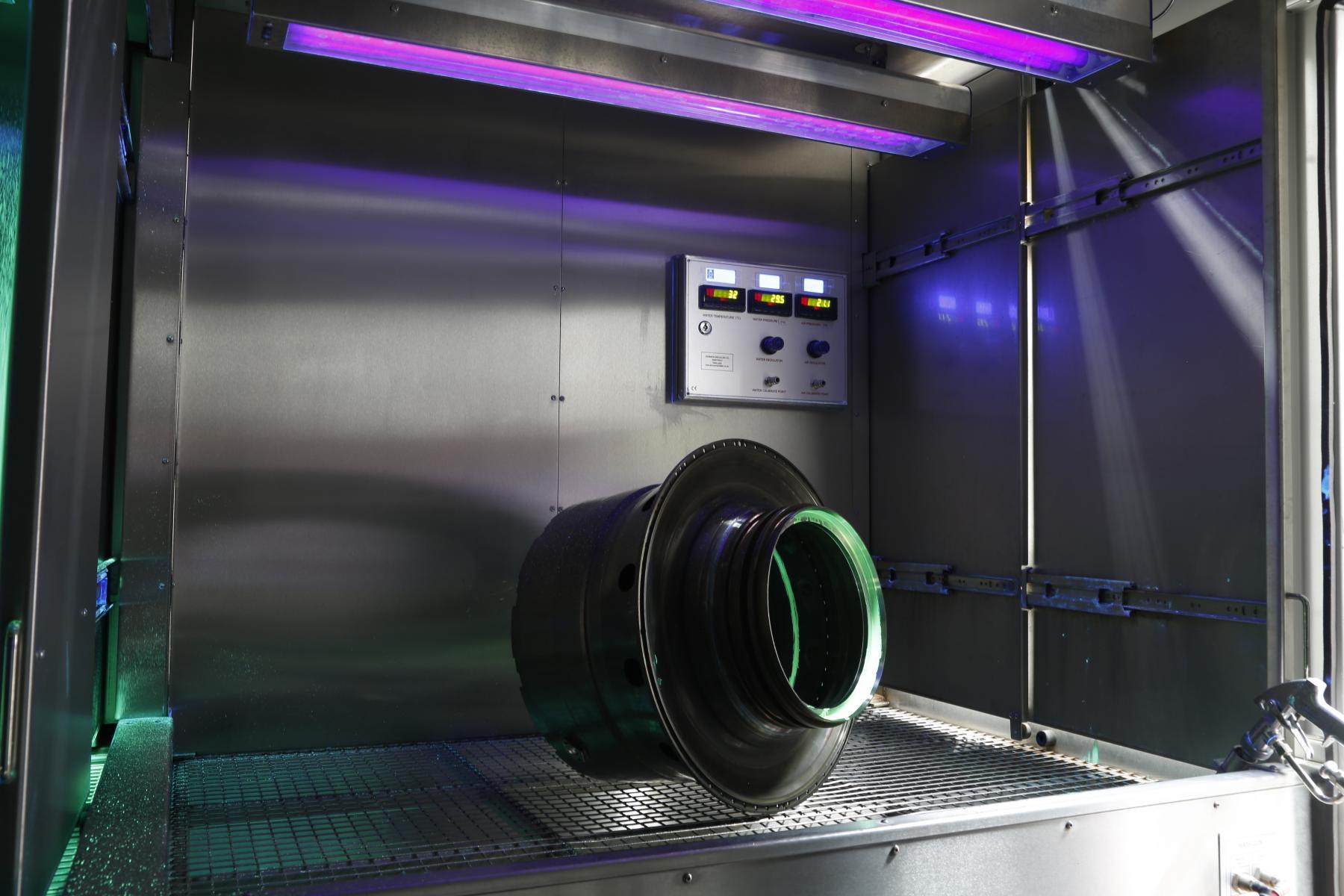

Non destructive testing fluorescent inspection TECHMANHEAD Etching For Penetrant Inspection One of the most critical steps in the penetrant inspection process is preparing the part for inspection. All coatings, such as paints,. One of the most critical steps of a liquid penetrant inspection is the surface preparation. Due to this the parts must be etched prior to the dye penetrant testing process. The process of etching is a chemical operation. Etching For Penetrant Inspection.

From www.athndt.uk

Etching of Components Prior to Testing ATHNDT Etching For Penetrant Inspection All coatings, such as paints,. Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can be. The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. The surface must be free of oil,. Due to. Etching For Penetrant Inspection.

From ultramat.com.tr

Dye Inspection Ultramat Makina Mühendislik Kontrol Etching For Penetrant Inspection One of the most critical steps of a liquid penetrant inspection is the surface preparation. One of the most critical steps in the penetrant inspection process is preparing the part for inspection. The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. Penetrant. Etching For Penetrant Inspection.

From hytekfinishes.com

Titanium Etch Hytek Finishes Etching For Penetrant Inspection The surface must be free of oil,. One of the most critical steps in the penetrant inspection process is preparing the part for inspection. All coatings, such as paints,. One of the most critical steps of a liquid penetrant inspection is the surface preparation. Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical. Etching For Penetrant Inspection.

From www.tec-science.com

Dye inspection (DPI) tecscience Etching For Penetrant Inspection The surface must be free of oil,. The process of etching is a chemical operation using a suitable chemical to remove a pre determined quantity of the material from the surface of the component. Penetrant inspection should take place before machining operations like shot blasting, peening or grinding unless chemical etching can be. If material smearing is a problem, an. Etching For Penetrant Inspection.