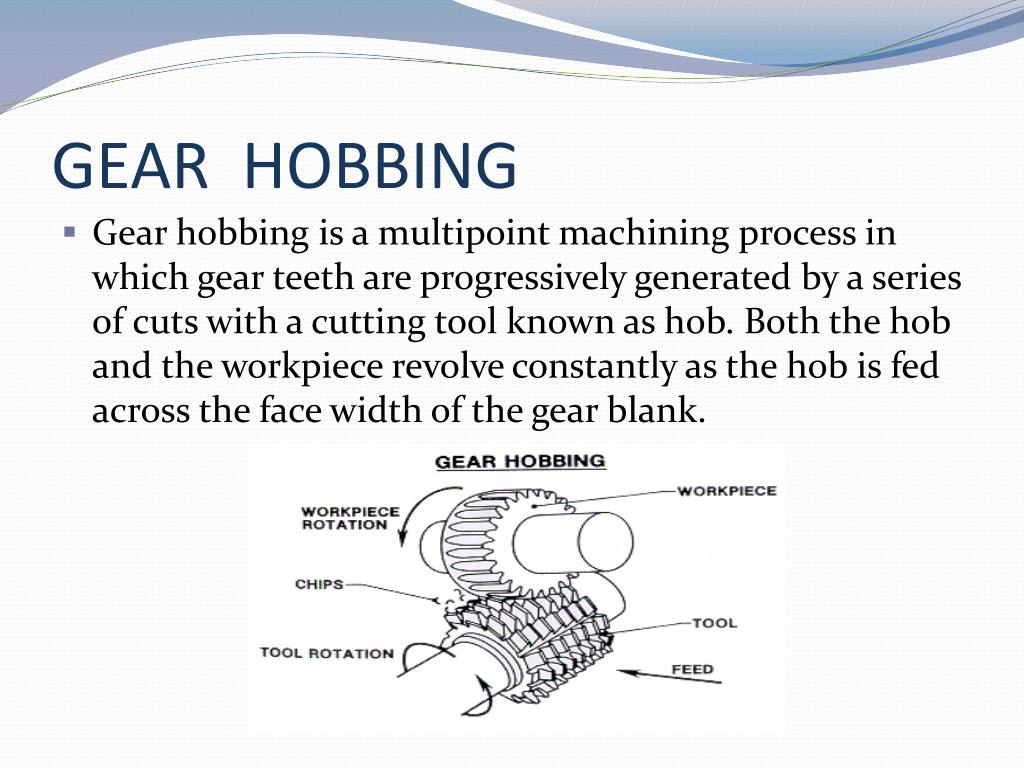

Gear Hobbing Definition . Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. Here we will get to know about the gear manufacturing process called “gear hobbing” which is used to manufacture most of the gears in this world. Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized machine tool called a hobbing. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The cutter profile on a. We will discuss about basics of gear hobbing, its working principle, parts, types of gear hobbing, advantages and disadvantages. This article will take a closer look at the process of gear hobbing, how it has evolved into the modern method widely used today, and. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing.

from www.slideserve.com

Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. Here we will get to know about the gear manufacturing process called “gear hobbing” which is used to manufacture most of the gears in this world. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. We will discuss about basics of gear hobbing, its working principle, parts, types of gear hobbing, advantages and disadvantages. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized machine tool called a hobbing. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. The cutter profile on a. This article will take a closer look at the process of gear hobbing, how it has evolved into the modern method widely used today, and.

PPT THE INDEXING MECHANISM OF GEAR HOBBING MACHINE PowerPoint

Gear Hobbing Definition The cutter profile on a. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized machine tool called a hobbing. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. This article will take a closer look at the process of gear hobbing, how it has evolved into the modern method widely used today, and. We will discuss about basics of gear hobbing, its working principle, parts, types of gear hobbing, advantages and disadvantages. The cutter profile on a. Here we will get to know about the gear manufacturing process called “gear hobbing” which is used to manufacture most of the gears in this world.

From www.researchgate.net

a Schematic diagram of the gear hobbing machine (source authors). b Gear Hobbing Definition We will discuss about basics of gear hobbing, its working principle, parts, types of gear hobbing, advantages and disadvantages. Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized machine tool called a hobbing. This article will take a closer look at the process of gear hobbing, how it has evolved into the. Gear Hobbing Definition.

From manufacturing-factory.com

The 3 Essential Methods for Gear Machining China Manufacturing parts Gear Hobbing Definition Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. The cutter profile on a. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. This article will take a closer look at the process of gear hobbing, how it has evolved into the modern method. Gear Hobbing Definition.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Gear Hobbing Definition The cutter profile on a. Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized machine tool called a hobbing. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing.. Gear Hobbing Definition.

From www.motorgearengineer.com

Gear Hobbing Service Introduction, Working, and Applications Gear Hobbing Definition The cutter profile on a. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Here we will get to know about the gear manufacturing process called “gear hobbing” which is used to manufacture most of the gears in this world. Gear hobbing machine (or hobbing gear machine) is a machining technique for making. Gear Hobbing Definition.

From www.youtube.com

Gear Shaping and Hobbing YouTube Gear Hobbing Definition This article will take a closer look at the process of gear hobbing, how it has evolved into the modern method widely used today, and. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool. Gear Hobbing Definition.

From learnmech.com

Gear Hobbing Parts, Working, Diagram, Advantages, Disadvantages Gear Hobbing Definition Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Gear hobbing is a machining process that involves cutting teeth into. Gear Hobbing Definition.

From mechanicaltalks.in

Gear Hobbing Parts, Working, Diagram, Advantages, Disadvantages Gear Hobbing Definition Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. We will discuss about basics of gear hobbing, its working principle, parts, types of gear hobbing, advantages and disadvantages. The cutter profile on a. Here we will get to know about the gear manufacturing process called “gear hobbing” which is used to. Gear Hobbing Definition.

From mechanicalbasics.com

Gear Hobbing Machine With FAQs & Video Mechanical Basics Gear Hobbing Definition This article will take a closer look at the process of gear hobbing, how it has evolved into the modern method widely used today, and. We will discuss about basics of gear hobbing, its working principle, parts, types of gear hobbing, advantages and disadvantages. Gear hobbing is a process in which gear is cut by a generating process by rotating. Gear Hobbing Definition.

From www.maxwelltools.com

What is Gear Hobbing? Maxwell Tools Company Gear Hobbing Definition Here we will get to know about the gear manufacturing process called “gear hobbing” which is used to manufacture most of the gears in this world. The cutter profile on a. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time. Gear Hobbing Definition.

From www.zhygear.com

Simulation and Verification of Threedirection Dexel Model for Spur Gear Hobbing Definition Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. We will discuss about basics of gear hobbing, its working principle, parts, types of gear hobbing, advantages and disadvantages. This article will take a closer look at the process of gear hobbing, how it has evolved into the. Gear Hobbing Definition.

From www.emag.com

Gear Hobbing Machines for Precise Gear Hobbing Gear Hobbing Definition The cutter profile on a. We will discuss about basics of gear hobbing, its working principle, parts, types of gear hobbing, advantages and disadvantages. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. This article will take a closer look at the process of gear hobbing, how it has evolved into. Gear Hobbing Definition.

From true-gear.com

Explaining Gear Shaping & Gear Hobbing Gear Hobbing Definition The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. This article will take a closer look at the process of gear hobbing, how it has evolved into the modern method widely used today, and. Gear hobbing machine. Gear Hobbing Definition.

From www.researchgate.net

Basic kinematics and essential parameters of gear hobbing Download Gear Hobbing Definition This article will take a closer look at the process of gear hobbing, how it has evolved into the modern method widely used today, and. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Hobbing is. Gear Hobbing Definition.

From www.youtube.com

Gear Hobbing Process Compilation Kompilasi Proses Gear Hobbing Gear Hobbing Definition The cutter profile on a. We will discuss about basics of gear hobbing, its working principle, parts, types of gear hobbing, advantages and disadvantages. This article will take a closer look at the process of gear hobbing, how it has evolved into the modern method widely used today, and. Here we will get to know about the gear manufacturing process. Gear Hobbing Definition.

From engineeringlearn.com

Gear Hobbing Machine Definition, Types, Uses, Working & Construction Gear Hobbing Definition The cutter profile on a. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Here we will get to know about the gear manufacturing process called “gear hobbing” which is used to manufacture most of the gears. Gear Hobbing Definition.

From techobey88.blogspot.com

Gear hobbing Gear Hobbing Definition The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. Hobbing is a manufacturing. Gear Hobbing Definition.

From www.laxmiusedmachine.com

Gear hobbing 4 things you should know about it Laxmi Metal Gear Hobbing Definition The cutter profile on a. Here we will get to know about the gear manufacturing process called “gear hobbing” which is used to manufacture most of the gears in this world. Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized machine tool called a hobbing. This article will take a closer look. Gear Hobbing Definition.

From www.zhygear.com

Gear Hobbing vs. Gear Shaping Choosing the Right Gear Cutting Method Gear Hobbing Definition The cutter profile on a. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. We will discuss about basics of gear hobbing, its working principle, parts, types of gear hobbing, advantages and disadvantages. Hobbing is a. Gear Hobbing Definition.

From gearhobbingsolutions.com

Gear hobbing process Overview CuttingEdge CNC Gear Hobbing Gear Hobbing Definition Here we will get to know about the gear manufacturing process called “gear hobbing” which is used to manufacture most of the gears in this world. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. This article will take a closer look at the process of gear hobbing, how it has evolved into. Gear Hobbing Definition.

From www.iqsdirectory.com

Worm Gear What Is It? How Is it Made? Types Of, Uses Gear Hobbing Definition Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Here we will get to. Gear Hobbing Definition.

From www.youtube.com

The process of Gear Hobbing. Engineer's Academy YouTube Gear Hobbing Definition Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized machine tool called a hobbing. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Here we will get to know. Gear Hobbing Definition.

From www.youtube.com

Gear Manufacturing Methods i.e.Gear Hobbing and Gear Shaping YouTube Gear Hobbing Definition Here we will get to know about the gear manufacturing process called “gear hobbing” which is used to manufacture most of the gears in this world. Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized machine tool called a hobbing. Gear hobbing is the process of generating gear teeth with a helical. Gear Hobbing Definition.

From www.semanticscholar.org

Figure 1 from CADBased Simulation of Gear hobbing Semantic Scholar Gear Hobbing Definition Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized machine tool called a hobbing. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Here we will get to know about the gear manufacturing process called “gear hobbing” which is used to manufacture most of the. Gear Hobbing Definition.

From www.researchgate.net

Gear hobbing process. Download Scientific Diagram Gear Hobbing Definition The gear blank and hob rotate continuously until all gear teeth are cut into the blank. This article will take a closer look at the process of gear hobbing, how it has evolved into the modern method widely used today, and. Here we will get to know about the gear manufacturing process called “gear hobbing” which is used to manufacture. Gear Hobbing Definition.

From www.researchgate.net

Concept of spiral bevel gear hobbing. Download Scientific Diagram Gear Hobbing Definition The cutter profile on a. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized machine tool called a hobbing. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized. Gear Hobbing Definition.

From www.wto-tools.com

Gear Hobbing Gear Hobbing Definition Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. This article will take a closer look at the process of. Gear Hobbing Definition.

From www.youtube.com

What are Gear Hobbing Cutting Parameters? Gear Hobbing Video Series Gear Hobbing Definition Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. We will discuss about basics of gear hobbing, its working principle, parts, types of gear hobbing, advantages and disadvantages. Hobbing is a manufacturing process that involves the. Gear Hobbing Definition.

From www.sourceint.com

Gear Hobbing and Shaping For Precision Source International Gear Hobbing Definition Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. We will discuss about basics of gear hobbing, its working principle, parts, types of gear hobbing, advantages and disadvantages. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. This. Gear Hobbing Definition.

From extrudergearbox.net

Hobbing The Gear Manufacturing Process Explained Gear Hobbing Definition Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. This article will take a closer look at the process of gear hobbing, how it has evolved into the modern method widely used today, and. Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized machine tool. Gear Hobbing Definition.

From thors.com

Gear Hobbing Cutting Parameters to Optimize the Hobbing Process Gear Hobbing Definition Here we will get to know about the gear manufacturing process called “gear hobbing” which is used to manufacture most of the gears in this world. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting. Gear Hobbing Definition.

From www.zhygear.com

Gear Hobbing Enhancing Efficiency and Precision in Gear Production Gear Hobbing Definition The cutter profile on a. This article will take a closer look at the process of gear hobbing, how it has evolved into the modern method widely used today, and. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with. Gear Hobbing Definition.

From www.mdpi.com

Energies Free FullText An Intelligent Deep Learning Technique for Gear Hobbing Definition Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized machine tool called a hobbing. This article will take a closer look at the process of gear hobbing, how it has evolved into the modern method widely used today, and. Gear hobbing is a machining process that involves cutting teeth into a gear. Gear Hobbing Definition.

From www.zhygear.com

Machining method of helical gear hobbing and shaping ZHY Gear Gear Hobbing Definition The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized machine tool called a hobbing. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter. Gear Hobbing Definition.

From thors.com

Gear Hobbing Cutting Parameters to Optimize the Hobbing Process Gear Hobbing Definition The cutter profile on a. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized. Gear Hobbing Definition.

From www.slideserve.com

PPT THE INDEXING MECHANISM OF GEAR HOBBING MACHINE PowerPoint Gear Hobbing Definition Hobbing is a manufacturing process that involves the cutting of gears, splines, and sprockets using a specialized machine tool called a hobbing. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The cutter profile on a. Here we will get to know about the gear manufacturing process called “gear hobbing” which is used. Gear Hobbing Definition.