Yellow Mesh Vs White Mesh . You may have noticed that some screens have yellow mesh while others have white mesh. yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. since the dyed mesh counts tend to be higher, thinner screen mesh, they hold a lot less emulsion and therefore sometimes can be. hey there !in this video i've shared my own experience on choosing a mesh count for silk screen t shirt printing. yellow mesh will increase your exposure time. a quick note, mesh will either be yellow or white in colour. There is plenty of difference between white and yellow mesh. The difference here is that the yellow mesh absorbs more. 1 minute read. Yellow mesh screens don’t cause light to. White, or more accurately, undyed. White mesh lets the emulsion expose faster. We suggest experimenting with different screen meshes. Not all mesh is the same and neither are printers. the threads can hold high tension levels and are more resistant to tearing and popping while on the press, compared to thin thread meshes.

from coanda.ca

a quick note, mesh will either be yellow or white in colour. yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. hey there !in this video i've shared my own experience on choosing a mesh count for silk screen t shirt printing. 1 minute read. The difference here is that the yellow mesh absorbs more. Do you prefer bolder prints? since the dyed mesh counts tend to be higher, thinner screen mesh, they hold a lot less emulsion and therefore sometimes can be. white mesh screens expose faster, but can lose some detail because the light scatters. White mesh lets the emulsion expose faster. Yellow mesh screens don’t cause light to.

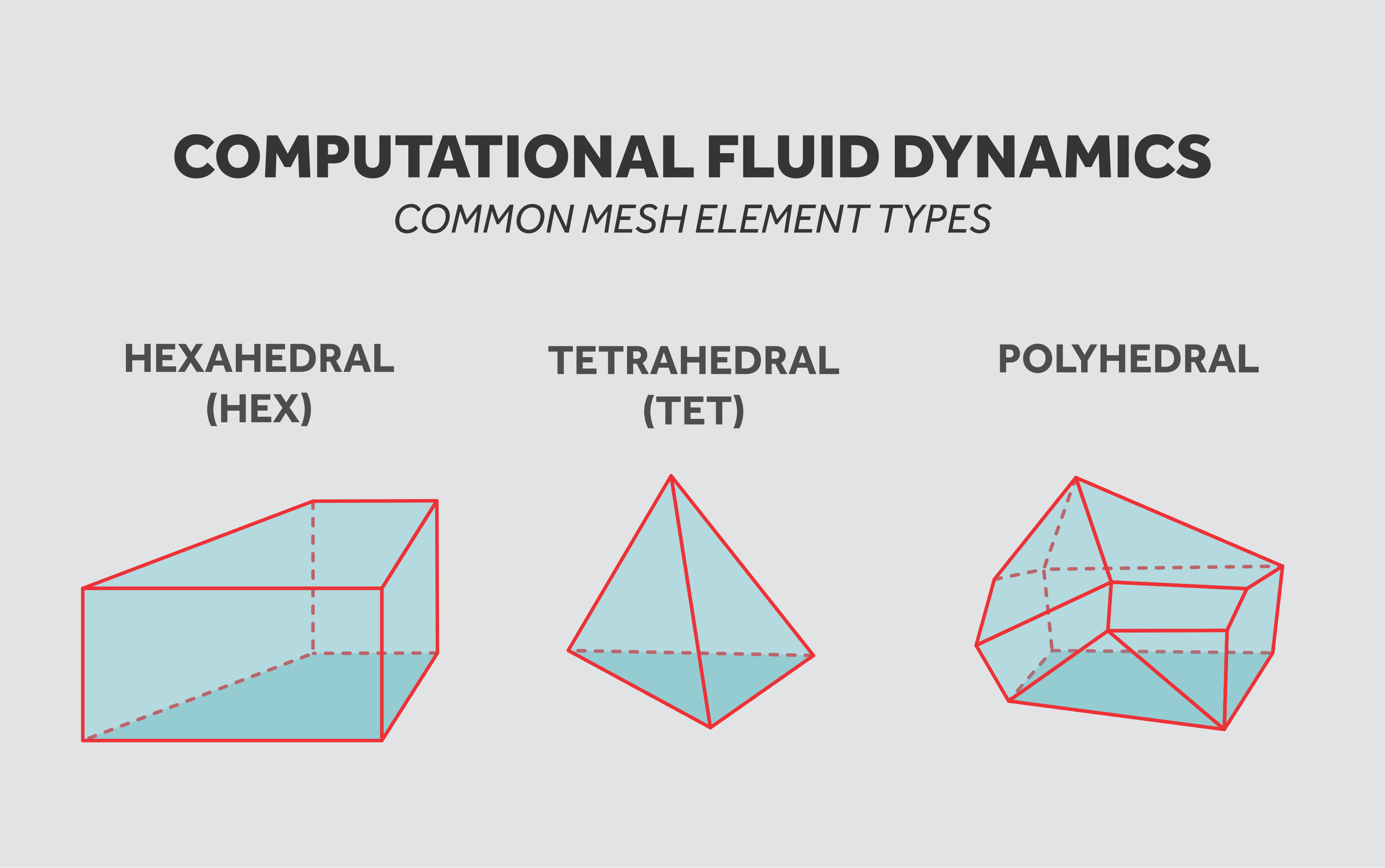

CFD Different Mesh Cell Types Coanda Research & Development

Yellow Mesh Vs White Mesh Not all mesh is the same and neither are printers. Yellow mesh screens don’t cause light to. a quick note, mesh will either be yellow or white in colour. hey there !in this video i've shared my own experience on choosing a mesh count for silk screen t shirt printing. 1 minute read. Do you prefer bolder prints? since the dyed mesh counts tend to be higher, thinner screen mesh, they hold a lot less emulsion and therefore sometimes can be. yellow mesh will increase your exposure time. We suggest experimenting with different screen meshes. White mesh lets the emulsion expose faster. There is plenty of difference between white and yellow mesh. Not all mesh is the same and neither are printers. yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. White, or more accurately, undyed. the threads can hold high tension levels and are more resistant to tearing and popping while on the press, compared to thin thread meshes. The difference here is that the yellow mesh absorbs more.

From parco-inc.com

60" Height Yellow Wire Mesh Panel Yellow Mesh Vs White Mesh There is plenty of difference between white and yellow mesh. 1 minute read. yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. Not all mesh is the same and neither are printers. since the dyed mesh counts tend to be higher, thinner screen mesh, they hold a lot less emulsion. Yellow Mesh Vs White Mesh.

From filterbag.com

US Mesh vs. Micron Yellow Mesh Vs White Mesh The difference here is that the yellow mesh absorbs more. yellow mesh will increase your exposure time. You may have noticed that some screens have yellow mesh while others have white mesh. white mesh screens expose faster, but can lose some detail because the light scatters. 1 minute read. White, or more accurately, undyed. since the. Yellow Mesh Vs White Mesh.

From coanda.ca

CFD Different Mesh Cell Types Coanda Research & Development Yellow Mesh Vs White Mesh hey there !in this video i've shared my own experience on choosing a mesh count for silk screen t shirt printing. White mesh lets the emulsion expose faster. You may have noticed that some screens have yellow mesh while others have white mesh. There is plenty of difference between white and yellow mesh. 1 minute read. yellow. Yellow Mesh Vs White Mesh.

From www.goldstartool.com

60" Wide Lemon Yellow Vinyl Mesh Fabric GoldStar Tool Yellow Mesh Vs White Mesh hey there !in this video i've shared my own experience on choosing a mesh count for silk screen t shirt printing. You may have noticed that some screens have yellow mesh while others have white mesh. a quick note, mesh will either be yellow or white in colour. White, or more accurately, undyed. the threads can hold. Yellow Mesh Vs White Mesh.

From www.pinterest.com

58" Yellow Poly Mesh Fabric by the yard 75 Poly, 17 Nylon, 8 Spandex Yellow Mesh Vs White Mesh The difference here is that the yellow mesh absorbs more. the threads can hold high tension levels and are more resistant to tearing and popping while on the press, compared to thin thread meshes. Yellow mesh screens don’t cause light to. We suggest experimenting with different screen meshes. There is plenty of difference between white and yellow mesh. . Yellow Mesh Vs White Mesh.

From www.dreamstime.com

Closeup of yellow mesh stock photo. Image of yellow, texture 57904056 Yellow Mesh Vs White Mesh We suggest experimenting with different screen meshes. yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. yellow mesh will increase your exposure time. hey there !in this video i've shared my own experience on choosing a mesh count for silk screen t shirt printing. White mesh lets the emulsion expose. Yellow Mesh Vs White Mesh.

From etissus.com

Yellow mesh fabric Yellow Mesh Vs White Mesh a quick note, mesh will either be yellow or white in colour. Do you prefer bolder prints? white mesh screens expose faster, but can lose some detail because the light scatters. There is plenty of difference between white and yellow mesh. White, or more accurately, undyed. 1 minute read. yellow mesh absorbs more light compared to. Yellow Mesh Vs White Mesh.

From www.youtube.com

Mesh vs NURBS YouTube Yellow Mesh Vs White Mesh 1 minute read. White mesh lets the emulsion expose faster. a quick note, mesh will either be yellow or white in colour. Do you prefer bolder prints? yellow mesh will increase your exposure time. the threads can hold high tension levels and are more resistant to tearing and popping while on the press, compared to thin. Yellow Mesh Vs White Mesh.

From www.solidstonefabrics.com

Solid Stone Fabrics Yellow Mesh Vs White Mesh hey there !in this video i've shared my own experience on choosing a mesh count for silk screen t shirt printing. the threads can hold high tension levels and are more resistant to tearing and popping while on the press, compared to thin thread meshes. yellow mesh will increase your exposure time. a quick note, mesh. Yellow Mesh Vs White Mesh.

From hendersontextiles.com

Mesh Fabric Henderson Textiles Yellow Mesh Vs White Mesh the threads can hold high tension levels and are more resistant to tearing and popping while on the press, compared to thin thread meshes. since the dyed mesh counts tend to be higher, thinner screen mesh, they hold a lot less emulsion and therefore sometimes can be. Not all mesh is the same and neither are printers. Do. Yellow Mesh Vs White Mesh.

From peacecommission.kdsg.gov.ng

Yellow Mesh Yellow Mesh Vs White Mesh a quick note, mesh will either be yellow or white in colour. White mesh lets the emulsion expose faster. hey there !in this video i've shared my own experience on choosing a mesh count for silk screen t shirt printing. since the dyed mesh counts tend to be higher, thinner screen mesh, they hold a lot less. Yellow Mesh Vs White Mesh.

From www.etsy.com

Yellow Mesh Etsy Yellow Mesh Vs White Mesh There is plenty of difference between white and yellow mesh. Yellow mesh screens don’t cause light to. Do you prefer bolder prints? You may have noticed that some screens have yellow mesh while others have white mesh. 1 minute read. yellow mesh will increase your exposure time. White mesh lets the emulsion expose faster. hey there !in. Yellow Mesh Vs White Mesh.

From lordvon64.blogspot.com

lordvon's stuff Unstructured vs. structured mesh occupancy Yellow Mesh Vs White Mesh White, or more accurately, undyed. 1 minute read. Do you prefer bolder prints? hey there !in this video i've shared my own experience on choosing a mesh count for silk screen t shirt printing. There is plenty of difference between white and yellow mesh. You may have noticed that some screens have yellow mesh while others have white. Yellow Mesh Vs White Mesh.

From www.julesborel.com

Yellow Mesh Yellow Mesh Vs White Mesh white mesh screens expose faster, but can lose some detail because the light scatters. We suggest experimenting with different screen meshes. the threads can hold high tension levels and are more resistant to tearing and popping while on the press, compared to thin thread meshes. 1 minute read. Yellow mesh screens don’t cause light to. hey. Yellow Mesh Vs White Mesh.

From www.goldstartool.com

Vinyl Mesh Lemon Yellow 60" Fabric GoldStar Tool Yellow Mesh Vs White Mesh White mesh lets the emulsion expose faster. Yellow mesh screens don’t cause light to. We suggest experimenting with different screen meshes. Not all mesh is the same and neither are printers. yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. The difference here is that the yellow mesh absorbs more. white. Yellow Mesh Vs White Mesh.

From www.dreamstime.com

Yellow Mesh Structure in Closeup with Backlight on Shine Morning Shows Yellow Mesh Vs White Mesh white mesh screens expose faster, but can lose some detail because the light scatters. You may have noticed that some screens have yellow mesh while others have white mesh. Do you prefer bolder prints? We suggest experimenting with different screen meshes. hey there !in this video i've shared my own experience on choosing a mesh count for silk. Yellow Mesh Vs White Mesh.

From www.decorsofacile.com

10" x 10yds Plain Mesh Colours red, white (Yellow sold out) Yellow Mesh Vs White Mesh White, or more accurately, undyed. White mesh lets the emulsion expose faster. Not all mesh is the same and neither are printers. We suggest experimenting with different screen meshes. Yellow mesh screens don’t cause light to. The difference here is that the yellow mesh absorbs more. hey there !in this video i've shared my own experience on choosing a. Yellow Mesh Vs White Mesh.

From printable.conaresvirtual.edu.sv

Printable Mesh Fabric Yellow Mesh Vs White Mesh yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. Not all mesh is the same and neither are printers. since the dyed mesh counts tend to be higher, thinner screen mesh, they hold a lot less emulsion and therefore sometimes can be. a quick note, mesh will either be yellow. Yellow Mesh Vs White Mesh.

From www.etsy.com

Yellow Mesh Etsy Yellow Mesh Vs White Mesh White, or more accurately, undyed. Not all mesh is the same and neither are printers. Do you prefer bolder prints? a quick note, mesh will either be yellow or white in colour. We suggest experimenting with different screen meshes. The difference here is that the yellow mesh absorbs more. hey there !in this video i've shared my own. Yellow Mesh Vs White Mesh.

From www.serverwatch.com

Mesh Networking Complete Guide to Understanding Mesh WiFi Yellow Mesh Vs White Mesh white mesh screens expose faster, but can lose some detail because the light scatters. 1 minute read. The difference here is that the yellow mesh absorbs more. yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. White mesh lets the emulsion expose faster. White, or more accurately, undyed. a. Yellow Mesh Vs White Mesh.

From www.canvasetc.com

Polyester Hex Mesh Yellow 60" W Mesh Fabric Canvas ETC. Yellow Mesh Vs White Mesh yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. white mesh screens expose faster, but can lose some detail because the light scatters. yellow mesh will increase your exposure time. We suggest experimenting with different screen meshes. The difference here is that the yellow mesh absorbs more. There is plenty. Yellow Mesh Vs White Mesh.

From decoplastnj.com

High Standard Mesh Yellow 6oz 38″x150′ Decoplast of NJ Yellow Mesh Vs White Mesh yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. the threads can hold high tension levels and are more resistant to tearing and popping while on the press, compared to thin thread meshes. There is plenty of difference between white and yellow mesh. White, or more accurately, undyed. You may have. Yellow Mesh Vs White Mesh.

From www.researchgate.net

Meshes used in the simulations (a) coarse mesh, (b) medium mesh, and Yellow Mesh Vs White Mesh yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. Do you prefer bolder prints? Not all mesh is the same and neither are printers. 1 minute read. since the dyed mesh counts tend to be higher, thinner screen mesh, they hold a lot less emulsion and therefore sometimes can be.. Yellow Mesh Vs White Mesh.

From www.etsy.com

Yellow Mesh Etsy Yellow Mesh Vs White Mesh since the dyed mesh counts tend to be higher, thinner screen mesh, they hold a lot less emulsion and therefore sometimes can be. The difference here is that the yellow mesh absorbs more. hey there !in this video i've shared my own experience on choosing a mesh count for silk screen t shirt printing. You may have noticed. Yellow Mesh Vs White Mesh.

From handymansworld.net

Rebar vs. Wire Mesh vs. Fiber Mesh Which One to Use? Handyman's World Yellow Mesh Vs White Mesh yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. White mesh lets the emulsion expose faster. White, or more accurately, undyed. Do you prefer bolder prints? The difference here is that the yellow mesh absorbs more. since the dyed mesh counts tend to be higher, thinner screen mesh, they hold a. Yellow Mesh Vs White Mesh.

From www.industrialsifter.net

Screen mesh number and particle size comparison table and related Yellow Mesh Vs White Mesh the threads can hold high tension levels and are more resistant to tearing and popping while on the press, compared to thin thread meshes. The difference here is that the yellow mesh absorbs more. White, or more accurately, undyed. Not all mesh is the same and neither are printers. yellow mesh absorbs more light compared to white mesh,. Yellow Mesh Vs White Mesh.

From www.ifabric.com

Yellow Stretch Mesh Fabric iFabric Yellow Mesh Vs White Mesh We suggest experimenting with different screen meshes. yellow mesh will increase your exposure time. Do you prefer bolder prints? the threads can hold high tension levels and are more resistant to tearing and popping while on the press, compared to thin thread meshes. since the dyed mesh counts tend to be higher, thinner screen mesh, they hold. Yellow Mesh Vs White Mesh.

From www.photos-public-domain.com

Yellow Metal Mesh with Round Holes Texture Picture Free Photograph Yellow Mesh Vs White Mesh white mesh screens expose faster, but can lose some detail because the light scatters. White, or more accurately, undyed. There is plenty of difference between white and yellow mesh. yellow mesh will increase your exposure time. 1 minute read. You may have noticed that some screens have yellow mesh while others have white mesh. yellow mesh. Yellow Mesh Vs White Mesh.

From www.dreamstime.com

Yellow Mesh Gradient Wave Covered with Copper Strips Stock Illustration Yellow Mesh Vs White Mesh White, or more accurately, undyed. Yellow mesh screens don’t cause light to. hey there !in this video i've shared my own experience on choosing a mesh count for silk screen t shirt printing. yellow mesh will increase your exposure time. You may have noticed that some screens have yellow mesh while others have white mesh. White mesh lets. Yellow Mesh Vs White Mesh.

From www.bathu.co.za

Mesh Edition 2.0 Yellow Bathu Yellow Mesh Vs White Mesh yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. hey there !in this video i've shared my own experience on choosing a mesh count for silk screen t shirt printing. Do you prefer bolder prints? since the dyed mesh counts tend to be higher, thinner screen mesh, they hold a. Yellow Mesh Vs White Mesh.

From www.all-wall.com

AllWall Yellow Fiberglass Mesh Drywall Tape 17/8" X 300' Yellow Mesh Vs White Mesh White mesh lets the emulsion expose faster. Not all mesh is the same and neither are printers. You may have noticed that some screens have yellow mesh while others have white mesh. yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. a quick note, mesh will either be yellow or white. Yellow Mesh Vs White Mesh.

From www.etsy.com

Yellow Mesh Etsy Yellow Mesh Vs White Mesh yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. 1 minute read. Do you prefer bolder prints? White mesh lets the emulsion expose faster. the threads can hold high tension levels and are more resistant to tearing and popping while on the press, compared to thin thread meshes. You may. Yellow Mesh Vs White Mesh.

From www.etsy.com

Yellow Mesh Etsy Yellow Mesh Vs White Mesh Do you prefer bolder prints? We suggest experimenting with different screen meshes. since the dyed mesh counts tend to be higher, thinner screen mesh, they hold a lot less emulsion and therefore sometimes can be. white mesh screens expose faster, but can lose some detail because the light scatters. White mesh lets the emulsion expose faster. the. Yellow Mesh Vs White Mesh.

From printex.id

Apa perbedaan antara white mesh dan yellow mesh Semua yang Perlu Anda Yellow Mesh Vs White Mesh yellow mesh absorbs more light compared to white mesh, and stops light scattering, therefore helping expose. Not all mesh is the same and neither are printers. the threads can hold high tension levels and are more resistant to tearing and popping while on the press, compared to thin thread meshes. There is plenty of difference between white and. Yellow Mesh Vs White Mesh.

From www.online-fabrics.co.uk

Body Mesh Bright Yellow Yellow Mesh Vs White Mesh You may have noticed that some screens have yellow mesh while others have white mesh. Not all mesh is the same and neither are printers. We suggest experimenting with different screen meshes. Yellow mesh screens don’t cause light to. white mesh screens expose faster, but can lose some detail because the light scatters. The difference here is that the. Yellow Mesh Vs White Mesh.