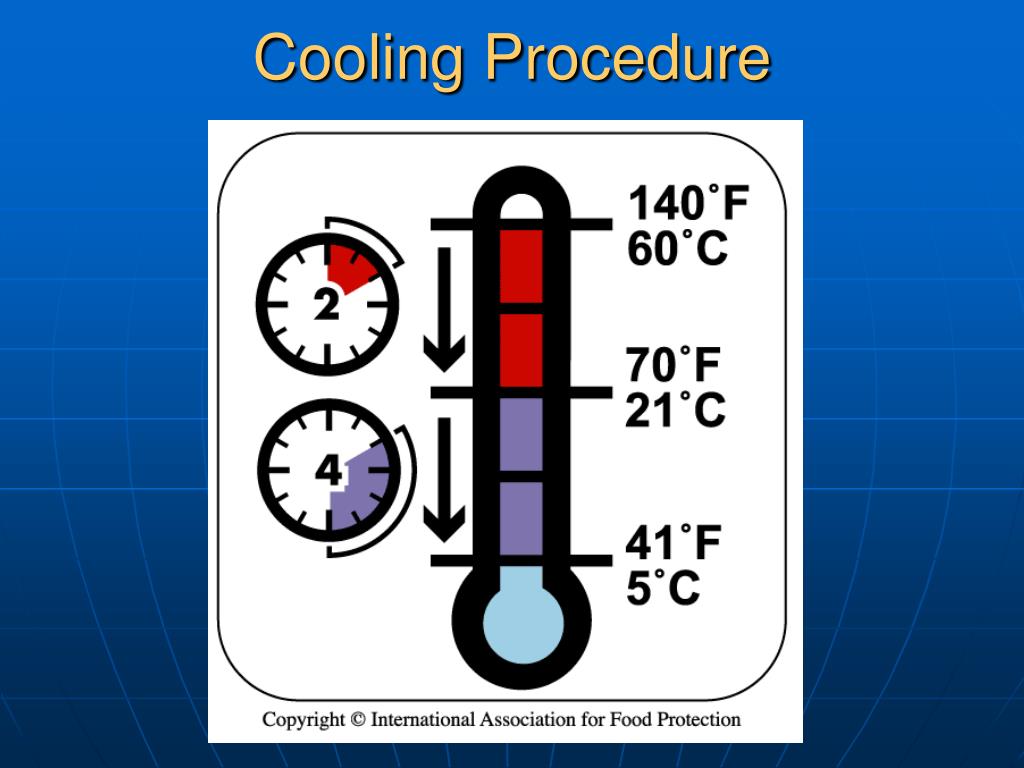

Food Safety Cooling Process . Encouraging or requiring kitchen managers to be certified in food safety. When prepping a large batch of hot food, plan ahead for the cooling method you plan to use. safe rapid cooling of food. The food code requires that all cooked foods not prepared for immediate service or hot held shall be. food safety programs and restaurants can improve cooling practices by: Food and drug administration's (fda) food code cooling guidelines. Focusing intervention efforts on independent and smaller restaurants. cooling methods fact sheet. After cooking, foods may be cooled in preparation for longer storage. Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours. food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. safe cooling times and temperatures.

from www.slideserve.com

food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. When prepping a large batch of hot food, plan ahead for the cooling method you plan to use. safe rapid cooling of food. The food code requires that all cooked foods not prepared for immediate service or hot held shall be. Food and drug administration's (fda) food code cooling guidelines. safe cooling times and temperatures. After cooking, foods may be cooled in preparation for longer storage. cooling methods fact sheet. Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours.

PPT Food Safety at Special Food Events PowerPoint Presentation, free

Food Safety Cooling Process cooling methods fact sheet. Focusing intervention efforts on independent and smaller restaurants. Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. food safety programs and restaurants can improve cooling practices by: food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. The food code requires that all cooked foods not prepared for immediate service or hot held shall be. Food and drug administration's (fda) food code cooling guidelines. cooling methods fact sheet. After cooking, foods may be cooled in preparation for longer storage. safe cooling times and temperatures. Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours. When prepping a large batch of hot food, plan ahead for the cooling method you plan to use. safe rapid cooling of food. Encouraging or requiring kitchen managers to be certified in food safety.

From www.pinterest.com

TwoStage Cooling Process Poster Food safety posters, Food safety and Food Safety Cooling Process food safety programs and restaurants can improve cooling practices by: Encouraging or requiring kitchen managers to be certified in food safety. After cooking, foods may be cooled in preparation for longer storage. The food code requires that all cooked foods not prepared for immediate service or hot held shall be. food safety requires that all leftovers be reheated. Food Safety Cooling Process.

From www.webstaurantstore.com

Avoiding the Danger Zone How to Cool Food Properly Food Safety Cooling Process After cooking, foods may be cooled in preparation for longer storage. When prepping a large batch of hot food, plan ahead for the cooling method you plan to use. Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours. food safety requires that all leftovers be reheated. Food Safety Cooling Process.

From www.webstaurantstore.com

Avoiding the Danger Zone How to Cool Food Properly Food Safety Cooling Process food safety programs and restaurants can improve cooling practices by: After cooking, foods may be cooled in preparation for longer storage. food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. When prepping a large batch of hot food, plan ahead for the cooling method you plan to use. Food and drug administration's. Food Safety Cooling Process.

From www.slideserve.com

PPT Food Handler Training PowerPoint Presentation, free download ID Food Safety Cooling Process Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours. food safety programs and restaurants can improve cooling practices by: food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. After cooking, foods may be cooled in preparation for longer storage.. Food Safety Cooling Process.

From www.fooddocs.com

Cooling Food Poster Download Free Poster Food Safety Cooling Process Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. cooling methods fact sheet. Encouraging or requiring kitchen managers to be certified in food safety. safe rapid cooling of food. Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below. Food Safety Cooling Process.

From www.slideserve.com

PPT SERVSAFE/Chapter 7 PowerPoint Presentation, free download ID Food Safety Cooling Process food safety programs and restaurants can improve cooling practices by: Food and drug administration's (fda) food code cooling guidelines. safe rapid cooling of food. Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. The food code requires that all cooked foods not prepared for immediate service or hot. Food Safety Cooling Process.

From www.slideserve.com

PPT Sous Vide PowerPoint Presentation, free download ID8854845 Food Safety Cooling Process food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. cooling methods fact sheet. The food code requires that all cooked foods not prepared for immediate service or hot held shall be. safe cooling times and temperatures. food safety programs and restaurants can improve cooling practices by: Tcs food must be. Food Safety Cooling Process.

From www.wechu.org

How to cool food properly The WindsorEssex County Health Unit Food Safety Cooling Process food safety programs and restaurants can improve cooling practices by: Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours. Focusing intervention efforts on independent and smaller restaurants. safe cooling times and temperatures. food safety requires that all leftovers be reheated to 165°f for at. Food Safety Cooling Process.

From foodsafetytrainingcertification.com

Cooling Food Safely Food Safety Cooling Process Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. cooling methods fact sheet. Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours. The food code requires that all cooked foods not prepared for immediate service or. Food Safety Cooling Process.

From foodsafetytrainingcertification.com

Cooling Food Safely Food Safety Cooling Process food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours. When prepping a large batch of hot food, plan ahead for the cooling method you plan to use. Cooling to the correct. Food Safety Cooling Process.

From exolgkipg.blob.core.windows.net

Time/Temperature Control For Safety Foods at Betty Benoit blog Food Safety Cooling Process Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours. safe rapid cooling of food. Food and drug administration's (fda) food code cooling guidelines. cooling methods fact sheet. Encouraging or requiring kitchen managers to be certified in food safety. Cooling to the correct internal temperature is. Food Safety Cooling Process.

From mavink.com

Cooling Food Safety Chart Food Safety Cooling Process The food code requires that all cooked foods not prepared for immediate service or hot held shall be. Food and drug administration's (fda) food code cooling guidelines. Focusing intervention efforts on independent and smaller restaurants. Encouraging or requiring kitchen managers to be certified in food safety. Cooling to the correct internal temperature is one of the most important food safety. Food Safety Cooling Process.

From www.templateroller.com

Nevada Food Cooling Process Tracking Chart Fill Out, Sign Online Food Safety Cooling Process food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. After cooking, foods may be cooled in preparation for longer storage. Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours. cooling methods fact sheet. food safety programs and restaurants. Food Safety Cooling Process.

From www.chefspot.com.au

Safe Food Temperatures Chef Spot Australia Food Safety Cooling Process The food code requires that all cooked foods not prepared for immediate service or hot held shall be. Food and drug administration's (fda) food code cooling guidelines. Encouraging or requiring kitchen managers to be certified in food safety. safe cooling times and temperatures. After cooking, foods may be cooled in preparation for longer storage. Focusing intervention efforts on independent. Food Safety Cooling Process.

From mavink.com

Cooling Food Safety Chart Food Safety Cooling Process Food and drug administration's (fda) food code cooling guidelines. Encouraging or requiring kitchen managers to be certified in food safety. food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. safe rapid cooling of food. After cooking, foods may be cooled in preparation for longer storage. Cooling to the correct internal temperature is. Food Safety Cooling Process.

From www.highspeedtraining.co.uk

Safe Temperatures for Food Storage Guide on Cooling & Chilling Times Food Safety Cooling Process After cooking, foods may be cooled in preparation for longer storage. When prepping a large batch of hot food, plan ahead for the cooling method you plan to use. The food code requires that all cooked foods not prepared for immediate service or hot held shall be. Tcs food must be cooled from 135°f to 70°f within 2 hours and. Food Safety Cooling Process.

From foodsafepal.com

What Is the Best Way to Prevent Poor Food Safety? FoodSafePal Food Safety Cooling Process food safety programs and restaurants can improve cooling practices by: The food code requires that all cooked foods not prepared for immediate service or hot held shall be. food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. safe cooling times and temperatures. Food and drug administration's (fda) food code cooling guidelines.. Food Safety Cooling Process.

From www.frigel.com

Process Cooling for Food Industry Frigel Industry Food Safety Cooling Process Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours. cooling methods fact sheet. After cooking, foods may be cooled in preparation for longer storage. Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. food safety. Food Safety Cooling Process.

From northslopechillers.com

Cooling in Food Processing North Slope Chillers Food Safety Cooling Process Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. Encouraging or requiring kitchen managers to be certified in food safety. The food code requires that all cooked foods not prepared for immediate service or hot held shall be. When prepping a large batch of hot food, plan ahead for the. Food Safety Cooling Process.

From foodsafetytrainingcertification.com

Cooling Food Safely TwoStage Process Food Safety Cooling Process The food code requires that all cooked foods not prepared for immediate service or hot held shall be. Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours. Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. Food. Food Safety Cooling Process.

From www.slideserve.com

PPT Food Safety at Special Food Events PowerPoint Presentation, free Food Safety Cooling Process cooling methods fact sheet. food safety programs and restaurants can improve cooling practices by: The food code requires that all cooked foods not prepared for immediate service or hot held shall be. safe cooling times and temperatures. Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. Focusing. Food Safety Cooling Process.

From www.webstaurantstore.com

Food Cooling Methods Explained staurantStore Food Safety Cooling Process After cooking, foods may be cooled in preparation for longer storage. food safety programs and restaurants can improve cooling practices by: Food and drug administration's (fda) food code cooling guidelines. Encouraging or requiring kitchen managers to be certified in food safety. Focusing intervention efforts on independent and smaller restaurants. safe cooling times and temperatures. food safety requires. Food Safety Cooling Process.

From foodsafetytrainingcertification.com

Cooling Food Safely Food Safety Cooling Process safe rapid cooling of food. Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours. When prepping a large batch of hot food, plan ahead for the cooling method you plan to use. Encouraging or requiring kitchen managers to be certified in food safety. Cooling to the. Food Safety Cooling Process.

From www.walkinrefrigerators.com

Walk in Refrigerators Food Safety Cooling Process food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. When prepping a large batch of hot food, plan ahead for the cooling method you plan to use. After cooking, foods may be cooled in preparation for longer storage. safe cooling times and temperatures. food safety programs and restaurants can improve cooling. Food Safety Cooling Process.

From store.foodsafetymarket.com

Cooling Food Infographic Poster FoodSafetyMarket Food Safety Cooling Process The food code requires that all cooked foods not prepared for immediate service or hot held shall be. safe rapid cooling of food. Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. Food and drug administration's (fda) food code cooling guidelines. food safety programs and restaurants can improve. Food Safety Cooling Process.

From www.fooddocs.com

What Are the 4 Steps of Food Safety? Tips to Follow Food Safety Cooling Process Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. Focusing intervention efforts on independent and smaller restaurants. Encouraging or requiring kitchen managers to be certified in food safety. Food and drug administration's (fda) food code cooling guidelines. food safety requires that all leftovers be reheated to 165°f for at. Food Safety Cooling Process.

From openlab.citytech.cuny.edu

Learning Materials for HMGT Labs Department of Hospitality Management Food Safety Cooling Process After cooking, foods may be cooled in preparation for longer storage. safe cooling times and temperatures. safe rapid cooling of food. Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours. cooling methods fact sheet. Food and drug administration's (fda) food code cooling guidelines. When. Food Safety Cooling Process.

From www.slideserve.com

PPT The Flow of Food Preparation PowerPoint Presentation ID1797291 Food Safety Cooling Process Focusing intervention efforts on independent and smaller restaurants. When prepping a large batch of hot food, plan ahead for the cooling method you plan to use. cooling methods fact sheet. The food code requires that all cooked foods not prepared for immediate service or hot held shall be. safe rapid cooling of food. Tcs food must be cooled. Food Safety Cooling Process.

From mungfali.com

Food Safety Cooling Chart Food Safety Cooling Process safe rapid cooling of food. cooling methods fact sheet. The food code requires that all cooked foods not prepared for immediate service or hot held shall be. food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. When prepping a large batch of hot food, plan ahead for the cooling method you. Food Safety Cooling Process.

From www.youtube.com

Cooking, Cooling and Reheating Food (HACCP Lesson Part 07) YouTube Food Safety Cooling Process After cooking, foods may be cooled in preparation for longer storage. food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. The food code requires that all cooked foods not prepared for immediate service or hot held shall be. When prepping a large batch of hot food, plan ahead for the cooling method you. Food Safety Cooling Process.

From www.statefoodsafety.com

TwoStage Cooling Process Food Safety Cooling Process Encouraging or requiring kitchen managers to be certified in food safety. After cooking, foods may be cooled in preparation for longer storage. Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. The food code requires that all cooked foods not prepared for immediate service or hot held shall be. . Food Safety Cooling Process.

From foodsafetytrainingcertification.com

Cooling Food Safely Food Safety Cooling Process Food and drug administration's (fda) food code cooling guidelines. food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. Tcs food must be cooled from 135°f to 70°f within 2 hours and completely cooled to 41°f or below within 6 hours. Focusing intervention efforts on independent and smaller restaurants. safe cooling times and. Food Safety Cooling Process.

From foodsafepal.com

How to Cool Foods Using the TwoStage Cooling Method Food Safety Cooling Process cooling methods fact sheet. Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. food safety requires that all leftovers be reheated to 165°f for at least 15 seconds. The food code requires that all cooked foods not prepared for immediate service or hot held shall be. safe. Food Safety Cooling Process.

From www.flickr.com

Cooling Poster showing how to safely cool food. Food & Community Food Safety Cooling Process safe cooling times and temperatures. safe rapid cooling of food. cooling methods fact sheet. Cooling to the correct internal temperature is one of the most important food safety operations to protect consumer health. The food code requires that all cooked foods not prepared for immediate service or hot held shall be. When prepping a large batch of. Food Safety Cooling Process.

From www.statefoodsafety.com

Fridge Storage for Food Safety Food Safety Cooling Process Encouraging or requiring kitchen managers to be certified in food safety. After cooking, foods may be cooled in preparation for longer storage. safe rapid cooling of food. Food and drug administration's (fda) food code cooling guidelines. Focusing intervention efforts on independent and smaller restaurants. safe cooling times and temperatures. Cooling to the correct internal temperature is one of. Food Safety Cooling Process.