Pin Manufacturing Process . The manufacturing process of metal pin fasteners typically includes the following steps: The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are being fitted. The modern manufacture of safety pins is completely automatic. Some fifty years after wealth of nations was published, inventors on both sides of the atlantic began building machines to automate the pin making process that had. Specialized machines have been developed to perform multiple steps,. They are also used in. Pin manufacturing is the process of creating bulk quantities of pins. Being able to produce pins with a high level of quality is directly related to. Cutting the raw material (such. The pin itself is a part of the pin joint and the main role of said system is to transfer crushing or shearing loads from the connected elements.

from www.mdpi.com

The pin itself is a part of the pin joint and the main role of said system is to transfer crushing or shearing loads from the connected elements. Specialized machines have been developed to perform multiple steps,. Cutting the raw material (such. Pin manufacturing is the process of creating bulk quantities of pins. The manufacturing process of metal pin fasteners typically includes the following steps: They are also used in. The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. Being able to produce pins with a high level of quality is directly related to. The modern manufacture of safety pins is completely automatic. Some fifty years after wealth of nations was published, inventors on both sides of the atlantic began building machines to automate the pin making process that had.

Applied Sciences Free FullText Transient Numerical Modelling of

Pin Manufacturing Process They are also used in. Cutting the raw material (such. In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are being fitted. Specialized machines have been developed to perform multiple steps,. The pin itself is a part of the pin joint and the main role of said system is to transfer crushing or shearing loads from the connected elements. Some fifty years after wealth of nations was published, inventors on both sides of the atlantic began building machines to automate the pin making process that had. The manufacturing process of metal pin fasteners typically includes the following steps: Being able to produce pins with a high level of quality is directly related to. They are also used in. Pin manufacturing is the process of creating bulk quantities of pins. The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. The modern manufacture of safety pins is completely automatic.

From mccormickind.com

Custom Pin Manufacturing Pin Manufacturing Process They are also used in. The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. Being able to produce pins with a high level of quality is directly related to. Cutting the raw material (such. Specialized machines have been developed to perform multiple steps,. Pin manufacturing is the process of creating bulk quantities. Pin Manufacturing Process.

From hxeqrcinv.blob.core.windows.net

Spring Dowel Pin Manufacturing Process at Dawn Johnson blog Pin Manufacturing Process Cutting the raw material (such. The manufacturing process of metal pin fasteners typically includes the following steps: The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. Specialized machines have been developed to perform multiple steps,. They are also used in. Pin manufacturing is the process of creating bulk quantities of pins. The. Pin Manufacturing Process.

From www.mdpi.com

Mathematics Free FullText A Machine Learning Approach for Pin Manufacturing Process The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. Cutting the raw material (such. The modern manufacture of safety pins is completely automatic. Being able to produce pins with a high level of quality is directly related to. In the manufacturing process, pins are essential in the assembly line since they hold. Pin Manufacturing Process.

From www.researchgate.net

Fabrication process of the InPbased pinphotodiode array... Download Pin Manufacturing Process The pin itself is a part of the pin joint and the main role of said system is to transfer crushing or shearing loads from the connected elements. The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. The manufacturing process of metal pin fasteners typically includes the following steps: Some fifty years. Pin Manufacturing Process.

From www.youtube.com

Dowel Pins Production Solid Dowel Threaded(Internal) Dowel Taper Pin Manufacturing Process The manufacturing process of metal pin fasteners typically includes the following steps: Cutting the raw material (such. The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. They are also used in. In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are. Pin Manufacturing Process.

From www.steelpipesfactory.com

Seamless Pipes Manufacturing How to Produce Seamless Steel Pipes? Pin Manufacturing Process Pin manufacturing is the process of creating bulk quantities of pins. In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are being fitted. The modern manufacture of safety pins is completely automatic. The pin itself is a part of the pin joint and the main role of said system. Pin Manufacturing Process.

From royalbrass.in

Our Manufacturing Process Royal Brass Products Pin Manufacturing Process The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. They are also used in. In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are being fitted. Some fifty years after wealth of nations was published, inventors on both sides of the. Pin Manufacturing Process.

From ambrasenatore.com

Manufacturing Of Hard Gelatin Capsules ambrasenatore Pin Manufacturing Process Specialized machines have been developed to perform multiple steps,. Being able to produce pins with a high level of quality is directly related to. The modern manufacture of safety pins is completely automatic. Cutting the raw material (such. Pin manufacturing is the process of creating bulk quantities of pins. In the manufacturing process, pins are essential in the assembly line. Pin Manufacturing Process.

From djausa.com

hairpin stator process layout DJA USA Pin Manufacturing Process Pin manufacturing is the process of creating bulk quantities of pins. The manufacturing process of metal pin fasteners typically includes the following steps: Specialized machines have been developed to perform multiple steps,. They are also used in. The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. Cutting the raw material (such. The. Pin Manufacturing Process.

From www.slideshare.net

How Piston Pin Manufactured and What Are Its Uses? Pin Manufacturing Process Some fifty years after wealth of nations was published, inventors on both sides of the atlantic began building machines to automate the pin making process that had. The manufacturing process of metal pin fasteners typically includes the following steps: Pin manufacturing is the process of creating bulk quantities of pins. They are also used in. Being able to produce pins. Pin Manufacturing Process.

From bedfordreinforced.com

The Pultrusion Process How Pultrusion Works (Pultruded Profiles) Pin Manufacturing Process Being able to produce pins with a high level of quality is directly related to. Specialized machines have been developed to perform multiple steps,. Some fifty years after wealth of nations was published, inventors on both sides of the atlantic began building machines to automate the pin making process that had. They are also used in. The manufacturing process in. Pin Manufacturing Process.

From www.pinterest.com

Mandrel Mill process Pin Manufacturing Process Pin manufacturing is the process of creating bulk quantities of pins. Some fifty years after wealth of nations was published, inventors on both sides of the atlantic began building machines to automate the pin making process that had. Cutting the raw material (such. Specialized machines have been developed to perform multiple steps,. They are also used in. The pin itself. Pin Manufacturing Process.

From www.lhecn.com

Production Process of Connector LHE Electronics Pin Manufacturing Process They are also used in. The modern manufacture of safety pins is completely automatic. In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are being fitted. Being able to produce pins with a high level of quality is directly related to. Specialized machines have been developed to perform multiple. Pin Manufacturing Process.

From www.youtube.com

Semiconductor Manufacturing Process Flow Chart YouTube Pin Manufacturing Process Pin manufacturing is the process of creating bulk quantities of pins. The manufacturing process of metal pin fasteners typically includes the following steps: The modern manufacture of safety pins is completely automatic. Cutting the raw material (such. Being able to produce pins with a high level of quality is directly related to. They are also used in. In the manufacturing. Pin Manufacturing Process.

From www.novoprecision.com

Pin Manufacturing Equipment Pin Manufacturing Process They are also used in. The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are being fitted. Cutting the raw material (such. Being able to produce pins with a high level of. Pin Manufacturing Process.

From mccormickind.com

Custom Pin Manufacturing Pin Manufacturing Process In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are being fitted. The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. Being able to produce pins with a high level of quality is directly related to. They are also used in.. Pin Manufacturing Process.

From www.semanticscholar.org

Figure 1 from Design and Fabrication Jig and Fixture for Pin Component Pin Manufacturing Process They are also used in. The manufacturing process of metal pin fasteners typically includes the following steps: The pin itself is a part of the pin joint and the main role of said system is to transfer crushing or shearing loads from the connected elements. The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are. Pin Manufacturing Process.

From www.rapiddirect.com

What's CNC Turning? Its Process, Operations, Advantages RapidDdirect Pin Manufacturing Process The modern manufacture of safety pins is completely automatic. Some fifty years after wealth of nations was published, inventors on both sides of the atlantic began building machines to automate the pin making process that had. Pin manufacturing is the process of creating bulk quantities of pins. They are also used in. The manufacturing process of metal pin fasteners typically. Pin Manufacturing Process.

From www.cdn-inc.com

Plastic Injection Molding Process Guide 2019 Full Process Explained Pin Manufacturing Process The pin itself is a part of the pin joint and the main role of said system is to transfer crushing or shearing loads from the connected elements. The manufacturing process of metal pin fasteners typically includes the following steps: Cutting the raw material (such. Pin manufacturing is the process of creating bulk quantities of pins. The manufacturing process in. Pin Manufacturing Process.

From studylib.net

Piston and Piston Pin Manufacturing Process Improvement Pin Manufacturing Process The modern manufacture of safety pins is completely automatic. Pin manufacturing is the process of creating bulk quantities of pins. Some fifty years after wealth of nations was published, inventors on both sides of the atlantic began building machines to automate the pin making process that had. Cutting the raw material (such. Being able to produce pins with a high. Pin Manufacturing Process.

From www.vrogue.co

Pin On Layered Svgs For Your Cutting Machine vrogue.co Pin Manufacturing Process Specialized machines have been developed to perform multiple steps,. In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are being fitted. The modern manufacture of safety pins is completely automatic. They are also used in. The pin itself is a part of the pin joint and the main role. Pin Manufacturing Process.

From www.mdpi.com

Materials Free FullText Wear Improvement of Tools in the Cold Pin Manufacturing Process Cutting the raw material (such. Pin manufacturing is the process of creating bulk quantities of pins. Some fifty years after wealth of nations was published, inventors on both sides of the atlantic began building machines to automate the pin making process that had. In the manufacturing process, pins are essential in the assembly line since they hold parts in place. Pin Manufacturing Process.

From imautomation.com

CWIEME Shanghai 2024 Exhibitions Pin Manufacturing Process Specialized machines have been developed to perform multiple steps,. In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are being fitted. The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. Pin manufacturing is the process of creating bulk quantities of pins.. Pin Manufacturing Process.

From www.mdpi.com

Applied Sciences Free FullText Transient Numerical Modelling of Pin Manufacturing Process Specialized machines have been developed to perform multiple steps,. In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are being fitted. Cutting the raw material (such. The manufacturing process of metal pin fasteners typically includes the following steps: The manufacturing process in the modern pin manufacturing plant, hundreds of. Pin Manufacturing Process.

From hxeqrcinv.blob.core.windows.net

Spring Dowel Pin Manufacturing Process at Dawn Johnson blog Pin Manufacturing Process In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are being fitted. The modern manufacture of safety pins is completely automatic. Specialized machines have been developed to perform multiple steps,. The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. They are. Pin Manufacturing Process.

From www.semanticscholar.org

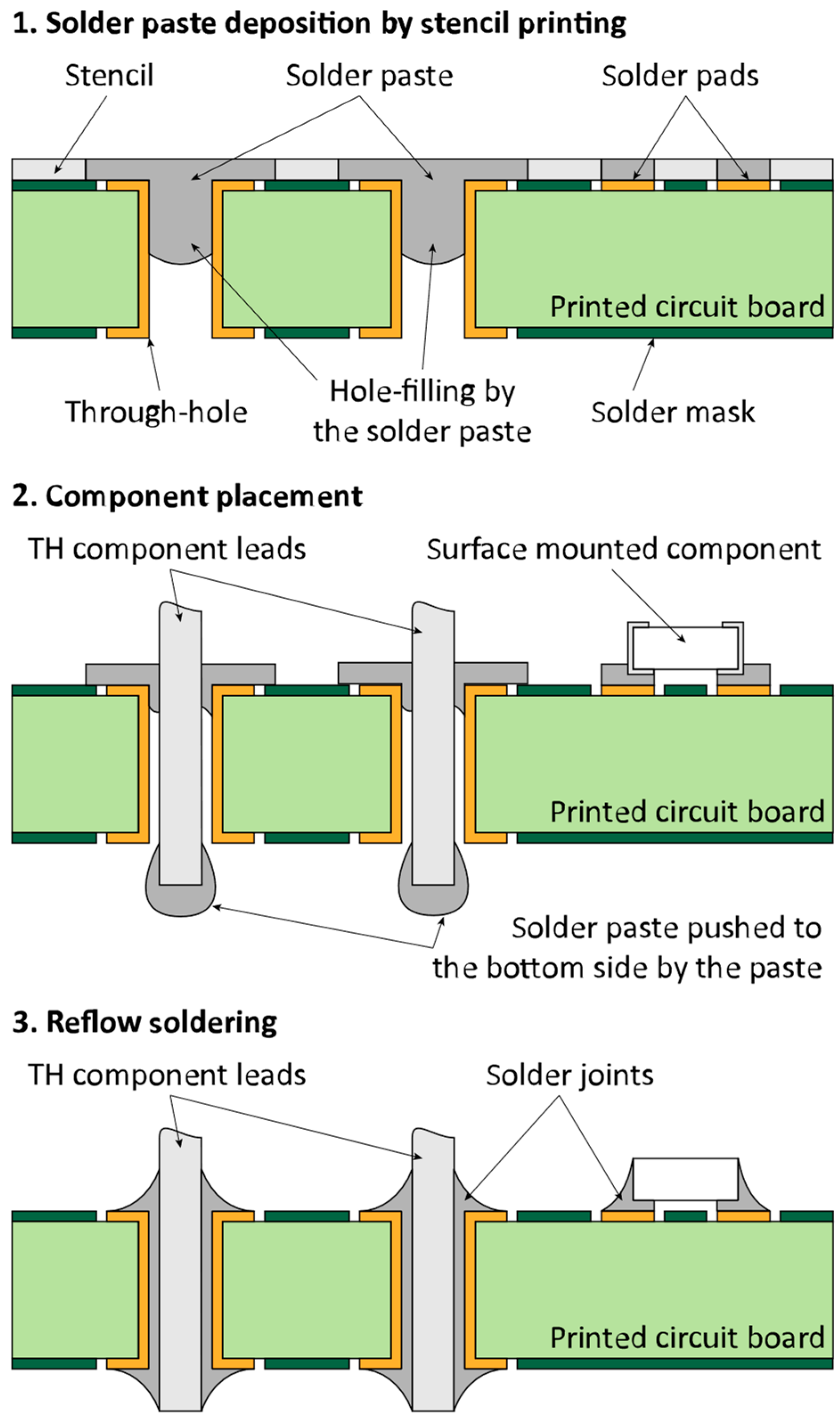

[PDF] Investigation for Use of Pin in Paste Reflow Process with Pin Manufacturing Process Some fifty years after wealth of nations was published, inventors on both sides of the atlantic began building machines to automate the pin making process that had. Specialized machines have been developed to perform multiple steps,. The manufacturing process of metal pin fasteners typically includes the following steps: Cutting the raw material (such. In the manufacturing process, pins are essential. Pin Manufacturing Process.

From www.researchgate.net

Aluminum beverage can technology process. Download Scientific Diagram Pin Manufacturing Process Cutting the raw material (such. Some fifty years after wealth of nations was published, inventors on both sides of the atlantic began building machines to automate the pin making process that had. They are also used in. In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are being fitted.. Pin Manufacturing Process.

From www.youtube.com

Ejector pins manufacturing process YouTube Pin Manufacturing Process Cutting the raw material (such. The pin itself is a part of the pin joint and the main role of said system is to transfer crushing or shearing loads from the connected elements. The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. The modern manufacture of safety pins is completely automatic. Specialized. Pin Manufacturing Process.

From www.researchgate.net

(PDF) Effect of Machine PinManufacturing Process Parameters by Plasma Pin Manufacturing Process The modern manufacture of safety pins is completely automatic. They are also used in. Being able to produce pins with a high level of quality is directly related to. Specialized machines have been developed to perform multiple steps,. Cutting the raw material (such. Some fifty years after wealth of nations was published, inventors on both sides of the atlantic began. Pin Manufacturing Process.

From djausa.com

Hairpin Motors DJA USA Pin Manufacturing Process Pin manufacturing is the process of creating bulk quantities of pins. In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are being fitted. Cutting the raw material (such. The manufacturing process of metal pin fasteners typically includes the following steps: Being able to produce pins with a high level. Pin Manufacturing Process.

From themechanicalengineering.com

What is Forming? Types of Forming Process [Notes & PDF] Pin Manufacturing Process Specialized machines have been developed to perform multiple steps,. They are also used in. Cutting the raw material (such. The modern manufacture of safety pins is completely automatic. Pin manufacturing is the process of creating bulk quantities of pins. The pin itself is a part of the pin joint and the main role of said system is to transfer crushing. Pin Manufacturing Process.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Pin Manufacturing Process The pin itself is a part of the pin joint and the main role of said system is to transfer crushing or shearing loads from the connected elements. The manufacturing process of metal pin fasteners typically includes the following steps: The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. Being able to. Pin Manufacturing Process.

From hxeqrcinv.blob.core.windows.net

Spring Dowel Pin Manufacturing Process at Dawn Johnson blog Pin Manufacturing Process Some fifty years after wealth of nations was published, inventors on both sides of the atlantic began building machines to automate the pin making process that had. The modern manufacture of safety pins is completely automatic. The pin itself is a part of the pin joint and the main role of said system is to transfer crushing or shearing loads. Pin Manufacturing Process.

From www.raypcb.com

What is Pin in Paste (PiP) Soldering Technology RAYPCB Pin Manufacturing Process Specialized machines have been developed to perform multiple steps,. Some fifty years after wealth of nations was published, inventors on both sides of the atlantic began building machines to automate the pin making process that had. The modern manufacture of safety pins is completely automatic. Being able to produce pins with a high level of quality is directly related to.. Pin Manufacturing Process.

From mungfali.com

Lithium Battery Manufacturing Process Pin Manufacturing Process Pin manufacturing is the process of creating bulk quantities of pins. The modern manufacture of safety pins is completely automatic. In the manufacturing process, pins are essential in the assembly line since they hold parts in place while other parts are being fitted. The manufacturing process in the modern pin manufacturing plant, hundreds of thousands of pins are produced daily.. Pin Manufacturing Process.