Leaf Spring Chemical Composition . operation and basic design. this study observed static conduct for a composite leaf spring in comparison to that of a steel leaf spring. aisi sae 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is commonly used in industrial applications as well as in. They also contain other alloy additives such as manganese, nickel, chrome, vanadium, and molybdenum. the study evaluates the stress distribution, deflection and fatigue life assessment of leaf springs made up of glass epoxy (62% glass fiber), carbon. this international standard specifies the technical specifications for leaf springs. they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for. the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. However, the essential element in the composition of spring steels is silicon. This international standard is applicable to leaf. Leaves are fastened together by the centre bolt, midway along the length of the. Generic diagram of a leaf spring pack, without eyes;

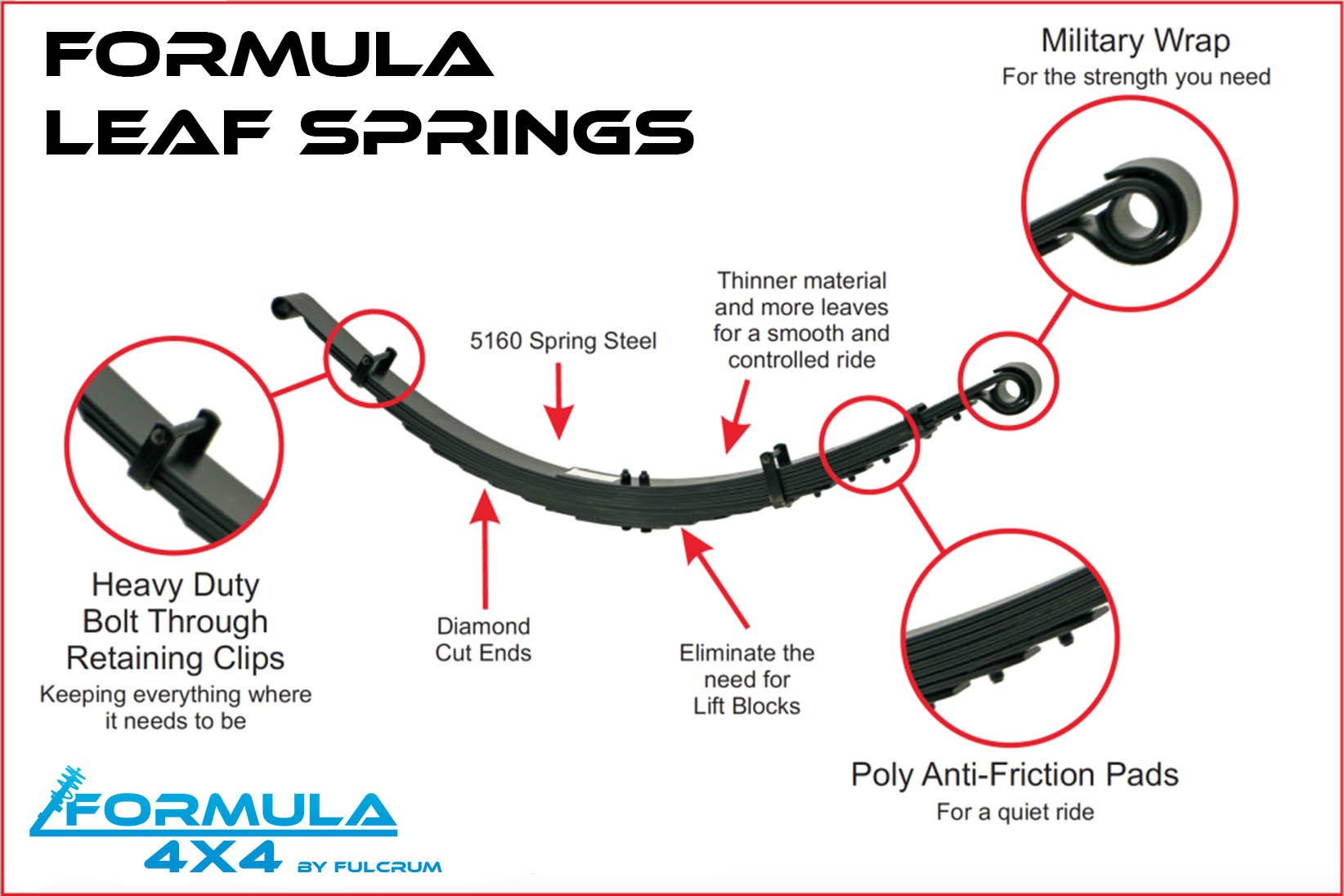

from fulcrumsuspensions.com.au

the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for. this international standard specifies the technical specifications for leaf springs. However, the essential element in the composition of spring steels is silicon. This international standard is applicable to leaf. aisi sae 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is commonly used in industrial applications as well as in. operation and basic design. Leaves are fastened together by the centre bolt, midway along the length of the. the study evaluates the stress distribution, deflection and fatigue life assessment of leaf springs made up of glass epoxy (62% glass fiber), carbon. Generic diagram of a leaf spring pack, without eyes;

Leaf Spring Suspension Leaf Springs Fulcrum Suspensions

Leaf Spring Chemical Composition This international standard is applicable to leaf. However, the essential element in the composition of spring steels is silicon. they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for. Generic diagram of a leaf spring pack, without eyes; This international standard is applicable to leaf. Leaves are fastened together by the centre bolt, midway along the length of the. the study evaluates the stress distribution, deflection and fatigue life assessment of leaf springs made up of glass epoxy (62% glass fiber), carbon. They also contain other alloy additives such as manganese, nickel, chrome, vanadium, and molybdenum. this study observed static conduct for a composite leaf spring in comparison to that of a steel leaf spring. operation and basic design. this international standard specifies the technical specifications for leaf springs. aisi sae 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is commonly used in industrial applications as well as in. the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such.

From www.superiorspring.net

What are Leaf Springs? Leaf Spring Chemical Composition operation and basic design. They also contain other alloy additives such as manganese, nickel, chrome, vanadium, and molybdenum. they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for. the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. However,. Leaf Spring Chemical Composition.

From fulcrumsuspensions.com.au

Leaf Spring Suspension Leaf Springs Fulcrum Suspensions Leaf Spring Chemical Composition aisi sae 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is commonly used in industrial applications as well as in. However, the essential element in the composition of spring steels is silicon. this international standard specifies the technical specifications for leaf springs. this study observed static conduct for a composite leaf spring in. Leaf Spring Chemical Composition.

From www.jpe-innovations.com

Flexure engineering fundamental Leaf spring JPE Leaf Spring Chemical Composition aisi sae 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is commonly used in industrial applications as well as in. the study evaluates the stress distribution, deflection and fatigue life assessment of leaf springs made up of glass epoxy (62% glass fiber), carbon. operation and basic design. Generic diagram of a leaf spring. Leaf Spring Chemical Composition.

From desklib.com

Analysis of Composite Leaf Springs Desklib Leaf Spring Chemical Composition operation and basic design. they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for. They also contain other alloy additives such as manganese, nickel, chrome, vanadium, and molybdenum. the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. . Leaf Spring Chemical Composition.

From feaforall.com

[Salome Meca Tutorial] Leaf Spring Material and Contact FEA Leaf Spring Chemical Composition This international standard is applicable to leaf. this international standard specifies the technical specifications for leaf springs. they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for. the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. Leaves are. Leaf Spring Chemical Composition.

From suspensionsecrets.co.uk

How To Calculate Spring Rates How To Adjust And Tune Suspension Secrets Leaf Spring Chemical Composition operation and basic design. the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. Leaves are fastened together by the centre bolt, midway along the length of the. They also contain other alloy additives such as manganese, nickel, chrome, vanadium, and molybdenum. this study observed static conduct for a. Leaf Spring Chemical Composition.

From deaverspring.com

What is the proper way to measure my leaf springs? Deaver Spring Inc Leaf Spring Chemical Composition operation and basic design. this study observed static conduct for a composite leaf spring in comparison to that of a steel leaf spring. Leaves are fastened together by the centre bolt, midway along the length of the. This international standard is applicable to leaf. They also contain other alloy additives such as manganese, nickel, chrome, vanadium, and molybdenum.. Leaf Spring Chemical Composition.

From www.ijraset.com

Design Analysis and Weight Optimization of Mono Leaf Spring by Using Leaf Spring Chemical Composition aisi sae 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is commonly used in industrial applications as well as in. the study evaluates the stress distribution, deflection and fatigue life assessment of leaf springs made up of glass epoxy (62% glass fiber), carbon. operation and basic design. the properties required of the. Leaf Spring Chemical Composition.

From www.sglcarbon.com

Compositeleafsprings SGL Carbon Leaf Spring Chemical Composition the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. They also contain other alloy additives such as manganese, nickel, chrome, vanadium, and molybdenum. This international standard is applicable to leaf. this international standard specifies the technical specifications for leaf springs. the study evaluates the stress distribution, deflection and. Leaf Spring Chemical Composition.

From lalithvarun.blogspot.com

What are LEAF SPRINGS...??? techcollage...!!! Leaf Spring Chemical Composition the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. Generic diagram of a leaf spring pack, without eyes; they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for. However, the essential element in the composition of spring steels is. Leaf Spring Chemical Composition.

From nisazpamo.weebly.com

Sae Leaf Spring Design Manual TOP Leaf Spring Chemical Composition Leaves are fastened together by the centre bolt, midway along the length of the. They also contain other alloy additives such as manganese, nickel, chrome, vanadium, and molybdenum. However, the essential element in the composition of spring steels is silicon. Generic diagram of a leaf spring pack, without eyes; aisi sae 5160 high carbon steel has excellent toughness, ductility. Leaf Spring Chemical Composition.

From www.theengineerspost.com

Leaf Spring Suspension Diagram, Parts, Types, Uses [PDF] Leaf Spring Chemical Composition However, the essential element in the composition of spring steels is silicon. the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. They also contain other alloy additives such as manganese, nickel, chrome, vanadium, and molybdenum. this international standard specifies the technical specifications for leaf springs. Leaves are fastened together. Leaf Spring Chemical Composition.

From www.ijraset.com

Design Analysis and Weight Optimization of Mono Leaf Spring by Using Leaf Spring Chemical Composition this international standard specifies the technical specifications for leaf springs. they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for. the study evaluates the stress distribution, deflection and fatigue life assessment of leaf springs made up of glass epoxy (62% glass fiber), carbon. This international standard is. Leaf Spring Chemical Composition.

From nisazpamo.weebly.com

Sae Leaf Spring Design Manual TOP Leaf Spring Chemical Composition the study evaluates the stress distribution, deflection and fatigue life assessment of leaf springs made up of glass epoxy (62% glass fiber), carbon. Generic diagram of a leaf spring pack, without eyes; the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. However, the essential element in the composition of. Leaf Spring Chemical Composition.

From www.ijraset.com

Design and Analysis of Steel Leaf Spring and Composite Leaf Spring Leaf Spring Chemical Composition They also contain other alloy additives such as manganese, nickel, chrome, vanadium, and molybdenum. they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for. the study evaluates the stress distribution, deflection and fatigue life assessment of leaf springs made up of glass epoxy (62% glass fiber), carbon. . Leaf Spring Chemical Composition.

From www.youtube.com

Animation How leaf spring works. YouTube Leaf Spring Chemical Composition this international standard specifies the technical specifications for leaf springs. Leaves are fastened together by the centre bolt, midway along the length of the. the study evaluates the stress distribution, deflection and fatigue life assessment of leaf springs made up of glass epoxy (62% glass fiber), carbon. this study observed static conduct for a composite leaf spring. Leaf Spring Chemical Composition.

From www.researchgate.net

(PDF) "STUDY OF THE CHEMICAL COMPOSITION OF THE SPRING LEAF AND THE Leaf Spring Chemical Composition they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for. the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. operation and basic design. this study observed static conduct for a composite leaf spring in comparison to that. Leaf Spring Chemical Composition.

From desklib.com

Analysis of Composite Leaf Springs Desklib Leaf Spring Chemical Composition the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. aisi sae 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is commonly used in industrial applications as well as in. However, the essential element in the composition of spring steels is silicon. Generic diagram of a. Leaf Spring Chemical Composition.

From leafsprings198.com

Leaf Spring Standards Ensuring Quality & Performance Leaf Spring Chemical Composition operation and basic design. This international standard is applicable to leaf. Leaves are fastened together by the centre bolt, midway along the length of the. this study observed static conduct for a composite leaf spring in comparison to that of a steel leaf spring. the properties required of the steels for springs are obtained by higher carbon. Leaf Spring Chemical Composition.

From www.slideserve.com

PPT LEAF SPRING PowerPoint Presentation, free download ID1617575 Leaf Spring Chemical Composition the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. Leaves are fastened together by the centre bolt, midway along the length of the. the study evaluates the stress distribution, deflection and fatigue life assessment of leaf springs made up of glass epoxy (62% glass fiber), carbon. this study. Leaf Spring Chemical Composition.

From www.researchgate.net

(PDF) Fatigue life improvement of parabolic leaf springs Process of Leaf Spring Chemical Composition They also contain other alloy additives such as manganese, nickel, chrome, vanadium, and molybdenum. this international standard specifies the technical specifications for leaf springs. Leaves are fastened together by the centre bolt, midway along the length of the. the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. they. Leaf Spring Chemical Composition.

From mechcontent.com

Semi Elliptical leaf spring Explained Diagram, Construction, Nipping Leaf Spring Chemical Composition aisi sae 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is commonly used in industrial applications as well as in. the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. the study evaluates the stress distribution, deflection and fatigue life assessment of leaf springs made. Leaf Spring Chemical Composition.

From www.ijraset.com

Design Analysis and Weight Optimization of Mono Leaf Spring by Using Leaf Spring Chemical Composition However, the essential element in the composition of spring steels is silicon. they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for. this international standard specifies the technical specifications for leaf springs. Generic diagram of a leaf spring pack, without eyes; operation and basic design. They also. Leaf Spring Chemical Composition.

From www.slideserve.com

PPT Leaf Springs Leaf Springs Manufacturer PowerPoint Presentation Leaf Spring Chemical Composition They also contain other alloy additives such as manganese, nickel, chrome, vanadium, and molybdenum. the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. aisi sae 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is commonly used in industrial applications as well as in. However, the. Leaf Spring Chemical Composition.

From www.plasticsnews.com

leaf spring takes top SPE Automotive Innovation award Leaf Spring Chemical Composition this international standard specifies the technical specifications for leaf springs. operation and basic design. This international standard is applicable to leaf. However, the essential element in the composition of spring steels is silicon. Leaves are fastened together by the centre bolt, midway along the length of the. the study evaluates the stress distribution, deflection and fatigue life. Leaf Spring Chemical Composition.

From www.dubizzle.com

Leaf Spring Vs Coil Spring, Difference, Functions & More Leaf Spring Chemical Composition aisi sae 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is commonly used in industrial applications as well as in. Leaves are fastened together by the centre bolt, midway along the length of the. they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for.. Leaf Spring Chemical Composition.

From sachinkhevariadesign.blogspot.com

Design and Manufacturing of Leaf Spring Design and Manufacturing Of Leaf Spring Chemical Composition Generic diagram of a leaf spring pack, without eyes; the study evaluates the stress distribution, deflection and fatigue life assessment of leaf springs made up of glass epoxy (62% glass fiber), carbon. the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. this international standard specifies the technical specifications. Leaf Spring Chemical Composition.

From www.youtube.com

Semielliptic Leaf spring in hindi YouTube Leaf Spring Chemical Composition they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for. this study observed static conduct for a composite leaf spring in comparison to that of a steel leaf spring. This international standard is applicable to leaf. Leaves are fastened together by the centre bolt, midway along the length. Leaf Spring Chemical Composition.

From roccofingal.blogspot.com

7+ leaf spring shackle diagram RoccoFingal Leaf Spring Chemical Composition However, the essential element in the composition of spring steels is silicon. this study observed static conduct for a composite leaf spring in comparison to that of a steel leaf spring. operation and basic design. This international standard is applicable to leaf. Leaves are fastened together by the centre bolt, midway along the length of the. they. Leaf Spring Chemical Composition.

From dxofdbvfe.blob.core.windows.net

Leaf Spring Design Guide at James Hoover blog Leaf Spring Chemical Composition Generic diagram of a leaf spring pack, without eyes; However, the essential element in the composition of spring steels is silicon. this international standard specifies the technical specifications for leaf springs. the study evaluates the stress distribution, deflection and fatigue life assessment of leaf springs made up of glass epoxy (62% glass fiber), carbon. Leaves are fastened together. Leaf Spring Chemical Composition.

From www.cnluen.com

leaf spring Buy leaf spring Product on LUENTrailer Parts Leaf Spring Chemical Composition they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for. However, the essential element in the composition of spring steels is silicon. This international standard is applicable to leaf. operation and basic design. Leaves are fastened together by the centre bolt, midway along the length of the. . Leaf Spring Chemical Composition.

From desklib.com

Analysis of Composite Leaf Springs Desklib Leaf Spring Chemical Composition operation and basic design. They also contain other alloy additives such as manganese, nickel, chrome, vanadium, and molybdenum. However, the essential element in the composition of spring steels is silicon. aisi sae 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is commonly used in industrial applications as well as in. they specify the. Leaf Spring Chemical Composition.

From www.researchgate.net

(a) Geometry of composite leaf spring body in longitudinal section, (b Leaf Spring Chemical Composition this study observed static conduct for a composite leaf spring in comparison to that of a steel leaf spring. Generic diagram of a leaf spring pack, without eyes; They also contain other alloy additives such as manganese, nickel, chrome, vanadium, and molybdenum. operation and basic design. this international standard specifies the technical specifications for leaf springs. Leaves. Leaf Spring Chemical Composition.

From desklib.com

Analysis of Composite Leaf Springs Desklib Leaf Spring Chemical Composition aisi sae 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is commonly used in industrial applications as well as in. This international standard is applicable to leaf. However, the essential element in the composition of spring steels is silicon. the properties required of the steels for springs are obtained by higher carbon contents and. Leaf Spring Chemical Composition.

From dreamcivil.com

Leaf spring Numericals Important Formulas & Numericals Dream Civil Leaf Spring Chemical Composition they specify the chemical composition, mechanical properties, heat treatment, surface condition, and quality control methods for the materials used for. the properties required of the steels for springs are obtained by higher carbon contents and alloying constituents such. aisi sae 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is commonly used in industrial. Leaf Spring Chemical Composition.