Aluminium Arc Welding Tips . In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. The best way to weld. 7020) series can be fusion welded with arc. Tig welding is a skill that must be taught by a. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig. Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and the need to work with different material thicknesses. Arc welding is commonly used for joining aluminium alloys. All commercial welding operations should have a written welding procedure specification (wps) for each weldment that is produced. In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. Most of the wrought grades in the 1xxx, 3xxx, 5xxx, 6xxx and medium strength 7xxx (e.g.

from diagramnanulik38.z22.web.core.windows.net

Tig welding is a skill that must be taught by a. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. All commercial welding operations should have a written welding procedure specification (wps) for each weldment that is produced. The best way to weld. In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig. Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and the need to work with different material thicknesses. 7020) series can be fusion welded with arc. Most of the wrought grades in the 1xxx, 3xxx, 5xxx, 6xxx and medium strength 7xxx (e.g. Arc welding is commonly used for joining aluminium alloys.

Arc Welding Techniques Pdf

Aluminium Arc Welding Tips Tig welding is a skill that must be taught by a. 7020) series can be fusion welded with arc. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. The best way to weld. Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and the need to work with different material thicknesses. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig. Arc welding is commonly used for joining aluminium alloys. Tig welding is a skill that must be taught by a. In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. All commercial welding operations should have a written welding procedure specification (wps) for each weldment that is produced. Most of the wrought grades in the 1xxx, 3xxx, 5xxx, 6xxx and medium strength 7xxx (e.g.

From www.arccaptain.com

GMAW Aluminum Welding Tips and Techniques Aluminium Arc Welding Tips Arc welding is commonly used for joining aluminium alloys. Tig welding is a skill that must be taught by a. 7020) series can be fusion welded with arc. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. Yes, you can weld aluminum, usually with tig welding (gtaw),. Aluminium Arc Welding Tips.

From gootutorials.blogspot.com

How To Use A Mig Welder To Weld Aluminum Aluminium Arc Welding Tips Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig. The best way to weld. All commercial welding operations should have a written welding procedure specification (wps) for each weldment that is produced. Tig welding is a skill that must be taught by a. Arc welding is. Aluminium Arc Welding Tips.

From proleantech.com

Arc Welding Vs. Gas Welding What's the Difference? Aluminium Arc Welding Tips Arc welding is commonly used for joining aluminium alloys. Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and the need to work with different material thicknesses. Most of the wrought grades in the 1xxx, 3xxx, 5xxx, 6xxx and medium strength 7xxx (e.g. In order to weld aluminum, you must use tig welding, a form of welding that. Aluminium Arc Welding Tips.

From ar.inspiredpencil.com

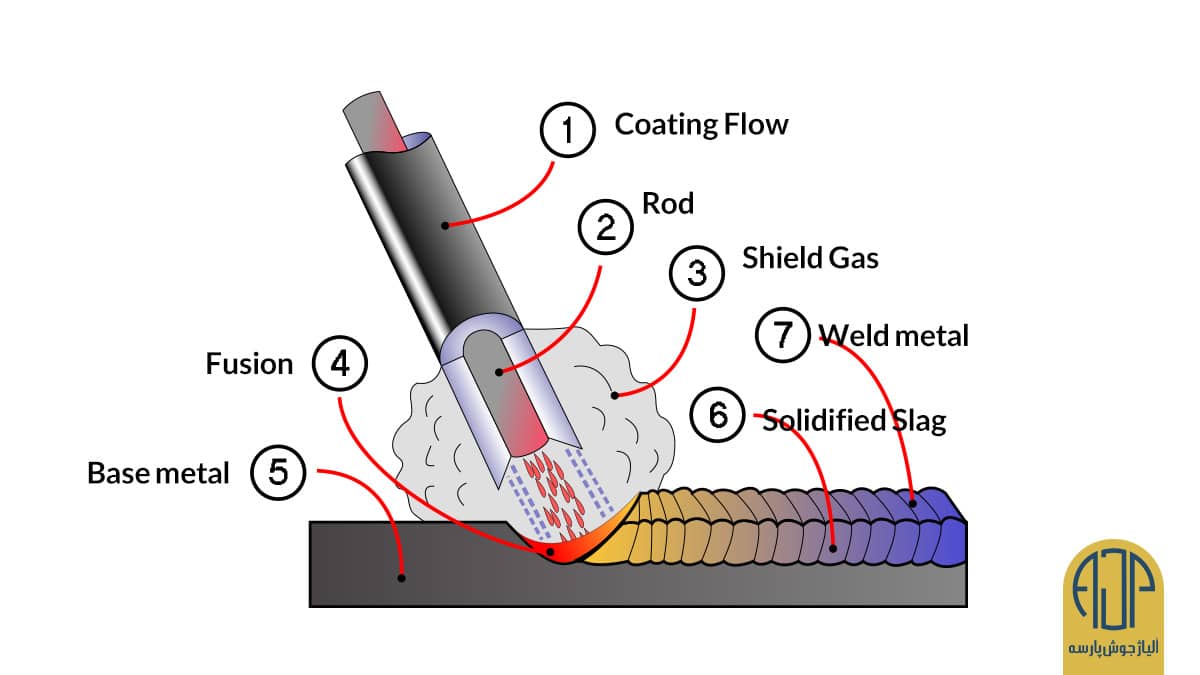

Arc Welding Diagram Aluminium Arc Welding Tips Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig. 7020) series can be fusion welded with arc. Most of the wrought grades in the 1xxx, 3xxx, 5xxx, 6xxx and medium strength 7xxx (e.g. The best way to weld. Tig welding is a skill that must be. Aluminium Arc Welding Tips.

From www.yk-longshun.com

Aluminum Arc Welding Rod Tips, Techniques, and Best Practices www.yk Aluminium Arc Welding Tips Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and the need to work with different material thicknesses. Tig welding is a skill that must be taught by a. 7020) series can be fusion welded with arc. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes. Aluminium Arc Welding Tips.

From socalweldtrainingschool.org

Gas Tungsten Arc Welding (TIG) II Weldments on Aluminum Aluminium Arc Welding Tips In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig. Most of the wrought grades in the 1xxx, 3xxx, 5xxx, 6xxx and medium strength 7xxx. Aluminium Arc Welding Tips.

From weldingpros.net

How to TIG Weld Steel and Aluminum Basics, Setup and Tips Aluminium Arc Welding Tips Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and the need to work with different material thicknesses. In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. The best way to weld. Yes, you can weld aluminum, usually with tig welding (gtaw), but. Aluminium Arc Welding Tips.

From weldguru.com

Arc Welding Explained What Is It & How Does It Work? Weld Guru Aluminium Arc Welding Tips In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. Arc welding is commonly used for joining aluminium alloys. Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and the need to work with different material thicknesses. 7020) series can be fusion welded with. Aluminium Arc Welding Tips.

From www.gemathis.com

Understanding Gas Metal Arc Welding G.E. MATHIS COMPANY Aluminium Arc Welding Tips Tig welding is a skill that must be taught by a. Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and the need to work with different material thicknesses. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig. Arc welding is commonly used for. Aluminium Arc Welding Tips.

From www.pinterest.com

Lesson 1 Striking an ARC Learn How to Weld Series Welding tips Aluminium Arc Welding Tips In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. 7020) series can be fusion welded with arc. Tig welding is a skill that. Aluminium Arc Welding Tips.

From weldguru.com

4 Main Types of Welding Processes (with diagrams) Aluminium Arc Welding Tips Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and the need to work with different material thicknesses. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other. Aluminium Arc Welding Tips.

From weldingtroop.com

Can You Weld Aluminum With an Arc Welder? All You Need to Know Aluminium Arc Welding Tips 7020) series can be fusion welded with arc. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig. In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. The best way to weld.. Aluminium Arc Welding Tips.

From pabloaresrichard.blogspot.com

Flux Cored Arc Welding PabloaresRichard Aluminium Arc Welding Tips In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. 7020) series can be fusion welded with arc. Factors that make aluminum difficult to. Aluminium Arc Welding Tips.

From sciencing.com

How to Weld Aluminum with an ARC Welder Sciencing Aluminium Arc Welding Tips Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and the need to work with different material thicknesses. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. The best way to weld. Arc welding is commonly used for joining aluminium alloys. 7020) series can be. Aluminium Arc Welding Tips.

From www.youtube.com

Shielded Metal Arc Welding Part 1 YouTube Aluminium Arc Welding Tips 7020) series can be fusion welded with arc. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. Tig welding is a skill that must be taught by a. The best way to weld. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also. Aluminium Arc Welding Tips.

From socalweldtrainingschool.org

Shielded Metal Arc Welding (Arc) I Fundamentals Arc Welding Aluminium Arc Welding Tips The best way to weld. Most of the wrought grades in the 1xxx, 3xxx, 5xxx, 6xxx and medium strength 7xxx (e.g. 7020) series can be fusion welded with arc. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig. Factors that make aluminum difficult to weld include. Aluminium Arc Welding Tips.

From www.pinterest.com

How to Weld Aluminum Without a Welder Brazing, Welding projects Aluminium Arc Welding Tips The best way to weld. All commercial welding operations should have a written welding procedure specification (wps) for each weldment that is produced. Most of the wrought grades in the 1xxx, 3xxx, 5xxx, 6xxx and medium strength 7xxx (e.g. Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and the need to work with different material thicknesses. 7020). Aluminium Arc Welding Tips.

From sensibledigs.com

How To Arc Weld Simple StepbyStep Guide Aluminium Arc Welding Tips 7020) series can be fusion welded with arc. In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig. In this blog post, we’ll. Aluminium Arc Welding Tips.

From www.researchgate.net

Manual metal arc welding. Download Scientific Diagram Aluminium Arc Welding Tips 7020) series can be fusion welded with arc. The best way to weld. Arc welding is commonly used for joining aluminium alloys. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring. Aluminium Arc Welding Tips.

From weldsmartly.com

Arc Welding Basics (Tips For Beginners) Weldsmartly Aluminium Arc Welding Tips In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. The best way to weld. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. Most of the wrought grades in the 1xxx, 3xxx,. Aluminium Arc Welding Tips.

From www.youtube.com

How to Strike an Arc Stick Welding Basics for Beginners YouTube Aluminium Arc Welding Tips Arc welding is commonly used for joining aluminium alloys. Most of the wrought grades in the 1xxx, 3xxx, 5xxx, 6xxx and medium strength 7xxx (e.g. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. The best way to weld. All commercial welding operations should have a written. Aluminium Arc Welding Tips.

From qaqctips.blogspot.com

Arc Welding QA/QC Tips & Guides Aluminium Arc Welding Tips The best way to weld. In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. Arc welding is commonly used for joining aluminium alloys. All commercial welding operations should have a written welding procedure specification (wps) for each weldment that is produced. Factors that make aluminum. Aluminium Arc Welding Tips.

From blog.thepipingmart.com

Gas Metal Arc Welding Advantages and Disadvantages Aluminium Arc Welding Tips Arc welding is commonly used for joining aluminium alloys. Most of the wrought grades in the 1xxx, 3xxx, 5xxx, 6xxx and medium strength 7xxx (e.g. In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. Factors that make aluminum difficult to weld include oxidation, porousness, impurities,. Aluminium Arc Welding Tips.

From weldingmastermind.com

11 Tips for TIG Welding Aluminum with DC Welding Mastermind Aluminium Arc Welding Tips In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. The best way to weld. Arc welding is commonly used for joining aluminium alloys.. Aluminium Arc Welding Tips.

From weldinghelmetpros.com

Aluminium Welding How to Weld Aluminium Aluminium Arc Welding Tips Tig welding is a skill that must be taught by a. 7020) series can be fusion welded with arc. All commercial welding operations should have a written welding procedure specification (wps) for each weldment that is produced. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig.. Aluminium Arc Welding Tips.

From blog.thepipingmart.com

How Does Metal Arc Welding Work And What Are Its Types? Aluminium Arc Welding Tips The best way to weld. 7020) series can be fusion welded with arc. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig. Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and the need to work with different material thicknesses. Arc welding is commonly. Aluminium Arc Welding Tips.

From exolhjqte.blob.core.windows.net

Tips For Arc Welding Beginners at Norma Reynolds blog Aluminium Arc Welding Tips Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. All commercial welding operations should have a written welding procedure specification (wps) for each weldment. Aluminium Arc Welding Tips.

From www.midwesternplants.org

Best Aluminum Welding Tips Aluminium Arc Welding Tips Arc welding is commonly used for joining aluminium alloys. All commercial welding operations should have a written welding procedure specification (wps) for each weldment that is produced. Tig welding is a skill that must be taught by a. 7020) series can be fusion welded with arc. In this blog post, we’ll delve into the realm of arc welding for aluminum,. Aluminium Arc Welding Tips.

From enginerileybannerol.z21.web.core.windows.net

Arc Welding Process Diagram Aluminium Arc Welding Tips In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. All commercial welding operations should have a written welding procedure specification (wps) for each weldment that is produced. In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your. Aluminium Arc Welding Tips.

From weldingheadquarters.com

The Complete Guide to Shielded Metal Arc Welding Welding Headquarters Aluminium Arc Welding Tips 7020) series can be fusion welded with arc. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. All commercial welding operations should have a written welding procedure specification (wps) for each weldment that is produced. Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and. Aluminium Arc Welding Tips.

From diagramnanulik38.z22.web.core.windows.net

Arc Welding Techniques Pdf Aluminium Arc Welding Tips Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and the need to work with different material thicknesses. In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. Tig welding is a skill that must be taught by a. All commercial welding operations should. Aluminium Arc Welding Tips.

From www.youtube.com

How to "Weld" Aluminum for Beginners YouTube Aluminium Arc Welding Tips The best way to weld. In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. Factors that make aluminum difficult to weld include oxidation,. Aluminium Arc Welding Tips.

From www.hollyfab.com

Common Welding Methods Aluminium Arc Welding Tips In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. Yes, you can weld aluminum, usually with tig welding (gtaw), but you can also do it with other arc welding processes like mig. Factors that make aluminum difficult to weld include oxidation, porousness, impurities, and the need to. Aluminium Arc Welding Tips.

From royalweldingwires.com

Ultimate Guide For Arc Welding Rod Types, Uses, And Tips Aluminium Arc Welding Tips Arc welding is commonly used for joining aluminium alloys. In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux. All commercial welding operations should have a written welding procedure specification (wps) for each weldment that is produced. 7020) series can be fusion welded with arc. Tig. Aluminium Arc Welding Tips.

From jkwelding.net

10 Arc Welding Safety Tips Houston, TX JK Welding, LLC Aluminium Arc Welding Tips The best way to weld. In this blog post, we’ll delve into the realm of arc welding for aluminum, exploring its advantages, difficulties, and expert tips for. Arc welding is commonly used for joining aluminium alloys. In order to weld aluminum, you must use tig welding, a form of welding that uses gas to protect your weld instead of flux.. Aluminium Arc Welding Tips.