What Is A Core Pin In Molding . core pins are used primarily in the plastic molding and die casting applications. one of the hardest components to design and maintain for good tool life is a core pin. due to the pins’ high strength, smaller diameters or sizes are possible, making themt suitable for molding miniature parts. All of them use a core pin. core pins are used in the plastic molding and die casting dies. core pins are used predominantly in the process of injection molding, allowing for internal features of molded parts to be formed. figure 1 depicts six of the more common methods for creating a through hole in a molded part. It is critical in creating. In most cases core pin are fixed in the plastic mold and are used to. A “core” is the separate and replaceable part of the die that forms an. determining how the part will be placed in the mold is critical in injection molding. They are a fixed element used to create a void providing the desired shape.

from www.injectionmouldingparts.com

one of the hardest components to design and maintain for good tool life is a core pin. due to the pins’ high strength, smaller diameters or sizes are possible, making themt suitable for molding miniature parts. core pins are used predominantly in the process of injection molding, allowing for internal features of molded parts to be formed. core pins are used primarily in the plastic molding and die casting applications. It is critical in creating. They are a fixed element used to create a void providing the desired shape. determining how the part will be placed in the mold is critical in injection molding. A “core” is the separate and replaceable part of the die that forms an. In most cases core pin are fixed in the plastic mold and are used to. core pins are used in the plastic molding and die casting dies.

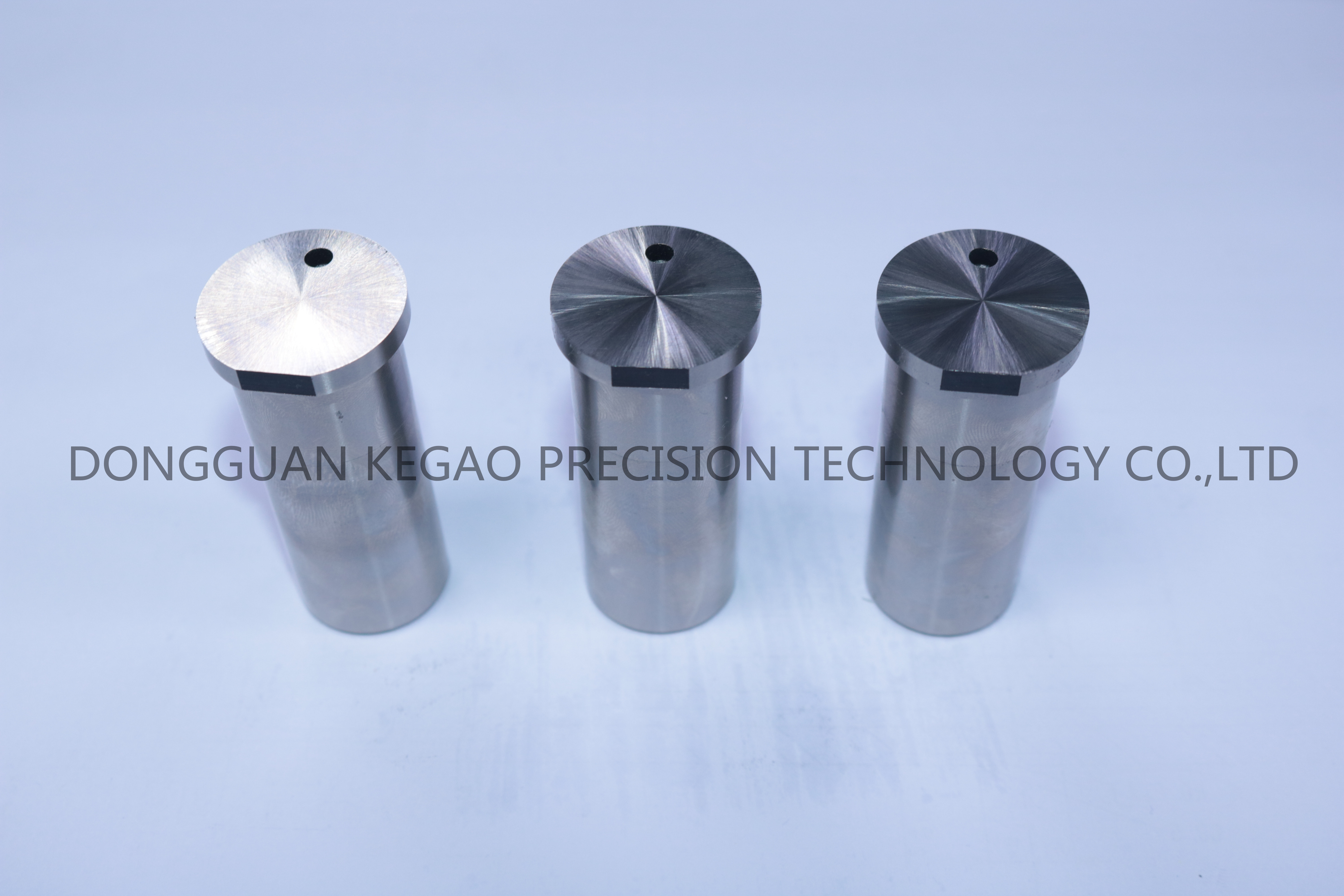

SKH51 Mold Core Pins , Core Cavity In Injection Molding DIN S652

What Is A Core Pin In Molding All of them use a core pin. core pins are used in the plastic molding and die casting dies. In most cases core pin are fixed in the plastic mold and are used to. core pins are used predominantly in the process of injection molding, allowing for internal features of molded parts to be formed. A “core” is the separate and replaceable part of the die that forms an. determining how the part will be placed in the mold is critical in injection molding. All of them use a core pin. figure 1 depicts six of the more common methods for creating a through hole in a molded part. due to the pins’ high strength, smaller diameters or sizes are possible, making themt suitable for molding miniature parts. They are a fixed element used to create a void providing the desired shape. one of the hardest components to design and maintain for good tool life is a core pin. It is critical in creating. core pins are used primarily in the plastic molding and die casting applications.

From www.sipindustry.com

Sip Industry Co.,Ltd Special step core pin What Is A Core Pin In Molding determining how the part will be placed in the mold is critical in injection molding. core pins are used primarily in the plastic molding and die casting applications. They are a fixed element used to create a void providing the desired shape. It is critical in creating. core pins are used predominantly in the process of injection. What Is A Core Pin In Molding.

From www.precision-mouldparts.com

1.2343 Long Mold Core Pins Precision Mould Parts For Plastic Injection Molding What Is A Core Pin In Molding In most cases core pin are fixed in the plastic mold and are used to. core pins are used in the plastic molding and die casting dies. core pins are used predominantly in the process of injection molding, allowing for internal features of molded parts to be formed. All of them use a core pin. figure 1. What Is A Core Pin In Molding.

From www.youtube.com

Lifter Pin Angle Calculation for Mold /Full Lecture/Hindi Contact 8871511975 For Full Program What Is A Core Pin In Molding one of the hardest components to design and maintain for good tool life is a core pin. core pins are used primarily in the plastic molding and die casting applications. In most cases core pin are fixed in the plastic mold and are used to. determining how the part will be placed in the mold is critical. What Is A Core Pin In Molding.

From www.precision-mouldparts.com

Customized Size Plastic Mold Core Pins With + / 0.01mm Tolerance What Is A Core Pin In Molding core pins are used in the plastic molding and die casting dies. They are a fixed element used to create a void providing the desired shape. figure 1 depicts six of the more common methods for creating a through hole in a molded part. due to the pins’ high strength, smaller diameters or sizes are possible, making. What Is A Core Pin In Molding.

From www.precision-mouldparts.com

Medical Mold Core Pins Plastic Mold Components With Good Polished What Is A Core Pin In Molding determining how the part will be placed in the mold is critical in injection molding. In most cases core pin are fixed in the plastic mold and are used to. figure 1 depicts six of the more common methods for creating a through hole in a molded part. due to the pins’ high strength, smaller diameters or. What Is A Core Pin In Molding.

From www.ada-precision.com

Medicalmoldcorepins ADA Precision What Is A Core Pin In Molding All of them use a core pin. It is critical in creating. due to the pins’ high strength, smaller diameters or sizes are possible, making themt suitable for molding miniature parts. They are a fixed element used to create a void providing the desired shape. determining how the part will be placed in the mold is critical in. What Is A Core Pin In Molding.

From www.plastopialtd.com

Mold Core for Injection Molding Plastopia What Is A Core Pin In Molding They are a fixed element used to create a void providing the desired shape. In most cases core pin are fixed in the plastic mold and are used to. core pins are used primarily in the plastic molding and die casting applications. core pins are used predominantly in the process of injection molding, allowing for internal features of. What Is A Core Pin In Molding.

From www.mould-part.com

DIN Standard Die Casting Core Pin Injection Molding What Is A Core Pin In Molding A “core” is the separate and replaceable part of the die that forms an. figure 1 depicts six of the more common methods for creating a through hole in a molded part. In most cases core pin are fixed in the plastic mold and are used to. All of them use a core pin. They are a fixed element. What Is A Core Pin In Molding.

From 84502394cf719282.en.made-in-china.com

Core Pin with Chinese High Precision Plastic Injection Moulding China Spare Parts and Machine Tool What Is A Core Pin In Molding one of the hardest components to design and maintain for good tool life is a core pin. determining how the part will be placed in the mold is critical in injection molding. It is critical in creating. They are a fixed element used to create a void providing the desired shape. A “core” is the separate and replaceable. What Is A Core Pin In Molding.

From www.mould-part.com

Injection Molding Straight Mold Core Pins What Is A Core Pin In Molding core pins are used primarily in the plastic molding and die casting applications. core pins are used predominantly in the process of injection molding, allowing for internal features of molded parts to be formed. It is critical in creating. figure 1 depicts six of the more common methods for creating a through hole in a molded part.. What Is A Core Pin In Molding.

From www.mesinc.net

MoldTooling Core Pin Designs MES Inc What Is A Core Pin In Molding core pins are used predominantly in the process of injection molding, allowing for internal features of molded parts to be formed. figure 1 depicts six of the more common methods for creating a through hole in a molded part. due to the pins’ high strength, smaller diameters or sizes are possible, making themt suitable for molding miniature. What Is A Core Pin In Molding.

From www.injectionmouldingparts.com

SKH51 Mold Core Pins , Core Cavity In Injection Molding DIN S652 What Is A Core Pin In Molding one of the hardest components to design and maintain for good tool life is a core pin. A “core” is the separate and replaceable part of the die that forms an. figure 1 depicts six of the more common methods for creating a through hole in a molded part. core pins are used primarily in the plastic. What Is A Core Pin In Molding.

From www.precision-mouldparts.com

ISO9001 Precision Core Pins For Die Casting Molding 4648HRC Hardness What Is A Core Pin In Molding A “core” is the separate and replaceable part of the die that forms an. core pins are used primarily in the plastic molding and die casting applications. In most cases core pin are fixed in the plastic mold and are used to. core pins are used in the plastic molding and die casting dies. determining how the. What Is A Core Pin In Molding.

From www.precision-mouldparts.com

QRO90 Material Precision Mold Core Pins / Injection Molding Pins With 46 48 HRC What Is A Core Pin In Molding It is critical in creating. core pins are used predominantly in the process of injection molding, allowing for internal features of molded parts to be formed. core pins are used in the plastic molding and die casting dies. due to the pins’ high strength, smaller diameters or sizes are possible, making themt suitable for molding miniature parts.. What Is A Core Pin In Molding.

From www.injectionmouldingparts.com

CNC Core Pin Injection Molding , HSS Metric Core Pins 0.001mm Accuracy What Is A Core Pin In Molding In most cases core pin are fixed in the plastic mold and are used to. core pins are used in the plastic molding and die casting dies. figure 1 depicts six of the more common methods for creating a through hole in a molded part. one of the hardest components to design and maintain for good tool. What Is A Core Pin In Molding.

From www.injectionmouldingparts.com

CrN Coating Core Pin Injection Molding HSS SKH51 Material 62HRC What Is A Core Pin In Molding figure 1 depicts six of the more common methods for creating a through hole in a molded part. one of the hardest components to design and maintain for good tool life is a core pin. due to the pins’ high strength, smaller diameters or sizes are possible, making themt suitable for molding miniature parts. determining how. What Is A Core Pin In Molding.

From www.youtube.com

Injection Molding 101 Ejector Pin Marks YouTube What Is A Core Pin In Molding In most cases core pin are fixed in the plastic mold and are used to. core pins are used in the plastic molding and die casting dies. one of the hardest components to design and maintain for good tool life is a core pin. core pins are used primarily in the plastic molding and die casting applications.. What Is A Core Pin In Molding.

From www.precision-mouldparts.com

ISO9001 High Accuracy Mold Core Pins Mold Parts For Plastic Injection Mold What Is A Core Pin In Molding They are a fixed element used to create a void providing the desired shape. core pins are used predominantly in the process of injection molding, allowing for internal features of molded parts to be formed. one of the hardest components to design and maintain for good tool life is a core pin. In most cases core pin are. What Is A Core Pin In Molding.

From www.precision-mouldparts.com

Nitrided 1.2344 Core Pin Injection Molding Parts / Aluminum Die Casting Auto Parts What Is A Core Pin In Molding core pins are used primarily in the plastic molding and die casting applications. They are a fixed element used to create a void providing the desired shape. one of the hardest components to design and maintain for good tool life is a core pin. It is critical in creating. A “core” is the separate and replaceable part of. What Is A Core Pin In Molding.

From www.precision-mouldparts.com

QRO90 Material Precision Mold Core Pins / Injection Molding Pins With 46 48 HRC What Is A Core Pin In Molding core pins are used in the plastic molding and die casting dies. figure 1 depicts six of the more common methods for creating a through hole in a molded part. In most cases core pin are fixed in the plastic mold and are used to. core pins are used primarily in the plastic molding and die casting. What Is A Core Pin In Molding.

From www.ptonline.com

How to Form a Hole with a Core Pin Part 2 Plastics Technology What Is A Core Pin In Molding figure 1 depicts six of the more common methods for creating a through hole in a molded part. due to the pins’ high strength, smaller diameters or sizes are possible, making themt suitable for molding miniature parts. All of them use a core pin. core pins are used predominantly in the process of injection molding, allowing for. What Is A Core Pin In Molding.

From www.precision-mouldparts.com

H13 TiAlN Coated Precision Mold Core Pins For Plastic Injection Moulding What Is A Core Pin In Molding It is critical in creating. core pins are used primarily in the plastic molding and die casting applications. core pins are used predominantly in the process of injection molding, allowing for internal features of molded parts to be formed. They are a fixed element used to create a void providing the desired shape. determining how the part. What Is A Core Pin In Molding.

From www.mould-part.com

Injection Mold Core Pin Rapid Prototyping With PVD Plating What Is A Core Pin In Molding All of them use a core pin. core pins are used primarily in the plastic molding and die casting applications. core pins are used predominantly in the process of injection molding, allowing for internal features of molded parts to be formed. In most cases core pin are fixed in the plastic mold and are used to. A “core”. What Is A Core Pin In Molding.

From www.precision-mouldparts.com

BeCu Copper Core Pin Injection Molding Components With Hole Thread What Is A Core Pin In Molding In most cases core pin are fixed in the plastic mold and are used to. figure 1 depicts six of the more common methods for creating a through hole in a molded part. due to the pins’ high strength, smaller diameters or sizes are possible, making themt suitable for molding miniature parts. All of them use a core. What Is A Core Pin In Molding.

From www.dgmfmoldclamps.com

Core Pins Mould Clamps Manufacturer What Is A Core Pin In Molding due to the pins’ high strength, smaller diameters or sizes are possible, making themt suitable for molding miniature parts. It is critical in creating. core pins are used in the plastic molding and die casting dies. All of them use a core pin. In most cases core pin are fixed in the plastic mold and are used to.. What Is A Core Pin In Molding.

From www.yubomold.com

Precision Core Pin Mold Yubo Mold Parts What Is A Core Pin In Molding figure 1 depicts six of the more common methods for creating a through hole in a molded part. due to the pins’ high strength, smaller diameters or sizes are possible, making themt suitable for molding miniature parts. A “core” is the separate and replaceable part of the die that forms an. one of the hardest components to. What Is A Core Pin In Molding.

From www.precisionmoldcomponents.com

Costomized Size Precision Mold Components Mold Core Pins SKD 61 Materials What Is A Core Pin In Molding one of the hardest components to design and maintain for good tool life is a core pin. They are a fixed element used to create a void providing the desired shape. core pins are used predominantly in the process of injection molding, allowing for internal features of molded parts to be formed. determining how the part will. What Is A Core Pin In Molding.

From www.precision-mouldparts.com

Die Casting Mold Core Pins And Sleeves With Turning Broaching Drilling Process What Is A Core Pin In Molding core pins are used primarily in the plastic molding and die casting applications. A “core” is the separate and replaceable part of the die that forms an. one of the hardest components to design and maintain for good tool life is a core pin. All of them use a core pin. core pins are used predominantly in. What Is A Core Pin In Molding.

From www.mould-part.com

DIN Standard Die Casting Core Pin Injection Molding What Is A Core Pin In Molding In most cases core pin are fixed in the plastic mold and are used to. It is critical in creating. core pins are used predominantly in the process of injection molding, allowing for internal features of molded parts to be formed. figure 1 depicts six of the more common methods for creating a through hole in a molded. What Is A Core Pin In Molding.

From www.mould-part.com

DIN Standard Die Casting Core Pin Injection Molding What Is A Core Pin In Molding In most cases core pin are fixed in the plastic mold and are used to. one of the hardest components to design and maintain for good tool life is a core pin. core pins are used in the plastic molding and die casting dies. due to the pins’ high strength, smaller diameters or sizes are possible, making. What Is A Core Pin In Molding.

From www.injectionmouldingparts.com

CrN Coating Core Pin Injection Molding HSS SKH51 Material 62HRC What Is A Core Pin In Molding In most cases core pin are fixed in the plastic mold and are used to. core pins are used primarily in the plastic molding and die casting applications. All of them use a core pin. figure 1 depicts six of the more common methods for creating a through hole in a molded part. determining how the part. What Is A Core Pin In Molding.

From dekmold.com

Precision Core Pins Manufacturer, Custom Core Pin for Mold What Is A Core Pin In Molding core pins are used primarily in the plastic molding and die casting applications. They are a fixed element used to create a void providing the desired shape. determining how the part will be placed in the mold is critical in injection molding. figure 1 depicts six of the more common methods for creating a through hole in. What Is A Core Pin In Molding.

From www.mould-part.com

Injection Mold Core Pin Rapid Prototyping With PVD Plating What Is A Core Pin In Molding core pins are used in the plastic molding and die casting dies. core pins are used predominantly in the process of injection molding, allowing for internal features of molded parts to be formed. They are a fixed element used to create a void providing the desired shape. determining how the part will be placed in the mold. What Is A Core Pin In Molding.

From www.precision-mouldparts.com

DAC Material Cooling Core Pin Injection Molding Components With Ra0.6 Polishness What Is A Core Pin In Molding core pins are used primarily in the plastic molding and die casting applications. due to the pins’ high strength, smaller diameters or sizes are possible, making themt suitable for molding miniature parts. core pins are used predominantly in the process of injection molding, allowing for internal features of molded parts to be formed. determining how the. What Is A Core Pin In Molding.

From www.youtube.com

17 kinds of injection mold angle pin core pulling mechanism(1) YouTube What Is A Core Pin In Molding core pins are used primarily in the plastic molding and die casting applications. It is critical in creating. determining how the part will be placed in the mold is critical in injection molding. All of them use a core pin. A “core” is the separate and replaceable part of the die that forms an. They are a fixed. What Is A Core Pin In Molding.