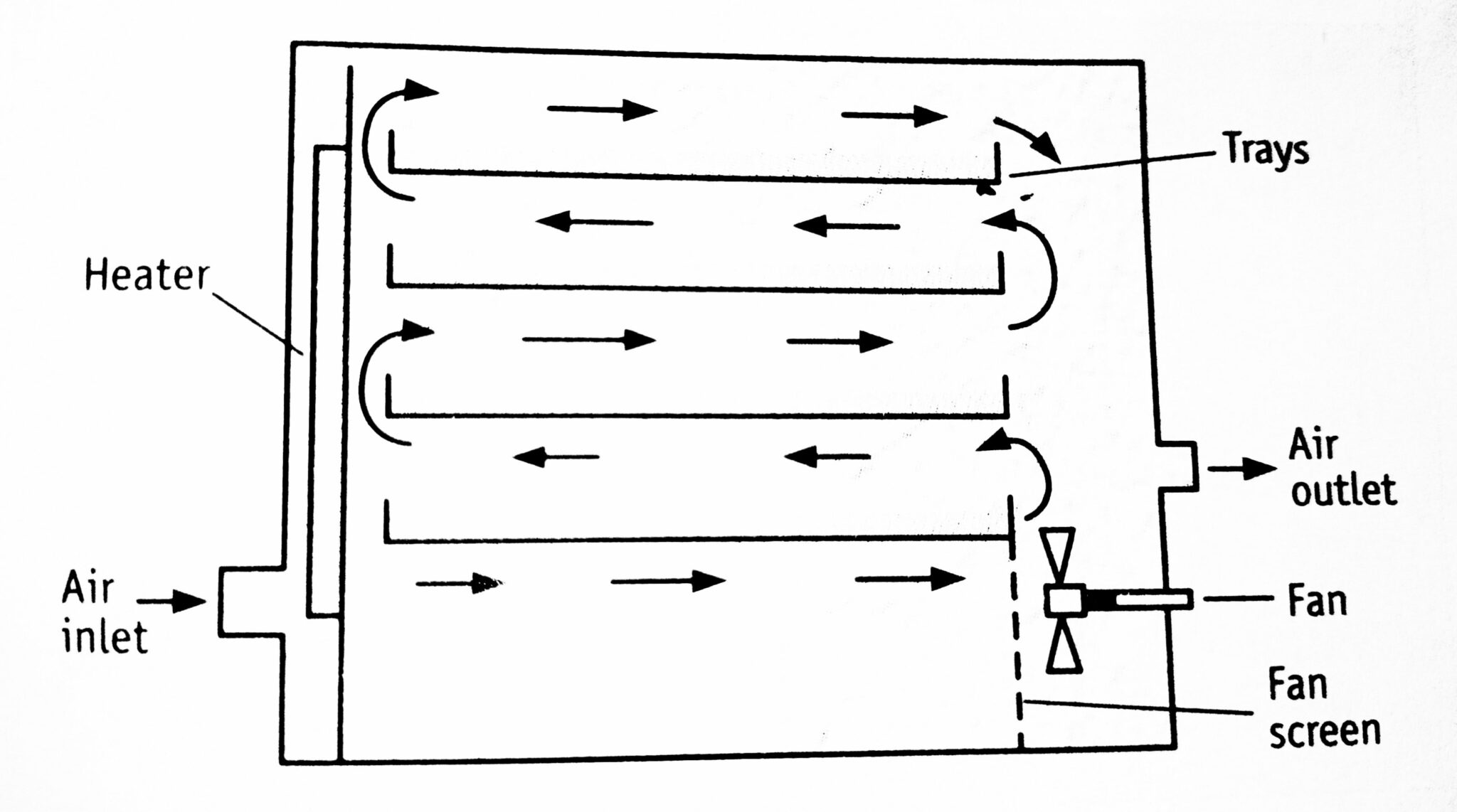

Tray Dryer Types . Direct dryers convectively heat a product through direct contact with the drying medium. In tray dryer, hot air generated by the electric heaters or steam in radiator coils is continuously circulated through the perforated trays with material to be dried. This dryer type operates by passing hot air over the surface of a wet solid that is spread over trays arranged in racks. The chief advantage of tray dryers, apart from their low initial. On the other hand, rotary dryers offer a higher capacity and greater flexibility in terms of material types that can be processed. It typically consists of trays stacked on top of each other within a chamber, where heated air circulates to facilitate the drying process. This type is most widely used in the food and pharmaceutical industries. Forced convection heating takes place to remove moisture from the solids placed on trays. A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches. Tray dryer can be used for drying sticky substances, pastes and granules, crystalline materials, precipitates etc. It is also used for drying crude drugs, chemicals powders and tablet granules including parts of equipment. Process dryers fall into two main types:

from pharmacyscope.com

Process dryers fall into two main types: This dryer type operates by passing hot air over the surface of a wet solid that is spread over trays arranged in racks. In tray dryer, hot air generated by the electric heaters or steam in radiator coils is continuously circulated through the perforated trays with material to be dried. This type is most widely used in the food and pharmaceutical industries. Direct dryers convectively heat a product through direct contact with the drying medium. On the other hand, rotary dryers offer a higher capacity and greater flexibility in terms of material types that can be processed. It typically consists of trays stacked on top of each other within a chamber, where heated air circulates to facilitate the drying process. The chief advantage of tray dryers, apart from their low initial. It is also used for drying crude drugs, chemicals powders and tablet granules including parts of equipment. Forced convection heating takes place to remove moisture from the solids placed on trays.

Tray Dryer Principle, Construction and Working Pharmacy Scope

Tray Dryer Types The chief advantage of tray dryers, apart from their low initial. Tray dryer can be used for drying sticky substances, pastes and granules, crystalline materials, precipitates etc. In tray dryer, hot air generated by the electric heaters or steam in radiator coils is continuously circulated through the perforated trays with material to be dried. Direct dryers convectively heat a product through direct contact with the drying medium. Forced convection heating takes place to remove moisture from the solids placed on trays. This dryer type operates by passing hot air over the surface of a wet solid that is spread over trays arranged in racks. The chief advantage of tray dryers, apart from their low initial. On the other hand, rotary dryers offer a higher capacity and greater flexibility in terms of material types that can be processed. A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches. Process dryers fall into two main types: This type is most widely used in the food and pharmaceutical industries. It typically consists of trays stacked on top of each other within a chamber, where heated air circulates to facilitate the drying process. It is also used for drying crude drugs, chemicals powders and tablet granules including parts of equipment.

From www.indiamart.com

Mild Steel SemiAutomatic 10 kW Tray Dryer, 200 415 V at Rs 550000 in Tray Dryer Types Direct dryers convectively heat a product through direct contact with the drying medium. In tray dryer, hot air generated by the electric heaters or steam in radiator coils is continuously circulated through the perforated trays with material to be dried. This dryer type operates by passing hot air over the surface of a wet solid that is spread over trays. Tray Dryer Types.

From www.tradeindia.com

Stainless Steel Tray Dryer at 300000.00 INR in Vasai The Global Tray Dryer Types In tray dryer, hot air generated by the electric heaters or steam in radiator coils is continuously circulated through the perforated trays with material to be dried. Tray dryer can be used for drying sticky substances, pastes and granules, crystalline materials, precipitates etc. On the other hand, rotary dryers offer a higher capacity and greater flexibility in terms of material. Tray Dryer Types.

From www.bhagwatipharma.co.in

Tray Dryer Manufacturers Tray Dryer Working Principle, Tray Dryers Tray Dryer Types In tray dryer, hot air generated by the electric heaters or steam in radiator coils is continuously circulated through the perforated trays with material to be dried. It typically consists of trays stacked on top of each other within a chamber, where heated air circulates to facilitate the drying process. On the other hand, rotary dryers offer a higher capacity. Tray Dryer Types.

From www.abucksinc.com

Tray Dryer, Tray Dryer Manufacturer, Tray Dryer Supplier, India Tray Dryer Types Tray dryer can be used for drying sticky substances, pastes and granules, crystalline materials, precipitates etc. A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches. This dryer type operates by passing hot air over the surface of a wet solid that is spread over trays arranged in racks. In tray dryer, hot. Tray Dryer Types.

From solutionpharmacy.in

Construction and Working of Tray Dryer Solution Parmacy Tray Dryer Types This type is most widely used in the food and pharmaceutical industries. On the other hand, rotary dryers offer a higher capacity and greater flexibility in terms of material types that can be processed. Direct dryers convectively heat a product through direct contact with the drying medium. It typically consists of trays stacked on top of each other within a. Tray Dryer Types.

From www.indiamart.com

Semi Automatic Tray Dryer, Capacity 24 To 192 Trays, ID 7235724255 Tray Dryer Types A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches. The chief advantage of tray dryers, apart from their low initial. On the other hand, rotary dryers offer a higher capacity and greater flexibility in terms of material types that can be processed. Tray dryer can be used for drying sticky substances, pastes. Tray Dryer Types.

From www.learnaboutpharma.com

Tray Dryer Principle, Construction, Working, Uses, Advantages and Tray Dryer Types Process dryers fall into two main types: The chief advantage of tray dryers, apart from their low initial. This dryer type operates by passing hot air over the surface of a wet solid that is spread over trays arranged in racks. In tray dryer, hot air generated by the electric heaters or steam in radiator coils is continuously circulated through. Tray Dryer Types.

From www.exportersindia.com

Tray Dryer Buy Tray Dryer in Mumbai Maharashtra India from Geberix Tray Dryer Types A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches. Direct dryers convectively heat a product through direct contact with the drying medium. It typically consists of trays stacked on top of each other within a chamber, where heated air circulates to facilitate the drying process. It is also used for drying crude. Tray Dryer Types.

From www.iqsdirectory.com

Types of Dryers Components, Types, Applications and Advantages Tray Dryer Types A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches. On the other hand, rotary dryers offer a higher capacity and greater flexibility in terms of material types that can be processed. This type is most widely used in the food and pharmaceutical industries. It typically consists of trays stacked on top of. Tray Dryer Types.

From vmindustriesindia.com

Tray Dryer Tray Dryers Industrial Tray Dryer, Tray Drying Tray Dryer Types It typically consists of trays stacked on top of each other within a chamber, where heated air circulates to facilitate the drying process. On the other hand, rotary dryers offer a higher capacity and greater flexibility in terms of material types that can be processed. A tray dryer is a widely used industrial drying equipment designed for drying various materials. Tray Dryer Types.

From www.iqsdirectory.com

Types of Dryers Components, Types, Applications and Advantages Tray Dryer Types It typically consists of trays stacked on top of each other within a chamber, where heated air circulates to facilitate the drying process. Tray dryer can be used for drying sticky substances, pastes and granules, crystalline materials, precipitates etc. On the other hand, rotary dryers offer a higher capacity and greater flexibility in terms of material types that can be. Tray Dryer Types.

From www.tradeindia.com

Automatic Industrial Tray Dryer at Best Price in Mumbai Duex Tray Dryer Types It is also used for drying crude drugs, chemicals powders and tablet granules including parts of equipment. A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches. In tray dryer, hot air generated by the electric heaters or steam in radiator coils is continuously circulated through the perforated trays with material to be. Tray Dryer Types.

From www.indiamart.com

RIDDHI SS AND MS Vacuum Tray Dryers, RDVTD, Riddhi Pharma Machinery Tray Dryer Types A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches. Direct dryers convectively heat a product through direct contact with the drying medium. It typically consists of trays stacked on top of each other within a chamber, where heated air circulates to facilitate the drying process. Tray dryer can be used for drying. Tray Dryer Types.

From sarahstechno.com

Tray Dryer Sarah's Techno Tray Dryer Types In tray dryer, hot air generated by the electric heaters or steam in radiator coils is continuously circulated through the perforated trays with material to be dried. Forced convection heating takes place to remove moisture from the solids placed on trays. Direct dryers convectively heat a product through direct contact with the drying medium. This dryer type operates by passing. Tray Dryer Types.

From pharmacyscope.com

Tray Dryer Principle, Construction and Working Pharmacy Scope Tray Dryer Types Forced convection heating takes place to remove moisture from the solids placed on trays. The chief advantage of tray dryers, apart from their low initial. This type is most widely used in the food and pharmaceutical industries. It typically consists of trays stacked on top of each other within a chamber, where heated air circulates to facilitate the drying process.. Tray Dryer Types.

From pharmaguides.in

1.21 Different types of dryers classification of dryer Tray Dryer Types The chief advantage of tray dryers, apart from their low initial. Process dryers fall into two main types: Forced convection heating takes place to remove moisture from the solids placed on trays. It typically consists of trays stacked on top of each other within a chamber, where heated air circulates to facilitate the drying process. A tray dryer is a. Tray Dryer Types.

From www.samaengineering.com

Pharmaceutical Line Tray Dryer Sama Engineering All Kinds of Tray Dryer Types A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches. This type is most widely used in the food and pharmaceutical industries. It is also used for drying crude drugs, chemicals powders and tablet granules including parts of equipment. On the other hand, rotary dryers offer a higher capacity and greater flexibility in. Tray Dryer Types.

From dir.indiamart.com

Tray Dryer tray drier Latest Price, Manufacturers & Suppliers Tray Dryer Types It is also used for drying crude drugs, chemicals powders and tablet granules including parts of equipment. A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches. Direct dryers convectively heat a product through direct contact with the drying medium. It typically consists of trays stacked on top of each other within a. Tray Dryer Types.

From www.indiamart.com

Mild Steel Automatic TRAY DRYER, 48, Capacity 120kg at best price in Thane Tray Dryer Types Direct dryers convectively heat a product through direct contact with the drying medium. Forced convection heating takes place to remove moisture from the solids placed on trays. Tray dryer can be used for drying sticky substances, pastes and granules, crystalline materials, precipitates etc. A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches.. Tray Dryer Types.

From www.iqsdirectory.com

Types of Dryers Components, Types, Applications and Advantages Tray Dryer Types Tray dryer can be used for drying sticky substances, pastes and granules, crystalline materials, precipitates etc. This type is most widely used in the food and pharmaceutical industries. This dryer type operates by passing hot air over the surface of a wet solid that is spread over trays arranged in racks. The chief advantage of tray dryers, apart from their. Tray Dryer Types.

From www.pinterest.com

10+ Images of Simple Tray dryer, Tray dryer diagram, Tray dryer Tray Dryer Types The chief advantage of tray dryers, apart from their low initial. This type is most widely used in the food and pharmaceutical industries. It is also used for drying crude drugs, chemicals powders and tablet granules including parts of equipment. This dryer type operates by passing hot air over the surface of a wet solid that is spread over trays. Tray Dryer Types.

From www.bosonmachinery.com

Tray Dryer ( Model 24/48/96/190) Boson Machinery Tray Dryer Types This dryer type operates by passing hot air over the surface of a wet solid that is spread over trays arranged in racks. This type is most widely used in the food and pharmaceutical industries. It is also used for drying crude drugs, chemicals powders and tablet granules including parts of equipment. Process dryers fall into two main types: It. Tray Dryer Types.

From www.iqsdirectory.com

Types of Dryers Components, Types, Applications and Advantages Tray Dryer Types The chief advantage of tray dryers, apart from their low initial. Tray dryer can be used for drying sticky substances, pastes and granules, crystalline materials, precipitates etc. Direct dryers convectively heat a product through direct contact with the drying medium. This type is most widely used in the food and pharmaceutical industries. On the other hand, rotary dryers offer a. Tray Dryer Types.

From pcdindustries.com

Tray Type Conventional Dryer / ECP Dryer PCD INDUSTRIES Tea Services Tray Dryer Types Direct dryers convectively heat a product through direct contact with the drying medium. Process dryers fall into two main types: On the other hand, rotary dryers offer a higher capacity and greater flexibility in terms of material types that can be processed. It typically consists of trays stacked on top of each other within a chamber, where heated air circulates. Tray Dryer Types.

From lambaudyog.com

TRAY DRYER Lamba Udyog Tray Dryer Types Process dryers fall into two main types: This type is most widely used in the food and pharmaceutical industries. The chief advantage of tray dryers, apart from their low initial. Direct dryers convectively heat a product through direct contact with the drying medium. Forced convection heating takes place to remove moisture from the solids placed on trays. Tray dryer can. Tray Dryer Types.

From www.indiamart.com

Mild Steel SemiAutomatic 48 Tray Dryer, Electric, Capacity 150 kg at Tray Dryer Types This dryer type operates by passing hot air over the surface of a wet solid that is spread over trays arranged in racks. Process dryers fall into two main types: Forced convection heating takes place to remove moisture from the solids placed on trays. This type is most widely used in the food and pharmaceutical industries. It typically consists of. Tray Dryer Types.

From www.chemicalslearning.com

Tray dryer Construction and Working Principle and Advantages Tray Dryer Types On the other hand, rotary dryers offer a higher capacity and greater flexibility in terms of material types that can be processed. Process dryers fall into two main types: This dryer type operates by passing hot air over the surface of a wet solid that is spread over trays arranged in racks. A tray dryer is a widely used industrial. Tray Dryer Types.

From www.indiamart.com

Automatic Stainless Steel Tray Dryer, Material Grade SS304, Capacity Tray Dryer Types This type is most widely used in the food and pharmaceutical industries. In tray dryer, hot air generated by the electric heaters or steam in radiator coils is continuously circulated through the perforated trays with material to be dried. The chief advantage of tray dryers, apart from their low initial. Direct dryers convectively heat a product through direct contact with. Tray Dryer Types.

From electricalworkbook.com

What is Tray Dryer? Working Principle, Construction, Diagram Tray Dryer Types A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches. Process dryers fall into two main types: Tray dryer can be used for drying sticky substances, pastes and granules, crystalline materials, precipitates etc. It is also used for drying crude drugs, chemicals powders and tablet granules including parts of equipment. On the other. Tray Dryer Types.

From www.indiamart.com

Standard 1296 Tray Dryers, Rs 450000 M.D. Engineering Company ID Tray Dryer Types Direct dryers convectively heat a product through direct contact with the drying medium. It typically consists of trays stacked on top of each other within a chamber, where heated air circulates to facilitate the drying process. A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches. In tray dryer, hot air generated by. Tray Dryer Types.

From dir.indiamart.com

Tray Dryer tray drier Latest Price, Manufacturers & Suppliers Tray Dryer Types Direct dryers convectively heat a product through direct contact with the drying medium. A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches. Process dryers fall into two main types: It is also used for drying crude drugs, chemicals powders and tablet granules including parts of equipment. Tray dryer can be used for. Tray Dryer Types.

From www.pinterest.com

You can add the multiple trays into Tray Dryer and get the best Tray Dryer Types Direct dryers convectively heat a product through direct contact with the drying medium. Process dryers fall into two main types: A tray dryer is a widely used industrial drying equipment designed for drying various materials in batches. The chief advantage of tray dryers, apart from their low initial. This type is most widely used in the food and pharmaceutical industries.. Tray Dryer Types.

From www.iqsdirectory.com

Types of Dryers Components, Types, Applications and Advantages Tray Dryer Types Forced convection heating takes place to remove moisture from the solids placed on trays. On the other hand, rotary dryers offer a higher capacity and greater flexibility in terms of material types that can be processed. In tray dryer, hot air generated by the electric heaters or steam in radiator coils is continuously circulated through the perforated trays with material. Tray Dryer Types.

From learnaboutpharma.com

Tray Dryer Principle, Construction, Working, Uses, Advantages and Tray Dryer Types Process dryers fall into two main types: It typically consists of trays stacked on top of each other within a chamber, where heated air circulates to facilitate the drying process. It is also used for drying crude drugs, chemicals powders and tablet granules including parts of equipment. The chief advantage of tray dryers, apart from their low initial. On the. Tray Dryer Types.

From in.pinterest.com

Advanced Tray Dryer for fertilizer industries to get the perfect drying Tray Dryer Types On the other hand, rotary dryers offer a higher capacity and greater flexibility in terms of material types that can be processed. This dryer type operates by passing hot air over the surface of a wet solid that is spread over trays arranged in racks. It typically consists of trays stacked on top of each other within a chamber, where. Tray Dryer Types.