How To Check That Tools And Equipment Are Free From Damage . Visual inspection is typically the. Ensure each tool has a unique identifier for tracking and management purposes. To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. Check for signs of wear, damage, or any visible. Check the power cord for cracking, fraying, and other signs of wear or faults in the cord insulation. Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. This systematic process involves assessing equipment for operational integrity, safety, and overall condition. What are safeguards and safeguarding?

from www.template.net

It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. What are safeguards and safeguarding? Visual inspection is typically the. To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. Check for signs of wear, damage, or any visible. Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. Check the power cord for cracking, fraying, and other signs of wear or faults in the cord insulation. This systematic process involves assessing equipment for operational integrity, safety, and overall condition. Ensure each tool has a unique identifier for tracking and management purposes.

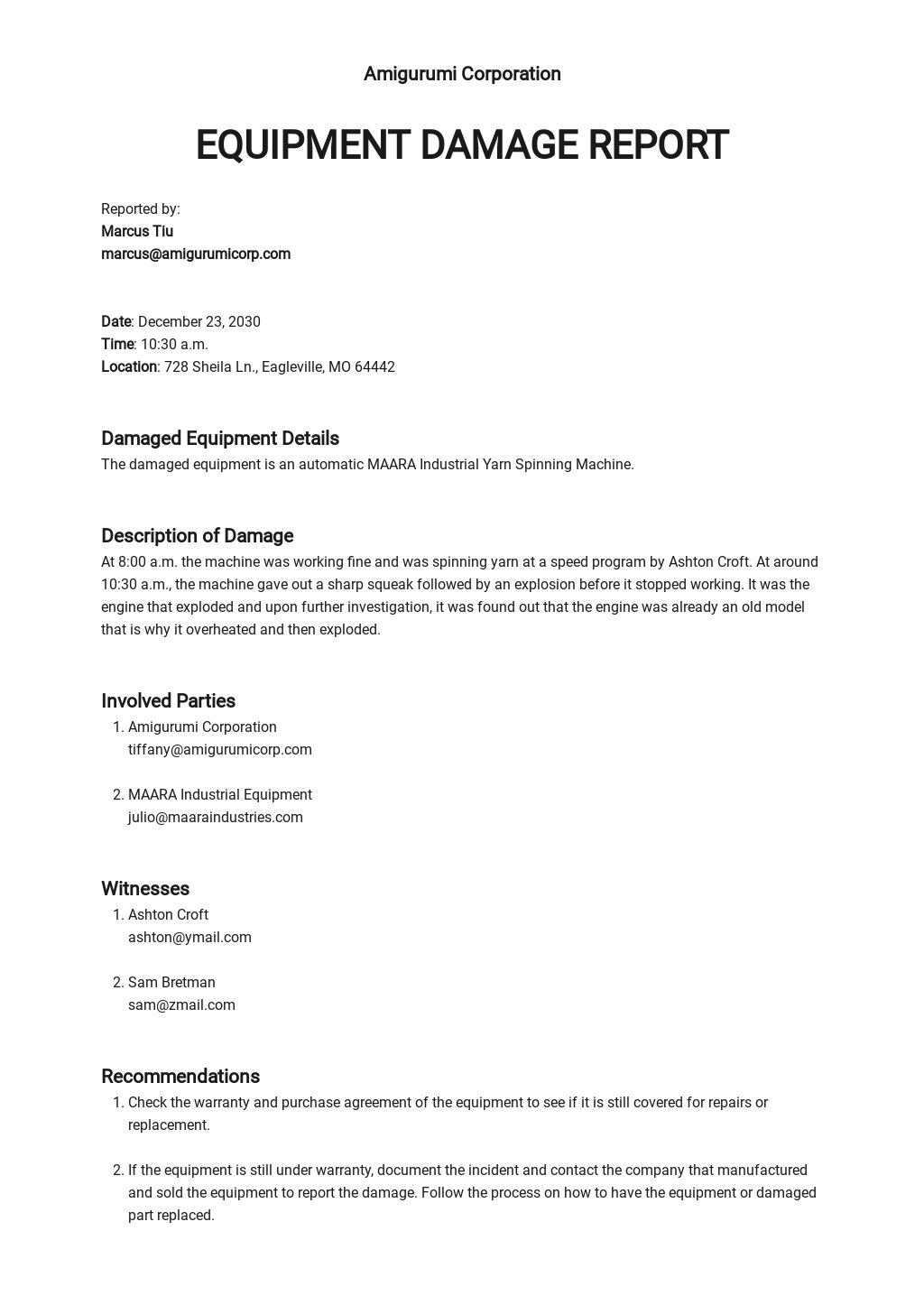

FREE Equipment Damage Report Template Google Docs, Word

How To Check That Tools And Equipment Are Free From Damage It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. Ensure each tool has a unique identifier for tracking and management purposes. Check for signs of wear, damage, or any visible. What are safeguards and safeguarding? This systematic process involves assessing equipment for operational integrity, safety, and overall condition. Check the power cord for cracking, fraying, and other signs of wear or faults in the cord insulation. To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. Visual inspection is typically the. Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration.

From www.animalia-life.club

Hammer Wrench Safety Handle How To Check That Tools And Equipment Are Free From Damage It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. Visual inspection is typically the. Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. What are safeguards and safeguarding? Check the power cord for cracking, fraying, and other signs of wear or. How To Check That Tools And Equipment Are Free From Damage.

From www.youtube.com

How to Prepare Electrical Hand & Power Tools Inspection Checklist YouTube How To Check That Tools And Equipment Are Free From Damage To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. Visual inspection is typically the. Use this checklist to inspect your workshop and tools to ensure they are safe and free from. How To Check That Tools And Equipment Are Free From Damage.

From sitemate.com

Electrical Tool Inspection Checklist (Free to use and customisable) How To Check That Tools And Equipment Are Free From Damage Ensure each tool has a unique identifier for tracking and management purposes. It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. This systematic process involves assessing equipment for operational integrity, safety, and overall condition. What are safeguards and safeguarding? Check the power cord for cracking, fraying, and other signs of wear or faults in. How To Check That Tools And Equipment Are Free From Damage.

From old.sermitsiaq.ag

Equipment Inspection Checklist Template How To Check That Tools And Equipment Are Free From Damage This systematic process involves assessing equipment for operational integrity, safety, and overall condition. What are safeguards and safeguarding? It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. Ensure each tool has a unique identifier for tracking and management purposes. Visual inspection is typically the. To ensure that tools and test equipment are free from. How To Check That Tools And Equipment Are Free From Damage.

From utorrentrocks809.weebly.com

Check Tools Equipment Free Damage Defects Free Programs, Utilities How To Check That Tools And Equipment Are Free From Damage To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. This systematic process involves assessing equipment for operational integrity, safety, and overall condition. Visual inspection is typically the. Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and. How To Check That Tools And Equipment Are Free From Damage.

From www.altoceanmarine.com

Damage Control Kit Altocean Marine How To Check That Tools And Equipment Are Free From Damage Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. What are safeguards and safeguarding? It involves thoroughly examining equipment components and surfaces for signs. How To Check That Tools And Equipment Are Free From Damage.

From exojyvgpm.blob.core.windows.net

How To Check Tools And Equipment Are Free From Damage at Luz Searles blog How To Check That Tools And Equipment Are Free From Damage What are safeguards and safeguarding? To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. Check for signs of wear, damage, or any visible. Check the power cord for cracking, fraying, and other signs of wear or faults in the cord insulation. Ensure each tool has a. How To Check That Tools And Equipment Are Free From Damage.

From worksafetyqld.com

How To Prevent Damage To Construction Equipment Work Safety QLD How To Check That Tools And Equipment Are Free From Damage Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. Ensure each tool has a unique identifier for tracking and management purposes. Check for signs of wear, damage, or any visible. What are safeguards and safeguarding? Check the power cord for cracking, fraying, and other signs of wear. How To Check That Tools And Equipment Are Free From Damage.

From www.sampleforms.com

FREE 11+ Damage Report Form Samples, PDF, MS Word, Google Docs, Excel How To Check That Tools And Equipment Are Free From Damage It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. Ensure each tool has a unique identifier for tracking and management purposes. This systematic process involves assessing equipment for operational integrity, safety, and overall condition. Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are. How To Check That Tools And Equipment Are Free From Damage.

From klalsnydg.blob.core.windows.net

Equipment Maintenance Checklist Sample at Charles Speier blog How To Check That Tools And Equipment Are Free From Damage To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. Check for signs of wear, damage, or any visible. Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. Check the power cord for cracking,. How To Check That Tools And Equipment Are Free From Damage.

From hsseworld.com

Defective Tools Safe Work PracticePhoto of today HSSE WORLD How To Check That Tools And Equipment Are Free From Damage Visual inspection is typically the. Check for signs of wear, damage, or any visible. It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. This systematic process involves assessing equipment for operational integrity, safety, and overall condition. Check the power cord for cracking, fraying, and other signs of wear or faults in the cord insulation.. How To Check That Tools And Equipment Are Free From Damage.

From www.slideserve.com

PPT Big Four Construction Hazards Electrical Hazards PowerPoint How To Check That Tools And Equipment Are Free From Damage Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. Ensure each tool has a unique identifier for tracking and management purposes. What are safeguards. How To Check That Tools And Equipment Are Free From Damage.

From www.youtube.com

Check condition of tools and Equipment YouTube How To Check That Tools And Equipment Are Free From Damage Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. Check for signs of wear, damage, or any visible. It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. What are safeguards and safeguarding? This systematic process involves assessing equipment for operational integrity,. How To Check That Tools And Equipment Are Free From Damage.

From hsseworld.com

Site Equipment and Tools Inspection Procedure HSSE WORLD How To Check That Tools And Equipment Are Free From Damage To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. Ensure each tool has a unique identifier for tracking and management purposes. Check the power cord for cracking, fraying, and other signs of wear or faults in the cord insulation. Use this checklist to inspect your workshop. How To Check That Tools And Equipment Are Free From Damage.

From workboots.com

Automotive Mechanic Tool Checklist Tradecraft How To Check That Tools And Equipment Are Free From Damage Visual inspection is typically the. Check for signs of wear, damage, or any visible. Check the power cord for cracking, fraying, and other signs of wear or faults in the cord insulation. To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. Use this checklist to inspect. How To Check That Tools And Equipment Are Free From Damage.

From www.templateroller.com

Heavy Equipment Daily Inspection Checklist Template Prior to Use on How To Check That Tools And Equipment Are Free From Damage Ensure each tool has a unique identifier for tracking and management purposes. What are safeguards and safeguarding? Visual inspection is typically the. To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. This systematic process involves assessing equipment for operational integrity, safety, and overall condition. It involves. How To Check That Tools And Equipment Are Free From Damage.

From www.dreamstime.com

Hand of Worker Man Hold Grinder Blades Broken . Dangers of Using Stock How To Check That Tools And Equipment Are Free From Damage Ensure each tool has a unique identifier for tracking and management purposes. It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. This systematic process involves assessing equipment for operational integrity, safety, and. How To Check That Tools And Equipment Are Free From Damage.

From www.youtube.com

Property Damage Assessment Using Proper Damage Assessment Tools For How To Check That Tools And Equipment Are Free From Damage Ensure each tool has a unique identifier for tracking and management purposes. This systematic process involves assessing equipment for operational integrity, safety, and overall condition. Visual inspection is typically the. To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. Check for signs of wear, damage, or. How To Check That Tools And Equipment Are Free From Damage.

From www.dreamstime.com

Inspecting Tools Royalty Free Stock Images Image 6189329 How To Check That Tools And Equipment Are Free From Damage Check for signs of wear, damage, or any visible. It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. Visual inspection is typically the. To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. Ensure each tool has a unique identifier for. How To Check That Tools And Equipment Are Free From Damage.

From www.youtube.com

How To Get Damage With Repair Tool [QuickGuide™] Battlefield 1 YouTube How To Check That Tools And Equipment Are Free From Damage What are safeguards and safeguarding? Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. Ensure each tool has a unique identifier for tracking and management purposes. Check for signs of wear, damage,. How To Check That Tools And Equipment Are Free From Damage.

From dxoqasvvg.blob.core.windows.net

How To Maintain Tools And Equipment at Sandra Cowan blog How To Check That Tools And Equipment Are Free From Damage Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. Check for signs of wear, damage, or any visible. This systematic process involves assessing equipment for operational integrity, safety, and overall condition. To ensure that tools and test equipment are free from damage or defect, in a safe. How To Check That Tools And Equipment Are Free From Damage.

From www.slideserve.com

PPT Inspect Items for Damage PowerPoint Presentation, free download How To Check That Tools And Equipment Are Free From Damage Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. Visual inspection is typically the. Check the power cord for cracking, fraying, and other signs of wear or faults in the cord insulation. Check for signs of wear, damage, or any visible. To ensure that tools and test. How To Check That Tools And Equipment Are Free From Damage.

From www.slideserve.com

PPT Arc Flash Safety PowerPoint Presentation ID6535535 How To Check That Tools And Equipment Are Free From Damage Check the power cord for cracking, fraying, and other signs of wear or faults in the cord insulation. This systematic process involves assessing equipment for operational integrity, safety, and overall condition. Visual inspection is typically the. It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. Check for signs of wear, damage, or any visible.. How To Check That Tools And Equipment Are Free From Damage.

From www.mazzellacompanies.com

The 6 Most Common Problems Found During a Rigging Gear Inspection How To Check That Tools And Equipment Are Free From Damage Ensure each tool has a unique identifier for tracking and management purposes. Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. Visual inspection is typically the. This systematic process involves assessing equipment for operational integrity, safety, and overall condition. What are safeguards and safeguarding? To ensure that. How To Check That Tools And Equipment Are Free From Damage.

From natoli.com

tool maintenance How To Check That Tools And Equipment Are Free From Damage What are safeguards and safeguarding? Visual inspection is typically the. To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. Check the power cord for. How To Check That Tools And Equipment Are Free From Damage.

From klalsnydg.blob.core.windows.net

Equipment Maintenance Checklist Sample at Charles Speier blog How To Check That Tools And Equipment Are Free From Damage Check the power cord for cracking, fraying, and other signs of wear or faults in the cord insulation. To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. What are safeguards and safeguarding? This systematic process involves assessing equipment for operational integrity, safety, and overall condition. Use. How To Check That Tools And Equipment Are Free From Damage.

From canalhr.com

Workplace Electrical Safety Guide What to Know Canal HR How To Check That Tools And Equipment Are Free From Damage To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. What are safeguards and safeguarding? Check the power cord for cracking, fraying, and other signs of wear or faults in the cord insulation. Use this checklist to inspect your workshop and tools to ensure they are safe. How To Check That Tools And Equipment Are Free From Damage.

From www.examples.com

Equipment Checklist 12+ Examples, Format, Pdf How To Check That Tools And Equipment Are Free From Damage Check for signs of wear, damage, or any visible. What are safeguards and safeguarding? Ensure each tool has a unique identifier for tracking and management purposes. It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition,. How To Check That Tools And Equipment Are Free From Damage.

From www.template.net

FREE Equipment Damage Report Template Google Docs, Word How To Check That Tools And Equipment Are Free From Damage Ensure each tool has a unique identifier for tracking and management purposes. Visual inspection is typically the. Check for signs of wear, damage, or any visible. To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. Use this checklist to inspect your workshop and tools to ensure. How To Check That Tools And Equipment Are Free From Damage.

From exojyvgpm.blob.core.windows.net

How To Check Tools And Equipment Are Free From Damage at Luz Searles blog How To Check That Tools And Equipment Are Free From Damage Visual inspection is typically the. Ensure each tool has a unique identifier for tracking and management purposes. What are safeguards and safeguarding? It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. Check the power cord for cracking, fraying, and other signs of wear or faults in the cord insulation. Check for signs of wear,. How To Check That Tools And Equipment Are Free From Damage.

From www.template.net

Editable Equipment Damage Report Template in Word, Pages, Google Docs How To Check That Tools And Equipment Are Free From Damage Check the power cord for cracking, fraying, and other signs of wear or faults in the cord insulation. It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. To ensure that tools and test equipment are free from damage or defect, in a safe and usable condition, within calibration, and correctly. Ensure each tool has. How To Check That Tools And Equipment Are Free From Damage.

From exojyvgpm.blob.core.windows.net

How To Check Tools And Equipment Are Free From Damage at Luz Searles blog How To Check That Tools And Equipment Are Free From Damage Check for signs of wear, damage, or any visible. This systematic process involves assessing equipment for operational integrity, safety, and overall condition. Ensure each tool has a unique identifier for tracking and management purposes. It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. Use this checklist to inspect your workshop and tools to ensure. How To Check That Tools And Equipment Are Free From Damage.

From www.pinterest.com

Equipment Damage Report How to create an equipment Damage Report How To Check That Tools And Equipment Are Free From Damage Check for signs of wear, damage, or any visible. What are safeguards and safeguarding? Check the power cord for cracking, fraying, and other signs of wear or faults in the cord insulation. This systematic process involves assessing equipment for operational integrity, safety, and overall condition. Ensure each tool has a unique identifier for tracking and management purposes. It involves thoroughly. How To Check That Tools And Equipment Are Free From Damage.

From www.machinerylubrication.com

How to Give Your Machine a Physical How To Check That Tools And Equipment Are Free From Damage Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. Check for signs of wear, damage, or any visible. Visual inspection is typically the. Ensure each tool has a unique identifier for tracking and management purposes. To ensure that tools and test equipment are free from damage or. How To Check That Tools And Equipment Are Free From Damage.

From www.examples.com

Equipment Checklist 12+ Examples, Format, Pdf How To Check That Tools And Equipment Are Free From Damage Use this checklist to inspect your workshop and tools to ensure they are safe and free from damage and are operating properly. Visual inspection is typically the. Check for signs of wear, damage, or any visible. It involves thoroughly examining equipment components and surfaces for signs of damage, wear, or deterioration. To ensure that tools and test equipment are free. How To Check That Tools And Equipment Are Free From Damage.