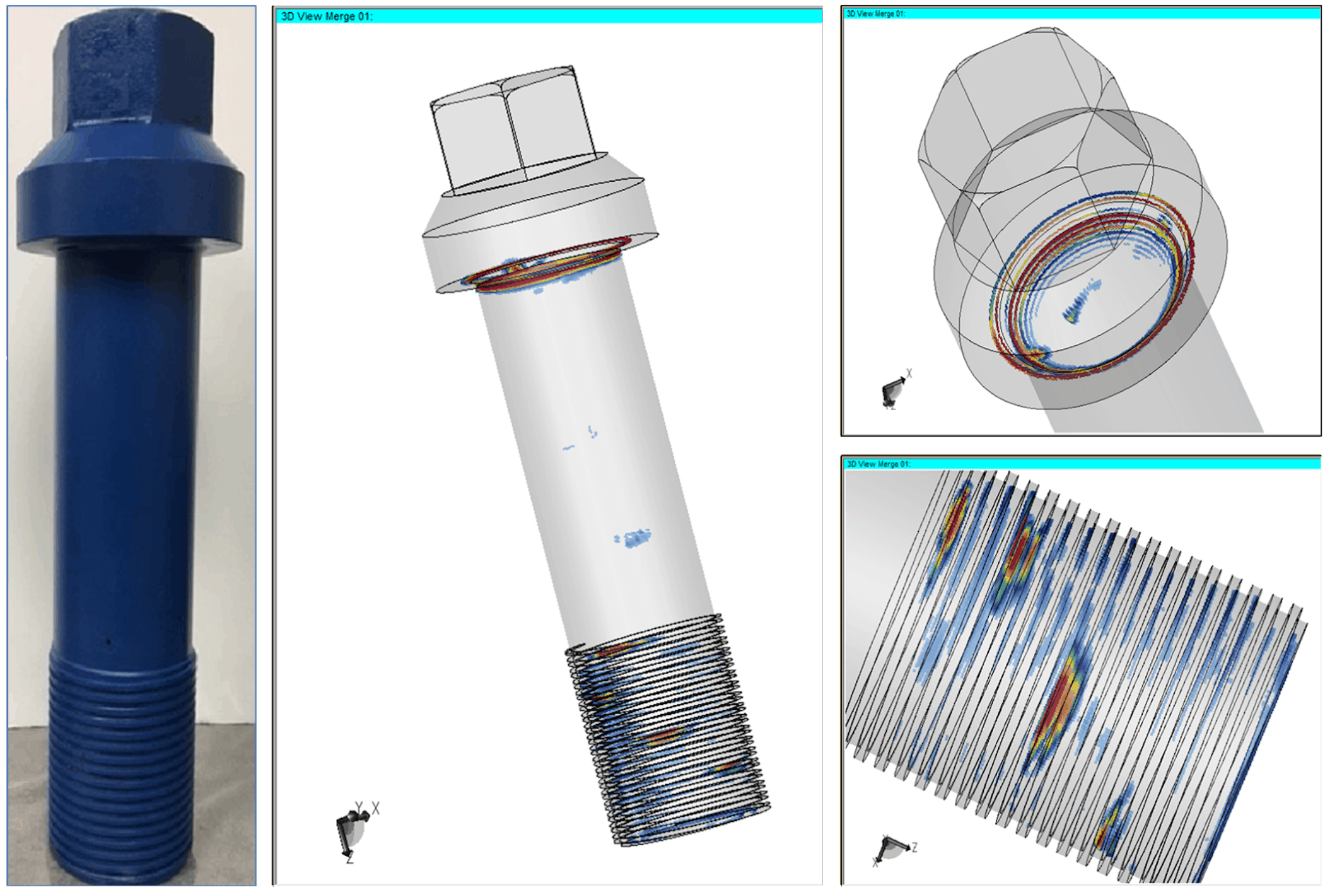

Threaded Hole Inspection . Eddy current technology provides a fast, clean way to inspect threaded holes. The measured result is displayed with display. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within the accepted tolerance so that it interacts with the mating part correctly. The go end of the plug is supposed. To inspect an internal thread, both ends of the thread plug are inserted into the threaded component. No thread, as well as partial thread condition because it compares. • measure circles at both ends of threaded hole. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. (8 equally spaced points) • construct a line through the centers of both circles • establish pierce. Ect is an ideal inspection method for verifying thread vs. In an application like this, eddy current probes are lowered into the threaded hole.

from www.zetec.com

Eddy current technology provides a fast, clean way to inspect threaded holes. • measure circles at both ends of threaded hole. To inspect an internal thread, both ends of the thread plug are inserted into the threaded component. In an application like this, eddy current probes are lowered into the threaded hole. No thread, as well as partial thread condition because it compares. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. The go end of the plug is supposed. (8 equally spaced points) • construct a line through the centers of both circles • establish pierce. Ect is an ideal inspection method for verifying thread vs. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within the accepted tolerance so that it interacts with the mating part correctly.

Bolt Inspection Zetec

Threaded Hole Inspection No thread, as well as partial thread condition because it compares. The measured result is displayed with display. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within the accepted tolerance so that it interacts with the mating part correctly. • measure circles at both ends of threaded hole. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. To inspect an internal thread, both ends of the thread plug are inserted into the threaded component. Eddy current technology provides a fast, clean way to inspect threaded holes. In an application like this, eddy current probes are lowered into the threaded hole. (8 equally spaced points) • construct a line through the centers of both circles • establish pierce. The go end of the plug is supposed. No thread, as well as partial thread condition because it compares. Ect is an ideal inspection method for verifying thread vs.

From www.youtube.com

Bolt Hole Inspection Demonstration YouTube Threaded Hole Inspection Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. In an application like this, eddy current probes are lowered into the threaded hole. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within. Threaded Hole Inspection.

From www.americanmachinist.com

Deephole inspection American Machinist Threaded Hole Inspection Eddy current technology provides a fast, clean way to inspect threaded holes. Ect is an ideal inspection method for verifying thread vs. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within the accepted tolerance so that it interacts with the mating part correctly. (8. Threaded Hole Inspection.

From insize.co.id

INSIZE 4676 Threaded Hole Location Gauge For CMM/Caliper (Spline shaft) Range; M3 M12 Insize Threaded Hole Inspection The measured result is displayed with display. Eddy current technology provides a fast, clean way to inspect threaded holes. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within the accepted tolerance so that it interacts with the mating part correctly. To inspect an internal. Threaded Hole Inspection.

From empipe.ca

Maintenance Hole Inspection Empipe Infrastructure Group Threaded Hole Inspection No thread, as well as partial thread condition because it compares. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. The measured result is displayed with display. (8 equally spaced points) • construct a line through the centers of both circles • establish pierce. • measure circles at. Threaded Hole Inspection.

From www.oldminibikes.com

Rare inspection hole option! Threaded Hole Inspection Ect is an ideal inspection method for verifying thread vs. Eddy current technology provides a fast, clean way to inspect threaded holes. To inspect an internal thread, both ends of the thread plug are inserted into the threaded component. The measured result is displayed with display. No thread, as well as partial thread condition because it compares. The go end. Threaded Hole Inspection.

From www.reddit.com

12 inch inspection hole for a vessel after some polishing r/Welding Threaded Hole Inspection Eddy current technology provides a fast, clean way to inspect threaded holes. (8 equally spaced points) • construct a line through the centers of both circles • establish pierce. • measure circles at both ends of threaded hole. To inspect an internal thread, both ends of the thread plug are inserted into the threaded component. The go end of the. Threaded Hole Inspection.

From news.thomasnet.com

MultiBall(TM) Thread Inspection Products Threaded Hole Inspection The go end of the plug is supposed. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. Eddy current technology provides a fast, clean way to inspect threaded holes. Ect is an ideal inspection method for verifying thread vs. To inspect an internal thread, both ends of the. Threaded Hole Inspection.

From www.thetoolanddieguy.com

Lesson 221 Another Way to Check The Location of Threaded Holes Threaded Hole Inspection In an application like this, eddy current probes are lowered into the threaded hole. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. No thread, as well as partial thread condition because it compares. • measure circles at both ends of threaded hole. (8 equally spaced points) •. Threaded Hole Inspection.

From willrich.com

Vermont Gage Tapped Threaded Hole Location Gages Flexible Type Willrich Precision Instruments Threaded Hole Inspection The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within the accepted tolerance so that it interacts with the mating part correctly. The go end of the plug is supposed. In an application like this, eddy current probes are lowered into the threaded hole. Ect. Threaded Hole Inspection.

From metrology.co.id

Ojiyas Threaded Hole Location Gauge CPG Metrology Threaded Hole Inspection The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within the accepted tolerance so that it interacts with the mating part correctly. The measured result is displayed with display. The go end of the plug is supposed. (8 equally spaced points) • construct a line. Threaded Hole Inspection.

From www.youtube.com

Gagemaker Tapered Thread Inspection Systems YouTube Threaded Hole Inspection Ect is an ideal inspection method for verifying thread vs. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within the accepted tolerance so that it interacts with the mating part correctly. The go end of the plug is supposed. To inspect an internal thread,. Threaded Hole Inspection.

From www.youtube.com

How to Cut an Inspection Hole YouTube Threaded Hole Inspection Ect is an ideal inspection method for verifying thread vs. Eddy current technology provides a fast, clean way to inspect threaded holes. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. No thread, as well as partial thread condition because it compares. In an application like this, eddy. Threaded Hole Inspection.

From facfox.com

Threaded Holes Guidelines for CNC Machining FacFox Docs Threaded Hole Inspection (8 equally spaced points) • construct a line through the centers of both circles • establish pierce. The measured result is displayed with display. No thread, as well as partial thread condition because it compares. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. Eddy current technology provides. Threaded Hole Inspection.

From www.yamawa.eu

Cored holes Direct tapping with no tool breakage Yamawa Threaded Hole Inspection In an application like this, eddy current probes are lowered into the threaded hole. (8 equally spaced points) • construct a line through the centers of both circles • establish pierce. To inspect an internal thread, both ends of the thread plug are inserted into the threaded component. No thread, as well as partial thread condition because it compares. The. Threaded Hole Inspection.

From www.youtube.com

Fastener Hole Inspection YouTube Threaded Hole Inspection Ect is an ideal inspection method for verifying thread vs. In an application like this, eddy current probes are lowered into the threaded hole. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within the accepted tolerance so that it interacts with the mating part. Threaded Hole Inspection.

From www.teamrapidtooling.com

Threaded Holes Types, Methods, and Precautions Threaded Hole Inspection Ect is an ideal inspection method for verifying thread vs. The measured result is displayed with display. In an application like this, eddy current probes are lowered into the threaded hole. • measure circles at both ends of threaded hole. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify. Threaded Hole Inspection.

From www.practicalmachinist.com

Thread Inspection An Overview of the Most Popular Methods Practical Machinist Threaded Hole Inspection Eddy current technology provides a fast, clean way to inspect threaded holes. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within the accepted tolerance so that it interacts with the mating part correctly. The go end of the plug is supposed. • measure circles. Threaded Hole Inspection.

From www.naganosankoh.jp

Holeinspection 株式会社 長野サンコー Threaded Hole Inspection In an application like this, eddy current probes are lowered into the threaded hole. The go end of the plug is supposed. • measure circles at both ends of threaded hole. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. Eddy current technology provides a fast, clean way. Threaded Hole Inspection.

From www.reddit.com

How accurate is probing a threaded hole? It works for the application I'm using but still Threaded Hole Inspection In an application like this, eddy current probes are lowered into the threaded hole. Eddy current technology provides a fast, clean way to inspect threaded holes. (8 equally spaced points) • construct a line through the centers of both circles • establish pierce. Ect is an ideal inspection method for verifying thread vs. • measure circles at both ends of. Threaded Hole Inspection.

From www.bannerengineering.com

Drilled Holes Inspection Threaded Hole Inspection To inspect an internal thread, both ends of the thread plug are inserted into the threaded component. The go end of the plug is supposed. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. Eddy current technology provides a fast, clean way to inspect threaded holes. In an. Threaded Hole Inspection.

From grabcad.com

Single Inspection Dimension for Holes GrabCAD Tutorials Threaded Hole Inspection • measure circles at both ends of threaded hole. To inspect an internal thread, both ends of the thread plug are inserted into the threaded component. Ect is an ideal inspection method for verifying thread vs. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are. Threaded Hole Inspection.

From www.madearia.com

What are the different types of holes in engineering? Threaded Hole Inspection No thread, as well as partial thread condition because it compares. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. Ect is an ideal inspection method for verifying thread vs. (8 equally spaced points) • construct a line through the centers of both circles • establish pierce. The. Threaded Hole Inspection.

From www.eng-tips.com

GD&T for Threaded holes Drafting Standards, GD&T & Tolerance Analysis EngTips Threaded Hole Inspection No thread, as well as partial thread condition because it compares. The measured result is displayed with display. Eddy current technology provides a fast, clean way to inspect threaded holes. Ect is an ideal inspection method for verifying thread vs. • measure circles at both ends of threaded hole. Threaded plug gages internal threads should be inspected using go/nogo cylindrical. Threaded Hole Inspection.

From www.mbvision.si

Thread Inspection MBvision hightech optical measuring systems Threaded Hole Inspection To inspect an internal thread, both ends of the thread plug are inserted into the threaded component. The go end of the plug is supposed. Ect is an ideal inspection method for verifying thread vs. Eddy current technology provides a fast, clean way to inspect threaded holes. The basic concept of a thread plug is to provide a quick inspection. Threaded Hole Inspection.

From www.mbvision.si

Thread Inspection MBvision hightech optical measuring systems Threaded Hole Inspection The go end of the plug is supposed. In an application like this, eddy current probes are lowered into the threaded hole. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. The measured result is displayed with display. To inspect an internal thread, both ends of the thread. Threaded Hole Inspection.

From toolingcrib.com

TruPos M5 x 8 True Position Hole Locators » Threaded Hole Inspection In an application like this, eddy current probes are lowered into the threaded hole. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within the accepted tolerance so that it interacts with the mating part correctly. The measured result is displayed with display. To inspect. Threaded Hole Inspection.

From pgisteel.com

Steel Plate Inspection Precision Grinding, Inc. Threaded Hole Inspection (8 equally spaced points) • construct a line through the centers of both circles • establish pierce. Ect is an ideal inspection method for verifying thread vs. The measured result is displayed with display. The go end of the plug is supposed. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors. Threaded Hole Inspection.

From www.ipqcco.com

Screw Hole Inspection Types, Features, Issues and Automatic Inspect Equipment Threaded Hole Inspection To inspect an internal thread, both ends of the thread plug are inserted into the threaded component. The measured result is displayed with display. Eddy current technology provides a fast, clean way to inspect threaded holes. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. In an application. Threaded Hole Inspection.

From www.zetec.com

Bolt Inspection Zetec Threaded Hole Inspection To inspect an internal thread, both ends of the thread plug are inserted into the threaded component. Ect is an ideal inspection method for verifying thread vs. (8 equally spaced points) • construct a line through the centers of both circles • establish pierce. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the. Threaded Hole Inspection.

From www.kemalmfg.com

How to Make Difference Between Threaded Holes and Tapped Holes for CNC Machining Applications Threaded Hole Inspection The measured result is displayed with display. No thread, as well as partial thread condition because it compares. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within the accepted tolerance so that it interacts with the mating part correctly. Threaded plug gages internal threads. Threaded Hole Inspection.

From grabcad.com

Single Inspection Dimension for Holes GrabCAD Tutorials Threaded Hole Inspection To inspect an internal thread, both ends of the thread plug are inserted into the threaded component. • measure circles at both ends of threaded hole. (8 equally spaced points) • construct a line through the centers of both circles • establish pierce. No thread, as well as partial thread condition because it compares. Ect is an ideal inspection method. Threaded Hole Inspection.

From willrich.com

What You Need To Know About Thread Inspection Willrich Precision Instruments Threaded Hole Inspection The go end of the plug is supposed. (8 equally spaced points) • construct a line through the centers of both circles • establish pierce. Threaded plug gages internal threads should be inspected using go/nogo cylindrical plug gages manufactured at the applicable internal thread minor diameter. The measured result is displayed with display. Ect is an ideal inspection method for. Threaded Hole Inspection.

From www.gdandtbasics.com

Applying Position Tolerances to Countersunk Fixed Fastener Assembly Conditions GD&T Basics Threaded Hole Inspection The go end of the plug is supposed. The measured result is displayed with display. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within the accepted tolerance so that it interacts with the mating part correctly. (8 equally spaced points) • construct a line. Threaded Hole Inspection.

From www.mbvision.si

Thread Inspection MBvision hightech optical measuring systems Threaded Hole Inspection No thread, as well as partial thread condition because it compares. In an application like this, eddy current probes are lowered into the threaded hole. The go end of the plug is supposed. (8 equally spaced points) • construct a line through the centers of both circles • establish pierce. Eddy current technology provides a fast, clean way to inspect. Threaded Hole Inspection.

From www.bannerengineering.com

Thread Hole Detection Threaded Hole Inspection Eddy current technology provides a fast, clean way to inspect threaded holes. In an application like this, eddy current probes are lowered into the threaded hole. No thread, as well as partial thread condition because it compares. Ect is an ideal inspection method for verifying thread vs. The basic concept of a thread plug is to provide a quick inspection. Threaded Hole Inspection.