Why Is Copper Wire Enameled . The enamel coating allows engineers to wind the wire tightly without the risk of short circuits, making it ideal for electromagnetic. Enameled copper wires boast excellent electrical conductivity. The enamel coating on copper wire, often referred to as magnet wire, is a crucial component in many. While the metal part of enameled wire is typically copper, the presence of insulating enamel may slightly reduce its conductivity compared to bare copper wire. Impact of enamel coating on copper wire. The copper core, coupled with the enamel insulation, creates a conductor with low resistance, minimizing energy loss during electrical transmission. Enamelled copper wire, also known as magnet wire or winding wire, is a copper conductor coated with a thin layer of insulating enamel. This insulation not only protects the wire but also provides electrical insulation. Enamel coated wire, also known as magnet wire or winding wire, is an essential component used in various electrical and electronic applications. Wire enamels are applied on copper and aluminum round and flat wires used in motors, transformers, generators and electrical measuring instruments. Enameled wires are copper or aluminium wires coated with a thin layer of enamel insulation. It makes them indispensable in applications where efficiency is paramount. However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. They are cured onto the wires.

from www.windingwire.net

Impact of enamel coating on copper wire. They are cured onto the wires. The enamel coating allows engineers to wind the wire tightly without the risk of short circuits, making it ideal for electromagnetic. Enamel coated wire, also known as magnet wire or winding wire, is an essential component used in various electrical and electronic applications. Enamelled copper wire, also known as magnet wire or winding wire, is a copper conductor coated with a thin layer of insulating enamel. Wire enamels are applied on copper and aluminum round and flat wires used in motors, transformers, generators and electrical measuring instruments. This insulation not only protects the wire but also provides electrical insulation. It makes them indispensable in applications where efficiency is paramount. However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. The copper core, coupled with the enamel insulation, creates a conductor with low resistance, minimizing energy loss during electrical transmission.

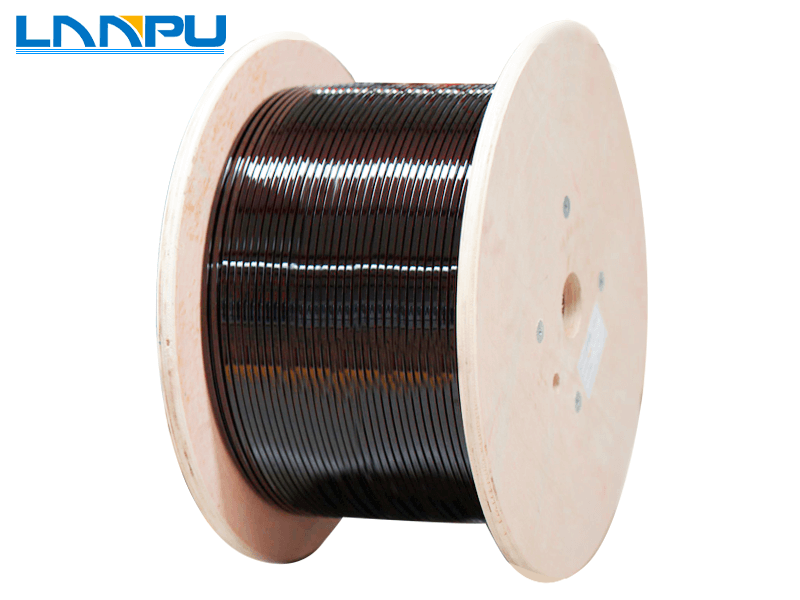

Enameled Flat(Rectangular) Copper Wire, copper wire, flat copper

Why Is Copper Wire Enameled Enamel coated wire, also known as magnet wire or winding wire, is an essential component used in various electrical and electronic applications. Enameled wires are copper or aluminium wires coated with a thin layer of enamel insulation. However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. Impact of enamel coating on copper wire. They are cured onto the wires. Wire enamels are applied on copper and aluminum round and flat wires used in motors, transformers, generators and electrical measuring instruments. It makes them indispensable in applications where efficiency is paramount. The copper core, coupled with the enamel insulation, creates a conductor with low resistance, minimizing energy loss during electrical transmission. Enamel coated wire, also known as magnet wire or winding wire, is an essential component used in various electrical and electronic applications. This insulation not only protects the wire but also provides electrical insulation. Enameled copper wires boast excellent electrical conductivity. The enamel coating on copper wire, often referred to as magnet wire, is a crucial component in many. While the metal part of enameled wire is typically copper, the presence of insulating enamel may slightly reduce its conductivity compared to bare copper wire. The enamel coating allows engineers to wind the wire tightly without the risk of short circuits, making it ideal for electromagnetic. Enamelled copper wire, also known as magnet wire or winding wire, is a copper conductor coated with a thin layer of insulating enamel.

From www.windingwire.net

Enameled Flat(Rectangular) Copper Wire, copper wire, flat copper Why Is Copper Wire Enameled However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. Enameled copper wires boast excellent electrical conductivity. The copper core, coupled with the enamel insulation, creates a conductor with low resistance, minimizing energy loss during electrical transmission. This insulation not only protects the wire but also provides electrical insulation. They are cured onto the wires. Enamel. Why Is Copper Wire Enameled.

From www.instructables.com

How to Get Tons of Free Enameled Copper Wire 4 Steps Instructables Why Is Copper Wire Enameled Impact of enamel coating on copper wire. Enameled copper wires boast excellent electrical conductivity. Wire enamels are applied on copper and aluminum round and flat wires used in motors, transformers, generators and electrical measuring instruments. It makes them indispensable in applications where efficiency is paramount. However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. Enameled. Why Is Copper Wire Enameled.

From www.tu-eshop.com

Enameled Copper Winding Wire35 AWG Why Is Copper Wire Enameled They are cured onto the wires. The enamel coating allows engineers to wind the wire tightly without the risk of short circuits, making it ideal for electromagnetic. While the metal part of enameled wire is typically copper, the presence of insulating enamel may slightly reduce its conductivity compared to bare copper wire. The copper core, coupled with the enamel insulation,. Why Is Copper Wire Enameled.

From www.indiamart.com

Enameled Copper Wire at best price in Udaipur by New Fakhri Industrial Why Is Copper Wire Enameled Wire enamels are applied on copper and aluminum round and flat wires used in motors, transformers, generators and electrical measuring instruments. The enamel coating on copper wire, often referred to as magnet wire, is a crucial component in many. The copper core, coupled with the enamel insulation, creates a conductor with low resistance, minimizing energy loss during electrical transmission. It. Why Is Copper Wire Enameled.

From www.electrical-cable.com

Enameled Wire, Copper enameled wire manufacturer Why Is Copper Wire Enameled Enameled copper wires boast excellent electrical conductivity. This insulation not only protects the wire but also provides electrical insulation. Enamelled copper wire, also known as magnet wire or winding wire, is a copper conductor coated with a thin layer of insulating enamel. The enamel coating allows engineers to wind the wire tightly without the risk of short circuits, making it. Why Is Copper Wire Enameled.

From www.pipingmaterial.ae

Enameled copper wire enamel insulated/ coated Cu wire Why Is Copper Wire Enameled The enamel coating on copper wire, often referred to as magnet wire, is a crucial component in many. The enamel coating allows engineers to wind the wire tightly without the risk of short circuits, making it ideal for electromagnetic. It makes them indispensable in applications where efficiency is paramount. Impact of enamel coating on copper wire. However, in certain applications,. Why Is Copper Wire Enameled.

From www.indiamart.com

Solid 35 mm Enameled Copper Wire, For Industrial, Wire Gauge 510 Why Is Copper Wire Enameled However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. Enameled copper wires boast excellent electrical conductivity. While the metal part of enameled wire is typically copper, the presence of insulating enamel may slightly reduce its conductivity compared to bare copper wire. The enamel coating allows engineers to wind the wire tightly without the risk of. Why Is Copper Wire Enameled.

From www.pipingmaterial.ae

Enameled copper wire enamel insulated/ coated Cu wire Why Is Copper Wire Enameled Enamelled copper wire, also known as magnet wire or winding wire, is a copper conductor coated with a thin layer of insulating enamel. Enamel coated wire, also known as magnet wire or winding wire, is an essential component used in various electrical and electronic applications. However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. The. Why Is Copper Wire Enameled.

From www.ztelecgroup.com

enameled copper wire Why Is Copper Wire Enameled Impact of enamel coating on copper wire. This insulation not only protects the wire but also provides electrical insulation. However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. The enamel coating on copper wire, often referred to as magnet wire, is a crucial component in many. Enamelled copper wire, also known as magnet wire or. Why Is Copper Wire Enameled.

From sh-jnl.en.made-in-china.com

Enameled Copper Wire China Enameled Wire and Enamelled Copper Wire Why Is Copper Wire Enameled This insulation not only protects the wire but also provides electrical insulation. Wire enamels are applied on copper and aluminum round and flat wires used in motors, transformers, generators and electrical measuring instruments. They are cured onto the wires. It makes them indispensable in applications where efficiency is paramount. Impact of enamel coating on copper wire. However, in certain applications,. Why Is Copper Wire Enameled.

From www.ztelecgroup.com

enameled copper wire Why Is Copper Wire Enameled Enameled wires are copper or aluminium wires coated with a thin layer of enamel insulation. Enameled copper wires boast excellent electrical conductivity. The copper core, coupled with the enamel insulation, creates a conductor with low resistance, minimizing energy loss during electrical transmission. However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. Wire enamels are applied. Why Is Copper Wire Enameled.

From www.amazon.com

ZJIEX Wire Enameled Copper Wire 3.52 Ounce Enameled Why Is Copper Wire Enameled The copper core, coupled with the enamel insulation, creates a conductor with low resistance, minimizing energy loss during electrical transmission. The enamel coating on copper wire, often referred to as magnet wire, is a crucial component in many. Enamelled copper wire, also known as magnet wire or winding wire, is a copper conductor coated with a thin layer of insulating. Why Is Copper Wire Enameled.

From www.shreemetal.co.in

Enameled Copper Wire Price in Kolkata, Enameled Copper Wire Manufacturer Why Is Copper Wire Enameled They are cured onto the wires. While the metal part of enameled wire is typically copper, the presence of insulating enamel may slightly reduce its conductivity compared to bare copper wire. Enameled copper wires boast excellent electrical conductivity. However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. Enamelled copper wire, also known as magnet wire. Why Is Copper Wire Enameled.

From www.windingwire.net

Enameled Flat(Rectangular) Copper Wire, copper wire, flat copper Why Is Copper Wire Enameled Impact of enamel coating on copper wire. The enamel coating on copper wire, often referred to as magnet wire, is a crucial component in many. Wire enamels are applied on copper and aluminum round and flat wires used in motors, transformers, generators and electrical measuring instruments. Enamel coated wire, also known as magnet wire or winding wire, is an essential. Why Is Copper Wire Enameled.

From www.jytopcable.com

Enameled Copper Wire,Enamelled Copper Winding Wires for Electrical Why Is Copper Wire Enameled Enamelled copper wire, also known as magnet wire or winding wire, is a copper conductor coated with a thin layer of insulating enamel. However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. Enameled copper wires boast excellent electrical conductivity. The enamel coating allows engineers to wind the wire tightly without the risk of short circuits,. Why Is Copper Wire Enameled.

From parcoscientific.com

Enameled Copper Wire Electricity Physics Why Is Copper Wire Enameled Enamel coated wire, also known as magnet wire or winding wire, is an essential component used in various electrical and electronic applications. It makes them indispensable in applications where efficiency is paramount. Enamelled copper wire, also known as magnet wire or winding wire, is a copper conductor coated with a thin layer of insulating enamel. They are cured onto the. Why Is Copper Wire Enameled.

From www.modern-wires.com.pk

Modern Wires Copper Enamel Wires Why Is Copper Wire Enameled However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. Enameled wires are copper or aluminium wires coated with a thin layer of enamel insulation. Enamelled copper wire, also known as magnet wire or winding wire, is a copper conductor coated with a thin layer of insulating enamel. Wire enamels are applied on copper and aluminum. Why Is Copper Wire Enameled.

From www.ultrafinecopperwire.com

0.08mm Self Bonding Enameled Copper Wire Enameled Wire Why Is Copper Wire Enameled The copper core, coupled with the enamel insulation, creates a conductor with low resistance, minimizing energy loss during electrical transmission. It makes them indispensable in applications where efficiency is paramount. Wire enamels are applied on copper and aluminum round and flat wires used in motors, transformers, generators and electrical measuring instruments. While the metal part of enameled wire is typically. Why Is Copper Wire Enameled.

From smartlabs.co.za

Enamelled Copper Wire — SmartLabs Why Is Copper Wire Enameled The enamel coating allows engineers to wind the wire tightly without the risk of short circuits, making it ideal for electromagnetic. Enamelled copper wire, also known as magnet wire or winding wire, is a copper conductor coated with a thin layer of insulating enamel. Wire enamels are applied on copper and aluminum round and flat wires used in motors, transformers,. Why Is Copper Wire Enameled.

From www.amardeepsteel.com

Enameled Copper Wire Manufacturer, Copper Enameler Wire Manufacturer in Why Is Copper Wire Enameled This insulation not only protects the wire but also provides electrical insulation. The copper core, coupled with the enamel insulation, creates a conductor with low resistance, minimizing energy loss during electrical transmission. Enamel coated wire, also known as magnet wire or winding wire, is an essential component used in various electrical and electronic applications. They are cured onto the wires.. Why Is Copper Wire Enameled.

From www.icstation.com

0.1mm×50m Enameled Copper Wire Insulated Winding Wire Why Is Copper Wire Enameled Wire enamels are applied on copper and aluminum round and flat wires used in motors, transformers, generators and electrical measuring instruments. The enamel coating on copper wire, often referred to as magnet wire, is a crucial component in many. It makes them indispensable in applications where efficiency is paramount. However, in certain applications, enameled wire might be more suitable, offering. Why Is Copper Wire Enameled.

From www.windingwire.net

Enameled Square Copper Wire, copper wire, Square copper winding wire Why Is Copper Wire Enameled They are cured onto the wires. Impact of enamel coating on copper wire. However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. While the metal part of enameled wire is typically copper, the presence of insulating enamel may slightly reduce its conductivity compared to bare copper wire. Enamel coated wire, also known as magnet wire. Why Is Copper Wire Enameled.

From lightning-safetech.com

copper lacquer wire0.1mm 0.9mmCable Copper Wire Wire Enameled Why Is Copper Wire Enameled Enameled copper wires boast excellent electrical conductivity. However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. This insulation not only protects the wire but also provides electrical insulation. Enamel coated wire, also known as magnet wire or winding wire, is an essential component used in various electrical and electronic applications. They are cured onto the. Why Is Copper Wire Enameled.

From www.ultrafinecopperwire.com

Enameled Copper Wire Why Is Copper Wire Enameled While the metal part of enameled wire is typically copper, the presence of insulating enamel may slightly reduce its conductivity compared to bare copper wire. Enamel coated wire, also known as magnet wire or winding wire, is an essential component used in various electrical and electronic applications. Impact of enamel coating on copper wire. Enamelled copper wire, also known as. Why Is Copper Wire Enameled.

From www.indiamart.com

Super Enameled Copper Wire at Rs 580/kilogram Enameled Copper Winding Why Is Copper Wire Enameled However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. Enamelled copper wire, also known as magnet wire or winding wire, is a copper conductor coated with a thin layer of insulating enamel. Impact of enamel coating on copper wire. The enamel coating on copper wire, often referred to as magnet wire, is a crucial component. Why Is Copper Wire Enameled.

From aluew.com

Enameled Copper Wire 0.100mm Enameled Copper Wire Enameled Aluminum Why Is Copper Wire Enameled The enamel coating on copper wire, often referred to as magnet wire, is a crucial component in many. Enameled wires are copper or aluminium wires coated with a thin layer of enamel insulation. Enameled copper wires boast excellent electrical conductivity. Enamel coated wire, also known as magnet wire or winding wire, is an essential component used in various electrical and. Why Is Copper Wire Enameled.

From www.xdmagnetwire.com

Rectangular Enameled Copper Wire Xiandeng HiTech Electric Why Is Copper Wire Enameled Enameled copper wires boast excellent electrical conductivity. Wire enamels are applied on copper and aluminum round and flat wires used in motors, transformers, generators and electrical measuring instruments. The enamel coating allows engineers to wind the wire tightly without the risk of short circuits, making it ideal for electromagnetic. While the metal part of enameled wire is typically copper, the. Why Is Copper Wire Enameled.

From atelier-yuwa.ciao.jp

Enamelled Copper Wire 10m atelieryuwa.ciao.jp Why Is Copper Wire Enameled This insulation not only protects the wire but also provides electrical insulation. The copper core, coupled with the enamel insulation, creates a conductor with low resistance, minimizing energy loss during electrical transmission. While the metal part of enameled wire is typically copper, the presence of insulating enamel may slightly reduce its conductivity compared to bare copper wire. They are cured. Why Is Copper Wire Enameled.

From www.ultrafinecopperwire.com

5000V Enameled Copper Wire Why Is Copper Wire Enameled However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. This insulation not only protects the wire but also provides electrical insulation. Enamelled copper wire, also known as magnet wire or winding wire, is a copper conductor coated with a thin layer of insulating enamel. They are cured onto the wires. The enamel coating on copper. Why Is Copper Wire Enameled.

From www.cnmagnetwire.com

Enamelled Flat Copper Wire,enameled wire,winding wires,varnished wire Why Is Copper Wire Enameled While the metal part of enameled wire is typically copper, the presence of insulating enamel may slightly reduce its conductivity compared to bare copper wire. Wire enamels are applied on copper and aluminum round and flat wires used in motors, transformers, generators and electrical measuring instruments. Enamelled copper wire, also known as magnet wire or winding wire, is a copper. Why Is Copper Wire Enameled.

From www.conectmed.com

Enameled Copper Wire And Enameled Aluminum Wire Difference Why Is Copper Wire Enameled The copper core, coupled with the enamel insulation, creates a conductor with low resistance, minimizing energy loss during electrical transmission. They are cured onto the wires. The enamel coating on copper wire, often referred to as magnet wire, is a crucial component in many. However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. Enameled copper. Why Is Copper Wire Enameled.

From core-electronics.com.au

Enamelled Copper Wire 0.5mm 24 B&S 100g 57m Australia Why Is Copper Wire Enameled However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. While the metal part of enameled wire is typically copper, the presence of insulating enamel may slightly reduce its conductivity compared to bare copper wire. The enamel coating on copper wire, often referred to as magnet wire, is a crucial component in many. Enameled copper wires. Why Is Copper Wire Enameled.

From www.electrical-cable.com

Enameled Wire, Copper enameled wire manufacturer Why Is Copper Wire Enameled However, in certain applications, enameled wire might be more suitable, offering additional electrical insulation. The copper core, coupled with the enamel insulation, creates a conductor with low resistance, minimizing energy loss during electrical transmission. The enamel coating allows engineers to wind the wire tightly without the risk of short circuits, making it ideal for electromagnetic. Enameled copper wires boast excellent. Why Is Copper Wire Enameled.

From jainsalescorp.in

Enameled Copper Wire JainSalesCorp Why Is Copper Wire Enameled Enameled copper wires boast excellent electrical conductivity. Enamelled copper wire, also known as magnet wire or winding wire, is a copper conductor coated with a thin layer of insulating enamel. The enamel coating on copper wire, often referred to as magnet wire, is a crucial component in many. Enamel coated wire, also known as magnet wire or winding wire, is. Why Is Copper Wire Enameled.

From www.salzergroup.net

Enameled Copper Wire Manufacturers in India, Enameled Copper Wire Why Is Copper Wire Enameled Impact of enamel coating on copper wire. The copper core, coupled with the enamel insulation, creates a conductor with low resistance, minimizing energy loss during electrical transmission. It makes them indispensable in applications where efficiency is paramount. The enamel coating on copper wire, often referred to as magnet wire, is a crucial component in many. Wire enamels are applied on. Why Is Copper Wire Enameled.