Turbine Gearbox Design . Gearbox and wind turbine design and application standards have contributed significantly to improvements in reliability over the past two. This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and analysis of the associated. Mechanical planetary multiplier gearboxes are highly important for wind power turbine operation, with gearbox units being. In order to address the essential and challenging issue on design optimization of wind turbine gearbox under wind load and gear manufacturing uncertainties, three contributions have been. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase.

from www.windsystemsmag.com

Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and analysis of the associated. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. In order to address the essential and challenging issue on design optimization of wind turbine gearbox under wind load and gear manufacturing uncertainties, three contributions have been. Mechanical planetary multiplier gearboxes are highly important for wind power turbine operation, with gearbox units being. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Gearbox and wind turbine design and application standards have contributed significantly to improvements in reliability over the past two.

Fundamentals of Wind Turbines Wind Systems Magazine

Turbine Gearbox Design The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and analysis of the associated. Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. In order to address the essential and challenging issue on design optimization of wind turbine gearbox under wind load and gear manufacturing uncertainties, three contributions have been. Gearbox and wind turbine design and application standards have contributed significantly to improvements in reliability over the past two. Mechanical planetary multiplier gearboxes are highly important for wind power turbine operation, with gearbox units being. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase.

From www.mdpi.com

Energies Free FullText Prognosis of the Remaining Useful Life of Turbine Gearbox Design Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. Gearbox and wind turbine design and application standards have contributed significantly to improvements in reliability over the past two. This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and analysis of the. Turbine Gearbox Design.

From gas-turbines.weebly.com

Gear Boxes & Accessory Drives Turbine Gearbox Design In order to address the essential and challenging issue on design optimization of wind turbine gearbox under wind load and gear manufacturing uncertainties, three contributions have been. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Gearbox manufacturers can optimize the design process to reduce weight. Turbine Gearbox Design.

From www.artec-machine.com

The Efficient ASeries turbo parallel shaft gearbox Turbine Gearbox Design In order to address the essential and challenging issue on design optimization of wind turbine gearbox under wind load and gear manufacturing uncertainties, three contributions have been. Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. Gearbox manufacturers can optimize the design process to reduce weight by. Turbine Gearbox Design.

From www.windfarmbop.com

Gearbox in wind turbines Wind farm BoP Turbine Gearbox Design Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. In order to address the essential and challenging issue on design optimization of wind turbine gearbox under wind load and gear manufacturing uncertainties, three contributions have been. Mechanical planetary multiplier gearboxes are highly important for wind power turbine. Turbine Gearbox Design.

From www.mesys.ag

A wind turbine gearbox template is now available for the MESYS Shaft Turbine Gearbox Design This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and analysis of the associated. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Mechanical planetary multiplier gearboxes are highly important for wind power turbine operation, with gearbox units being. Gearbox manufacturers. Turbine Gearbox Design.

From es.scribd.com

Gearbox for a Wind Turbine Brendan Speechley Chi Sun Wong Kevin Fan Turbine Gearbox Design Gearbox and wind turbine design and application standards have contributed significantly to improvements in reliability over the past two. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. Mechanical planetary multiplier gearboxes are highly important for wind power turbine operation, with gearbox units being. The typical. Turbine Gearbox Design.

From www.windpowerengineering.com

The effect of wind turbine gearbox maintenance on present and future Turbine Gearbox Design Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. In order to address the essential and challenging issue on design optimization of wind turbine. Turbine Gearbox Design.

From www.bearingtips.com

Bearings from NKE for wind turbine gearboxes and generators Bearing Tips Turbine Gearbox Design The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. This chapter focuses on the fundamentals of designing a gearbox for a wind turbine. Turbine Gearbox Design.

From mungfali.com

Wind Turbine Gearbox Design Turbine Gearbox Design In order to address the essential and challenging issue on design optimization of wind turbine gearbox under wind load and gear manufacturing uncertainties, three contributions have been. Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. Gearbox and wind turbine design and application standards have contributed significantly. Turbine Gearbox Design.

From www.researchgate.net

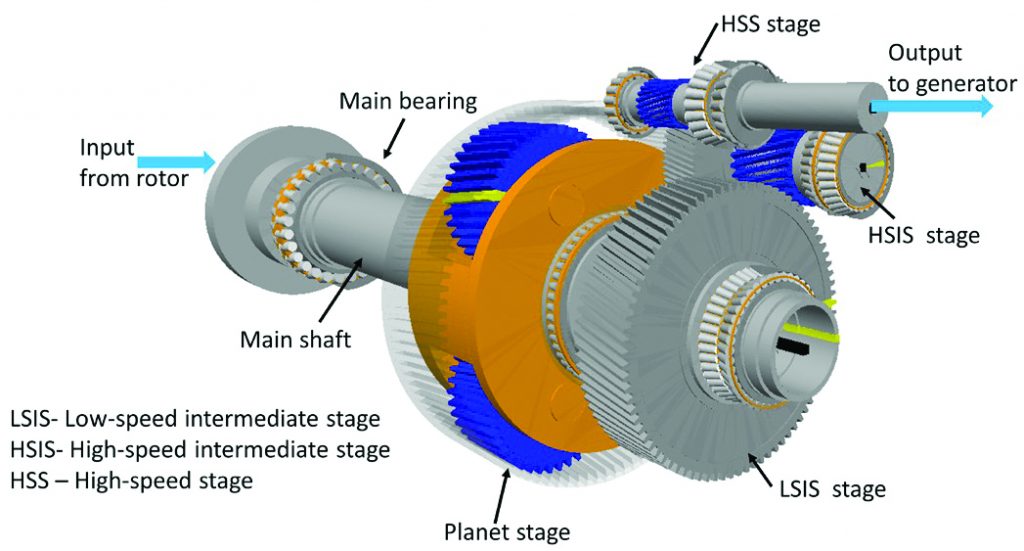

Typical modern design of a wind turbine gearbox (Onyx Insight 2019 Turbine Gearbox Design The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Gearbox and wind turbine design and application standards have contributed significantly to improvements in reliability over the past two. Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight. Turbine Gearbox Design.

From www.windpowerengineering.com

Why windturbine gearboxes fail to hit the 20year mark Turbine Gearbox Design This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and analysis of the associated. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. In order to address the essential and challenging issue on design optimization of wind turbine gearbox under wind. Turbine Gearbox Design.

From journals.sagepub.com

Vibration alleviation for wind turbine gearbox with flexible Turbine Gearbox Design This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and analysis of the associated. Gearbox and wind turbine design and application standards have contributed significantly to improvements in reliability over the past two. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed. Turbine Gearbox Design.

From www.coroflot.com

Wind Turbine Gearbox CAD Modeling by Drew Stroud at Turbine Gearbox Design This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and analysis of the associated. Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. Mechanical planetary multiplier gearboxes are highly important for wind power turbine operation, with gearbox units being. In order to. Turbine Gearbox Design.

From www.pengky.cn

Cylindrical gear transmission mechanism and gearbox horizontal axis Turbine Gearbox Design Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Gearbox and wind turbine design and application standards have contributed significantly to improvements in. Turbine Gearbox Design.

From www.reliabilityconnect.com

Wind Turbines Electrical Reliability RELIABILITY CONNECT® Turbine Gearbox Design In order to address the essential and challenging issue on design optimization of wind turbine gearbox under wind load and gear manufacturing uncertainties, three contributions have been. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. This chapter focuses on the fundamentals of designing a gearbox. Turbine Gearbox Design.

From dhhiindia.com

2.5MW wind turbine gearbox DALIAN HUARUI HEAVY INDUSTRY INDIA COMPANY Turbine Gearbox Design The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. This chapter focuses on the fundamentals of designing a gearbox for a wind turbine. Turbine Gearbox Design.

From www.pinterest.com

آشنایی کامل با نحوه عملکرد گیربکس در توربین بادی جی دی Turbine Gearbox Design Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. In order to address the essential and challenging issue on design optimization of wind turbine. Turbine Gearbox Design.

From www.windsystemsmag.com

Fundamentals of Wind Turbines Wind Systems Magazine Turbine Gearbox Design This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and analysis of the associated. Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. Mechanical planetary multiplier gearboxes are highly important for wind power turbine operation, with gearbox units being. The typical design. Turbine Gearbox Design.

From link.springer.com

Gearbox of Wind Turbine SpringerLink Turbine Gearbox Design The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Gearbox and wind turbine design and application standards have contributed significantly to improvements in reliability over the past two. In order to address the essential and challenging issue on design optimization of wind turbine gearbox under wind. Turbine Gearbox Design.

From www.zonpoo.com

Wind Turbine Gearbox Manufacturer and Supplier Zonpoo Turbine Gearbox Design This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and analysis of the associated. In order to address the essential and challenging issue on design optimization of wind turbine gearbox under wind load and gear manufacturing uncertainties, three contributions have been. Mechanical planetary multiplier gearboxes are highly important for wind power turbine operation, with gearbox. Turbine Gearbox Design.

From antasyaalinda.blogspot.com

Diagram Wind Turbine Parts Turbine Gearbox Design In order to address the essential and challenging issue on design optimization of wind turbine gearbox under wind load and gear manufacturing uncertainties, three contributions have been. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. This chapter focuses on the fundamentals of designing a gearbox. Turbine Gearbox Design.

From types.blog

Exploring Types of Gearbox Used in Wind Turbine Turbine Gearbox Design Gearbox and wind turbine design and application standards have contributed significantly to improvements in reliability over the past two. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight. Turbine Gearbox Design.

From www.indiamart.com

Industrial Turbine Gearbox at Rs 10000 औद्योगिक गियर बॉक्स in Turbine Gearbox Design This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and analysis of the associated. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight. Turbine Gearbox Design.

From mungfali.com

Wind Turbine Gearbox Design Turbine Gearbox Design The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. Gearbox and wind turbine design and application standards have contributed significantly to improvements in. Turbine Gearbox Design.

From www.mdpi.com

Energies Free FullText Time Domain Modeling and Analysis of Turbine Gearbox Design Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation. Turbine Gearbox Design.

From www.guomaodrive.com

The inside of gearbox motor generator for wind turbine Blog Turbine Gearbox Design This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and analysis of the associated. Mechanical planetary multiplier gearboxes are highly important for wind power turbine operation, with gearbox units being. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Gearbox manufacturers. Turbine Gearbox Design.

From www.windsystemsmag.com

Bearing and gearbox failures Challenge to wind turbines Wind Systems Turbine Gearbox Design The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. In order to address the essential and challenging issue on design optimization of wind turbine gearbox under wind load and gear manufacturing uncertainties, three contributions have been. Mechanical planetary multiplier gearboxes are highly important for wind power. Turbine Gearbox Design.

From www.zonpoo.com

Windmill and Turbine Gearbox Supplier Zonpoo Turbine Gearbox Design Mechanical planetary multiplier gearboxes are highly important for wind power turbine operation, with gearbox units being. In order to address the essential and challenging issue on design optimization of wind turbine gearbox under wind load and gear manufacturing uncertainties, three contributions have been. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert. Turbine Gearbox Design.

From wes.copernicus.org

WES Input torque measurements for wind turbine gearboxes using fiber Turbine Gearbox Design Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and. Turbine Gearbox Design.

From www.engineering-thailand.com

Modular bearing system for Wind turbine gearboxes Turbine Gearbox Design Mechanical planetary multiplier gearboxes are highly important for wind power turbine operation, with gearbox units being. Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed. Turbine Gearbox Design.

From www.stresstech.com

Grinding Quality Inspection at Wind Turbine Gearbox Expert Moventas Turbine Gearbox Design Mechanical planetary multiplier gearboxes are highly important for wind power turbine operation, with gearbox units being. This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and analysis of the associated. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. In order. Turbine Gearbox Design.

From www.windpowerengineering.com

What journal bearings may contribute to wind turbine gearboxes Turbine Gearbox Design Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation. Turbine Gearbox Design.

From mungfali.com

Wind Turbine Gearbox Design Turbine Gearbox Design Results provide important conclusions regarding the optimal design of wind turbine gearboxes with the lowest volumes and weight and, therefore, the maximum. This chapter focuses on the fundamentals of designing a gearbox for a wind turbine and analysis of the associated. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor. Turbine Gearbox Design.

From www.powertransmissionworld.com

Powerful analysis of wind turbine gearboxes Power Transmission World Turbine Gearbox Design Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. Gearbox and wind turbine design and application standards have contributed significantly to improvements in reliability over the past two. The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the. Turbine Gearbox Design.

From www.researchgate.net

Basic design and kinematic properties of a stage for a wind Turbine Gearbox Design The typical design lifetime of a utility wind turbine is 20 years, but the gearboxes, which convert the rotor blades rotational speed of. Gearbox manufacturers can optimize the design process to reduce weight by introducing advanced engineering simulation and test methods early in the design phase. Mechanical planetary multiplier gearboxes are highly important for wind power turbine operation, with gearbox. Turbine Gearbox Design.