Welding Keyhole . You can use it for open groove weld joints and butt joints. Figure 1 is a graphic illustration of the three weld modes. In welding, a keyhole refers to a hole that is formed at the leading edge of the molten weld metal. As the heat source progresses, the. Keyhole welding requires metals with poor thermal conductivity. This method is ideal for applications that demand strong, durable bonds with minimal material distortion. It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. Conduction mode, transition keyhole mode, and penetration or keyhole mode. Keyhole welding is a kind of laser welding. In keyhole welding, a gap is left between the two parts that you’re welding together. With keyhole laser welding, very high beam intensities are used to process the material. There are three basic weld modes, which correspond to the level of peak power density contained within the focus spot size: Keyhole welding is commonly utilized in heavy machinery. The two sides of the plates burn out to create a weld pool if predisposed to heat. The keyhole welding principle is based on an arc with particularly high energy density.

from www.findlight.net

The keyhole welding principle is based on an arc with particularly high energy density. In welding, a keyhole refers to a hole that is formed at the leading edge of the molten weld metal. The two sides of the plates burn out to create a weld pool if predisposed to heat. It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. You can use it for open groove weld joints and butt joints. There are three basic weld modes, which correspond to the level of peak power density contained within the focus spot size: Figure 1 is a graphic illustration of the three weld modes. Conduction mode, transition keyhole mode, and penetration or keyhole mode. This method is ideal for applications that demand strong, durable bonds with minimal material distortion. In keyhole welding, a gap is left between the two parts that you’re welding together.

Laser Keyhole Welding with Deep Learning

Welding Keyhole This method is ideal for applications that demand strong, durable bonds with minimal material distortion. In welding, a keyhole refers to a hole that is formed at the leading edge of the molten weld metal. In keyhole welding, a gap is left between the two parts that you’re welding together. The two sides of the plates burn out to create a weld pool if predisposed to heat. There are three basic weld modes, which correspond to the level of peak power density contained within the focus spot size: Keyhole welding is commonly utilized in heavy machinery. You can use it for open groove weld joints and butt joints. Keyhole welding is a kind of laser welding. As the heat source progresses, the. The keyhole welding principle is based on an arc with particularly high energy density. Figure 1 is a graphic illustration of the three weld modes. Keyhole welding requires metals with poor thermal conductivity. It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. This method is ideal for applications that demand strong, durable bonds with minimal material distortion. Conduction mode, transition keyhole mode, and penetration or keyhole mode. With keyhole laser welding, very high beam intensities are used to process the material.

From www.ionix.fi

Laser Welding Ionix Oy Welding Keyhole It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. In keyhole welding, a gap is left between the two parts that you’re welding together. You can use it for open groove weld joints and butt joints. There are three basic weld. Welding Keyhole.

From www.mdpi.com

JMMP Free FullText High Seam Surface Quality in Keyhole Laser Welding Keyhole It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. Figure 1 is a graphic illustration of the three weld modes. In welding, a keyhole refers to a hole that is formed at the leading edge of the molten weld metal. In. Welding Keyhole.

From www.thefabricator.com

The evolution of laser welding technology Welding Keyhole The two sides of the plates burn out to create a weld pool if predisposed to heat. With keyhole laser welding, very high beam intensities are used to process the material. The keyhole welding principle is based on an arc with particularly high energy density. This method is ideal for applications that demand strong, durable bonds with minimal material distortion.. Welding Keyhole.

From www.mdpi.com

JMMP Free FullText High Seam Surface Quality in Keyhole Laser Welding Keyhole You can use it for open groove weld joints and butt joints. Conduction mode, transition keyhole mode, and penetration or keyhole mode. As the heat source progresses, the. Keyhole welding is a kind of laser welding. This method is ideal for applications that demand strong, durable bonds with minimal material distortion. The two sides of the plates burn out to. Welding Keyhole.

From www.findlight.net

Laser Keyhole Welding with Deep Learning Welding Keyhole Conduction mode, transition keyhole mode, and penetration or keyhole mode. With keyhole laser welding, very high beam intensities are used to process the material. This method is ideal for applications that demand strong, durable bonds with minimal material distortion. The keyhole welding principle is based on an arc with particularly high energy density. You can use it for open groove. Welding Keyhole.

From www.youtube.com

Keyhole Laser Welding of Aluminum FLOW3D WELD YouTube Welding Keyhole The keyhole welding principle is based on an arc with particularly high energy density. It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. This method is ideal for applications that demand strong, durable bonds with minimal material distortion. Keyhole welding is. Welding Keyhole.

From tiptig.com

Keyhole TIG Welding • TIP TIG® Welding Keyhole As the heat source progresses, the. The two sides of the plates burn out to create a weld pool if predisposed to heat. With keyhole laser welding, very high beam intensities are used to process the material. It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results. Welding Keyhole.

From waterwelders.com

What is a Keyhole in Welding? A Complete Guide WaterWelders Welding Keyhole There are three basic weld modes, which correspond to the level of peak power density contained within the focus spot size: Keyhole welding is a kind of laser welding. This method is ideal for applications that demand strong, durable bonds with minimal material distortion. As the heat source progresses, the. Conduction mode, transition keyhole mode, and penetration or keyhole mode.. Welding Keyhole.

From www.researchgate.net

Schematic of laser keyhole welding process. Download Scientific Diagram Welding Keyhole Keyhole welding is a kind of laser welding. In keyhole welding, a gap is left between the two parts that you’re welding together. Figure 1 is a graphic illustration of the three weld modes. With keyhole laser welding, very high beam intensities are used to process the material. This method is ideal for applications that demand strong, durable bonds with. Welding Keyhole.

From www.thefabricator.com

Should your operation convert from spot welding to laser keyhole Welding Keyhole This method is ideal for applications that demand strong, durable bonds with minimal material distortion. The keyhole welding principle is based on an arc with particularly high energy density. Keyhole welding is commonly utilized in heavy machinery. Keyhole welding requires metals with poor thermal conductivity. It differs from tig welding in that the arc energy is focused on a small. Welding Keyhole.

From www.youtube.com

Visualization of Keyhole in NdYAG Laser Welding with CAVILUX Welding Keyhole Conduction mode, transition keyhole mode, and penetration or keyhole mode. Keyhole welding requires metals with poor thermal conductivity. The two sides of the plates burn out to create a weld pool if predisposed to heat. The keyhole welding principle is based on an arc with particularly high energy density. With keyhole laser welding, very high beam intensities are used to. Welding Keyhole.

From www.youtube.com

TIP TIGfocus Stainless Steel Welding THE SINGLE Welding Keyhole The two sides of the plates burn out to create a weld pool if predisposed to heat. There are three basic weld modes, which correspond to the level of peak power density contained within the focus spot size: As the heat source progresses, the. With keyhole laser welding, very high beam intensities are used to process the material. In keyhole. Welding Keyhole.

From www.researchgate.net

Schematization of the keyhole laser welding process. Download Welding Keyhole You can use it for open groove weld joints and butt joints. Conduction mode, transition keyhole mode, and penetration or keyhole mode. It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. Keyhole welding requires metals with poor thermal conductivity. With keyhole. Welding Keyhole.

From camvaceng.com

An Introduction to Laser Welding Cambridge Vacuum Engineering Welding Keyhole The two sides of the plates burn out to create a weld pool if predisposed to heat. In keyhole welding, a gap is left between the two parts that you’re welding together. This method is ideal for applications that demand strong, durable bonds with minimal material distortion. In welding, a keyhole refers to a hole that is formed at the. Welding Keyhole.

From www.thefabricator.com

Converting from laser spot welding to keyhole laser welding Welding Keyhole This method is ideal for applications that demand strong, durable bonds with minimal material distortion. Conduction mode, transition keyhole mode, and penetration or keyhole mode. Keyhole welding is commonly utilized in heavy machinery. With keyhole laser welding, very high beam intensities are used to process the material. In welding, a keyhole refers to a hole that is formed at the. Welding Keyhole.

From www.youtube.com

Half keyhole technique to making thick back bead ! TIG Welding Welding Keyhole In welding, a keyhole refers to a hole that is formed at the leading edge of the molten weld metal. As the heat source progresses, the. Keyhole welding requires metals with poor thermal conductivity. With keyhole laser welding, very high beam intensities are used to process the material. Conduction mode, transition keyhole mode, and penetration or keyhole mode. The keyhole. Welding Keyhole.

From www.researchgate.net

Schematic of Keyhole TIG welding process. Download Scientific Diagram Welding Keyhole It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. You can use it for open groove weld joints and butt joints. The two sides of the plates burn out to create a weld pool if predisposed to heat. This method is. Welding Keyhole.

From www.k-tig.com

What is KTIG Keyhole TIG Welding The Fastest Way to Weld Welding Keyhole As the heat source progresses, the. The two sides of the plates burn out to create a weld pool if predisposed to heat. It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. Figure 1 is a graphic illustration of the three. Welding Keyhole.

From furrubs.com

Keyhole Laser Welding Explained Technique and Benefits Laser Welding Welding Keyhole Keyhole welding requires metals with poor thermal conductivity. Figure 1 is a graphic illustration of the three weld modes. In keyhole welding, a gap is left between the two parts that you’re welding together. Keyhole welding is commonly utilized in heavy machinery. There are three basic weld modes, which correspond to the level of peak power density contained within the. Welding Keyhole.

From www.acsys.de

Metal welding ACSYS Lasermaschinen Welding Keyhole As the heat source progresses, the. Keyhole welding is a kind of laser welding. There are three basic weld modes, which correspond to the level of peak power density contained within the focus spot size: It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep. Welding Keyhole.

From waterwelders.com

What is a Keyhole in Welding? A Complete Guide WaterWelders Welding Keyhole There are three basic weld modes, which correspond to the level of peak power density contained within the focus spot size: The keyhole welding principle is based on an arc with particularly high energy density. The two sides of the plates burn out to create a weld pool if predisposed to heat. It differs from tig welding in that the. Welding Keyhole.

From www.findlight.net

Laser Keyhole Welding with Deep Learning Welding Keyhole In keyhole welding, a gap is left between the two parts that you’re welding together. Figure 1 is a graphic illustration of the three weld modes. Conduction mode, transition keyhole mode, and penetration or keyhole mode. This method is ideal for applications that demand strong, durable bonds with minimal material distortion. There are three basic weld modes, which correspond to. Welding Keyhole.

From www.findlight.net

Laser Keyhole Welding with Deep Learning Welding Keyhole With keyhole laser welding, very high beam intensities are used to process the material. As the heat source progresses, the. It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. In welding, a keyhole refers to a hole that is formed at. Welding Keyhole.

From www.researchgate.net

Schematic sketch of a pulsed laser keyhole welding of zinccoated Welding Keyhole Keyhole welding is commonly utilized in heavy machinery. Keyhole welding requires metals with poor thermal conductivity. In keyhole welding, a gap is left between the two parts that you’re welding together. The two sides of the plates burn out to create a weld pool if predisposed to heat. As the heat source progresses, the. Keyhole welding is a kind of. Welding Keyhole.

From www.youtube.com

Full Welds With the Keyhole Technique YouTube Welding Keyhole The keyhole welding principle is based on an arc with particularly high energy density. This method is ideal for applications that demand strong, durable bonds with minimal material distortion. The two sides of the plates burn out to create a weld pool if predisposed to heat. In keyhole welding, a gap is left between the two parts that you’re welding. Welding Keyhole.

From www.youtube.com

Keyhole tig weld the thickstainless steel plate YouTube Welding Keyhole In keyhole welding, a gap is left between the two parts that you’re welding together. The keyhole welding principle is based on an arc with particularly high energy density. It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. This method is. Welding Keyhole.

From workshopinsider.com

Laser Beam Welding LBM What You Need To Know Insider Welding Keyhole It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. Figure 1 is a graphic illustration of the three weld modes. In keyhole welding, a gap is left between the two parts that you’re welding together. There are three basic weld modes,. Welding Keyhole.

From www.youtube.com

Keyhole Laser Welding of Dissimilar Materials FLOW3D WELD YouTube Welding Keyhole As the heat source progresses, the. There are three basic weld modes, which correspond to the level of peak power density contained within the focus spot size: Conduction mode, transition keyhole mode, and penetration or keyhole mode. Keyhole welding is commonly utilized in heavy machinery. You can use it for open groove weld joints and butt joints. Figure 1 is. Welding Keyhole.

From weldguru.com

What is Laser Welding (LBW)? & How Does it Work? Welding Keyhole The keyhole welding principle is based on an arc with particularly high energy density. With keyhole laser welding, very high beam intensities are used to process the material. Keyhole welding requires metals with poor thermal conductivity. You can use it for open groove weld joints and butt joints. It differs from tig welding in that the arc energy is focused. Welding Keyhole.

From amadaweldtech.com

Laser Welding Modes Laser Keyhole Welding AMADA WELD TECH Welding Keyhole The two sides of the plates burn out to create a weld pool if predisposed to heat. Keyhole welding is commonly utilized in heavy machinery. The keyhole welding principle is based on an arc with particularly high energy density. As the heat source progresses, the. Figure 1 is a graphic illustration of the three weld modes. This method is ideal. Welding Keyhole.

From www.youtube.com

Keyhole Laser Welding with 50kW Laser Power EN YouTube Welding Keyhole Keyhole welding requires metals with poor thermal conductivity. As the heat source progresses, the. With keyhole laser welding, very high beam intensities are used to process the material. There are three basic weld modes, which correspond to the level of peak power density contained within the focus spot size: The keyhole welding principle is based on an arc with particularly. Welding Keyhole.

From www.mig-welding.co.uk

TIG Tutorial Butt Welds and Tacking Welding Keyhole Keyhole welding requires metals with poor thermal conductivity. Keyhole welding is commonly utilized in heavy machinery. It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. The keyhole welding principle is based on an arc with particularly high energy density. Figure 1. Welding Keyhole.

From www.youtube.com

Laser Keyhole Welding FLOW3D WELD YouTube Welding Keyhole As the heat source progresses, the. It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. Keyhole welding is commonly utilized in heavy machinery. There are three basic weld modes, which correspond to the level of peak power density contained within the. Welding Keyhole.

From www.mdpi.com

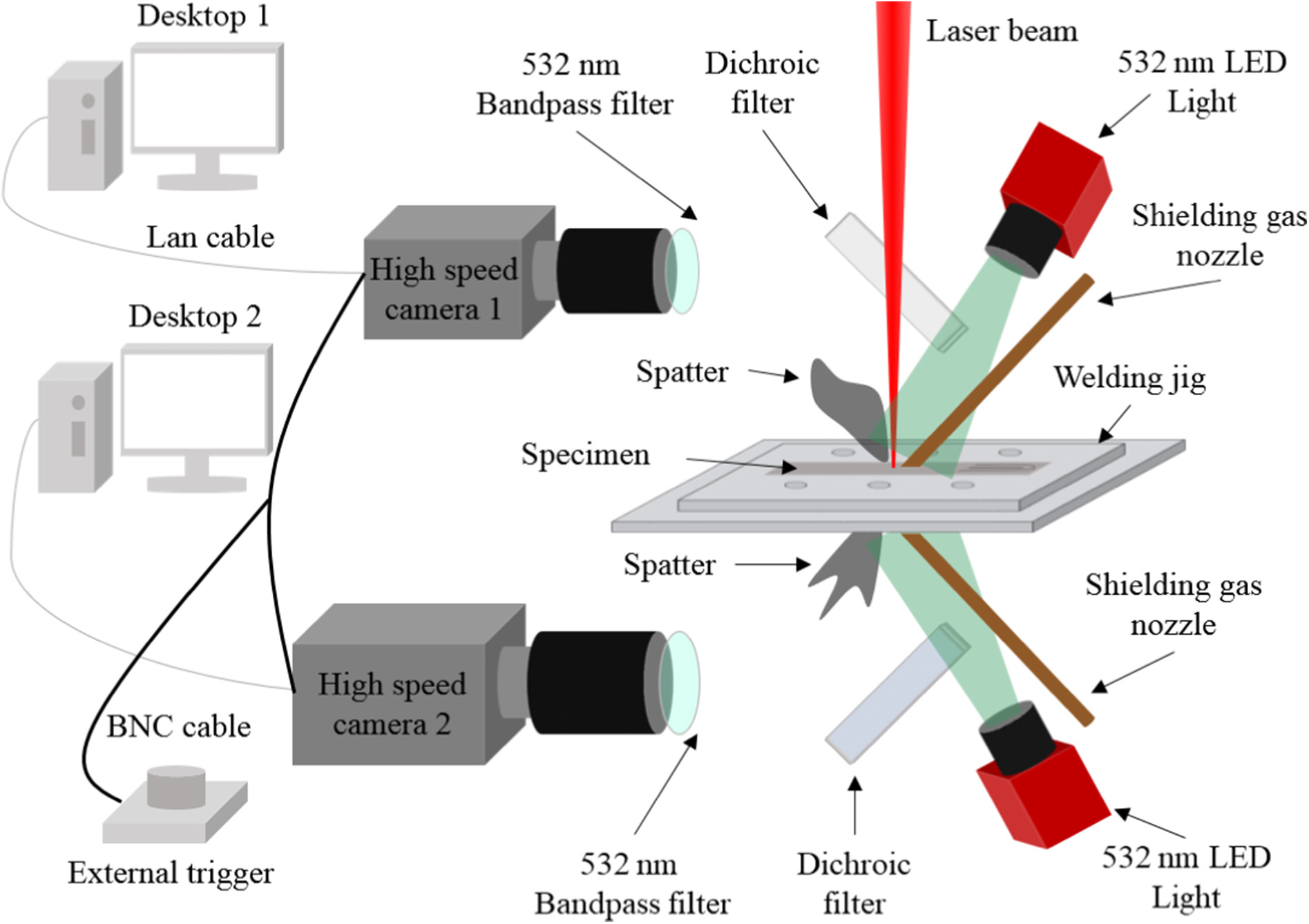

Metals Free FullText Online Detection of Keyhole Status in a Laser Welding Keyhole It differs from tig welding in that the arc energy is focused on a small as opposed to a large area, which results in deep and narrow penetration. The keyhole welding principle is based on an arc with particularly high energy density. Keyhole welding requires metals with poor thermal conductivity. This method is ideal for applications that demand strong, durable. Welding Keyhole.

From www.researchgate.net

Schematic illustration of laser keyhole welding of Al/steel butt Welding Keyhole As the heat source progresses, the. In keyhole welding, a gap is left between the two parts that you’re welding together. With keyhole laser welding, very high beam intensities are used to process the material. Keyhole welding is commonly utilized in heavy machinery. There are three basic weld modes, which correspond to the level of peak power density contained within. Welding Keyhole.