Thread Gage Tolerance Chart . Thread gages are made to class x tolerances. 77 rows to use the standard pitch diameter chart for thread plug gages, match the thread size you are working with to the chart's listed sizes. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. *parameters and results are rounded to 8 decimal places. *suggested gage tolerance is calculated using. Tolerances are written as a combination of a tolerance band, signified by an. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. 1/2” above 1/2” threads per inch to and incl. The information below can be used to calculate the values of thread tolerances defined by iso 965/1.

from www.zerofast.com

The information below can be used to calculate the values of thread tolerances defined by iso 965/1. *suggested gage tolerance is calculated using. Tolerances are written as a combination of a tolerance band, signified by an. 1/2” above 1/2” threads per inch to and incl. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. 77 rows to use the standard pitch diameter chart for thread plug gages, match the thread size you are working with to the chart's listed sizes. Thread gages are made to class x tolerances. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. *parameters and results are rounded to 8 decimal places.

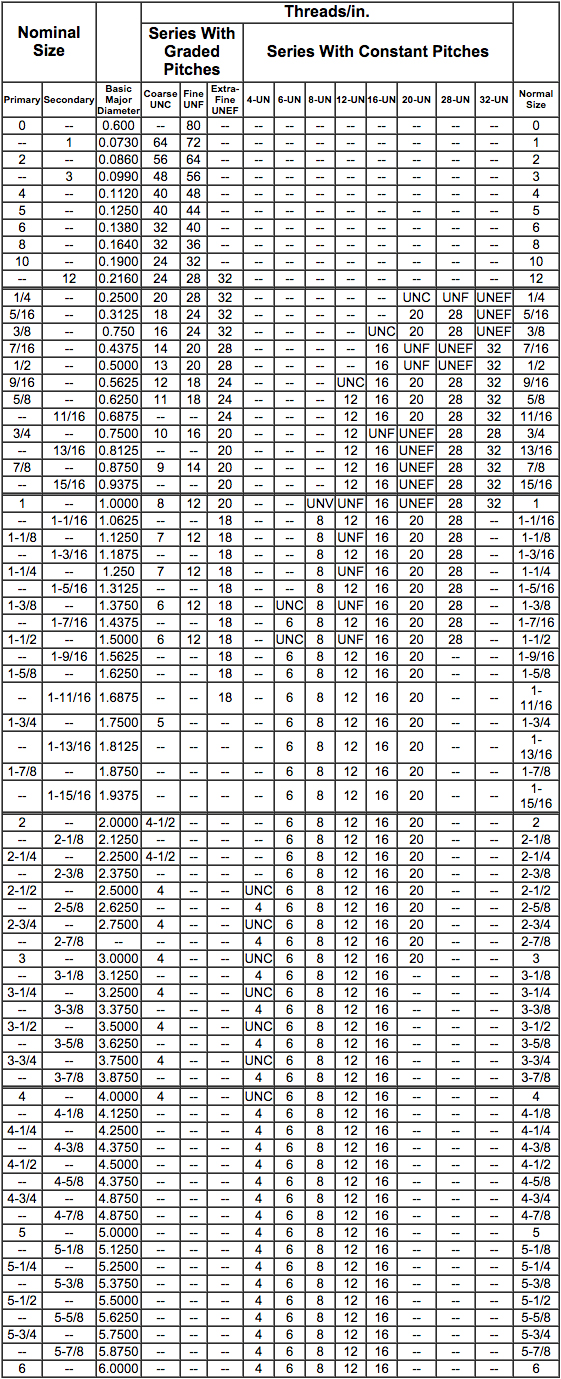

Thread Chart Standard zero products inc.

Thread Gage Tolerance Chart Tolerances are written as a combination of a tolerance band, signified by an. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. The information below can be used to calculate the values of thread tolerances defined by iso 965/1. *parameters and results are rounded to 8 decimal places. Tolerances are written as a combination of a tolerance band, signified by an. *suggested gage tolerance is calculated using. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. 1/2” above 1/2” threads per inch to and incl. 77 rows to use the standard pitch diameter chart for thread plug gages, match the thread size you are working with to the chart's listed sizes. Thread gages are made to class x tolerances. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d.

From mavink.com

Iso 8015 Diameter Tolerance Chart Thread Gage Tolerance Chart This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. 77 rows to use the standard pitch diameter chart for thread plug gages, match the thread size you are working with to the chart's listed sizes. 1/2” above 1/2” threads per inch to and incl. Thread gages are made to class x. Thread Gage Tolerance Chart.

From louisekirk.z19.web.core.windows.net

Metric Thread Tolerance Chart Pdf Thread Gage Tolerance Chart *suggested gage tolerance is calculated using. *parameters and results are rounded to 8 decimal places. Thread gages are made to class x tolerances. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. Tolerances are written as a combination of a tolerance band, signified by an. 30 rows click here to see. Thread Gage Tolerance Chart.

From mavink.com

Gage Makers Tolerance Chart Thread Gage Tolerance Chart See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. *parameters and results are rounded to 8 decimal places. The information below can be used to calculate the values of thread tolerances defined by iso 965/1. 77. Thread Gage Tolerance Chart.

From mavink.com

Gage Makers Tolerance Chart Thread Gage Tolerance Chart *parameters and results are rounded to 8 decimal places. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. The information below can be used to calculate the values of thread tolerances defined by iso 965/1. *suggested gage tolerance is calculated using. Tolerances are written as a combination of a tolerance band, signified by an.. Thread Gage Tolerance Chart.

From www.judgetool.com

Pipe Thread Ring Gages NPT NPTF ANPT Judge Tool & Gage Thread Gage Tolerance Chart *suggested gage tolerance is calculated using. Tolerances are written as a combination of a tolerance band, signified by an. 1/2” above 1/2” threads per inch to and incl. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. Thread gages are made to class x tolerances. See asme b89.7.3.1 for more information. Thread Gage Tolerance Chart.

From www.thomasnet.com

All About Pipe and Hose Threads Thread Gage Tolerance Chart Thread gages are made to class x tolerances. 77 rows to use the standard pitch diameter chart for thread plug gages, match the thread size you are working with to the chart's listed sizes. *parameters and results are rounded to 8 decimal places. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. This calculator. Thread Gage Tolerance Chart.

From titangage.com

Thread Ring & Setting Plug Gages Titan Gage Thread Gage Tolerance Chart Thread gages are made to class x tolerances. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. The information below can be used to calculate the values of thread tolerances defined by iso 965/1. 1/2” above 1/2” threads per. Thread Gage Tolerance Chart.

From bceweb.org

Spline Tolerance Chart A Visual Reference of Charts Chart Master Thread Gage Tolerance Chart 1/2” above 1/2” threads per inch to and incl. *suggested gage tolerance is calculated using. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. 77 rows to use the standard pitch diameter chart for thread plug gages, match the thread size you are working with to the chart's listed sizes. This calculator will determine. Thread Gage Tolerance Chart.

From ar.inspiredpencil.com

Metric Thread Tolerance Chart Thread Gage Tolerance Chart See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. 77 rows to use the standard pitch diameter chart for thread plug. Thread Gage Tolerance Chart.

From www.fastenerdata.co.uk

Fastenerdata THREAD CHART 10b Fastener Specifications Thread Gage Tolerance Chart 30 rows click here to see how major, minor and pitch diameter tolerances are applied. *suggested gage tolerance is calculated using. *parameters and results are rounded to 8 decimal places. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical. Thread Gage Tolerance Chart.

From willrich.com

Thread Gage Design and Thread Gages Designations Willich Thread Gage Tolerance Chart 1/2” above 1/2” threads per inch to and incl. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. *suggested gage tolerance is calculated using. Tolerances are written as a combination of a tolerance band, signified by an. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. Thread gages. Thread Gage Tolerance Chart.

From www.youtube.com

METRIC THREAD ISO TOLERANCE CALCULATOR YouTube Thread Gage Tolerance Chart The information below can be used to calculate the values of thread tolerances defined by iso 965/1. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. Tolerances are written as a combination of a tolerance band, signified by an.. Thread Gage Tolerance Chart.

From mavink.com

Npt Thread Tolerance Chart Thread Gage Tolerance Chart 1/2” above 1/2” threads per inch to and incl. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. The information below can be used to calculate the values of thread tolerances defined by iso 965/1. Thread gages are made to class x tolerances. *suggested gage tolerance is calculated using. *parameters and results are rounded. Thread Gage Tolerance Chart.

From vermontgage.com

Product and Technical Support Resources Vermont Gage Thread Gage Tolerance Chart The information below can be used to calculate the values of thread tolerances defined by iso 965/1. Thread gages are made to class x tolerances. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. *suggested gage tolerance is calculated using. *parameters and results are rounded to 8 decimal places. Tolerances are. Thread Gage Tolerance Chart.

From www.qualitymag.com

Thread Classes and Setting Plug Gages 20191001 Quality Magazine Thread Gage Tolerance Chart See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. 77 rows to use the standard pitch diameter chart for thread plug gages, match the thread size you are working with to the chart's listed sizes. Thread gages are made to class x tolerances. The information below can be used to calculate the values of. Thread Gage Tolerance Chart.

From www.scribd.com

10. Gage Tolerances PDF Thread Gage Tolerance Chart 30 rows click here to see how major, minor and pitch diameter tolerances are applied. *parameters and results are rounded to 8 decimal places. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. Thread gages are made to class x tolerances. *suggested gage tolerance is calculated using. Tolerances are written as. Thread Gage Tolerance Chart.

From cncpartschina03.blogspot.com

cnc turning parts Metric thread gages standard pitch diameter chart Thread Gage Tolerance Chart *suggested gage tolerance is calculated using. The information below can be used to calculate the values of thread tolerances defined by iso 965/1. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. This calculator will determine the gage class. Thread Gage Tolerance Chart.

From www.zerofast.com

Thread Chart Standard zero products inc. Thread Gage Tolerance Chart This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. The information below can be used to calculate the values of thread tolerances defined by iso 965/1. *suggested gage tolerance is calculated using. 1/2” above 1/2” threads per inch to and incl. Thread gages are made to class x tolerances. 30 rows. Thread Gage Tolerance Chart.

From mungfali.com

Gage Block Tolerance Chart Thread Gage Tolerance Chart 30 rows click here to see how major, minor and pitch diameter tolerances are applied. *suggested gage tolerance is calculated using. 77 rows to use the standard pitch diameter chart for thread plug gages, match the thread size you are working with to the chart's listed sizes. Thread gages are made to class x tolerances. The information below can be. Thread Gage Tolerance Chart.

From www.scribd.com

Thread Tolerances Cutting Tools Machining Thread Gage Tolerance Chart 77 rows to use the standard pitch diameter chart for thread plug gages, match the thread size you are working with to the chart's listed sizes. The information below can be used to calculate the values of thread tolerances defined by iso 965/1. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. Tolerances are. Thread Gage Tolerance Chart.

From westportcorp.com

Charts ANSIThread Gage Chart WESTport Corp. Thread Gage Tolerance Chart *parameters and results are rounded to 8 decimal places. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. Tolerances are written as a combination of a tolerance band, signified by an. The information below can be. Thread Gage Tolerance Chart.

From freyabaxter.z13.web.core.windows.net

6h Thread Tolerance Chart Thread Gage Tolerance Chart This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. 77 rows to use the standard pitch diameter chart for thread plug gages, match the thread size you are working with to the chart's listed sizes. Thread. Thread Gage Tolerance Chart.

From classdbgregg.z21.web.core.windows.net

6h Thread Tolerance Chart Thread Gage Tolerance Chart *suggested gage tolerance is calculated using. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. 77 rows to use the standard pitch diameter chart for thread plug gages, match the thread size you are working with to the chart's listed sizes. The information below can be used to calculate the values of thread tolerances. Thread Gage Tolerance Chart.

From vdocuments.mx

Metric Thread Gages Gage Assembly · Metric Thread Gages ANSI / ASME Thread Gage Tolerance Chart *parameters and results are rounded to 8 decimal places. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. The information below can be used to calculate the values of thread tolerances defined by iso 965/1. *suggested gage tolerance is calculated using. 30 rows click here to see how major, minor and. Thread Gage Tolerance Chart.

From willrich.com

Gagemakers Tolerance Chart Willich Precision Instruments Thread Gage Tolerance Chart Tolerances are written as a combination of a tolerance band, signified by an. 1/2” above 1/2” threads per inch to and incl. The information below can be used to calculate the values of thread tolerances defined by iso 965/1. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. This calculator will determine the gage. Thread Gage Tolerance Chart.

From www.qualitymag.com

Thread Classes and Setting Plug Gages 20191001 Quality Magazine Thread Gage Tolerance Chart See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. Thread gages are made to class x tolerances. Tolerances are written as. Thread Gage Tolerance Chart.

From www.ring-plug-thread-gages.com

Solid vs Adjustable Screw Thread Ring Gages Tolerance Thread Gage Tolerance Chart 1/2” above 1/2” threads per inch to and incl. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. Thread gages are made to class x tolerances. *suggested gage tolerance is calculated using. See asme b89.7.3.1 for. Thread Gage Tolerance Chart.

From www.teachtoearn.in

Gagemakers Tolerance Chart Willich Precision Instruments, 40 OFF Thread Gage Tolerance Chart See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. 1/2” above 1/2” threads per inch to and incl. Tolerances are written as a combination of a tolerance band, signified by an. *parameters and results are rounded to 8 decimal places. 30 rows click here to see how major, minor and pitch diameter tolerances are. Thread Gage Tolerance Chart.

From www.engineersedge.com

External Pipe Thread Design, Specifications and NPT Pipe Thread Thread Gage Tolerance Chart See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. Tolerances are written as a combination of a tolerance band, signified by an. *parameters and results are rounded to 8 decimal places. The information below can be used to calculate the values of thread tolerances defined by iso 965/1. *suggested gage tolerance is calculated using.. Thread Gage Tolerance Chart.

From vdocuments.mx

Metric Thread Gages Standard Pitch Diameter · PDF fileGAGE ASSEMBLY Thread Gage Tolerance Chart Tolerances are written as a combination of a tolerance band, signified by an. The information below can be used to calculate the values of thread tolerances defined by iso 965/1. *suggested gage tolerance is calculated using. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. 1/2” above 1/2” threads per inch to and incl.. Thread Gage Tolerance Chart.

From mavink.com

Thread Fit Class Chart Thread Gage Tolerance Chart Thread gages are made to class x tolerances. 1/2” above 1/2” threads per inch to and incl. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. The information below can be used to calculate the values. Thread Gage Tolerance Chart.

From www.gaugestools.com

Series gaugestools Thread Gage Tolerance Chart This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. 77 rows to use the standard pitch diameter chart for thread plug gages, match the thread size you are working with to the chart's listed sizes. *suggested gage tolerance is calculated using. Tolerances are written as a combination of a tolerance band,. Thread Gage Tolerance Chart.

From www.judgetool.com

Thread Plug Gages STI (HELICOIL) Titanium Nitride Coated (Inch Thread Gage Tolerance Chart See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. The information below can be used to calculate the values of thread tolerances defined by iso 965/1. Tolerances are written as a combination of a tolerance band, signified by an. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical. Thread Gage Tolerance Chart.

From nabgauge.com

How to use API 72 Thread Gauges Northern Gauge Thread Gage Tolerance Chart *parameters and results are rounded to 8 decimal places. *suggested gage tolerance is calculated using. Thread gages are made to class x tolerances. Tolerances are written as a combination of a tolerance band, signified by an. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. 77 rows to use the standard. Thread Gage Tolerance Chart.

From mungfali.com

Metric Thread Gage Chart Thread Gage Tolerance Chart The information below can be used to calculate the values of thread tolerances defined by iso 965/1. See asme b89.7.3.1 for more information on the 10% rule and options beyond this rule. 30 rows click here to see how major, minor and pitch diameter tolerances are applied. 1/2” above 1/2” threads per inch to and incl. Tolerances are written as. Thread Gage Tolerance Chart.