Surface Coating For Adhesion . Understanding how adhesion and the spread of corrosion under the coating are influenced by surface roughness entails. Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. A rough surface provides additional mechanical interlocking at the interface;. Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote.

from www.semanticscholar.org

Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. Understanding how adhesion and the spread of corrosion under the coating are influenced by surface roughness entails. The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. A rough surface provides additional mechanical interlocking at the interface;. Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote.

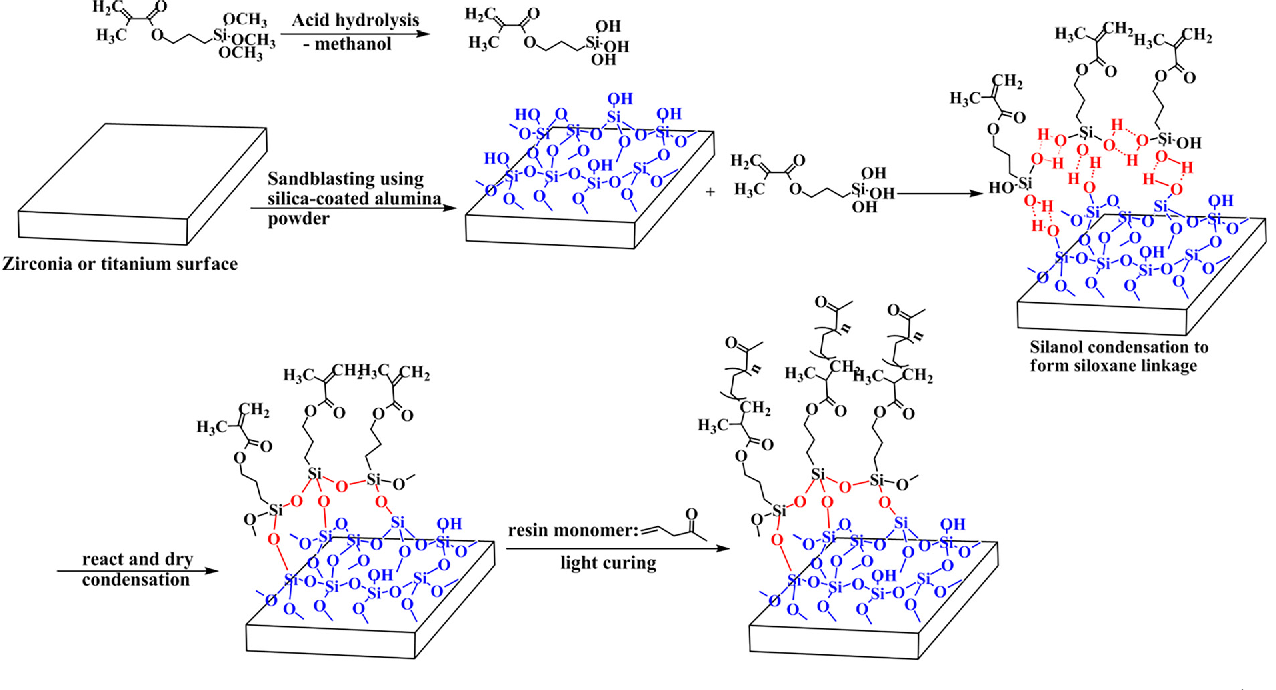

Figure 1 from Silane adhesion mechanism in dental applications and

Surface Coating For Adhesion Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; Understanding how adhesion and the spread of corrosion under the coating are influenced by surface roughness entails. Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. A rough surface provides additional mechanical interlocking at the interface;. In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote.

From www.stevenabbott.co.uk

Pressure Sensitive Adhesives Practical Adhesion Science Prof Steven Surface Coating For Adhesion Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. A rough surface provides additional mechanical interlocking at the interface;. Roughness imparts additional surface area with which the adhesive can make. Surface Coating For Adhesion.

From www.researchgate.net

Schematic diagrams of typical antiadhesive coatings. (a) Hydrophilic Surface Coating For Adhesion In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. Understanding how adhesion and the spread of corrosion under the coating are influenced by surface roughness entails. Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. Adhesion of a coating is defined as the resistance of. Surface Coating For Adhesion.

From www.semanticscholar.org

Figure 1 from Silane adhesion mechanism in dental applications and Surface Coating For Adhesion The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote.. Surface Coating For Adhesion.

From www.mdpi.com

Coatings Free FullText Innovative Surface Modification Procedures Surface Coating For Adhesion In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; Adhesion of a coating is defined as the. Surface Coating For Adhesion.

From www.jvsbs.com

Assessment Testing JVS Building Services Surface Coating For Adhesion A rough surface provides additional mechanical interlocking at the interface;. Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. Understanding how adhesion and the spread of corrosion under the coating are influenced by surface roughness entails. Roughness imparts additional surface area with which the adhesive. Surface Coating For Adhesion.

From www.steeldata.info

Adhesion failure Coating defects Surface Coating For Adhesion Understanding how adhesion and the spread of corrosion under the coating are influenced by surface roughness entails. A rough surface provides additional mechanical interlocking at the interface;. Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. Roughness imparts additional surface area with which the adhesive. Surface Coating For Adhesion.

From onlinelibrary.wiley.com

Understanding Surface Adhesion in Nature A Peeling Model Gu 2016 Surface Coating For Adhesion Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. Roughness imparts additional. Surface Coating For Adhesion.

From www.researchgate.net

Underwater adhesion performance of adhesive coatings made of mammalian Surface Coating For Adhesion Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. A rough surface provides additional mechanical interlocking at the interface;. Adhesion of a coating is defined as the resistance of the coating to be removed from. Surface Coating For Adhesion.

From www.raptorblaster.com

Creating an Anchor Pattern For Surface Coatings Surface Coating For Adhesion In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. A rough surface provides additional mechanical interlocking at the interface;. Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. Roughness imparts additional surface area with which the. Surface Coating For Adhesion.

From www.mdpi.com

JFB Free FullText Antibacterial Adhesion Strategy for Dental Surface Coating For Adhesion Understanding how adhesion and the spread of corrosion under the coating are influenced by surface roughness entails. Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. In. Surface Coating For Adhesion.

From www.researchgate.net

Schematic illustration of adhesion measurement for paint film formed on Surface Coating For Adhesion Understanding how adhesion and the spread of corrosion under the coating are influenced by surface roughness entails. Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. Surface modification and. Surface Coating For Adhesion.

From www.mdpi.com

Direct Bonding Method for Completely Cured Polyimide by Surface Surface Coating For Adhesion The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. Understanding how adhesion and the spread of corrosion under. Surface Coating For Adhesion.

From www.frontiersin.org

Frontiers Implication of Surface Properties, Bacterial Motility, and Surface Coating For Adhesion In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. A rough surface provides additional mechanical interlocking at the interface;. Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; Adhesion of a coating is defined as the resistance of the coating to be removed from. Surface Coating For Adhesion.

From www.mdpi.com

IJMS Free FullText Antibacterial Surface Treatment for Orthopaedic Surface Coating For Adhesion A rough surface provides additional mechanical interlocking at the interface;. Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; In summary, from a mechanical adhesion standpoint, liquid coatings with. Surface Coating For Adhesion.

From www.mdpi.com

Coatings Free FullText Water and Ice Adhesion to Solid Surfaces Surface Coating For Adhesion Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. The relationship between surface wetting. Surface Coating For Adhesion.

From pubs.acs.org

Solventborne Polymer Coatings Drying, Film Formation, Stress Evolution Surface Coating For Adhesion Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. In summary, from a mechanical. Surface Coating For Adhesion.

From www.mdpi.com

Coatings Free FullText Acrylic PressureSensitive Adhesive Surface Coating For Adhesion The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. Understanding how adhesion and the spread of corrosion under the coating are influenced by surface roughness entails. Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. A. Surface Coating For Adhesion.

From www.aculon.com

Silver Adhesion Promotion Surface Coating Improve Silver Adhesion Surface Coating For Adhesion Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. A rough surface provides additional mechanical interlocking at the interface;. In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. Adhesion of a coating is defined as the resistance of the coating to be removed from the. Surface Coating For Adhesion.

From www.mdpi.com

IJMS Free FullText Antibacterial Surface Treatment for Orthopaedic Surface Coating For Adhesion In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. A rough surface provides additional mechanical interlocking at the interface;. Adhesion of a coating is defined as the resistance of the coating to be. Surface Coating For Adhesion.

From www.mdpi.com

Coatings Free FullText Environmentally Friendly Plasma Activation Surface Coating For Adhesion The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; Understanding how adhesion and the spread of corrosion. Surface Coating For Adhesion.

From www.mdpi.com

Coatings Free FullText Adhesion in Bitumen/Aggregate System Surface Coating For Adhesion Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. Understanding how adhesion and the spread of corrosion under the coating are influenced by surface roughness entails. A rough surface provides additional mechanical interlocking at the interface;. Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; The relationship. Surface Coating For Adhesion.

From www.caplinq.com

Adhesion Primers & Promoters Surface Treatments CAPLINQ Corporation Surface Coating For Adhesion The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. A rough surface provides additional mechanical interlocking at the interface;. Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. In summary, from a mechanical adhesion standpoint, liquid. Surface Coating For Adhesion.

From www.karnakcorp.com

How to perform an adhesion test on a roof KARNAK Surface Coating For Adhesion Understanding how adhesion and the spread of corrosion under the coating are influenced by surface roughness entails. A rough surface provides additional mechanical interlocking at the interface;. Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote.. Surface Coating For Adhesion.

From www.degruyter.com

Recent advance in surface modification for regulating cell adhesion and Surface Coating For Adhesion Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating.. Surface Coating For Adhesion.

From www.ibibleacademy.org

Eksik konsol konuşma super hydrophobic coating Surface Coating For Adhesion Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. A rough surface provides additional mechanical interlocking at the interface;. Adhesion of a coating is defined as the resistance of the coating to be removed from the. Surface Coating For Adhesion.

From paint-test-equipment.co.uk

Adhesion Tester Pull Off Tester Paint Test Equipment Surface Coating For Adhesion Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. A rough surface provides additional mechanical interlocking at the interface;. Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; Understanding. Surface Coating For Adhesion.

From www.mdpi.com

Coatings Free FullText Development in Additive Methods in Aramid Surface Coating For Adhesion Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. A rough surface provides additional mechanical interlocking at the interface;. The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. Understanding how adhesion and the spread of corrosion. Surface Coating For Adhesion.

From www.iqsdirectory.com

Adhesive Tape What Is It? How Is It Made? Uses, Application Surface Coating For Adhesion A rough surface provides additional mechanical interlocking at the interface;. Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. Understanding how adhesion and the spread of corrosion under the coating are influenced by surface roughness entails. Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; In summary,. Surface Coating For Adhesion.

From www.beilstein-journals.org

Fullerenes as adhesive layers for mechanical peeling of metallic Surface Coating For Adhesion The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; A rough surface provides additional mechanical interlocking at the interface;. Understanding. Surface Coating For Adhesion.

From www.mdpi.com

IJMS Free FullText Antibacterial Surface Treatment for Orthopaedic Surface Coating For Adhesion Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. A rough surface provides additional mechanical interlocking at the interface;. Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; The. Surface Coating For Adhesion.

From www.defelsko.com

Finish Coatings System Adhesion and Test Methods Resources DeFelsko Surface Coating For Adhesion The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. Adhesion of a coating is defined as the resistance of the coating to be removed from the substrate the single most important requirement for. A rough surface provides additional mechanical interlocking at the interface;. Roughness imparts additional surface area with which the. Surface Coating For Adhesion.

From www.mdpi.com

Coatings Free FullText Comparative Study of Resin and Silane Surface Coating For Adhesion The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. A rough surface provides additional mechanical interlocking at the interface;. In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. Adhesion of a coating is defined as the resistance of the coating to be. Surface Coating For Adhesion.

From eureka.patsnap.com

Steel plate surface coating adhesion testing device Eureka Patsnap Surface Coating For Adhesion Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. Roughness imparts additional surface area with which the adhesive can make contact when forming a bond; The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. A rough surface provides additional mechanical interlocking at the interface;. In. Surface Coating For Adhesion.

From aurorascicorp.com

PVD Coating System Buying Guide Aurora Scientific Corp Surface Coating For Adhesion In summary, from a mechanical adhesion standpoint, liquid coatings with low surface tension and low viscosity help promote. Understanding how adhesion and the spread of corrosion under the coating are influenced by surface roughness entails. A rough surface provides additional mechanical interlocking at the interface;. Roughness imparts additional surface area with which the adhesive can make contact when forming a. Surface Coating For Adhesion.

From www.slideshare.net

Perfecting PFOAfree PTFE Coating Adhesion on Stainless Guidewires Surface Coating For Adhesion Understanding how adhesion and the spread of corrosion under the coating are influenced by surface roughness entails. Surface modification and coatings are utilized for purposes of adhesion, wettability, biocompatibility, scratch and abrasion. The relationship between surface wetting and adhesion is the first factor to be considered in designing a coating. A rough surface provides additional mechanical interlocking at the interface;.. Surface Coating For Adhesion.