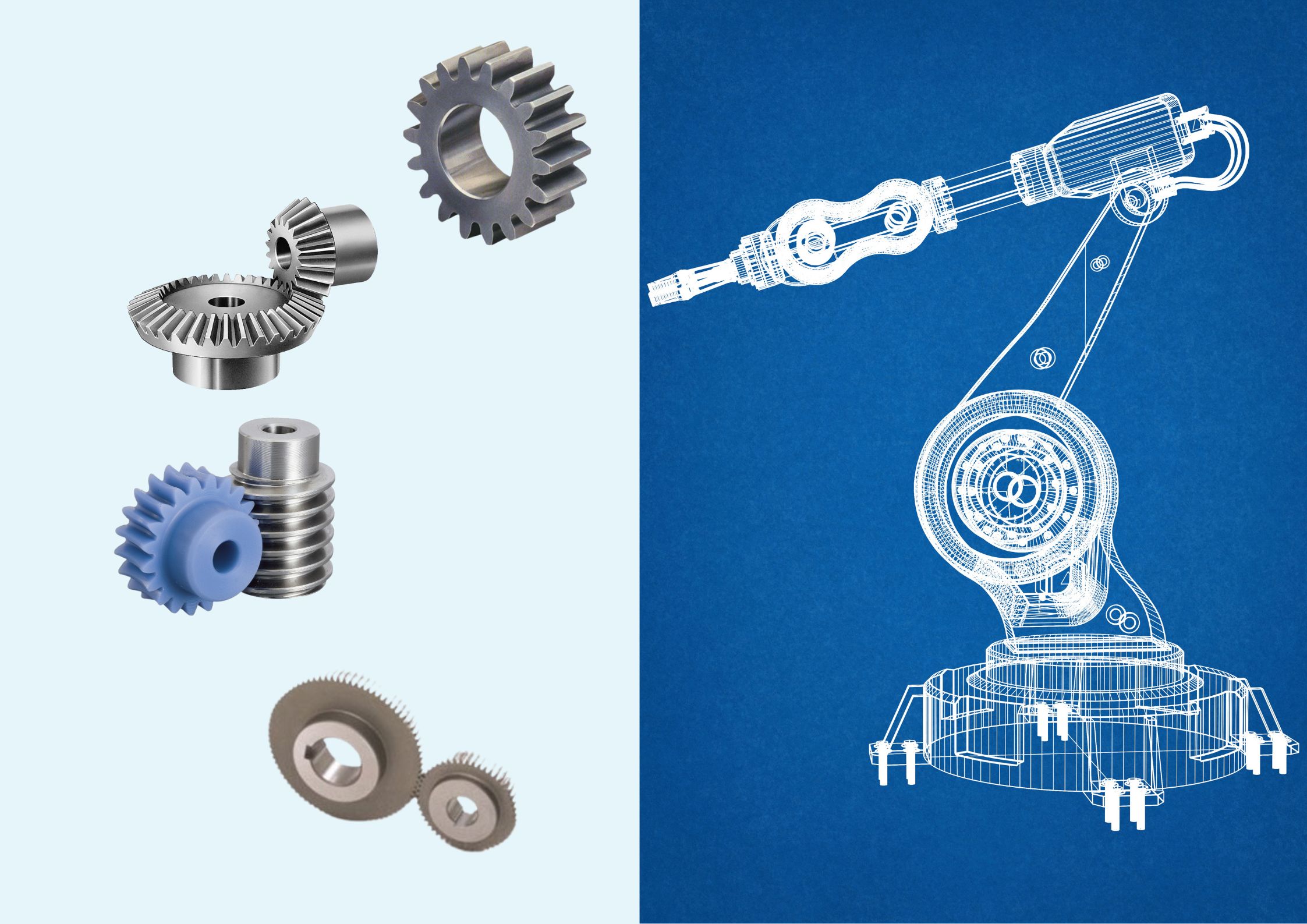

Bevel Gear With Example . And spiral bevel gears, which have curved teeth and provide. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears.

from ar.inspiredpencil.com

In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. And spiral bevel gears, which have curved teeth and provide.

Bevel Gear Examples

Bevel Gear With Example Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. And spiral bevel gears, which have curved teeth and provide. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts.

From www.tec-science.com

Bevel gears tecscience Bevel Gear With Example Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. And spiral bevel gears, which have curved teeth and provide. Bevel gears, characterized by their conical shape and teeth along the. Bevel Gear With Example.

From www.mrosupply.com

Bevel Gears A Deeper Look at Their Applications Bevel Gear With Example Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the. Bevel Gear With Example.

From www.bostongear.com

Bevel Gear Bevel Gear With Example Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. And spiral bevel gears, which have curved teeth and provide.. Bevel Gear With Example.

From www.mechanicalbooster.com

Types of Gears Complete Explanation Mechanical Booster Bevel Gear With Example Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between. Bevel Gear With Example.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear With Example And spiral bevel gears, which have curved teeth and provide. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. Unlike cylindrical gears, they offer diverse configurations, including. Bevel Gear With Example.

From www.mechanicalbooster.com

Types of Gears Spur Gear, Helical Gear, Bevel Gear etc. Mechanical Bevel Gear With Example Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. And spiral bevel gears, which have curved teeth and provide. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel. Bevel Gear With Example.

From www.researchgate.net

The dynamic model of a spiral bevel gear system with rotational degrees Bevel Gear With Example Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. And spiral bevel gears, which have curved teeth and provide. Bevel gears are used with bevel pinions. Bevel Gear With Example.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear With Example In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. And spiral bevel gears, which have curved teeth and. Bevel Gear With Example.

From www.linquip.com

4 Main Types of Bevel Gears Linquip Bevel Gear With Example Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between. Bevel Gear With Example.

From www.linngear.com

Bevel Gears Linn Gear Manufactures Bevel Gear With Example Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. And spiral bevel gears, which have curved teeth and provide. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears are used with bevel pinions. Bevel Gear With Example.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear With Example Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between. Bevel Gear With Example.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Bevel Gear With Example Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. And spiral bevel gears, which have curved teeth and. Bevel Gear With Example.

From www.iqsdirectory.com

Speed Reducers Types, Efficiency, Maintenance, and Gear Ratio Bevel Gear With Example Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. Unlike cylindrical gears, they offer diverse. Bevel Gear With Example.

From cadbull.com

Bevel Gear 36T and Bevel Pinion gear Section detailed drawings are Bevel Gear With Example And spiral bevel gears, which have curved teeth and provide. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel. Bevel Gear With Example.

From marinerspointpro.com

Types of Bevel Gears and Their Functions Marinerspointpro Bevel Gear With Example Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. And spiral bevel gears, which have curved teeth and provide.. Bevel Gear With Example.

From www.americangearinc.com

Gallery of Our Straight Bevel Gears American Gear, Inc. Bevel Gear With Example Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. And spiral bevel gears, which have curved teeth and. Bevel Gear With Example.

From marinerspointpro.com

Types of Bevel Gears and Their Functions Marinerspointpro Bevel Gear With Example Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. Bevel gears are used with bevel pinions to create. Bevel Gear With Example.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear With Example Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. Bevel gears, characterized by their conical shape and teeth along. Bevel Gear With Example.

From www.alamy.com

Sample of bevel gear set. Bevel gears are gears where the axes of the Bevel Gear With Example And spiral bevel gears, which have curved teeth and provide. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular.. Bevel Gear With Example.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Bevel Gear With Example In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears are used with bevel pinions to create. Bevel Gear With Example.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Bevel Gear With Example And spiral bevel gears, which have curved teeth and provide. Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. In contrast to cylindrical gears, where the rotary. Bevel Gear With Example.

From www.engineeringcommons.org

Engineering Commons LLC Making Bevel Gears Bevel Gear With Example Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. And spiral bevel gears, which have curved teeth and provide.. Bevel Gear With Example.

From www.slideserve.com

PPT Bevel Gear Exercise PowerPoint Presentation, free download ID Bevel Gear With Example Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. And spiral bevel gears, which have curved teeth and provide. Bevel gears, characterized by their conical shape and teeth along the. Bevel Gear With Example.

From thors.com

Gears Bevel and Hypoid Gear Terminology Course Bevel Gear With Example Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. And spiral bevel gears, which have curved teeth and provide. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. In contrast to cylindrical gears, where the rotary axes are always. Bevel Gear With Example.

From www.tec-science.com

Bevel gears tecscience Bevel Gear With Example Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. And spiral bevel gears, which have curved teeth and provide. Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. Unlike cylindrical gears, they offer diverse configurations, including. Bevel Gear With Example.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Bevel Gear With Example And spiral bevel gears, which have curved teeth and provide. Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears, characterized by their conical shape and teeth along the. Bevel Gear With Example.

From www.slideshare.net

Bevel gears Bevel Gear With Example Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. And spiral bevel gears, which have. Bevel Gear With Example.

From www.tec-science.com

How does a differential gear work? tecscience Bevel Gear With Example Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts. Bevel Gear With Example.

From www.pinterest.com.au

Different types of Gears. Gears, Spiral bevel gear, Bevel gear Bevel Gear With Example Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. And spiral bevel gears, which have curved teeth and provide. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel. Bevel Gear With Example.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Bevel Gear With Example And spiral bevel gears, which have curved teeth and provide. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. In contrast to cylindrical gears, where the. Bevel Gear With Example.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear With Example Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. Bevel gears, characterized by their conical shape and teeth along the conical surface, serve the purpose of transmitting rotational motion between intersecting shafts. Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily. Bevel Gear With Example.

From ar.inspiredpencil.com

Bevel Gear Examples Bevel Gear With Example In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. Bevel gears, characterized by their conical shape and teeth along. Bevel Gear With Example.

From www.engineersgallery.com

Understand Mechanical Gear Bevel Gear Engineers Gallery Bevel Gear With Example Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel gears. Bevel gears, characterized by their conical shape and teeth along. Bevel Gear With Example.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Bevel Gear With Example And spiral bevel gears, which have curved teeth and provide. Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. In contrast to cylindrical gears, where the rotary axes are always arranged parallel to each other, the axes of gear shafts can be rotated by any angle by using bevel. Bevel Gear With Example.

From blogs.sw.siemens.com

Simulate Bevel Gears Accurately and Efficiently Simcenter Bevel Gear With Example Unlike cylindrical gears, they offer diverse configurations, including straight, spiral, or hypoid teeth, each influencing the gear’s performance and characteristics. And spiral bevel gears, which have curved teeth and provide. Bevel gears are used with bevel pinions to create mechanical systems that change speed and torque primarily in perpendicular. Bevel gears, characterized by their conical shape and teeth along the. Bevel Gear With Example.