Energy Consumption In Paper Making Process . Secpr ¼ eprocess p ð2þ where, secpr is the specific primary energy consumption of a process unit; while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. life cycle energy consumption for paper industry. The energy consumed by paper production refers to the input of all. the paper industry is heavily using energy during all the phases of the manufacturing process. In mills that use chemical pulping, roughly half of the higher heating value of. in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost.

from www.intechopen.com

while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. Secpr ¼ eprocess p ð2þ where, secpr is the specific primary energy consumption of a process unit; in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. The energy consumed by paper production refers to the input of all. life cycle energy consumption for paper industry. In mills that use chemical pulping, roughly half of the higher heating value of. the paper industry is heavily using energy during all the phases of the manufacturing process.

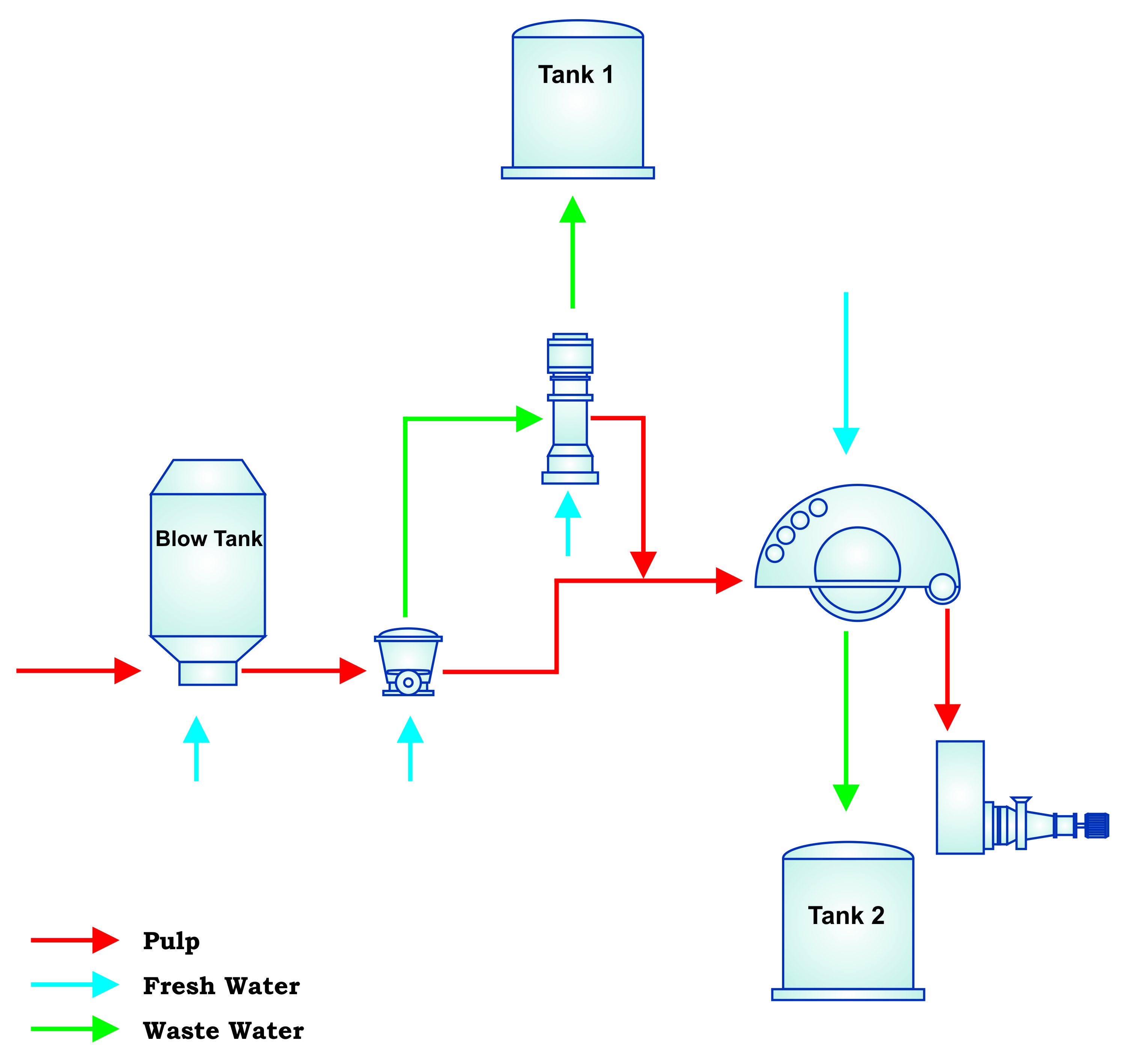

Retrofit Approach for the Reduction of Water and Energy Consumption in Pulp and Paper Production

Energy Consumption In Paper Making Process In mills that use chemical pulping, roughly half of the higher heating value of. in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. life cycle energy consumption for paper industry. Secpr ¼ eprocess p ð2þ where, secpr is the specific primary energy consumption of a process unit; In mills that use chemical pulping, roughly half of the higher heating value of. The energy consumed by paper production refers to the input of all. in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. the paper industry is heavily using energy during all the phases of the manufacturing process.

From www.holmen.com

How paper is made in a TMP process Energy Consumption In Paper Making Process the paper industry is heavily using energy during all the phases of the manufacturing process. in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. The energy consumed by paper production refers to the input of all. In mills that use chemical pulping, roughly half of the higher. Energy Consumption In Paper Making Process.

From goenergylink.com

Top 4 Energy Consumers in the Paper Manufacturing Industry EnergyLink Energy Consumption In Paper Making Process The energy consumed by paper production refers to the input of all. while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. the paper industry is heavily using energy during all the phases of the manufacturing process. life cycle energy consumption. Energy Consumption In Paper Making Process.

From templates.peakboard.com

Overview of energy consumption simple energy management system according to ISO 50001 Energy Consumption In Paper Making Process in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. Secpr ¼ eprocess p ð2þ where, secpr is the specific primary energy consumption of a process unit; life cycle energy consumption for paper industry. In mills that use chemical pulping, roughly half of the higher heating value of.. Energy Consumption In Paper Making Process.

From www.alamy.com

Infographics of the process of making paper from wood and production data and world paper Energy Consumption In Paper Making Process in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. the paper industry is heavily using energy during all the phases of the manufacturing process. Secpr ¼ eprocess p ð2þ where, secpr is the specific primary energy consumption of a process unit; In mills that use chemical pulping, roughly. Energy Consumption In Paper Making Process.

From paperexcellence.com

Reusable Energy for Our Energy Management Paper Excellence Energy Consumption In Paper Making Process while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. Secpr ¼ eprocess p ð2þ where, secpr is the specific primary energy consumption of a process unit; in paper making, the pulp making process is responsible for 62% of energy use, 45%. Energy Consumption In Paper Making Process.

From paper-pulp-wconsult.com

WCONSULT Professional Energy Consumption In Paper Making Process In mills that use chemical pulping, roughly half of the higher heating value of. life cycle energy consumption for paper industry. while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. Secpr ¼ eprocess p ð2þ where, secpr is the specific primary. Energy Consumption In Paper Making Process.

From www.researchgate.net

Distribution of electricity consumption in SCpaper production Download Scientific Diagram Energy Consumption In Paper Making Process life cycle energy consumption for paper industry. while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. In mills that use chemical pulping, roughly half of the higher heating value of. The energy consumed by paper production refers to the input of. Energy Consumption In Paper Making Process.

From www.designcomponents.com

papermaking process infographic Design Components Energy Consumption In Paper Making Process while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. The energy consumed by paper production refers to the input of all. In mills that use chemical pulping, roughly half of the higher heating value of. Secpr ¼ eprocess p ð2þ where, secpr. Energy Consumption In Paper Making Process.

From www.alfredmank.com

A Closer Look at the Paper Production Process MANK Energy Consumption In Paper Making Process the paper industry is heavily using energy during all the phases of the manufacturing process. while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries,. Energy Consumption In Paper Making Process.

From www.craiyon.com

Illustration of energy consumption in a paper machine on Craiyon Energy Consumption In Paper Making Process life cycle energy consumption for paper industry. in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. Secpr ¼ eprocess p. Energy Consumption In Paper Making Process.

From www.slideserve.com

PPT Pulp and Paper Processes for Sustainable Production PowerPoint Presentation ID234520 Energy Consumption In Paper Making Process in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy. Energy Consumption In Paper Making Process.

From www.social.cummins.com

Cogeneration examples across industries Cummins Inc. Energy Consumption In Paper Making Process in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. The energy consumed by paper production refers to the input of all. life cycle energy consumption for paper industry. while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use. Energy Consumption In Paper Making Process.

From www.e-education.psu.edu

Energy Production and Consumption in the United States EBF 301 Global Finance for the Earth Energy Consumption In Paper Making Process in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. Secpr ¼ eprocess p ð2þ where, secpr is the specific primary energy consumption of a process unit; in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. life. Energy Consumption In Paper Making Process.

From halifaxcc.edu

PAPER MAKING PROCESS Energy Consumption In Paper Making Process life cycle energy consumption for paper industry. in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. the paper industry. Energy Consumption In Paper Making Process.

From www.mdpi.com

Processes Free FullText Modeling and Simulation of Energy Systems A Review Energy Consumption In Paper Making Process while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. the paper industry is heavily using energy during all the phases of the manufacturing process. In mills that use chemical pulping, roughly half of the higher heating value of. Secpr ¼ eprocess. Energy Consumption In Paper Making Process.

From www.packaging4europe.com

Resource Conservation Overview Packaging4Europe Energy Consumption In Paper Making Process In mills that use chemical pulping, roughly half of the higher heating value of. Secpr ¼ eprocess p ð2þ where, secpr is the specific primary energy consumption of a process unit; The energy consumed by paper production refers to the input of all. in paper making, the pulp making process is responsible for 62% of energy use, 45% of. Energy Consumption In Paper Making Process.

From www.youtube.com

The Paper Making Process 1 (English) YouTube Energy Consumption In Paper Making Process in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. Secpr ¼ eprocess p ð2þ where, secpr is the specific primary energy consumption of a process unit; In mills that use chemical pulping, roughly half of the higher heating value of. the paper industry is heavily using energy. Energy Consumption In Paper Making Process.

From wwf.panda.org

Industry key to conserving forests as demand for wood projected to triple by 2050 WWF Energy Consumption In Paper Making Process in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy. Energy Consumption In Paper Making Process.

From www.slideshare.net

Paper Consumption Presentation Energy Consumption In Paper Making Process The energy consumed by paper production refers to the input of all. Secpr ¼ eprocess p ð2þ where, secpr is the specific primary energy consumption of a process unit; in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. the paper industry is heavily using energy during all the. Energy Consumption In Paper Making Process.

From www.researchgate.net

Energy consumption in semiconductor manufacturing process tools. Download Scientific Diagram Energy Consumption In Paper Making Process Secpr ¼ eprocess p ð2þ where, secpr is the specific primary energy consumption of a process unit; while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. life cycle energy consumption for paper industry. The energy consumed by paper production refers to. Energy Consumption In Paper Making Process.

From www.intechopen.com

Retrofit Approach for the Reduction of Water and Energy Consumption in Pulp and Paper Production Energy Consumption In Paper Making Process In mills that use chemical pulping, roughly half of the higher heating value of. in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. the paper industry is heavily using energy during all the phases of the manufacturing process. Secpr ¼ eprocess p ð2þ where, secpr is the specific. Energy Consumption In Paper Making Process.

From exohuqsax.blob.core.windows.net

Electrical Energy Requirements For Manufacturing Processes at Samatha Kuss blog Energy Consumption In Paper Making Process in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. Secpr ¼ eprocess p ð2þ where, secpr is the specific primary energy consumption of a process unit; In mills that use chemical pulping, roughly half of the higher heating value of. life cycle energy consumption for paper industry. . Energy Consumption In Paper Making Process.

From reurasia.com

Waste To Energy How This Processes Really Work? Energy Consumption In Paper Making Process In mills that use chemical pulping, roughly half of the higher heating value of. in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. Secpr ¼ eprocess p ð2þ. Energy Consumption In Paper Making Process.

From www.scribd.com

Austin Reducing Energy Consumption in Paper Making Using APC and Optimisation PDF PDF Energy Consumption In Paper Making Process in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. In mills that use chemical pulping, roughly half of the higher heating value of. The energy consumed by paper production refers to the input of all. life cycle energy consumption for paper industry. while global paper and. Energy Consumption In Paper Making Process.

From www.efficientpowertech.com

Energy Management Process Efficient Power Tech Energy Consumption In Paper Making Process The energy consumed by paper production refers to the input of all. life cycle energy consumption for paper industry. in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for. Energy Consumption In Paper Making Process.

From www.slideserve.com

PPT Paper Consumption PowerPoint Presentation, free download ID6125190 Energy Consumption In Paper Making Process In mills that use chemical pulping, roughly half of the higher heating value of. while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for. Energy Consumption In Paper Making Process.

From www.optiwee.com

Electricity consumption of paper production by recycling or trees Ideas for a green and Energy Consumption In Paper Making Process The energy consumed by paper production refers to the input of all. the paper industry is heavily using energy during all the phases of the manufacturing process. while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. in paper making, the. Energy Consumption In Paper Making Process.

From oee.nrcan.gc.ca

Energy Use in Canada Trends Publications Natural Resources Canada Energy Consumption In Paper Making Process while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. life cycle energy consumption for paper industry. in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. The energy consumed by. Energy Consumption In Paper Making Process.

From www.researchgate.net

Energy and material flows in the pulp and paper production process. Download Scientific Diagram Energy Consumption In Paper Making Process in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. life cycle energy consumption for paper industry. The energy consumed by paper production refers to the input of all. in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for. Energy Consumption In Paper Making Process.

From www.energy.gov

Bandwidth Study U.S. Pulp and Paper Manufacturing Department of Energy Energy Consumption In Paper Making Process Secpr ¼ eprocess p ð2þ where, secpr is the specific primary energy consumption of a process unit; while global paper and paperboard output increased by over 25% between 2000 and 2017, the sector’s global energy use rose by less than 5%, indicating a. in particular, the pulp and paper industry ranks fourth in terms of energy consumption among. Energy Consumption In Paper Making Process.

From blog.scienceandentertainmentexchange.org

Energy Efficiency, Industrial Efficiency — The National Academies Energy Consumption In Paper Making Process in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. life cycle energy consumption for paper industry. Secpr ¼ eprocess p ð2þ where, secpr is the specific primary. Energy Consumption In Paper Making Process.

From paperexcellence.com

Energy Management Reusable Energy Paper Excellence Energy Consumption In Paper Making Process in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. life cycle energy consumption for paper industry. In mills that use chemical pulping, roughly half of the higher heating value of. the paper industry is heavily using energy during all the phases of the manufacturing process. while. Energy Consumption In Paper Making Process.

From www.slideserve.com

PPT Pulp and Paper Processes for Sustainable Production PowerPoint Presentation ID234520 Energy Consumption In Paper Making Process the paper industry is heavily using energy during all the phases of the manufacturing process. in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. The energy consumed by paper production refers to the input of all. while global paper and paperboard output increased by over 25% between. Energy Consumption In Paper Making Process.

From www.slideshare.net

All about paper making process Energy Consumption In Paper Making Process in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. Secpr ¼ eprocess p ð2þ where, secpr is the specific primary energy consumption of a process unit; the. Energy Consumption In Paper Making Process.

From www.intechopen.com

Retrofit Approach for the Reduction of Water and Energy Consumption in Pulp and Paper Production Energy Consumption In Paper Making Process life cycle energy consumption for paper industry. in particular, the pulp and paper industry ranks fourth in terms of energy consumption among industries, accounting for almost. in paper making, the pulp making process is responsible for 62% of energy use, 45% of ghg emissions, 48% of. while global paper and paperboard output increased by over 25%. Energy Consumption In Paper Making Process.