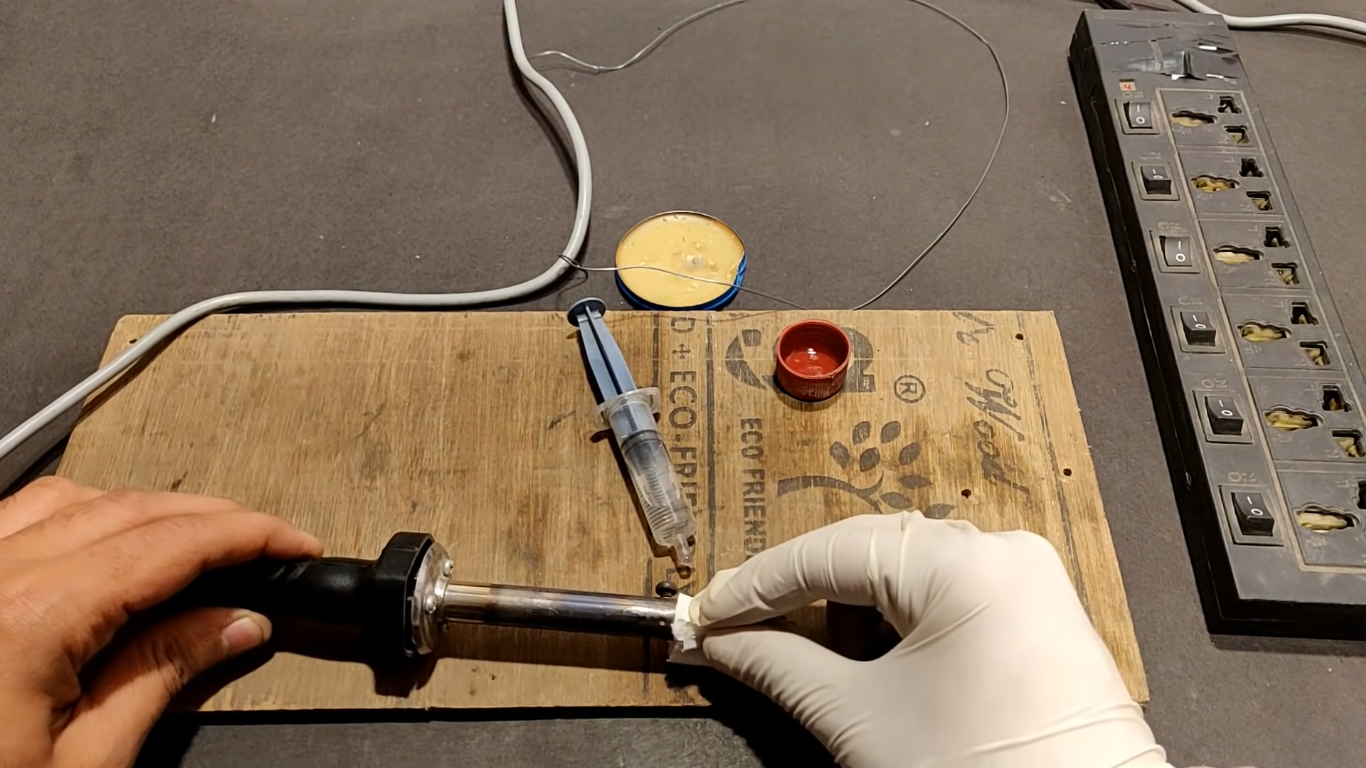

Solder Joint Not Sticking . This should allow some of the heat to. to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was connected to a check). They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an inefficient electrical connection and a weak mechanical bond. solder one joint, then move to a joint further away, then back to a joint near the first, etc. For example you will never get solder to stick to aluminum. When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. solder will not stick to just any metal. The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to melt the solder and get it to flow onto the joint.

from electronicshacks.com

They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an inefficient electrical connection and a weak mechanical bond. solder will not stick to just any metal. The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to melt the solder and get it to flow onto the joint. to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was connected to a check). This should allow some of the heat to. When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. For example you will never get solder to stick to aluminum. solder one joint, then move to a joint further away, then back to a joint near the first, etc.

Solder Not Sticking How to Fix That? ElectronicsHacks

Solder Joint Not Sticking The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to melt the solder and get it to flow onto the joint. The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to melt the solder and get it to flow onto the joint. For example you will never get solder to stick to aluminum. to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was connected to a check). They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an inefficient electrical connection and a weak mechanical bond. solder will not stick to just any metal. When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. This should allow some of the heat to. solder one joint, then move to a joint further away, then back to a joint near the first, etc.

From electronicshacks.com

Solder Not Sticking How to Fix That? ElectronicsHacks Solder Joint Not Sticking The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to melt the solder and get it to flow onto the joint. They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an inefficient electrical connection and a weak mechanical bond. This should allow. Solder Joint Not Sticking.

From electronicshacks.com

Solder Not Sticking How to Fix That? ElectronicsHacks Solder Joint Not Sticking solder one joint, then move to a joint further away, then back to a joint near the first, etc. When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to. Solder Joint Not Sticking.

From electronicshacks.com

Solder Not Sticking How to Fix That? ElectronicsHacks Solder Joint Not Sticking For example you will never get solder to stick to aluminum. When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to melt the solder and get it to flow onto. Solder Joint Not Sticking.

From www.circuitbasics.com

Tips for Good Soldering Technique Circuit Basics Solder Joint Not Sticking For example you will never get solder to stick to aluminum. solder one joint, then move to a joint further away, then back to a joint near the first, etc. to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was. Solder Joint Not Sticking.

From qtech-us.com

How does soldering iron act on PCB Qtech Technology Co. Ltd Solder Joint Not Sticking to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was connected to a check). When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. solder one joint, then move to. Solder Joint Not Sticking.

From www.reddit.com

why is solder not sticking to the iron? r/soldering Solder Joint Not Sticking The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to melt the solder and get it to flow onto the joint. This should allow some of the heat to. They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an inefficient electrical connection. Solder Joint Not Sticking.

From www.reddit.com

PLL solder not sticking to point r/360hacks Solder Joint Not Sticking They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an inefficient electrical connection and a weak mechanical bond. solder one joint, then move to a joint further away, then back to a joint near the first, etc. The oxidized layer on the tip can create a barrier between the tip and. Solder Joint Not Sticking.

From www.youtube.com

How to remove damaged or stripped screw (solder method) FIX of solder Solder Joint Not Sticking For example you will never get solder to stick to aluminum. This should allow some of the heat to. When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to melt. Solder Joint Not Sticking.

From www.reddit.com

why is solder not sticking to the iron? r/soldering Solder Joint Not Sticking When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. solder one joint, then move to a joint further away, then back to a joint near the first, etc. The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to. Solder Joint Not Sticking.

From pcbtoolexpert.com

Top 6 Reasons Why Your Solder Won't Stick PCB Tool Expert Solder Joint Not Sticking This should allow some of the heat to. For example you will never get solder to stick to aluminum. solder will not stick to just any metal. They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an inefficient electrical connection and a weak mechanical bond. The oxidized layer on the tip. Solder Joint Not Sticking.

From dxoavcpqb.blob.core.windows.net

Solder Not Sticking To Pad at Marie Alderman blog Solder Joint Not Sticking When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. For example you will never get solder to stick to aluminum. to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was. Solder Joint Not Sticking.

From www.youtube.com

Repair Soldering Iron Solder NOT sticking to the Tip , how to Clean Solder Joint Not Sticking They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an inefficient electrical connection and a weak mechanical bond. to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was connected to a check). . Solder Joint Not Sticking.

From electronicshacks.com

Solder Not Sticking How to Fix That? ElectronicsHacks Solder Joint Not Sticking When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. This should allow some of the heat to. to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was connected to a. Solder Joint Not Sticking.

From dxoiycdjd.blob.core.windows.net

Solder Good Connection at Myron Shibata blog Solder Joint Not Sticking to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was connected to a check). This should allow some of the heat to. The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder. Solder Joint Not Sticking.

From www.instructables.com

How to CORRECTLY Solder a Copper Pipe 6 Steps (with Pictures) Solder Joint Not Sticking They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an inefficient electrical connection and a weak mechanical bond. When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. For example you will never get solder to stick to aluminum. The oxidized layer. Solder Joint Not Sticking.

From electronicshacks.com

Solder Not Sticking How to Fix That? ElectronicsHacks Solder Joint Not Sticking When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. This should allow some of the heat to. They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an inefficient electrical connection and a weak mechanical bond. to repair this, you will. Solder Joint Not Sticking.

From www.youtube.com

How to repair a soldering iron Solder NOT sticking to the Tip YouTube Solder Joint Not Sticking solder will not stick to just any metal. When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was connected to. Solder Joint Not Sticking.

From www.youtube.com

Solder Iron Fix, Not sticking solder, Not melting solder, Heating But Solder Joint Not Sticking When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an inefficient electrical connection and a weak mechanical bond. solder will not stick to just any metal. solder one joint, then. Solder Joint Not Sticking.

From www.rlctalk.com

Solder Not Sticking To Copper; Why And How To Fix It? Solder Joint Not Sticking They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an inefficient electrical connection and a weak mechanical bond. This should allow some of the heat to. solder will not stick to just any metal. solder one joint, then move to a joint further away, then back to a joint near. Solder Joint Not Sticking.

From www.instructables.com

How to Make a Proper Western Union Solder Joint 4 Steps (with Solder Joint Not Sticking solder will not stick to just any metal. For example you will never get solder to stick to aluminum. This should allow some of the heat to. solder one joint, then move to a joint further away, then back to a joint near the first, etc. When the solder does melt, it may not “wet” the joint properly,. Solder Joint Not Sticking.

From www.reddit.com

Why is the solder not sticking properly to the highlighted part? I've Solder Joint Not Sticking For example you will never get solder to stick to aluminum. When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. This should allow some of the heat to. solder one joint, then move to a joint further away, then back to a joint near the first, etc. . Solder Joint Not Sticking.

From www.youtube.com

Solder NOT sticking to the Tip of soldering iron How to clean and re Solder Joint Not Sticking This should allow some of the heat to. solder one joint, then move to a joint further away, then back to a joint near the first, etc. solder will not stick to just any metal. For example you will never get solder to stick to aluminum. When the solder does melt, it may not “wet” the joint properly,. Solder Joint Not Sticking.

From electronicshacks.com

Solder Not Sticking How to Fix That? ElectronicsHacks Solder Joint Not Sticking The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to melt the solder and get it to flow onto the joint. solder will not stick to just any metal. solder one joint, then move to a joint further away, then back to a joint near the first, etc.. Solder Joint Not Sticking.

From dxokkmdhl.blob.core.windows.net

How To Get A Good Solder Joint at Brent Miller blog Solder Joint Not Sticking to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was connected to a check). solder one joint, then move to a joint further away, then back to a joint near the first, etc. For example you will never get solder. Solder Joint Not Sticking.

From dxoavcpqb.blob.core.windows.net

Solder Not Sticking To Pad at Marie Alderman blog Solder Joint Not Sticking solder will not stick to just any metal. When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was connected to. Solder Joint Not Sticking.

From www.youtube.com

Repair Soldering Iron Solder not sticking to tip How to clean Solder Joint Not Sticking solder will not stick to just any metal. When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. For example you will never get solder to stick to aluminum. The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to. Solder Joint Not Sticking.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Solder Joint Not Sticking They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an inefficient electrical connection and a weak mechanical bond. For example you will never get solder to stick to aluminum. to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg. Solder Joint Not Sticking.

From schematiclibpinite101.z21.web.core.windows.net

How To Solder Wiring Solder Joint Not Sticking They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an inefficient electrical connection and a weak mechanical bond. to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was connected to a check). . Solder Joint Not Sticking.

From www.reddit.com

Help with solder not sticking r/soldering Solder Joint Not Sticking to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was connected to a check). This should allow some of the heat to. When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting. Solder Joint Not Sticking.

From electronicshacks.com

Solder Not Sticking How to Fix That? ElectronicsHacks Solder Joint Not Sticking solder one joint, then move to a joint further away, then back to a joint near the first, etc. This should allow some of the heat to. For example you will never get solder to stick to aluminum. The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to melt. Solder Joint Not Sticking.

From www.youtube.com

Cold, Fractured, Broken Solder Joints Spotting and Fixing Them YouTube Solder Joint Not Sticking to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was connected to a check). For example you will never get solder to stick to aluminum. When the solder does melt, it may not “wet” the joint properly, meaning it won’t make. Solder Joint Not Sticking.

From www.rlctalk.com

Solder Not Sticking To Copper; Why And How To Fix It? Solder Joint Not Sticking solder one joint, then move to a joint further away, then back to a joint near the first, etc. to repair this, you will have to solder directly to the trace that connected to the ext pad, or to the leg of the chip (if it was connected to a check). solder will not stick to just. Solder Joint Not Sticking.

From www.rlctalk.com

Solder Not Sticking To Copper; Why And How To Fix It? Solder Joint Not Sticking When the solder does melt, it may not “wet” the joint properly, meaning it won’t make a strong, lasting connection. The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to melt the solder and get it to flow onto the joint. They are caused by insufficient heat during the soldering. Solder Joint Not Sticking.

From www.youtube.com

Solder not sticking on Soldering iron Soldering Iron Repair Aay Solder Joint Not Sticking For example you will never get solder to stick to aluminum. The oxidized layer on the tip can create a barrier between the tip and the solder, making it harder to melt the solder and get it to flow onto the joint. They are caused by insufficient heat during the soldering process, causing the solder to melt partially, creating an. Solder Joint Not Sticking.

From www.youtube.com

How to Solder Properly 5 Soldering Joint Splices YouTube Solder Joint Not Sticking solder one joint, then move to a joint further away, then back to a joint near the first, etc. solder will not stick to just any metal. For example you will never get solder to stick to aluminum. This should allow some of the heat to. When the solder does melt, it may not “wet” the joint properly,. Solder Joint Not Sticking.