Rebar Defects . Fixing rebar the right way. Corrosion of reinforcements is frequent due to chemical attacks, fire, and accidental cutting. Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. Here are a few examples of rebar in need of repair, and how to properly correct the problem. As you can clearly see in this picture, the rebar that was originally placed inside of this concrete structure has become exposed. Errors during reinforcement installation could lead to serious concrete deterioration. This can happen for many reasons, but what is going on here is called “spalling.” For instance, inadequate chair bars and insufficient tying of reinforcement would cause. It identifies key factors such as chloride ion penetration and concrete carbonization that primarily influence rebar. Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging within concrete. After the cause of steel damage is determined, it can be repaired by either replacing deteriorated bars or supplementing partially deteriorated bars. Identifying defects or inconsistencies in rebar can be difficult during fabrication.

from www.semanticscholar.org

Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging within concrete. It identifies key factors such as chloride ion penetration and concrete carbonization that primarily influence rebar. For instance, inadequate chair bars and insufficient tying of reinforcement would cause. Errors during reinforcement installation could lead to serious concrete deterioration. Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. Here are a few examples of rebar in need of repair, and how to properly correct the problem. This can happen for many reasons, but what is going on here is called “spalling.” Corrosion of reinforcements is frequent due to chemical attacks, fire, and accidental cutting. As you can clearly see in this picture, the rebar that was originally placed inside of this concrete structure has become exposed. Identifying defects or inconsistencies in rebar can be difficult during fabrication.

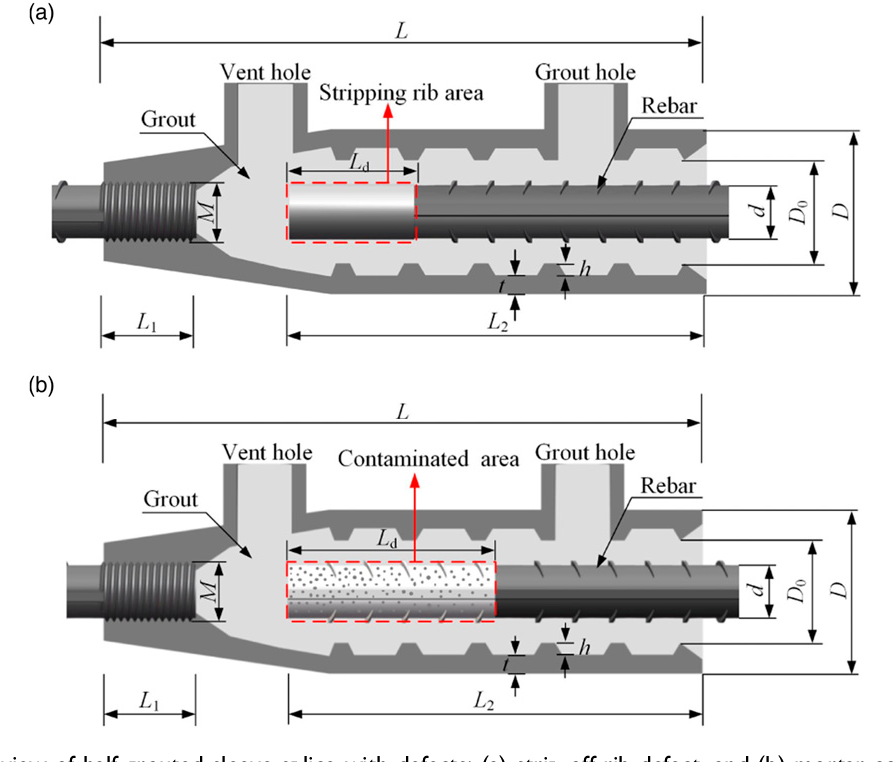

Figure 1 from Mechanical properties of cast halfgrouted sleeve splice

Rebar Defects This can happen for many reasons, but what is going on here is called “spalling.” Errors during reinforcement installation could lead to serious concrete deterioration. As you can clearly see in this picture, the rebar that was originally placed inside of this concrete structure has become exposed. Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging within concrete. After the cause of steel damage is determined, it can be repaired by either replacing deteriorated bars or supplementing partially deteriorated bars. This can happen for many reasons, but what is going on here is called “spalling.” For instance, inadequate chair bars and insufficient tying of reinforcement would cause. Identifying defects or inconsistencies in rebar can be difficult during fabrication. It identifies key factors such as chloride ion penetration and concrete carbonization that primarily influence rebar. Corrosion of reinforcements is frequent due to chemical attacks, fire, and accidental cutting. Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. Here are a few examples of rebar in need of repair, and how to properly correct the problem. Fixing rebar the right way.

From www.researchgate.net

Inversion results for simple tunnel lining defects. (a) depicts a Rebar Defects Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging within concrete. Errors during reinforcement installation could lead to serious concrete deterioration. As you can clearly see in this picture, the rebar that was originally placed inside of this concrete structure has become exposed. For instance, inadequate chair bars and insufficient tying of reinforcement. Rebar Defects.

From paddyengineering.blogspot.com

Causes For Defects In Concrete Structures Rebar Defects For instance, inadequate chair bars and insufficient tying of reinforcement would cause. Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging within concrete. Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. As you can clearly see in this picture, the rebar that was originally placed inside. Rebar Defects.

From technoweld.com.au

The Most Common Welding Defects Causes and Remedies Rebar Defects Errors during reinforcement installation could lead to serious concrete deterioration. For instance, inadequate chair bars and insufficient tying of reinforcement would cause. After the cause of steel damage is determined, it can be repaired by either replacing deteriorated bars or supplementing partially deteriorated bars. Fixing rebar the right way. Here are a few examples of rebar in need of repair,. Rebar Defects.

From huazhusteel.en.made-in-china.com

Steel Deformed Rebar Standard Steel Rebar Reinforcing Steel Bars Steel Rebar Defects Errors during reinforcement installation could lead to serious concrete deterioration. Identifying defects or inconsistencies in rebar can be difficult during fabrication. Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging within concrete. Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. Fixing rebar the right way. After. Rebar Defects.

From www.stainlesssteelrebar.org

Why does rebar corrode? Stainless Steel Rebar worldstainless Rebar Defects It identifies key factors such as chloride ion penetration and concrete carbonization that primarily influence rebar. Corrosion of reinforcements is frequent due to chemical attacks, fire, and accidental cutting. Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. Here are a few examples of rebar in need of repair, and how to properly correct. Rebar Defects.

From www.semanticscholar.org

Figure 11 from Rebar Detection in Concrete Based on GPR Bscan Rebar Defects It identifies key factors such as chloride ion penetration and concrete carbonization that primarily influence rebar. As you can clearly see in this picture, the rebar that was originally placed inside of this concrete structure has become exposed. Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging within concrete. For instance, inadequate chair. Rebar Defects.

From www.eng-tips.com

Scratch on Rebar Metal and Metallurgy engineering EngTips Rebar Defects This can happen for many reasons, but what is going on here is called “spalling.” Fixing rebar the right way. Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging within concrete. After the cause of steel damage is determined, it can be repaired by either replacing deteriorated bars or supplementing partially deteriorated bars.. Rebar Defects.

From www.researchgate.net

Sandwich structure of the surface film on the steel rebar sample and Rebar Defects Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging within concrete. After the cause of steel damage is determined, it can be repaired by either replacing deteriorated bars or supplementing partially deteriorated bars. Identifying defects or inconsistencies in rebar can be difficult during fabrication. As you can clearly see in this picture, the. Rebar Defects.

From www.machinemfg.com

6 Common Welding Defects in Rebar Construction Prevention Tips Rebar Defects Errors during reinforcement installation could lead to serious concrete deterioration. Here are a few examples of rebar in need of repair, and how to properly correct the problem. This can happen for many reasons, but what is going on here is called “spalling.” As you can clearly see in this picture, the rebar that was originally placed inside of this. Rebar Defects.

From www.machinemfg.com

6 Common Welding Defects in Rebar Construction Prevention Tips Rebar Defects Here are a few examples of rebar in need of repair, and how to properly correct the problem. Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. Errors during reinforcement installation could lead to serious concrete deterioration. It identifies key factors such as chloride ion penetration and concrete carbonization that primarily influence rebar. This. Rebar Defects.

From www.researchgate.net

The arrangement of rebars and defect before the casting of specimen Rebar Defects Fixing rebar the right way. Identifying defects or inconsistencies in rebar can be difficult during fabrication. Errors during reinforcement installation could lead to serious concrete deterioration. After the cause of steel damage is determined, it can be repaired by either replacing deteriorated bars or supplementing partially deteriorated bars. For instance, inadequate chair bars and insufficient tying of reinforcement would cause.. Rebar Defects.

From compraco.com.br

6 common defects when welding steel rebar prevention tips COMPRACO Rebar Defects Errors during reinforcement installation could lead to serious concrete deterioration. For instance, inadequate chair bars and insufficient tying of reinforcement would cause. Identifying defects or inconsistencies in rebar can be difficult during fabrication. Fixing rebar the right way. Here are a few examples of rebar in need of repair, and how to properly correct the problem. It identifies key factors. Rebar Defects.

From www.machinemfg.com

6 Common Welding Defects in Rebar Construction Prevention Tips Rebar Defects This can happen for many reasons, but what is going on here is called “spalling.” As you can clearly see in this picture, the rebar that was originally placed inside of this concrete structure has become exposed. Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. Identifying defects or inconsistencies in rebar can be. Rebar Defects.

From www.dreamstime.com

Deformed Steel. Rebar. Its Surface is Often Deformed To Promote a Rebar Defects Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. This can happen for many reasons, but what is going on here is called “spalling.” Fixing rebar the right way. Errors during reinforcement installation could lead to serious concrete deterioration. After the cause of steel damage is determined, it can be repaired by either replacing. Rebar Defects.

From www.engineeringcivil.com

Different Failures in RCC Buildings Civil Engineering Portal Rebar Defects Errors during reinforcement installation could lead to serious concrete deterioration. Corrosion of reinforcements is frequent due to chemical attacks, fire, and accidental cutting. Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging within concrete. Fixing rebar the right way. As you can clearly see in this picture, the rebar that was originally placed. Rebar Defects.

From www.mdpi.com

Sensors Free FullText Evaluation of the Size of a Defect in Rebar Defects Fixing rebar the right way. Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging within concrete. Corrosion of reinforcements is frequent due to chemical attacks, fire, and accidental cutting. Here are a few examples of rebar in need of repair, and how to properly correct the problem. As you can clearly see in. Rebar Defects.

From www.researchgate.net

XACT for NDT, demonstrating that pavement and rebar defects can be Rebar Defects Errors during reinforcement installation could lead to serious concrete deterioration. It identifies key factors such as chloride ion penetration and concrete carbonization that primarily influence rebar. Corrosion of reinforcements is frequent due to chemical attacks, fire, and accidental cutting. Here are a few examples of rebar in need of repair, and how to properly correct the problem. For instance, inadequate. Rebar Defects.

From www.researchgate.net

Steelsurface defects in the NEUDET dataset (a) crazing, (b Rebar Defects As you can clearly see in this picture, the rebar that was originally placed inside of this concrete structure has become exposed. It identifies key factors such as chloride ion penetration and concrete carbonization that primarily influence rebar. Identifying defects or inconsistencies in rebar can be difficult during fabrication. Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using. Rebar Defects.

From www.mdpi.com

Sustainability Free FullText Using Radar and Rebar Defects Errors during reinforcement installation could lead to serious concrete deterioration. Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging within concrete. Corrosion of reinforcements is frequent due to chemical attacks, fire, and accidental cutting. Here are a few examples of rebar in need of repair, and how to properly correct the problem. Fixing. Rebar Defects.

From www.researchgate.net

(a) is a simulated concrete bridge deck (slab) with embedded defects Rebar Defects Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. This can happen for many reasons, but what is going on here is called “spalling.” Fixing rebar the right way. Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging within concrete. Errors during reinforcement installation could lead to. Rebar Defects.

From ar.inspiredpencil.com

Rolling Process Defects Rebar Defects Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. After the cause of steel damage is determined, it can be repaired by either replacing deteriorated bars or supplementing partially deteriorated bars. It identifies key factors such as chloride ion penetration and concrete carbonization that primarily influence rebar. Here are a few examples of rebar. Rebar Defects.

From www.materialsperformance.com

Corrosion Effects on the Durability of Reinforced Concrete Structures Rebar Defects Here are a few examples of rebar in need of repair, and how to properly correct the problem. Errors during reinforcement installation could lead to serious concrete deterioration. Fixing rebar the right way. It identifies key factors such as chloride ion penetration and concrete carbonization that primarily influence rebar. Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using. Rebar Defects.

From fitnespic.pw

Hot rolling bar defects Rebar Defects After the cause of steel damage is determined, it can be repaired by either replacing deteriorated bars or supplementing partially deteriorated bars. Corrosion of reinforcements is frequent due to chemical attacks, fire, and accidental cutting. Identifying defects or inconsistencies in rebar can be difficult during fabrication. Fixing rebar the right way. Sandberg can undertake detailed reinforced concrete investigation and rebar. Rebar Defects.

From www.mdpi.com

Sustainability Free FullText Using Radar and Rebar Defects For instance, inadequate chair bars and insufficient tying of reinforcement would cause. Fixing rebar the right way. Identifying defects or inconsistencies in rebar can be difficult during fabrication. After the cause of steel damage is determined, it can be repaired by either replacing deteriorated bars or supplementing partially deteriorated bars. It identifies key factors such as chloride ion penetration and. Rebar Defects.

From stock.adobe.com

New fresh concrete surface with problem and might expose Rebar Defects Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. Fixing rebar the right way. This can happen for many reasons, but what is going on here is called “spalling.” Corrosion of reinforcements is frequent due to chemical attacks, fire, and accidental cutting. Identifying defects or inconsistencies in rebar can be difficult during fabrication. After. Rebar Defects.

From www.youtube.com

How to Fix Rebar Couplers ll Rebar Coupler Installation YouTube Rebar Defects Here are a few examples of rebar in need of repair, and how to properly correct the problem. Identifying defects or inconsistencies in rebar can be difficult during fabrication. This can happen for many reasons, but what is going on here is called “spalling.” As you can clearly see in this picture, the rebar that was originally placed inside of. Rebar Defects.

From www.researchgate.net

Fracture morphology comparison between different rebar failure modes Rebar Defects It identifies key factors such as chloride ion penetration and concrete carbonization that primarily influence rebar. After the cause of steel damage is determined, it can be repaired by either replacing deteriorated bars or supplementing partially deteriorated bars. Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. Here are a few examples of rebar. Rebar Defects.

From www.semanticscholar.org

Figure 1 from Mechanical properties of cast halfgrouted sleeve splice Rebar Defects This can happen for many reasons, but what is going on here is called “spalling.” Here are a few examples of rebar in need of repair, and how to properly correct the problem. Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. After the cause of steel damage is determined, it can be repaired. Rebar Defects.

From www.hamasteel.com

An Introduction To Deformed Rebars And Its Applications Rebar Defects Here are a few examples of rebar in need of repair, and how to properly correct the problem. It identifies key factors such as chloride ion penetration and concrete carbonization that primarily influence rebar. Corrosion of reinforcements is frequent due to chemical attacks, fire, and accidental cutting. Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan. Rebar Defects.

From www.academia.edu

(PDF) Inspection of Defects on Rebar in Rebar Defects After the cause of steel damage is determined, it can be repaired by either replacing deteriorated bars or supplementing partially deteriorated bars. For instance, inadequate chair bars and insufficient tying of reinforcement would cause. Errors during reinforcement installation could lead to serious concrete deterioration. Sandberg can undertake detailed reinforced concrete investigation and rebar mapping using either ferroscan or gpr. It. Rebar Defects.

From www.researchgate.net

(PDF) Using Radar and Deep Learning to Rapidly Rebar Defects Corrosion of reinforcements is frequent due to chemical attacks, fire, and accidental cutting. Errors during reinforcement installation could lead to serious concrete deterioration. Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging within concrete. Identifying defects or inconsistencies in rebar can be difficult during fabrication. After the cause of steel damage is determined,. Rebar Defects.

From www.eng-tips.com

Scratch on Rebar Metal and Metallurgy engineering EngTips Rebar Defects This can happen for many reasons, but what is going on here is called “spalling.” For instance, inadequate chair bars and insufficient tying of reinforcement would cause. Identifying defects or inconsistencies in rebar can be difficult during fabrication. Here are a few examples of rebar in need of repair, and how to properly correct the problem. Fixing rebar the right. Rebar Defects.

From www.machinemfg.com

6 Common Welding Defects in Rebar Construction Prevention Tips Rebar Defects Errors during reinforcement installation could lead to serious concrete deterioration. Corrosion of reinforcements is frequent due to chemical attacks, fire, and accidental cutting. After the cause of steel damage is determined, it can be repaired by either replacing deteriorated bars or supplementing partially deteriorated bars. This can happen for many reasons, but what is going on here is called “spalling.”. Rebar Defects.

From plainsight.ai

Product Defect Detection Plainsight Rebar Defects Identifying defects or inconsistencies in rebar can be difficult during fabrication. It identifies key factors such as chloride ion penetration and concrete carbonization that primarily influence rebar. Errors during reinforcement installation could lead to serious concrete deterioration. As you can clearly see in this picture, the rebar that was originally placed inside of this concrete structure has become exposed. This. Rebar Defects.

From buyersask.com

Rebar Problems In Concrete Foundations, Slabs, and Walls Buyers Ask Rebar Defects Errors during reinforcement installation could lead to serious concrete deterioration. After the cause of steel damage is determined, it can be repaired by either replacing deteriorated bars or supplementing partially deteriorated bars. For instance, inadequate chair bars and insufficient tying of reinforcement would cause. Ferroscan and ground penetrating radar (gpr) both offer an effective means of reinforcement detection and imaging. Rebar Defects.