When Countersinking Rivet Holes In A Material . from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head height of the fastener countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a.

from www.pbo.co.uk

countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head height of the fastener from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below.

How to drill out and set rivets mending a broken spinnaker pole

When Countersinking Rivet Holes In A Material countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head height of the fastener from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a.

From www.kitplanes.com

Those Rivet Holes KITPLANES When Countersinking Rivet Holes In A Material countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the. When Countersinking Rivet Holes In A Material.

From www.csfabs.co.uk

Countersunk Holes in Sheet Metal C&S Fabrications When Countersinking Rivet Holes In A Material countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or. When Countersinking Rivet Holes In A Material.

From www.yorkshireprofiles.co.uk

Countersinking Metal Yorkshire Profiles When Countersinking Rivet Holes In A Material from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw,. When Countersinking Rivet Holes In A Material.

From www.alamy.com

Countersinking holes with a electric drill Stock Photo Alamy When Countersinking Rivet Holes In A Material from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render. When Countersinking Rivet Holes In A Material.

From www.manmadediy.com

A Guide to Selecting the Perfect Drill Bit for Every Project ManMadeDIY When Countersinking Rivet Holes In A Material from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render. When Countersinking Rivet Holes In A Material.

From www.brunbergs.net

Countersinking Large Screw Holes Above it All When Countersinking Rivet Holes In A Material countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the. When Countersinking Rivet Holes In A Material.

From giotawhrz.blob.core.windows.net

How To Pop Rivet Without A Rivet Gun at Fannie Knight blog When Countersinking Rivet Holes In A Material from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or. When Countersinking Rivet Holes In A Material.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The When Countersinking Rivet Holes In A Material countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or. When Countersinking Rivet Holes In A Material.

From www.dreamstime.com

Drilling and Countersinking Holes in Metal, Wood and Other Materials When Countersinking Rivet Holes In A Material countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. the depth of a countersink hole should be such that it allows the head of a. When Countersinking Rivet Holes In A Material.

From www.kitplanes.com

Dimpling for Beauty and Speed KITPLANES When Countersinking Rivet Holes In A Material countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head. When Countersinking Rivet Holes In A Material.

From giouyhsne.blob.core.windows.net

Define Countersink Bolt at Shelia Mead blog When Countersinking Rivet Holes In A Material countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet. When Countersinking Rivet Holes In A Material.

From www.dreamstime.com

Drilling Holes in a Piece of Wood. Countersinking the Hole for Wood When Countersinking Rivet Holes In A Material countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head. When Countersinking Rivet Holes In A Material.

From capablemachining.com

Mechanical Riveting Different types of rivet Capable Machining When Countersinking Rivet Holes In A Material from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head height of the. When Countersinking Rivet Holes In A Material.

From www.dreamstime.com

Drilling Holes in a Piece of Wood. Countersinking the Hole for Wood When Countersinking Rivet Holes In A Material from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw,. When Countersinking Rivet Holes In A Material.

From www.kitplanes.com

Debunking Deburring KITPLANES When Countersinking Rivet Holes In A Material countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the. When Countersinking Rivet Holes In A Material.

From engineersbible.com

Countersunk Hole Size for Socket Flat Head (ANSI Metric) When Countersinking Rivet Holes In A Material from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or. When Countersinking Rivet Holes In A Material.

From peacecommission.kdsg.gov.ng

Countersinking When Countersinking Rivet Holes In A Material countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head. When Countersinking Rivet Holes In A Material.

From www.youtube.com

Punching Countersunk Holes YouTube When Countersinking Rivet Holes In A Material countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw,. When Countersinking Rivet Holes In A Material.

From engineeringlearn.com

Types of Rivets and Their Uses [with Pictures & Names] Engineering Learn When Countersinking Rivet Holes In A Material the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head height of the fastener from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet. When Countersinking Rivet Holes In A Material.

From glasstec.net

D35 45° diamond countersink for countersinking glass holes Solid When Countersinking Rivet Holes In A Material countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. the depth of a countersink hole should be such that it allows the head of a. When Countersinking Rivet Holes In A Material.

From www.dreamstime.com

Drilling and Countersinking Holes in Metal, Wood and Other Materials When Countersinking Rivet Holes In A Material the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head height of the fastener countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit. When Countersinking Rivet Holes In A Material.

From www.dreamstime.com

Drilling Holes in a Piece of Wood. Countersinking the Hole for Wood When Countersinking Rivet Holes In A Material countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the. When Countersinking Rivet Holes In A Material.

From www.alamy.com

Drilling holes in a piece of wood. Countersinking the hole for wood When Countersinking Rivet Holes In A Material from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw,. When Countersinking Rivet Holes In A Material.

From www.scribd.com

Comparisonoftigh00lang Comparison of Tightness of 78 Machine When Countersinking Rivet Holes In A Material countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet. When Countersinking Rivet Holes In A Material.

From www.youtube.com

Counter Sunk Holes YouTube When Countersinking Rivet Holes In A Material countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. the depth of a countersink hole should be such that it allows the head of a. When Countersinking Rivet Holes In A Material.

From www.dreamstime.com

Countersinking Holes for Metal Carpenter S Screws. Minor Carpentry Work When Countersinking Rivet Holes In A Material the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head height of the fastener from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet. When Countersinking Rivet Holes In A Material.

From sendcutsend.com

The Benefits of Countersinking SendCutSend When Countersinking Rivet Holes In A Material countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head. When Countersinking Rivet Holes In A Material.

From www.pbo.co.uk

How to drill out and set rivets mending a broken spinnaker pole When Countersinking Rivet Holes In A Material the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head height of the fastener from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet. When Countersinking Rivet Holes In A Material.

From www.novacam.com

3D countersink measurement noncontact and automated Novacam When Countersinking Rivet Holes In A Material from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head height of the. When Countersinking Rivet Holes In A Material.

From heritageequipment.com

Aircraft hot Dimpling Machine for rivet countersinking dimpler ATI 247PD When Countersinking Rivet Holes In A Material countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw,. When Countersinking Rivet Holes In A Material.

From exywynssb.blob.core.windows.net

What Is A Counterbored Hole at Micheal Bagley blog When Countersinking Rivet Holes In A Material countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a. from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet. When Countersinking Rivet Holes In A Material.

From blog.austinhardware.com

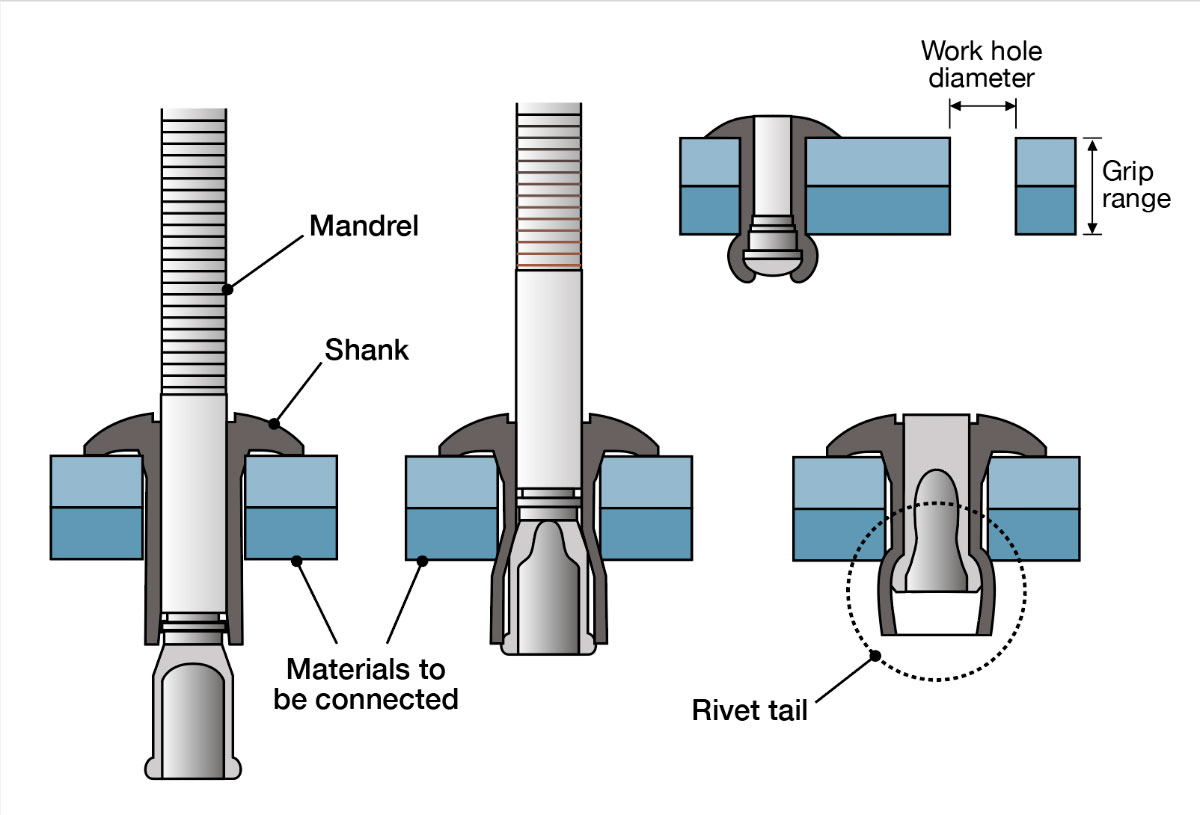

The Austin Hardware® Guide to Blind Rivets, Part One When Countersinking Rivet Holes In A Material from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or. When Countersinking Rivet Holes In A Material.

From www.kitplanes.com

Those Rivet Holes KITPLANES When Countersinking Rivet Holes In A Material from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head height of the. When Countersinking Rivet Holes In A Material.

From www.alamy.com

Drilling and countersinking holes in metal, wood and other materials When Countersinking Rivet Holes In A Material from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. the depth of a countersink hole should be such that it allows the head of a countersunk bolt, screw, or rivet to sit flush with or below the surface of the surrounding material, which typically matches the head height of the. When Countersinking Rivet Holes In A Material.

From rosewoodissues.com

What is a Countersink Bit Wood Issues, Wood tools and Guide When Countersinking Rivet Holes In A Material from cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. countersink holes are an essential feature in many manufacturing projects, allowing screws and bolts to sit flush with or below. countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render. When Countersinking Rivet Holes In A Material.